00:38

00:38

This machine was designed for automatic can feeding, weighing, filling and failed packs detect & delete. It’s suitable for packaging powdery & grainy product, such as: milk powder, spice,herb glutamate, solid beverage, white sugar, dextrose, fodder, coffee power, solid medicament, powdery & grainy additive, dyestuff, etc. Main Characters: 1. The application of GMP 2. PLC Touch-screen and HMI : set the parameter , easy to control. 4. Servo auger screw : servo motor auger screw measure 5. Unique design to hold the bottle upper when filling , so not dust 6. Sensor control , no bottle no filling

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 01:06

01:06

Model DPM-SLM-A Driving Mode Servo motor Yield(pcs/min) 20-100 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 09:02

09:02

SR series Non-PVC soft bag IV-solution production line is the highest efficiency product line, which is compiling all the most advanced technique. Used for the automatic filling of 50~5000ml conventional infusion, special infusion, flushing/urination, parenteral nutrients , antibiotic and special medicine. Advantage: 1. For patent design, The production line becomes bag making , filling and sealing integrated machine its length is compressed 1/3, the area of workshop and air-conditioner purify are decreased 1/3, so it can decrease the investment cost and use cost in furthest. 2. Because taking off the bag cross-connecting procedure, the reliability of production line can be raised more. Main Characteristic • Applying the advanced technology, it has reasonable structure and stable, reliable feature. •The filling system adopts mass flowmeter to metering, high precision and wide range for filling quantity, and can realize CIP/SIP. • It has high arranges. The servo system, PLC, pneumatic elements and so on, are complete select and use international brand, assure to run in steady and reliable. Technical parameter: TYPE SRD1A / 1200 SRD2A/2500 SRD4A / 5000 SRS6A /7500 SRDI2A / 15000 Main Parameters 1200 bags/h 2500bags/h 5000 bags/h 7500 bags/h 15000 bags/h Capacity 100ml,250ml,500ml Q'ty/ cycle 1 2 4 6 12 InterfaceMethods Boat interface Double tube interface Power Source 3 Phases 380V 50Hz Power 8KW 22KW 30KW 30KW 30KW Process

Huizhou Pingfang PharmaEngineering CO., LTD established in 2004, who is a professional manufacturer focusing on IV solution production line and vacuum blood collection tube production line. Our machinery has features of high-level automation, stable performance, which make us enjoy a high market share over the world.

Contact Supplier 00:08

00:08

Product name 304L Stainless Steel Round Tube 304:0cr18ni9, 0cr17ni8 201:1cr17mn6ni5n,1cr13mn9ni1n 316:0cr17ni12 or as customer’s request Size(round pipe) 9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35, 60, 63.5, 73, 76.2, 88.9, 101.6, 114.3, 127, 133, 159, 168, 219 mm or customized Size (square pipe) 10×10,12×12,18×18,23×23,38×38,50×50,70×70,100×100,20×10, 23×10,24×12, 25×13,36×23,40×20,50×20,60×15,75×45,80×60, 95×45,100×60,150×100 mm or customized Size (oval pipe) 30×15,80×40 mm os customized Thickness 0.24-30 mm Length 6m or according to customer’s request Outer diameter 6-630mm Tolerance Outer diameter :±0.2mm Thickness :±0.02mm Length :±0.5mm Process method Code drawn, annealed with nitrogen protection, ultrasonic,automatic shape, polished Finishing A: sanded B: 400#-600# mirror C: hairline brushed D: TIN titanlum E: HL brushed & mirror (two kinds of finishing for one pipe) Chemical composition (%) Grade C ≤ Si ≤ Mn ≤ P ≤ S ≤ Ni Cr 316L 0.08 0.75 2.00 0.045 0.03 8.00-11.00 18.00-20.00 Physical property Grade YS (MPa) TS (MPa) Elongtion HRB 316L ≥205 ≥520 5 (%)≥40% ≤90

Established in 2008, we devote ourselves into the business of stainless steel sheet,pipe,coil,etc. After fast and stable development, we are the very company with the most complete categories. The factory occupies a total area of 40,00 ㎡. Our main products are: 8K Mirror sheet, HL, NO.4 sheet. They are widely used in elevator decoration, Luxurious doors, outdoor projects, wall decoration, advertisement nameplates, furniture, kitchenware, sanitary ware, ceiling, corridor, hotel hall, shop facade and various stainless steel series.

Contact Supplier 01:13

01:13

MIC 18-6 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. Recent export news: (click for check news) We sold one to The Republic of Angola on April 25,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:49

01:49

MIC 18-18-1 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 4-5mm. cause bottle itself has different when produced. (requires steady pressure and temperature at 0-4degree). 2. Bottle capping machine is qualified for Chinese capping standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum cap and crown cap are ok problem working on our capping machine(different capping head), We use our own technical drawing and own processing machine, to make sure our capping head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Wet glue labeling macchine 5> Liquid level detective machine 6> Metal element detective machine 7> CIP cleaning system Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. DGF18-18-1 triple machine washing, filling in one, is on the base of introducing, digesting and absorbing foreign advanced technology. It is mainly used for soft drinks, juice, beer and other beverages without gas washing bottle, filling and capping. Its structure is advanced, stable, reliable, safe operation, convenient maintenance, the use of frequency conversion speed control, high production efficiency, is the ideal equipment for small and medium sized beverage factory. The production process of the machine are as follows: conveyor chain and triple a machine directly connected, bottles by conveyor chain through a screw into bottle shifting wheel by shifting the bottle star wheel transfer to three synthetic filling machine, into the filling machine of the bottle by retaining the bottom of the bottle holder. The whole machine equipment adopts a closed window, and the sealing window height is higher than the highest point of the equipment, and there is a proper passage in the bottle. →We sold one to The Republic of Yemen on MAY 31,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:04

01:04

Model SLM-A Driving Mode Servo motor Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized depends on client product Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:29

00:29

Vibrating Cooling Conveyor is an auxiliary machine of the precision preformer to avoid stickiness and deformation of the rubber blanks.The part of the machine which directly contact rubber blanks is made of stainless steel. Rubber blank travelles through vibrating method,avoid the stickiness and deformation,the long cooling stroke,max.travel stroke upto 50 meter,cool down fully and the dry effect is prominent. Operator can adjust the vibrating frequency manually,applied for the wide range of rubbr blanks. The material of machine unit is SUS304 stainless steel to avoid the corrosion, For small size rubber blanks, can be directly cooled down by wind; For the heavy weight and much heat rubber blanks, can be cooled by circulation water from external water tank to intensify the cooling effect of rubber blanks,especially with prominent effect for FKM,NBR,CR,EPDM, pelleting, bearing seals, oil seals, O-rings, rubber flakes etc. 1.This is auxiliary machine of the precision preformer to avoid stickiness and deformation of the rubber blanks,the part of the machine which directly contact rubber blanks is made of stainless steel. 2.Small floor space,saving space 3.Suitable for liquid release agent,powder release agent or derect air -cooling. 4.Applicable to FKM,NBR,CR,EPDM and other rubber compounds,and granulation,bearing seals,oil seals,O-rings,Ling strips,Flakes of various kinds of blank. 5.Reasonble design,line hidden inside,connect all the parts of the machine with an aviation plug,easy to disassembly and installation. Technical Parameter Items Unit LSZ1050 LSZ1200 Groove diameter mm 1050 1200 Groove width mm 240 400 Groove height mm 1600 1600 Material running distance mm 35000 50000 Helical pitch mm 110 110 Width of inlet mm 650 650 Height of inlet (From the ground level)mm mm 300 300 Width of outlet mm 245 245 Height of outlet (From the ground level) mm 1650 1650 Conveying Speed (adjustable) m/min 6~8 6~8 Motor power kw 0.75*2 3.7 Motor power for cooling fan kw 3.7 1.1*2 External Dimension (LXWXH) m 2.15*1.35*2.56 3*1.5*2.56 Total weight T 1.2 1.5

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 01:45

01:45

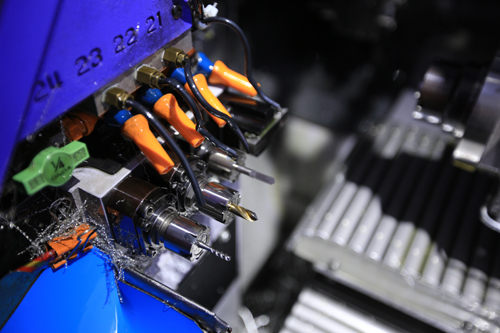

MOQ:1000pcs JM provides machinery machining parts, and parts assembling services, owns horizontal machining center, five/four-axis linkage CNC machines, turn-mill combination, large-sized CNC turning center, and the ability of all-round comprehensive machining services of precision CNC lathe, automatic lathe and various kinds of general machining equipment. JM can implement machining of each series of high-precision mechanical parts, and turning, grinding and precision numerical control of various shapes of materials e.g. Sectional material, disk type parts, casting parts, forging parts, pipe fittings, bend pipe materials and squeezing parts. JM may design and develop new products according to the drawings and samples of customers. BRASS MACHINING PARTS JMBMP JMBMP-001 JMBMP-002 JMBMP-003 JMBMP-004 JMBMP-005 JMBMP-006 JMBMP-007 JMBMP-008 JMBMP-009 JMBMP-010 JMBMP-011 STEEL MACHINING PARTS JMSMP JMSMP-001 JMSMP-002 JMSMP-003 JMSMP-004 JMSMP-005 JMSMP-006 JMSMP-007 JMSMP-008 JMSMP-009 JMSMP-010 JMSMP-011 JMSMP-012 JMSMP-013 CNC Turning Parts-CANADA PROJECT CNC Turning Parts-CANADA PROJECT ALUMINUM MACHINING PARTS JMAMP-001 JMAMP-002 JMAMP-003 JMAMP-004 JMAMP-005 JMAMP-006 JMAMP-007 JMAMP-008 JMAMP-009

Shanghai Jian & Mei Industry and Trade Co., Ltd. is the company which manufacture and export fasteners and metal hardware, founded in 2006, with import-export authority. Now, 80% products export to all over the world and 20% sell in domestic market.

Contact Supplier 01:59

01:59

4-rope Dual Scoop grab is an efficient tool for loading and unloading sands, coal, mineral powder and bulk chemical fertilizer. The mechanical structure for opening & closing is succinct and original. It is easy to use and can work under any circumstances in order. The grab is equipped for the crane which has two hoisting drums and used for grabbing bulk materials. Now the grabs are widely used in ports, electricity, vessel, metallurgy, preservation and transportation, and are exported in batches. Using 3D Virtual Design, by Collision and Interference Checking and taking Dynamic Simulation Test, the products can be showed in the stage of design Intuitively, which can secure the product’s quality and outward appearance. By Simulating the various working conditions the bulk grab may service for, using ANSYS to strength check and Optimize the main parts of the equipment which make the weight distribution more reasonable, stress distribution more optimization and the service life longer. The 4-rope Dual Scoop Grab has 6 types as following:

Shanghai Janus Grab Co., Ltd is a global reputed grab specialist, with more than 30 years experience in grabs design, R&D, and manufacturing. Highly educated professionals in steel structure, hydraulic and electric system make Janus grabs competitive in world-wide markets.

Contact Supplier 00:44

00:44

●Applicable for concocting finished products or mixing different phases of materials in coating, dyes, pigments, printing inks, pesticide and paper-making industries, etc. It can be fitted with many kinds of mixers, which are suitable for different working conditions. ●As per different requirements, the kettle is able to be made into many types such as vacuum type, normal-pressure type, pressure-proof type, cooling type, heating type and so on. ●Various blades as paddle, frame and anchor with low-speed running can be chosen. Also the kettle, normally with single layer structure can be made into normal –pressure type, pressure- proof type, etc.

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier 00:52

00:52

Pass box(also pass through box) is an auxiliary device for clean room. It is mainly used for transferring of small items between clean areas of different classes of cleanliness, also between clean area and non-clean area, to reduce the number of times the clean room is opened, and to reduce the possibility of polluting the clean room to a minimum level. The pass box is made of stainless steel and is plain and smooth. The double doors are interlocked to each other to effectively prevent air exchange and cross-contamination. They are equipped with electronic or mechanical interlocking devices and ultraviolet germicidal lamps. Dynamic pass box can remain self-cleaning, it also has the function as air locks to prevent air convection between different clean rooms.

Shanghai Marya Pharmaceutical Engineering & Project Co., Ltd is a professional Pharmaceutical EPC(Engineering Procurement Construction) supplier based in Shanghai. We mainly focus on the business of Pharmaceutical Turnkey Project, Pharmaceutical Machinery and Cleanroom Turnkey Project.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery