00:00

00:00

Structure of the PVC co-extrusion foamed board line: Outer surface layer is rigid PVC and inner layer foamed PVC, it feature in low machine and formula cost compared with PVC skinned foamed plate, meanwhile, the product and parameters( 1.22m width with 5-20mm thickness product dimension, ~0.5g/cm3 density, 50-75 Rockwell hardness) are all equal or better. Also, the surface of the product can be printed or laminated to get different patterns. The machine consists main extruder & co-extruder, distributor, calibrator moulding block, cooling rack, haul off, cutter & stacker. Type ZJFB-1220 Product width 1220mm Product thickness 5-25mm Capacity 200-500kg/h Extruder type SJZ80/156&SJZ65/132 Mould spec. 1400mm Total power ~220kw

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 01:34

01:34

Automatic piston filling machine is a volume type liquid filling machine which widely used in filling for medicine liquid like cough syrup Main characteristics : 1. One year Guarantee. 2. One year free spare parts will be shipped with the machine. 3. We can help install the production line or machine , the customer need to provide the room, board, round tickets and pay $60/day to our Technician. 4. These machines are easy to maintain and clean, no special tools are required. 5. Accuracy: ± 0.3%. (for 1000ml) 6. Two servo motor control 7. CE approved and production comply with GMP standard .

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 01:38

01:38

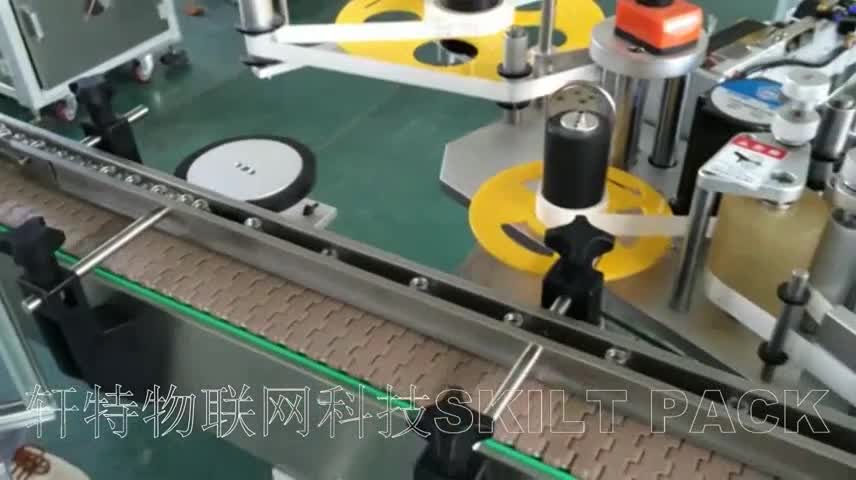

Model PLM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-200 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 550W Weight(kg) 260 Machine size 1800(L) 800 (W) 1500 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:35

00:35

Model RPLM-ALX924 Labeling way Online printing and labeling Operating Direction From right to left Print and peal speed(mm/second) DPM and PEM 4″/5″:50-400(mm/second) /6″:50-300 (mm/second) Printing length 10-1000mm Printing Width ALX924:106mm Ribbon save function 6mm No print area material specification Self-adhesive sticker Labeling Speed(pcs/min) ≤70 ( Depends on the size of label objects) Labeling Precision (mm) ±1mm (Depends on flatness of label objects surface) communication port Standard RS232、RS485 Control port Reserved Applicable of label(mm) Width ≤50、length ≤100 Inner diameter of label roll 76mm Outer diameter of label roll 350mm (max) Conveyor for top labeling machine Belt Conveyor for round labeling machine chain plate Total motor power(w) 500 Voltage 380V 60HZ air source 0.6 mpa

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:30

01:30

Model RPLM-ALX924 Labeling way Online printing and labeling Operating Direction From right to left Print and peal speed(mm/second) DPM and PEM 4″/5″:50-400(mm/second) /6″:50-300 (mm/second) Printing length 10-1000mm Printing Width ALX924:106mm Ribbon save function 6mm No print area material specification Self-adhesive sticker Labeling Speed(pcs/min) ≤70 ( Depends on the size of label objects) Labeling Precision (mm) ±1mm (Depends on flatness of label objects surface) communication port Standard RS232、RS485 Control port Reserved Applicable of label(mm) Width ≤50、length ≤100 Inner diameter of label roll 76mm Outer diameter of label roll 350mm (max) Conveyor for top labeling machine Belt Conveyor for round labeling machine chain plate Total motor power(w) 500 Voltage 380V 60HZ air source 0.6 mpa

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:00

00:00

Equipped with six-axis controlling technology and special cantilever flying optics, and also aluminum alloy structure The laser keeps still to avoid any damage to the laser in certain cutting area German gear and rack, precision ball screw, linear guide allow high precision and little noise Excellent dust removing system and scrap collecting device improve the processing environment greatly. The cutting head is a drawer-like type offering the possibility of mounting two different focus lengths, allowing very easy removing, changing and cleaning of the cutting lens, reducing the machine’s down time, whenever the lens needs to be checked. Advanced beam controlling technology. Wherever the cutting head moves, the beam diameter keeps the same, which ensures stable cutting Equipped with axis control of laser, and fast moving function, thus the moving speed of X1 axis can reach 40m/min. Big table cutting With big table cutting area and high speed No limited to the sheet material size Any big size can be customized flexibly Laser source Germany famous IPG Laser source is with high performance, long stability. More than 100000 hours work-life of pumped diode Wide range of operating wavelengths, single-mode and multi-mode options Suction unit With improved suction system for fumes and smokes, scrap pieces and heavy dust fall through the cutting tables into separate boxes that can easily be taken away from the side of the machine. Big table cutting Laser source Suction unit Application: Available for cutting such metal sheet as stainless steel, carbon steel, copper, brass, alloy steel, aluminum, gold, silver, titanium and so on. Widely used in the sheet metal processing, shipbuilding, automobile, rail transportation, agriculture machinery, advertising board ,kitchen utensils, machinery, elevator and so on.

As a professional and energetic enterprise in the sheet metal processing industry, Suzhou Lead Laser Technology Co., Ltd manufactures high performance of laser cutting machine and laser welding machine for various applications with two production facilities in China.

Contact Supplier 00:21

00:21

Model PWM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-220 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-100 mm length 15-80 mm The suitable size of labeling objects Customized depends on client product Printer use air 5kg/cm ² Power(w) 600W Weight(kg) 200 Machine size 1800(L) 800 (W) 1300 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:18

01:18

Model DLM-ALS104 Driving Mode German Avery 104 Yield(pcs/min) 20-160 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-160 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:43

00:43

Feature • Stainless steel blade • Cutting Body Material: Aluminum Alloy • Cutting body surface treatment: Plastic – spraying • Apply to cut PVC pipe, PPR pipe, PE pipe, EXP pipe or other aluminum plastic pipe Parameters Model PC-323 Cutting type Wiring Duct Cutting range Max 42mm Length 230mm Weight 0.68 kg Application Used in panel shop , electrical switch cabinet assembly line , any places where small sizes of duct cutting work is needed.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 00:40

00:40

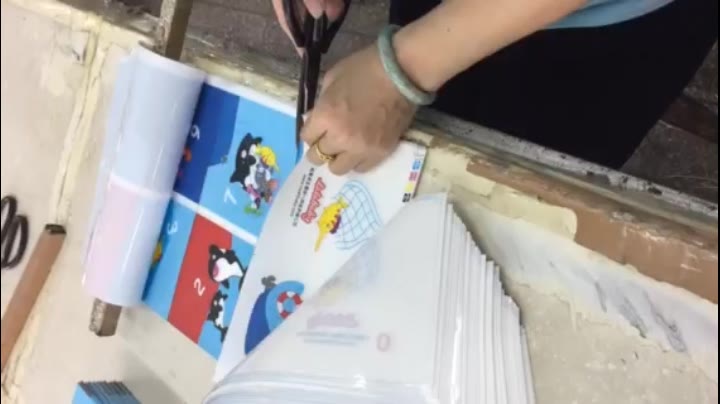

The eva foam childrens book are one kind of children's book. The materials is the high density eva. The produce by cutting the eva into pieces, then mounted with card paper. The eva foam children book produce is same as the board book. The eva foam children book moq is 3,000 copies each title. Welcome your custom inquiry about the eva foam children book. 1. The weight of the EVA Foam Childrens Book Printing? Usually weight is 100~300g one book, depend on your size. However this kind book, materials is very light, good for delivery. EVA Foam Childrens Book Printing's Size: 16.7 x 16.7cm Pages: 22 pages Thickness: 28.6mm Materials: silk printing on the 4mm EVA foam MOQ: 3,000 piece Sample Cost: $100/title Sample Lead Time: 1 week Mass production lead time: 10~15 days Loading Port: Shanghai, China Payment: 30% deposit + balance, by T/T Q: The special for the light book, right? A: Yes it is special for the light weight. Because the major materials is EVA / sponge, pressing EVA materials. One book could produce by many pages, and could be puzzle style. And the 3~5mm thickness EVA, the final book come out with very thick spine, seems a big book. The style book is loved by the children, parents, and publishing house.

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 02:01

02:01

Brief Introduction YX Die Type Milk Candy Production Line, the traditional milk candy making machine, High-degree automation ensures of stale production and saves time, labor force and occupation to serve purpose of reducing the cost Milk candy making process Sugar melting--Storage tank-- Milk cooker --Cooling table--Extruder--Jam pump--Rope sizer--Forming--Swing conveyor and cooling tunnle --Packing The functions of each machine. 1) Sugar melting tank: heating raw material, strirring and shaving 2) Storage tank: storage the sugar syrup and and filting pure syrup. 3) Milk candy cooker: jacket layer heating by steam, rotating speed-adjustable scraper 4) Cooling Table: cooling the milk candy syrup, jacket layer 5) Extruder: 4 or 6 heads extruding the milk candy dough at the same time. 6) Jam Pump: filling the inside gam or chocolate syrup. 7) Rope Sizer: pull the centerfilled candy dough more even and smooth 8)Forming machine: chain type forming moulds inside, die forming the final milk candy. 9) Swing and cooling machine: seperate and cooling final toffee candy into the cooling tunnel 10) Packing machine: various packing machine available. Technical Parameters Output 200~300kg/h Speed 1000-1200Pc/min Max.Candy Weight As per candy size Min.Candy Weight 3g Steam Pressure 0.5~0.7MPa Steam Consumption 250~400kg/h Cooling System Requirement Room Temperature: 20~25℃ Humidity: 40-45% Power 50kw/380V Length 25m Gross Weight 5000kg Tips on the Milk candy production line: 1) The whole line equipped the international motor: ABB motor, Danfoss invertor, SS materials 2) Heating by steam 3) Various shapes milk candy can be produced by changing moulds 4) Milk candy size and weight effects the final output 5) One/ two colors/center fillied milk candy can be made Pictures and final milk candy samples:

Shanghai Yixun Machinery Manufacturing Co., LTD is an experienced manufacturer integrated with design, manufacture, installment and service. The main products are cake machine, biscuit machine, candy machine and cookies machine in shanghai China. ISO and CE certificates we got 10 years ago, and the goods exported to120+ countries. Workshop tour is welcome.

Contact Supplier 01:35

01:35

Brief introduction This product belongs to our company's innovative design of drug ,cream,food packaging machinery, It’s applicable to plastic, paper, aluminum and aluminum composite sealed packaging for capsules, tablets, big honeyed pills, candy, liquids, pastes, disposable syringes and special objects in pharmaceuticals, health products, foods, cosmetics, medical equipment and other industries. The machine adopts microcomputer programming control, frequency control and touch panel operation, with high degree of automation. It is an ideal blister packaging equipment. Samples

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery