00:00

00:00

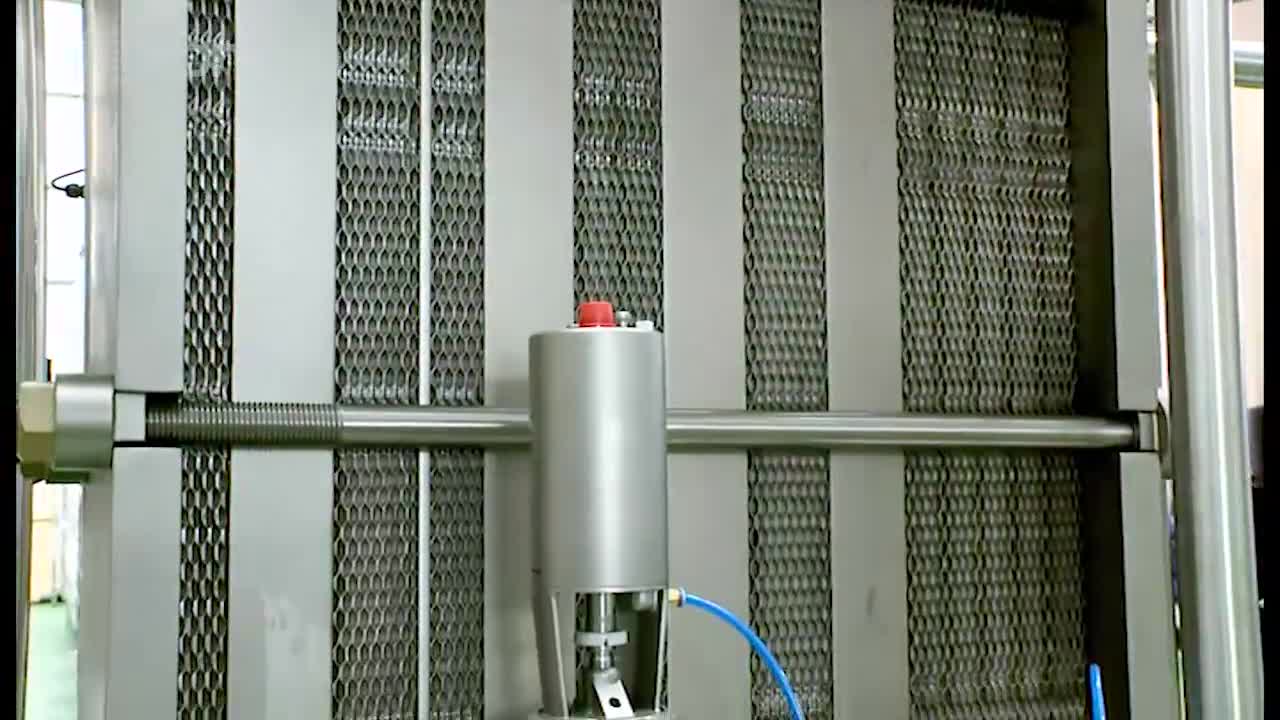

Linear screw capping machine is improved from the same type abroad, which adapt to market demand. It is universal in many bottle specifications. The machine adopt mechanical electrical integration technology, which applied in pharmaceutical, pesticide, chemical, foodstuff, cosmetic etc.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 01:47

01:47

Company Info Established in 1996, Shanghai Changlong Industrial Equipment Co., Ltd. is an enterprise specialized in designing and researching various series of plate type(tubular) heat exchangers, plate type(tubular) whole set sterilizer units, ice cream whole set equipment, concentrators, degassing units, tanks and vessels etc., providing a chain of services including design, manufacturing, installation, commissioning and training etc. Our products not only enjoy high reputation in the country, but also have been exported to Germany, Japan, Australia, Russia, Southeast Aisa and Mid East., etc. Changlong is certified to ISO9001:2000 Quality System. Changlong have been working on several specific prodcuts which makes us an expert. Our product are wildly applied in milk, cream, yoghurt, beer, chilli sauce, ketchup, tamato sauce, juice and beverage. Coconut milk Coconut Water Juice Milk Fresh Milk Soymilk Yoghurt Beer Beverage We have the confidence to provide you the products and service you need. Two-section ice cream cooling(cooling and heat recovery of dispensing water) Material: 85℃→35℃→5℃ Recovery of dispensing water: Ice water: (4:1)2℃→12℃ Two-section ice cream cooling Material: 85℃→40℃→5℃ Recovery of dispensing water: (3:1)30℃→42℃ Ice water: (4:1)2℃→12℃ Technical Parameter Model Flow rate Material diameter Medium diameter Outline dimensions Weight (l/h) (mm) (mm) (mm) (kg) BR16-JZH-8B 1000 Φ25 Φ38 600*310*1320 750 BR16-JZH-10B 2000 Φ38 Φ38 800*310*1320 850 BR26-JZH-16B 3000 Φ51 Φ38/51 1000*460*1520 950 BR26-JZH-20B 4000 Φ51 Φ38/51 1100*460*1520 1050 BR26-JZH-24B 5000 Φ51 Φ38/51 1200*460*1520 1150 BR4-JZH-30B 6000 Φ63 Φ51/63 1200*700*1550 1180 BR4-JZH-36B 8000 Φ63 Φ51/63 1300*700*1550 1280 BR56-JZH-42B 10000 Φ76 Φ51/76 1500*810*1600 1450 Material cooling(two-sectioncooling) Material: 65℃→35℃→5℃ Cooling water: (tower water 2.5:1)30℃→42℃ Ice water: (3:1)2℃→12℃ Technical Parameter Model Flow rate Material diameter Medium diameter Outline dimensions Weight (l/h) (mm) (mm) (mm) (kg) BR1-JZH-2.5B 1000 Φ25 Φ25 550*285*810 150 BR1-JZH-5B 2000 Φ25/38 Φ38 600*285*810 220 BR16-JZH-10B 3000 Φ38 Φ38 800*350*1320 750 BR26-JZH-15B 6000 Φ51 Φ51 1000*460*1520 950 BR26-JZH-25B 10000 Φ51 Φ63 1200*460*1520 1050 BR26-JZH-35B 15000 Φ63 Φ63 1400*460*1520 1150 BR4-JZH-45B 20000 Φ76 Φ76 1500*700*4550 1250 BR56-JZH-65B 30000 Φ76 Φ101 1700*810*1600 1350

Established in 1996,Shanghai Changlong Industrial Equipment Co.,Ltd. is an enterprise specialized in sterilizer equipment, including designing and researching various series of plate type(tubular) heat exchangers,plate type (tubular) whole set sterilizer units, ice cream whole set equipment, concentrators,degassing units,tanks and vessels etc,.providing a chain of services including design,manufacturing,installation,commissioning and training etc.for the equipment and projects.

Contact Supplier 01:41

01:41

Product Name Copper or Alunminum Conductor Plastic Insulated Power Cable for Rated Voltage up to and Including 26/35kV Standard The product is manufactured according to the standards of IEC 60502 and GB/T 12706-2008 or IEC, BS, DIN, and ICEA up on repuest. Applications The product is suitable for using in power distribution networks or fixed installations for industrial equipments with rated voltage up to and including 26/35kV. Operating Characteristics 1. XLPE Insulated Electrical Cable for rated power frequency voltage Uo/U: 3.6/6kV ~26/35kV Max. Permissible continuous operating temperature of conductor: 90℃. Max. Short-circuit temperature shall not exceed 250℃ ( 5s Max. Duration ). The ambient temperature under installation shall not below 0℃. The bending radius of single-core cable shall not less than 20 times of the cable diameter. The bending radius of three-core cable shall not less than 15 times of the cable diameter. 2. XLPE Insulated Electrical Cable for rated power frequency voltage Uo/U: 0.6/1kV. Max. Permissible continuous operating temperature of conductor: 90℃.). Max. Short-circuit temperature shall not exceed 250℃ ( 5s Max. Duration ). The ambient temperature under installation shall not below 0℃. The bending radius of a cable shall not less than 15 times of the cable diameter. 3. PVC Insulated Electrical Cable for rated power frequency voltage Uo/U: 0.6/1kV. Max. Permissible continuous operating temperature of conductor: 70℃. Max. Short-circuit temperature shall not exceed 160℃ ( 5s Max. Duration ). The ambient temperature under installation shall not below 0℃. The bending radius of a cable shall not less than 15 times of the cable diameter.

Wuxi Jiangnan Cable Co., Ltd., founded in 1985, is a National Key Hi-Tech. Enterprise, mainly manufacturing integrates wires and cables. By the end of 2015, With a floor space of more than 500,000 square meters, total built-up area of 350,000 square meters, and total assets worth above RMB 7 billion, the Company now has an employee size of 3,000-odd persons, of which, middle and high-level technical and managerial personnel with diploma of junior college or above make up more than 30 per cent of the Company’s total employees. In addition to boasting more than 1,400 sets (units) of China and the world first-class production and testing devices, the Company takes the lead in realizing whole-process dynamic monitoring and management over its logistics, capital flow, and human resources by virtue of its ERP network information management system, HER H.R. management system, and OA system, thus IT-based management in the Company comes true.

Contact Supplier 00:44

00:44

Improved efficiency and throughput Cascading material combines with material from the rotor to form a denser particle population, which optimises reduction by increasing the chance of a good rock-on-rock collision. This most efficient use of the rock on-rock crushing action leads to improved crusher efficiency and increased throughput, giving the operator more value for money by providing more inter-particle action where it is needed most in the crushing chamber. The unmatched producer of superior concrete and asphalt aggregate Less cement can be used and stronger concrete created by using Barmac S-Series VSI product. The Barmac S-Series VSI combines high velocity impact crushing with high pressure attrition grinding to produce high volumes of cubically shaped product. Continuous control of the product shape and gradation provides a product which meets the size distribution required. A proven producer of quality manufactured sand Superior particle shape and consistent gradation are a direct result of the rock-on rock principle of the S-Series VSI crusher. Impact, grinding and abrading within the crusher simulates the action of nature, eroding the particles to a cubical shape. The only viable crusher for extremely abrasive fine material The rock-on-rock crushing principle of the Barmac S-Series VSI minimises metallic wear resulting in low maintenance and wear costs. The low wear of internal components ensures extremely low contamination of fi ne products by wearing metal parts. The User-Friendly VSI crusher The roof lifter has been developed to provide quick and easy access to the internal workings of the Barmac S-Series VSI. This allows for rapid rotor and wear part changes and minimises down time while maximising availability. The simple and reliable design of the roof lifter means only one person is required for operation and can eliminate the requirement for an external crane. The cascade feed system The Barmac S-Series VSI uses the cascade feed system to introduce a second stream of material, in a controlled quantity, into the crushing chamber turbulence. This causes a supercharging of the particle population within the chamber, thereby improving the energy transfer between the particles. The cascade feature enables the operator to make optimal use of the power available and to manipulate the product grading and shape to best suit their requirements. The cascade feed system provides: • Higher crusher throughputs for the same power consumption. • Maximum use of available power without fear of motor overload. • Gradation control to optimise product fractions. • ‘Free’ crushing at no extra expense to the operator. • Shape control. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. The S Series Vertical Shaft Impact(VSI) crusher was improved on basis of the technology of Barmac,it has had a huge impact on the global quarrying and minerals processing industries. The Barmac S-Series VSI is unique due to its crushing process. Whereas most other types of crusher use metallic parts to crush rock, the Barmac VSI uses the rock fed into the machine to crush itself. This autogenous crushing process produces the best-shaped aggregate on the market today. The high velocity impact crushing achieved in a Barmac S-Series VSI improves the soundness and shape of stone, reducing product moisture and easing the screening task while producing superior products at a minimum cost.

Shanghai WHITE LAI Road and Bridge Machinery Co., Ltd is a renowned crushing and screening machinery equipment provider in China. We provide our clients with a whole series of crushing and screening machinery equipment, including hydraulic cone crusher, jaw crusher, impact crusher, vertical shaft impact crusher, vibrating screening and all complete set of stone crushing and sand making production lines. Our products had passed the quality system certification of ISO9001:2008, and the European CE certificate.

Contact Supplier 01:18

01:18

Model DLM-A Driving Mode SERVO MOTOR Yield(pcs/min) 20-150 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-180 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:26

01:26

Model PM-DPM-A Driving Mode Servo motor Yield(pcs/min) 30-200 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-120 mm length 15-200 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 1000W Weight(kg) 500 Machine size 2800(L) 1200 (W) 1600 (H) mm (machine size can made as client need )

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:05

01:05

Model PLM-S Driving Mode Servo motor Yield(pcs/min) 10-80(depends on product and label size) Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-150 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 850W Weight(kg) 360 Machine size 2300(L) 800 (W) 1500 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:43

00:43

Catalogue Download Feature • Precision locator for terminal positions. • 1.2 metric tones pressure with minimal hand effort. • Interchangeable die set. • Crimp MC3* with optional die set. Parameters Model LY-2546B Capacity MC4: 2.5,4,6mm2 Length 215 mm Weight 0.5 kg

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 02:29

02:29

MOQ:500kg JM can produce a variety of non-standard hardware components in combination and process different metal materials, such as carbon steel, alloy steel, stainless steel, aluminum, zinc aluminum alloy and coppers.etc. JM can design and manufacturing special products according to the drawings or samples for your requirements. Custom Bolt| LEARN MORE Custom Nut| LEARN MORE Custom Screw| LEARN MORE Custom Washer| LEARN MORE

Shanghai Jian & Mei Industry and Trade Co., Ltd. is the company which manufacture and export fasteners and metal hardware, founded in 2006, with import-export authority. Now, 80% products export to all over the world and 20% sell in domestic market.

Contact Supplier 00:48

00:48

1. Can suitable to screw cap and press cap 2 type caps. 2. Torque force can adjust. 3. The cap is placed in the hopper to automatically cover, In the process of the sensor will automatically detect the positive and negative cover. 4. Qualified cover will automatically loading through cap loading guide, then begin capping. 5. Press cap head in the first station, screw cap head in second station. 6. Press type cap will though first cap head to press cap. Screw cap head will through second cap head in second station. 7. The torque force of the screw cap can be adjusted. Cover with anti-theft ring, straw hat and bottle tight with the cap can be applied. Adjustment is convenient, the machine is more precise.

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:56

00:56

Item Description Material L Finish CBRKT1 Cuplock Board Brakcet 1'-3-3/4" Q235 1'-3-3/4" Hot-Dip Galvanized CBRKT2 Cuplock Board Brakcet 1'-10-1/4" Q235 1'-10-1/4" Hot-Dip Galvanized CBRKT3 Cuplock Board Brakcet 2'-7-5/16" Q235 2'-7-5/16" Hot-Dip Galvanized dimension,surface,material and style can be specified 1)Cuplock scaffolds have less basic structures, are easy be installed and discharged. 2)Cuplock scaffolding system suits all sorts of buidling structures. 3)Cuplock systems reduces time limit for proiects with less freight. 4)Surface Finish:Hot Dip Galvanized;Electro Galvanized;Spray painting.Dimension,material and style also can be specified .

Wuxi Chenyuan Construction Equipment Co.,ltd is located in Dongfeng Industrial Park, Qianqiao Town, Huishan Development Zone, Wuxi, Jiangsu, China. Here in the city we have well-known Taihu Lake with beautiful landscapes.

Contact Supplier 00:35

00:35

Characteristic 1.Using new-style producing & control system , together with high precision and high speed related weighing & control instruments , which has the advantage of multi-function , high stability and expansibility .completely adapt to the highly continuous and repeated industrial manufacture. 2.Hauing the function of over-dosing restraining ,wrap self-correcting and over-weight warning. 3.The machine is a set of highly electro-mechanical integrated device. Computer control system and imported high-precision weighing sensors are adopted . All the parts which directly contact with products are made of 304 stainless steel. 4.Bag grip device is changeable for fitting different bag size. 5.Chemical grand belt coveyor or PVC flight conveyor optional 6.Industrial bag sealing or seaming device optional

Shanghai kunbu packaging Machinery Co.,Ltd .Is collection of research and development , manufacturing ,sale and service in the integration of automatic packaging machinery .We Specialized in Snacks food , biscuit ,powder , nut ,liquid , paste and frozen food ,agricultural chemical products and automatic packaging conveyor system .Our machines are exported to Europe, America, Southeast Asia, the Middle East, Russia and the surrounding more than and 50 countries .

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery