01:03

01:03

After adjusting, this case sealing machine folds the top flaps and seal both the top and bottom with tape automatically. Main features : 1. Warning device. 2. Can be adjusted for different products. 3. The components are tested for thousand time 4. The tape track is even, straight and looks good. 5. Strong applicability and high efficiency 6. Easy operation, low failure, long service time.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 01:14

01:14

Model DPM-A Driving Mode SERVO MOTOR Yield(pcs/min) 30-200 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 1000W Weight(kg) 500 Machine size 2000(L) 1200 (W) 1600 (H) mm (machine size can made as client need )

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:26

01:26

Model PM-DPM Driving Mode Servo motor Yield(pcs/min) 30-180 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 1000W Weight(kg) 500 Machine size 2900(L) 1200 (W) 1600 (H) mm (machine size can made as client need )

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:19

01:19

Model ELM-S Driving Mode Servo motor Operating direction Left or Right Labeling position Top and two more sides on egg carton Conveyor speed ≤40 (m/min) Label Specifications Adhesive sticker , opaque label The application of label object Customized as the egg carton The application of label Height 20-180mm Length 25-300mm The inner diameter of label roll 76mm The outer diameter of label roll 350mm(max) Voltage (In China) AC220V 50/60HZ Single phase

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:03

01:03

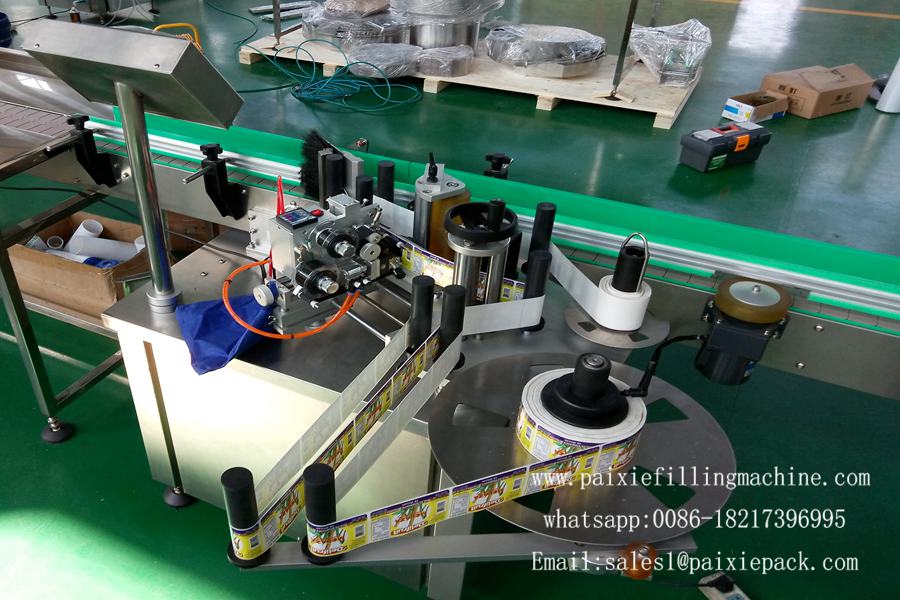

Overview : The Paixie Pack labeling machine have different types full automatic labeling machine suitable for round /flat /square/ irregular shape bottles . We have three types of the labeling machine adhesive labeling machine, glue wet labeling machine ,sleeve shrink labeling machine . Our Labeling machine is also suitable for all kinds of one side two sides neck labeling and so on. 1.Configuration oftaliban type coping mechanism, to ensure product delivery smoothly, and effectively eliminate bottle of high error in itself; 2.Configure automatic bottle body, guide the bottle before automatically separate spacing, ensure follow-up guide bottle, conveying and stick mark stability; 3.Mixer equipment mainly senior materials using 304 stainless steel and aluminum alloy, in line with the GMP standard production, overall structure and firm, the beauty is generous. 4.In pieces the electrical equipment USES is Panasonic servo motor, Mitsubishi electric eye, ensure the accuracy and speed stick mark requirements. After sale service : (1) Long life service (2) One year warranty (3) Offering free parts for one year (4) Engnieers available to service machinery overseas

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 01:17

01:17

Jiangyin Metallurgy Hydraulic baling presses are applied in steel mills, recycling plants, ferrous and non-ferrous smelting industries to press scrap metal (steel, copper, aluminum, stainless steel, discarded automobiles, etc.) into acceptable furnace charges in shapes of cuboids, cylinders and octagons. There are cutting blades on all three sides of the loading box so that oversized sheets and sections can be handled with ease. The metal recycling baler is built for speed, with hard wear plates in the bale box, a return-line filter which reduces wear and tear on hydraulic components. The combined features of YD metal baler result in a low-cost, reliable and effective machine. YDQ-135A is most suitable for aluminum cans, pipes, cables, iron sheet and so on. To find out more about our briquetting machines, email us to yj.oversea@gmail.com or call us at +86-18651010951 Parameter Value Name YDQ-135A Main cylinder pressure 1350kn Door cylinder pressure 500kn Lock-door cylinder pressure 150kn*2 System working pressure High 25Mpa, low 16Mpa Host overall dimensions 4300*1750*2100mm (L*W*H) Density ≥2t/m3 Press box size 1400*600*600mm Bale size 240*600mm Bale weight 70~90kg Output in one shift 10~16t/8h Machine weight About 6ton Motor Model Y160M-4 Rated power 18.5kw Rated speed 1470r/min Power specs 380V, 50HZ (changeable) Pump Model 80YCY14-1B Nominal displacement 80ml/r Rated pressure 31.5Mpa Control system Manual operation Delivery One 20GP container could load one set

The most experienced manufacturer of metal recycling equipment… Jiangyin Metallurgy Hydraulic Machinery factory (short name : Jiangyin Hydraulic) was originally set up in 1997 to manufacture and market briquetting press, metal balers, alligator shears, metal shears and other non ferrous scrap metal processing equipment. During the last two decade we have installed 3000 systems , build the entire quality controlling standards and cultivated an experienced technique&after sales tea.

Contact Supplier 00:18

00:18

Model XTHZ-10 Driving Mode Servo motor labeling methods The bottle is stand into, stand labeling, stand out Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The size of bottle Outer diameter 20-100mm, height 25-200mm The size of label Height 20-180 mm length 25-200 mm Printer to use air 5kg/cm ² Voltage AC220V 50/60HZ Single side (Can customized as buyer need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:07

01:07

Model PWM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-220 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-100 mm length 15-80 mm The suitable size of labeling objects Customized depends on client product Printer use air 5kg/cm ² Power(w) 600W Weight(kg) 200 Machine size 1800(L) 800 (W) 1300 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:47

00:47

Item Material L Finish KS-V-1000 Q235,∮48.3*2.75~3.5 1000mm Powder Coated KS-V-1500 Q235,∮48.3*2.75~3.5 1500mm Powder Coated KS-V-2000 Q235,∮48.3*2.75~3.5 2000mm Powder Coated KS-V-2500 Q235,∮48.3*2.75~3.5 2500mm Powder Coated KS-V-3000 Q235,∮48.3*2.75~3.5 3000mm Powder Coated hundreds of colour can be chosen in pantone for powder coated finish dimension,surface,material and style can be specified 1)Kwikstage types of scaffolding system is quick to erect and strip. 2)All components are securely joint by high tensile steel V and C pressing parts. 3)High stability in suspended structure or on uneven ground. 4)Maximum time saving, labour saving and material saving. 5)Kwikstage type scaffolding have different functions using with different accessories. 6)Kwikstage types of scaffolding is widely used for massive concrete construction or high-rise tower staircase in Australia, Africa and China.

Wuxi Chenyuan Construction Equipment Co.,ltd is located in Dongfeng Industrial Park, Qianqiao Town, Huishan Development Zone, Wuxi, Jiangsu, China. Here in the city we have well-known Taihu Lake with beautiful landscapes.

Contact Supplier 00:12

00:12

Dimension:5800MM*2500MM*2600MM Core: Modified EPS, mineral wool, rock wool, glass wool Core density: Modified EPS: 25g Rock wool /mineral wool: 70g Glass wool: 50g Panel thickness: 40mm ( or customized) Steel thickness: 0.3mm (or according to the customer requirements) Dimension after folded: 400mm Application: Residence, office, factory, toilet, etc. Advantages: Fire insulation, saving cost, saving time, wide application

Zhengchuang Machinery is a manufacturer of high-end roll forming machine in Asia. Wuxi Zhengchuang Cold Bending Technology Co., Ltd was establish in 1995, with more than 20 years history in cold bending industrial area. Our company is located in Wuxi city, Jiangsu Province, floor area is about 15,000M2. We are professional manufacturing all kinds of cold bending machines, with the 23 years development, we use modern management, professional scientific research, advanced manufacturing technique and impeccable after-sales system, we obtain national high-tech enterprise title, until now our company has more than 80 employees. What we offer? Zhengchuang is mainly produce color steel tile roll forming machine, glazed tile roll forming machine, C/Z purline roll forming machine, quick change roll forming machine, deck floor roll forming machine, guardrail roll forming machine, downpipe roll forming machine, automotive frame roll forming machine, steel silo roll forming machine etc. We can make more than 20 series 100 kinds machines. The end product is widely used in grain storage, storeroom, workshop, supermarket shelves, photovotaic industry, villa, integration wall space, residence, and all kinds of heated housing construction project. Zhengchuang machine can meet growing demand of construction enterprise, auto industry and steel production enterprise.

Contact Supplier 05:07

05:07

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” This HR Cut to Length Line series is applicable to coils of various specifications. It is used for the producing flattened plate through the procedure of uncoiling, flattening and cutting to required width and length. This line consists of loading cut, single pivot uncoiler, pre-leveler, hydraulic loop bridge, deviation corrector, fine leveler, servo length gauge, shear, belt conveyor, reversal discharger, stacker, discharging cart, servo transmission system, hydraulic system, etc. The machine performance has reached the international standard. This cut to length line series coil thickness range can be from 1.0mm to 12.0mm and coil width can be from 900mm to 2200mm,all these size steel coils are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of Cut To Length Line Model TML6X2000 TML8X2000 TML12X2200 Material Type HR HR HR Coil Thickness(mm) 1.0-6.0 2.0-8.0 3.0-12.0 Plate Width(mm) 900-2000 900-2200 900-2200 Cutting precision(mm) ±1.0 ±1.0 ±1.0 Line Speed(m/min) 0-28 0-28 0-25 Coil Weight(T) 30 30 35 Finish Plate Length(mm) 1000-6000 1000-8000 2000-12000 Occupied Area(m) 26X9 28X9 35X10 Power(kw) 110 140 220

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 23:51

23:51

Brief Introduction YX Toast Bread Production Line suits for small space bakery facotry and bread shops. it baked by the hot wind rotary oven machine. Making cake process: Mixing --Dough Dividing--Forming--Proofer--Baking--Cooling--Slicer--Packing. Each machine function: 1) Spiral Mixer: putting flour, water and so on into the tank. two speed, two direction mixing. 2) Dough Dividing: 10/20/30/36 dough divider and rounder available. combined divider and rounder. 3) Toast forming machine: adjust the dough thinkness, expel the air into the dough, lower noise, forming the toast bread dough 4) Proofer: hot water offer enough temprature and humidity which can be ajusted by PLC panel. inside hot wind cycling. 5) Hot wind rotary oven: gas/electric/diesel rotary oven for baking. 12*/32/64/128 trays suits for your requirement. 6) Cooling line: natural cooling by the PU conveyor or cooling cake on the trolleys. 7) Slicer: devider the baked toast bread into small pieces 8)Packing machine: various packing type available. Tips on the whole line: Machines takes area: 15*10m Output: 70-200kg/h toast bread size can be customized toast bread and normal bun bread can be made Machine pictures and bread samples:

Shanghai Yixun Machinery Manufacturing Co., LTD is an experienced manufacturer integrated with design, manufacture, installment and service. The main products are cake machine, biscuit machine, candy machine and cookies machine in shanghai China. ISO and CE certificates we got 10 years ago, and the goods exported to120+ countries. Workshop tour is welcome.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery