01:23

01:23

Horizontal triple pouch packing machine an automatic finish bag forming, filling, easy tear notch making, print date, finished bag discharged. Characteristics: 1) PLC control, English and man-machine interface, operating easy and simple maintain. 2) Bagging, sealing and filling is relatively independent of the system 3) Could fill powder, granule or liquid product by change filling device,two or even more products are nice with one machine. 4) Digital temperature controller for vertical and horizontal sealing, intuitive and accurate. 5) Sanitary package for your product and perfect package appearance. 6) Easy and fast adjustment of change over, smooth performance and low noise Sensible safety device and no pollution during production to get Friendly working environment

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 00:00

00:00

It is suitable for stand up/ pouch, flat pouch filling sealing The machine is an automatic packing machine for premade bags. It can meet the requirment which needs different specifications, big volume but small capacity. It can not only pack 3-side or 4-side sealed bag, but even also bags with hanging hole, standing pouches and shaped bags etc. It is applicable of powder,granule,liquid,paste and blocks etc by using different measuring devices. It is convenient to switch the bag type. Features: 1 Equipped with different metering device, it can realize packing different material such as powder, liquid, granule, sauce etc. 2 Various bag type, it is very easy to change. 3 Simple in structure, easy to operate and maintain.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 06:32

06:32

The whole filling line is with servo motor controlled bottle Filling machine , capping machine and cap feeder ,labeling machine , and case packing system , total line . Features: 1. One year Guarantee , one year free spare parts 2. These machines are easy to maintain and clean, no special tools are required. 3. Accuracy: ± 0.3%. (for 1000ml) 4. two servo motor control 5. Filling nozzles with suck function and other unique design of the main machine to avoid leakage or spill out . 6. CE approved , and with 20 years for manufacturing and designing filling machine .

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 01:02

01:02

Our portable snow melting mats are specifically designed for you to create a safe, convenient and slip-resistant walkway for your family during the cold winter days. Snow melting mats could enable you to get a clean and safe passageway melting snow or ice automatically. The durable and effective melting system is undoubtedly the ideal alternative to the traditional way of snow and ice removal. Global Agents Wanted Click for more details Category Floor Cleaning/ Sapce Heating/ Roof Snow Melting/ Passageway Snow Melting/ Car Windshield Heating Pad Shipping

We are a professional Chinese manufacturer majoring in the production of snow melting mats efficient and convenient to save you out of the series of trouble like snow shoveling, salting and slipping.

Contact Supplier 01:02

01:02

MIC 18-18-6 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Bottle capping machine is qualified for Chinese cappinng standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum cap and crown cap are ok problem working on our capping machine (with different capping head), We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> CIP cleaning system 7> CIP cleaning liquid recycle system 8> Ink date printer (LINX BRAND) Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. Recent export news: (click for check news)

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:18

01:18

Model DLM-ALS104 Driving Mode German Avery 104 Yield(pcs/min) 20-180 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-160 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 02:19

02:19

The max.working pressure for JYZH200 high pressure precision preformer is up to 40 Mpa.It can strain rubber compound of different hardness with higher efficiency, It can achieve in prefoming while straining,and strain the rubber compound with accelerant. The strain accuracy is up to 300 meshes,rubber compound will not be scorched. This precision preformer is with humanized design and easy operatinon,and less force to open ram head,the comprehensive safety control and impressive notice to ensure better security performance. It is a type of rubber blank manufacturing equipment with high efficiency and high accuracy. This machine can process a wide range of rubber material, and is able to extrude rubber blanks of ring, rectangle, strip and odd shapes. It is especially suitable to produce sealing members, oil seal, tyre valves, bottle closures, tennis balls and shoe soles, etc. It integrates a variety of different functions such as vacuuming, filtrating, extruding, cutting, weighing, counting, etc. Technical parameter Items Unit JYZ200H JYZ250H Barrel inside diameter mm 200 250 Total power KW 21.6 21.6 Max. extruding pressure MPa 40 25/36 Max. barrel temperature °C 95 95 Max. die diameter mm 125 190 Rubber weight range g 0.1~300 0.1~5000 Rubber blank weight accuracy % ±1.0 ±1.0 Single feeding volume kg 25/40 60 Cutter speed r/min 35~300 23~300 External dimension(L×W×H) m 4.7×1.35×1.85 5.6×1.35×1.85 Weight t 4.6 5 Product advantages: 1.With higher pressure and faster extrusion speed, filtration and cutting ,simultaneously can be realized to prevent secondary contamination of rubber compound 2.PLC control system and touch screen operator interface.Color touch screen to input data and password protection. 3.1000 products technics database available to connect anytime. 4.Variable inverter controlled infinite speed regulation for cutter speed. 5.Closed circuit feedback of electronic scale, one key automatic calibration of the weight of rubber blank. 6.Reliable safety performance. There are interlocks when close ram head, the cutter rotates and ram moves forwards and retracts. 7.Graphic and text display for failure point and cause 8.Barrel adopts separated structure, Extended center, for easy cleaning. 9.Reducing residual air in rubber blank by vacuum system. 10.Stainless steel conveyer for reducing compound contamination. 11.Fully automatic hydraulic door opening and closing card can reduce labor intensity and improve production efficiency. 12.Accept high-end customization

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 00:41

00:41

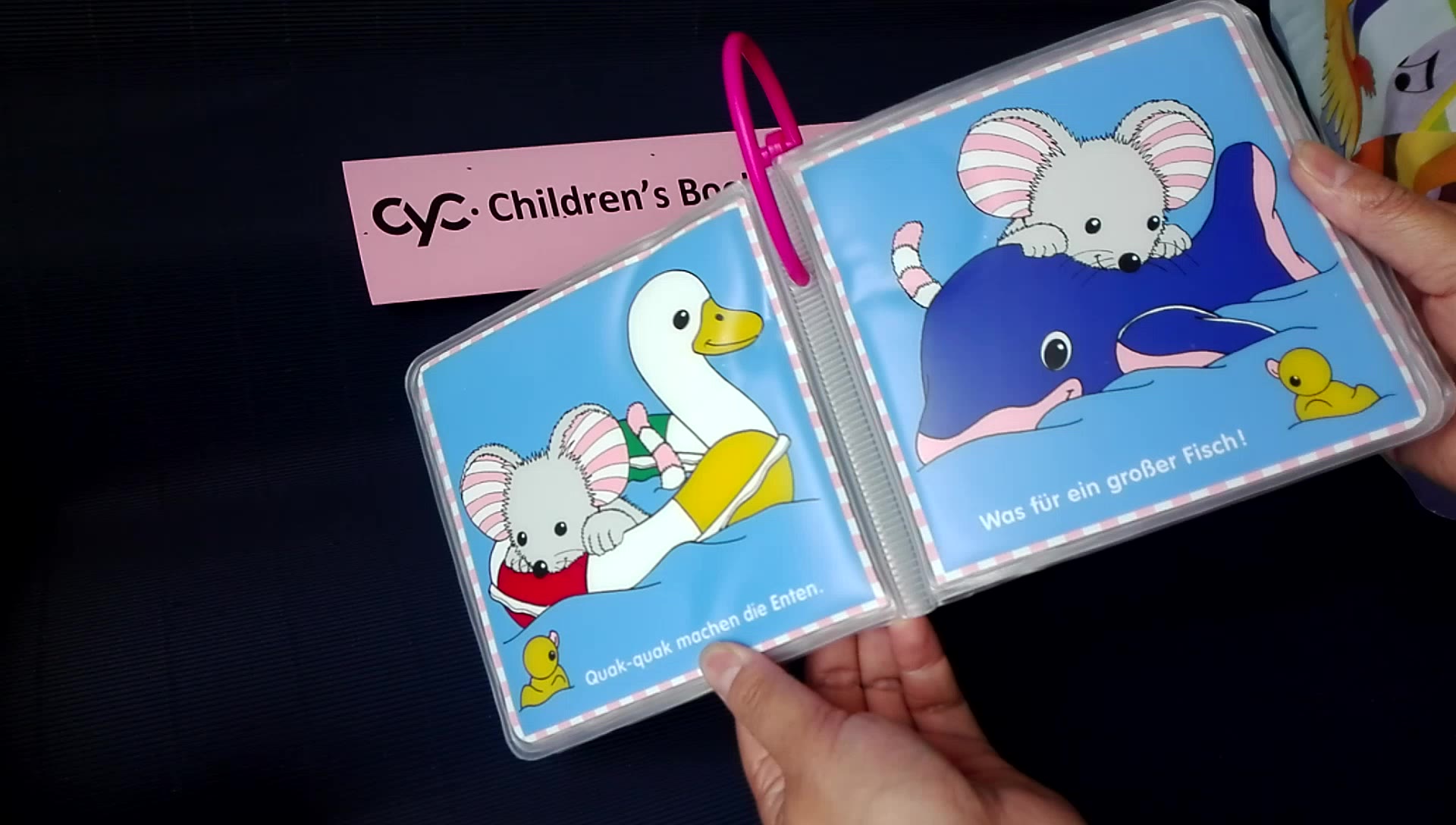

Nice to meet you here, We are the only company focus on the Children Book printing company with 22 year industry experience. Present company have 90+ skilled workers, take in all over the world’s Children Book printing business. Size 15 x 15 cm Page 8 pages Materials 100% recycle PEVA + Sponge Package each put into polybag with header card MOQ 3000 copies / title Approx Unit Price $0.6~1.10 Sample Cost $125 ~ $250 Sample Lead Time 15 days Mass Production Lead Time 30~45 days Shipping Term FOB Shanghai, China / CIF destination Port Payment Term T/T, T/T+L/C Q: Where are you location? A: we locate in Shanghai, China. It is the biggest port of China very convenient shipping cargo to each port of the world. Q: What’s the size of the such book? A:the size is 15x15cm, square book. Q: How many pages of such bath book? A: It is 8 pages include the cover. However we could produce the book with 8 pages, 10 pages, 12 pages or more. Q: What’s the materials? It is EVA materials, 100% recycle materials, FREE PHTHALATE. Here is our materials testing certification. We guarantee our materials comply with the CE certification, the EN71 1-3 and FREE Phthalate, if fail we could re-produce the baby book for you. Q: it is waterproof plastic, right? A: Yes, it is waterproof, but you couldn’t call them plastic materials, it is correct name is EVA baby bath book, or call them waterproof floating book. Q: What’s the MOQ to printing such book? A: The initial book request 3000 copies per title. Usually you may have different title, such as the 4 title complete one set of the books. There should be 3000 copies * 4 title, total printing 12,000 copies book. Q: How long could be finishing such the mass production? A: Mass production usually take 30~45 days finishing. Q: How much the cost for above books of mass production, such as your MOQ 4 title * 3000 copies = 12,000 copes? A: This book have one extra accessories, the plastic ring, the cost is US$0.9 ~1.25 depend you have other request, such as the header and package. Q: I don’t know exact effect of my book finally come out, could I produce the sample book first? A: of course, could be. Sample we usually printing 5 sets, send you 3 sets, we have 2 sets. One set in case you for the testing, another set set up as reference for the mass production. Q: How long will take for the sample?. A: Sample usually take 2 weeks finishing, we usually work out the layout sending you to double checking he printing content, then start the printing and assemble. Q: How much the cost for the sample? A: About all the baby bath book, the sample cost is approaching same. It is US$ 250/ title. If you have 4 titles, the will consider combine the printing plate, such condition, the sample cost is US$ 125/title. Q: Which port you will shipping out the mass copies? A: we shipping from Shanghai to your appointed port. Usually take 7~25~35 days arriving at destination port, depend on your country. Q: What’s your shipping term? A: Present we have 2 shipping terms, one is FOB shanghai, China and CIF destination Port. Q: What’s your payment term? A: Present our payment term is 30% T/T + balance paid before shipping. Or 30% deposit + balance paid by L/C at sight.

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:23

00:23

MOQ:1000kg JM can design and manufacturing special products according to the drawings or samples for your requirements CUSTOM BOLT CUSTOM NUT CUSTOM SCREW MACHINING PARTS STAMPING PARTS SHEET METAL PARTS COLD WORK PARTS

Shanghai Jian & Mei Industry and Trade Co., Ltd. is the company which manufacture and export fasteners and metal hardware, founded in 2006, with import-export authority. Now, 80% products export to all over the world and 20% sell in domestic market.

Contact Supplier 00:11

00:11

Overview Automate bottle filling capping for small bottles , it is a high performance compact piston pump liquid filling machine and can be customized. We also can equip the peristaltic pump for filling. The system aseptically and precisely fills liquid to small bottles. An optional diving nozzle mechanism plunges the filling nozzles into the container for increased production speeds without splashing, and we can produce the different filing nozzles for your different speed requirement. Filling volumes are programmable and can be adjusted from the touch screen. Characteristics ● It is applicable to different-shaped bottles and plastic bottles: PP , PE , PVC ,glass bottle and mould bottle. ● The bottle-in and bottle-out has specialized structure .It doesn't drop bottles or nip bottles ● The part which touches the liquid medicine is made of SS304 stainless material completely, meeting the requirement of CE GMP. ● It can be connected with the bottle-washing machine and the label-attaching machine to form a complete set of produce line.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:14

00:14

Product description 1.The mineral water filling machine has three functions for bottle rinsing, filling and capping, which are composed in one body of the machine . The whole process is full automatic. 2. This machine is used in filling mineral water, drinking water, flavor water, etc. in bottles made of polyester and plastics . 3. The filling packaging operation is faster and more stable because the micro pressure filling operation of the new type is adopted . There the output and benefit of the machine is higher than the machinery of the same specifications . 4. PLC control, full automatic working . 5. Touch-screen control panel, easy operation. 6. Singel positional adjustable central transmission post, more stable lable transmission . 7. Screw rod of separate bottle: stable transportation of bottles. 8. Label control sensor shelf: original creation tail surface and sensor are combined to improce the precision of cutting the material .

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 03:06

03:06

Major Characteristics: 1.Standardization, Diversification Automation Informatization 2.Standardization: GMP standard for pharmaceuticals & Food ISO CE UL 3.Diversification &Automation More specifications/more material/multi bottle type/more cap type/automatically bottle unscramble/filling/capping/production line 4.Small and light, beautiful appearance

Huituo is a leading manufacturer of intelligent packing machinery, focus on providing customized filling and capping solution. Our vision is “helping customer realize brand dream”, which pushes us continuously improving, including servo intelligent capping machine and other equipment that have reached the international leading level.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery