00:09

00:09

Wholesale tools / Mechanics tools / Tools / Basic tools / Hand tools / Measuring Tools / Measuring Tape For Workshop / Home work / Construction / Measuring Tools 564601 Nylon wrap blade with better wear-proof ability and high performance spring Measuring Tape Double Side Printing Model: 2m(6ft) x 16mm(5/8'') 3m(10ft)*16mm(5/8'') 5m(16ft)*19mm(3/4'') 5m(16ft) x 25mm(1'') 7.5m(25ft)*25mm(1'') 8m(26ft)*25mm(1'') Material of Tape: Steel / Fiberglass Material of Case: Electroplate / ABS Finish of Blade: Yellow Coated / Nylon Coated Finish of Case: Rubber / Chrome Plated Thickness of Tape: 0.1-0.13mm Hook Common / Magnetic Application: Measuring Accuracy II Class Customers Logo: Color Sticker / Printing Package: Color Box / Anti-thief Blister / Plastic Hang Card Plastic Hanger / Flag label MOQ: 1200pcs Sample Time: 1) Existing Items Sample time: 7- 10 days 2) Customized items Sample time: Will check after receiving all details. Production Capacity: 100,000 Pieces / Month Delivery Time: Within 45-60 Days after Receiving the Deposit Payment Terms: T/T,L/C Model pcs/inner box pcs/carton L(cm)/CTN W(cm)/CTN H(cm)/CTN G.W/N.W/carton(kgs) 5m(16ft) x 27 mm(1-1/16'') 12 60 43 33 29 21/20 7.5m(25ft) x 27 mm(1-1/16'') 6 60 43 36 34 25/24 8m(26ft) x 27 mm(1-1/16'') 6 60 46 39 36 26/25

We (Landing tools). is one of the leading exporters of tools, hardware and householdware in China. we have built kinds of professional teams to support our operation. SALES TEAM, which has a exact grasp and understanding of clients' requirements. Make prompt, clear and complete replies according to different markets and quality requests of products. R&D TEAM has the full ability to organize and actualize preponderant production against the drawings and samples. PACKAGING & APPEARANCE DESIGN TEAM, in accordance with clients' requests, we supply the different appearances of products, color assortment, packaging design and making. SOURCING TEAM, which is familiar with the full range information in our field. We offer steady, highest cost-effective products. QC TEAM has established complete and comprehensive assessment system of suppliers Documentation team provide our clients with timely, secure and suitable mode of storage and transportation. Our goal is to supply Ideal Solutions for the full process. We will make our remaining efforts to meet and exceed the requirements of customers. We are ready to serve for every potential customers and sincerely looking forward to cooperate with you in the future.

Contact Supplier 01:21

01:21

Grinding system SFSP hammer mill for layer chicken feed Features of hammer mill for layer chicken feed: -We adopt the progressive technological programs, well-designed; -Hammer room like droplet, it can effectively eliminate material run into this room. -Optimize the arrangement of knives, adjust the gap between knives and sifters. -Many precision testings to insure equipments running smoothly and reduce noise, optimal performance. -Creative hammer process with low power, the twice hammer structure like "W", it can enhance the rubbing action, then reduce the power it needs, increased production of 25%, -Movable and opened operation door, new modal of sifter install tool, make the operation humanistic and convenient. -Critical components are imported, their service life is longer, maintenance cost is also cheap. -Carbide bit sifters with special processing. Technical Parameters of hammer mill for layer chicken feed: Model 120*40 120*50 120*60 120*80 Capacity 11-22t/h 18-33t/h 24-40t/h 38-55t/h Power 75/90KW 90/110KW 132/160KW 200/220KW Applications: The hammer mill for layer chicken feed is designed for crushing materials like corn, durra, bean and wheat, etc. And the hammer mill is widely used in feed industry, grain industry, etc. The pulverizing machine can grind many different kinds of raw materials efficiently. Liyang Yuda Machinery Co.,Ltd is specialized in manufacturing hammer mill, poultry hammer mill, livestock hammer mill, feed grinding machine, etc. Packaging & Shipping Clients visit

YuDa Machinery CO., LTD is located in the beautiful national AAAA level tourist area—Tianmu Lake along zhongguancun science and technology industrial park, Jiangsu. She is a professional high—tech enterprise engaged in grain and oil machinery, forage, fertilizer and feed machinery manufacturing. The company covers 34500 square meters, construction area of 27895 square meters, she gathers industry technical elite from Nanjing agricultural university, Jiangsu university and other scientific research institutions for technical cooperation. The company has passed national ISO9001: 2008 quality management system certification, European CE certification and SGS certification.

Contact Supplier 00:00

00:00

This machine is specially designed for vacuum or non-vacuum and spinning or non-spinning sealing operation for screw-socket bottle(tin),with advantages such as good availability, high automation, reliable sealing ,easy operation and maintenance and nice-looking appearance.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 02:00

02:00

Company Info Established in 1996, Shanghai Changlong Industrial Equipment Co., Ltd. is an enterprise specialized in designing and researching various series of plate type(tubular) heat exchangers, plate type(tubular) whole set sterilizer units, ice cream whole set equipment, concentrators, degassing units, tanks and vessels etc., providing a chain of services including design, manufacturing, installation, commissioning and training etc. Our products not only enjoy high reputation in the country, but also have been exported to Germany, Japan, Australia, Russia, Southeast Aisa and Mid East., etc. Changlong is certified to ISO9001:2000 Quality System. Changlong have been working on several specific prodcuts which makes us an expert. Our product are wildly applied in milk, cream, yoghurt, beer, chilli sauce, ketchup, tamato sauce, juice and beverage. Coconut milk Coconut Water Juice Milk Fresh Milk Soymilk Yoghurt Beer Beverage We have the confidence to provide you the products and service you need. Product description It is applicable to heating, sterilization, heat-preservation and cooling etc. technology requirements of fresh milk, fruit beverage and alcohol etc. heat sensitive liquids. The equipment has such features an high heat recovery, energy saving and low consumption, compact structure, simple operation and convenient maintenance etc. Control methods--semi-automatic control, full-automatic control(PLC control, touch screen display) Main accessories--material pump, balancing tank, hot water system, temperature controller and recorder, electric control sysem etc. Production capacity--0.5--50t/h Sterilizing temperature--85-95 degree Heat preservation period--15--30s Techinical Parameter Name BR1-PUT-8B BR16-PUT-13B BR26-PUT-28B BR26-PUT-52B Production capacity t/h 1 2 5 10 Heat exchanging area m2 8 13 28 52 Temperature of material inlet ℃ 5 5 5 5 Temperature of material outlet ℃ 5 5 5 5 Sterilizing temperature ℃ 85-95 85-95 85-95 85-95 Heat preservation period s 25 25 25 25 Ice water temperature ℃ 1 1 1 1 Ice water consumption multiple 3 3 3 3 Cooling water consumption multiple 2 2 2 2 Connector size mm 32 38 51 51 Energy consumption kw 3 3 6 10 Outline dimensions mm 1500*1500*1800 1800*2000*1800 2200*2000*2000 2600*2000*2200

Established in 1996,Shanghai Changlong Industrial Equipment Co.,Ltd. is an enterprise specialized in sterilizer equipment, including designing and researching various series of plate type(tubular) heat exchangers,plate type (tubular) whole set sterilizer units, ice cream whole set equipment, concentrators,degassing units,tanks and vessels etc,.providing a chain of services including design,manufacturing,installation,commissioning and training etc.for the equipment and projects.

Contact Supplier 01:12

01:12

Model PLM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-200 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 550W Weight(kg) 260 Machine size 1800(L) 800 (W) 1500 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:42

00:42

Model DPM-ALS104 Driving Mode German Avery Yield(pcs/min) 30-200 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-160 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 1000W Weight(kg) 500 Machine size 2900(L) 1200 (W) 1600 (H) mm (machine size can made as client need )

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:53

00:53

Model BFM-D Driving Mode Servo motor Yield(pcs/min) 20-120 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-80 mm length 15-100 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:22

01:22

Upright polypropylene bag infusion (vertical bag). Fourth generation infusion packaging container, can set bag adopts the fully closed infusion method , avoid secondary pollution, the bag body is made of the secondary forming process and seamless welding technology ,improve the transparency of the product, and completely eliminate soft bag leakage phenomenon. Item Equipment model CPP4 CPP6 CPP8 CPP10 CPP12 Design production 400P/H 6000P/H 8000P/h 10000P/h 12000P/h Bottle embryo material BOPP Cavity spacing 95.25mm The power supply 380V , 50Hz , Three phase four wire system Heating power 160KW 160KW 160KW 192KW 192KW

Huizhou Pingfang PharmaEngineering CO., LTD established in 2004, who is a professional manufacturer focusing on IV solution production line and vacuum blood collection tube production line. Our machinery has features of high-level automation, stable performance, which make us enjoy a high market share over the world.

Contact Supplier 01:58

01:58

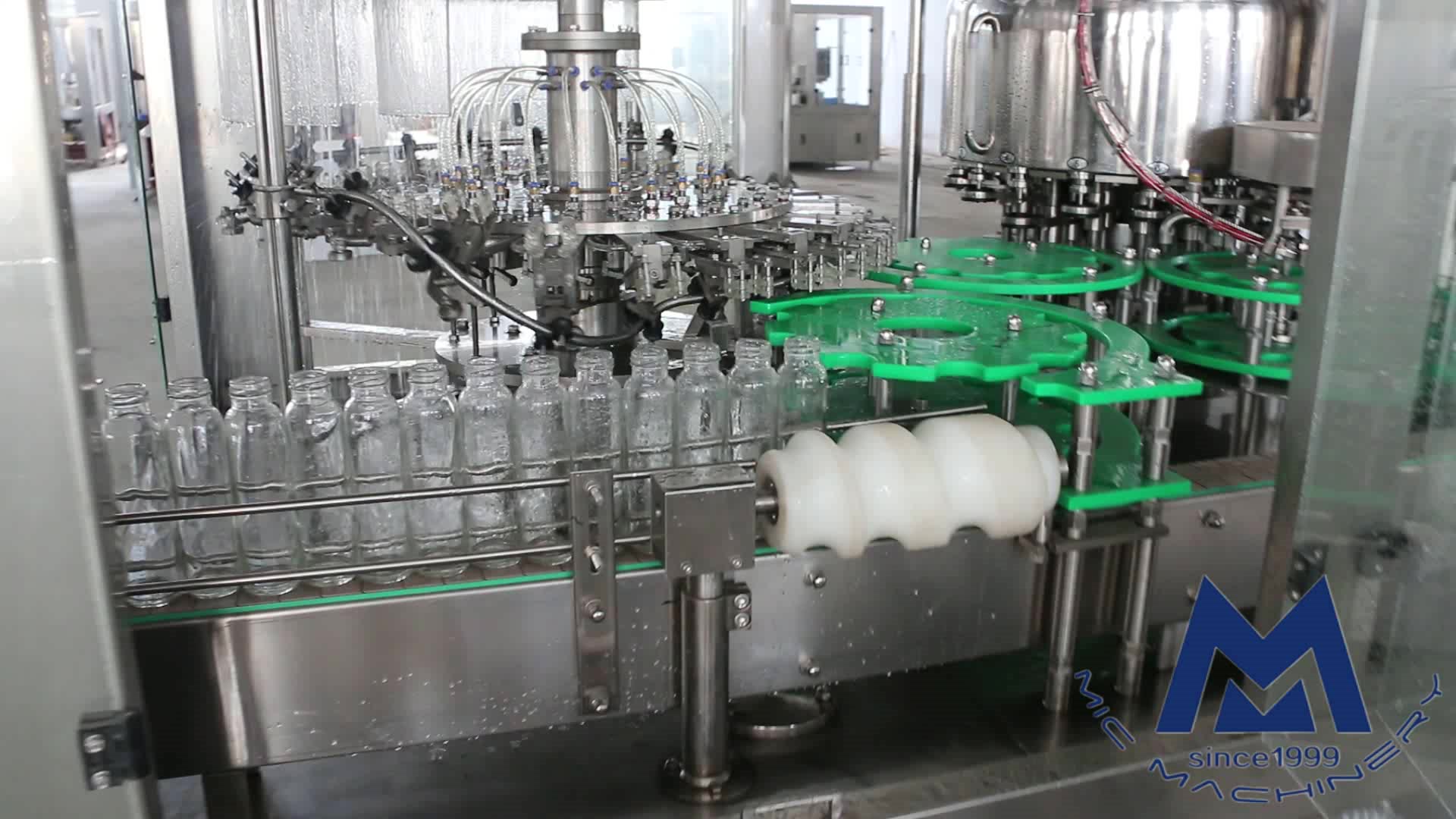

MIC 12-1 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> CIP cleaning system 7> CIP cleaning liquid recycle system 8> Ink date printer (LINX BRAND) Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. Recent export news: (click for check news) →We sold one to the United States of America on May 18,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:12

01:12

MIC 18-18-1 It is applicable for glass bottle filling capping machine for whisky, alcohol drinks and spirit. (if need hot filling temperature at 85-90 degree) Adopt products: whisky ,alcohol drinks, spirit, chivas, liquor, vodka, vinegar, soy sauce etc liquid products. Machine working principle: 1. Negative pressure filling(slightly), controled by pressure, accuracy is +/-1%,liquid level difference is not more than 4-5mm(cause bottle has difference when it produced). easy adjustmeant on liquid level. 2. Glass bottle capping machine is qualified for Chinese capping standard, and no air leakage at all, machine capping rate is 99.5%. 3. About oxygen content, we have device nitrogen filling for replace air. 4. About gems sterilizing, we could use bottle invertor for the cap, and pasteurization for juice, hot filling for can. and sterilizing tunnel (with cooling spray) for second steilizing and cool off. 3. Aluminum cap and crown cap are ok problem working on our capping machine(different capping head), We use our own technical drawing and own processing machine, to make sure our capping head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Nitrogen filling machine 7> CIP cleaning system 8> Pasteurization, inventor and sterilizing tunnel. 9> Glass bottle air washing machine Related machines are: Glass bottle filling machine, glass bottle capper, glass bottling companies, bottle filling machine, bottle equiment, bottle filling, bottle filling capping machine, bottle filler, bottle capper, bottle capping machine, crown bottle capper, bottle capping machine price, Whisky filling capping machine, vodka filling capping machine, liquor filling machine, spirit filling machine. Lately news for shipment: We sold one to

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:12

01:12

Model PLM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-180(depends on product and label size) Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-150 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 550W Weight(kg) 260 Machine size 1800(L) 800 (W) 1500 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 06:34

06:34

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” TDG Series Directly Forming to Square and Rectangular Tube Mill Only one set of rollers can be continuously produced within a certain range of rectangular steel pipe, using the international advanced multi-radius combination molding process and high-frequency welding, forming by multi-channel symmetrical bending. It can be divided into small side bending, boardside bending, free bending at closed side, high frequency welding, precision straightening, produce the exact size and good quality pipe after cut off. Characteristic: One set mold roller can produces a range of rectangular tubes. This machine has characteristics such as no replace spindle, no remove roller stand and quick change rollers. Save mold, save time. Four square corner deformation part which can save extra deformation process then save energy consumption and equipment load. Specification of Directly Forming to Square and Rectangular Tube Mill SPECIFICATIONS: TDG250X250 TDG300X300 - Material to be processed Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon - Type Square & Rectangular tube Square & Rectangular tube Square 100 x 100 – 250 x 250 mm 120 x 120 – 300 x 300 mm mm Rectangular 100 x 160 –150 x 250 mm 120 x 180 – 200 x 300 mm - Wall thickness 2.0 mm – 10.0 mm 3.5 mm – 12.7 mm - Tube length 6.0 m - 12.0 m 6.0 m - 12.0 m - Line Speed Max. 32m/min Max. 25 m/min - Welding Method Solid State High Frequency Welding Solid State High Frequency Welding - Forming Method Directly Forming to Square and Rectangular tube Directly Forming to Square and Rectangular tube Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery