00:41

00:41

This machine is widely used for the labeling of round containers for food, medicine, fine chemical and etc, such as oral liquid bottles,ampoule bottles,syringes,needle rube sleeves,hoses,cultural supplies and so on. This machine adopts servo motor for control. The human-machine touch screen is convenient and easy to operate; the rich failure display function can realize high-speed labeling.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 01:38

01:38

Model PLM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-200 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 550W Weight(kg) 260 Machine size 1800(L) 800 (W) 1500 (H) mm

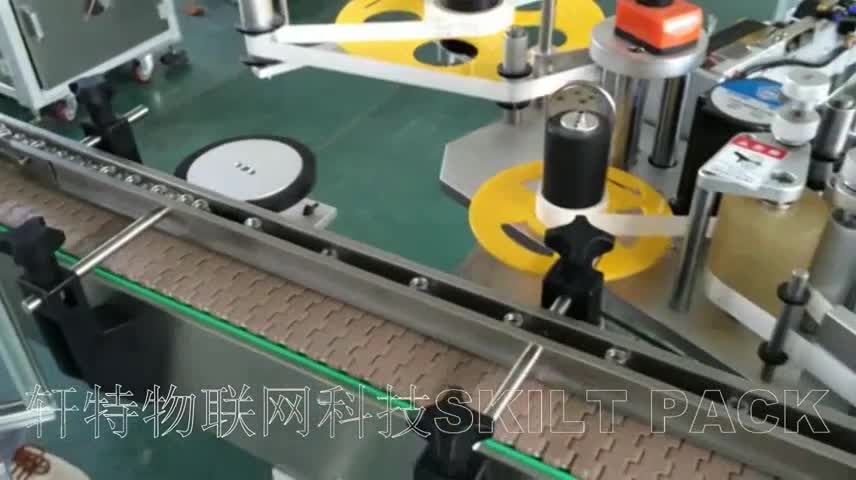

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:12

01:12

Model PLM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-200 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 550W Weight(kg) 260 Machine size 1800(L) 800 (W) 1500 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:42

00:42

Model HPLM-A Driving Mode Servo motor labeling methods The bottle is stand into, stand labeling, stand out Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The size of bottle Outer diameter 20-100mm, height 25-200mm The size of label Height 20-180 mm length 25-200 mm Printer to use air 5kg/cm ² Voltage AC220V 50/60HZ Single side (Can customized as buyer need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:30

00:30

Model DPM-A Driving Mode servo motor Yield(pcs/min) 30-200 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 1000W Weight(kg) 500 Machine size 2000(L) 1200 (W) 1600 (H) mm (machine size can made as client need )

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:02

01:02

Suitable for transporting and storing fuel. Shape and size can be custom made. 40' Fuel Tank Container2 40' Fuel Tank Container Fuel Tank Container 2 Fuel Tank Container

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 01:22

01:22

Catalogue Download Feature • Hexagon /round crimping type for swaging or fishing terminals. • Dies could be OEM as per different terminals sizes, like round is welcome too. • C shape head design for convenient operation. • Head could be rotated 180 degree. For flexible operation in confined place. • Fitted with safety valve. When pressure reach to limited max pressure,s afety-value will release pressure automatically, which prevent over pressure. • Standard nine set of dies, include 4 6 10 16 35 50 70 Parameters Model HP-70CW Terminal Type wire rope fishing/swaging terminals Crimping Capacity Steel wire ropes Φ1-8mm Output 5 T Ram Stroke 12 mm Length/Weight 305mm /1.6kg Application Our cable crimper mainly used for electrical working, State Grid construction, underground cable construction, Building construction etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 01:27

01:27

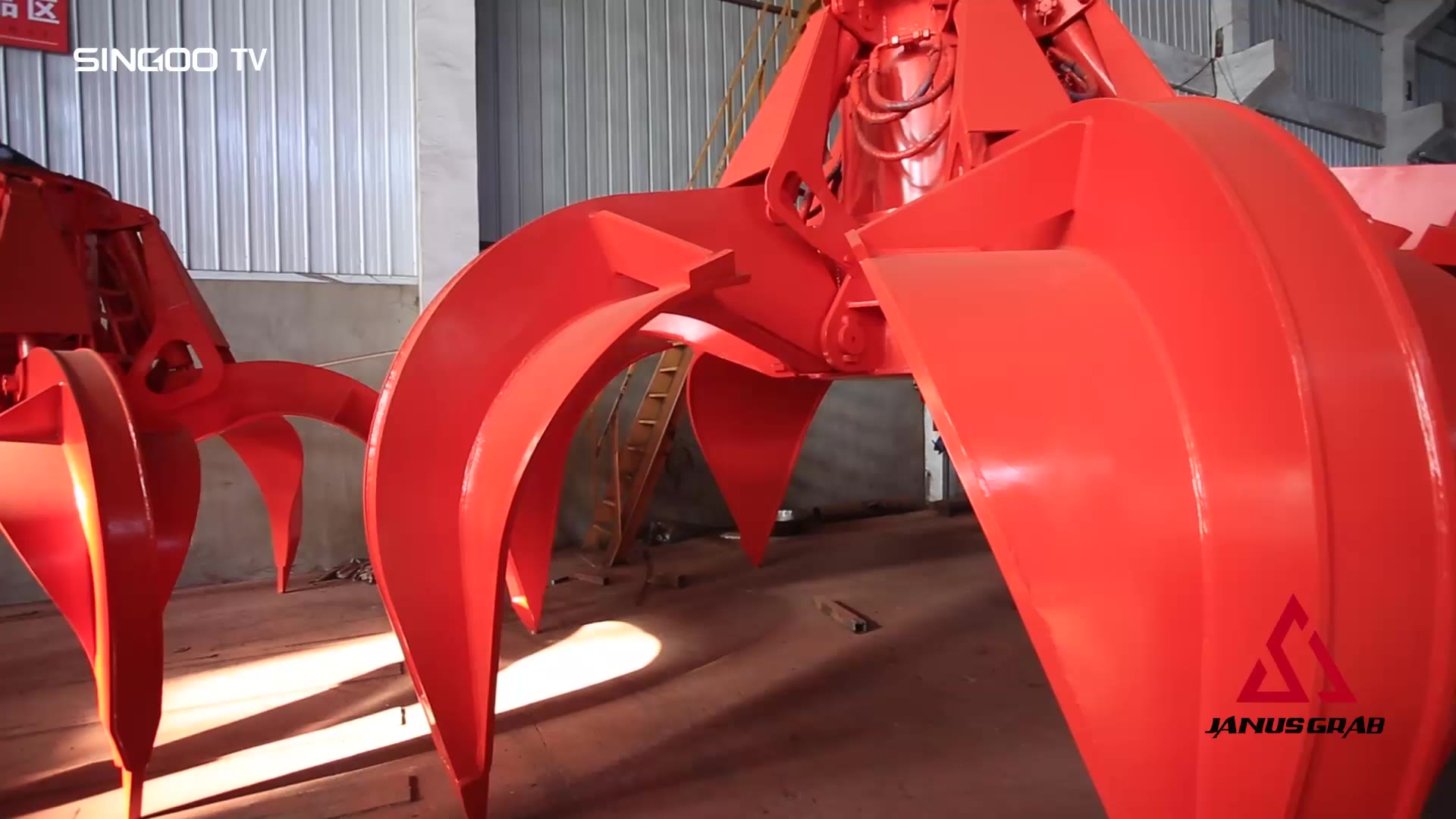

Motor-Hydraulic Scrap Steel Grab has hydraulic power and control system itself, and the hydraulic power system is imported from Europe and USA. The grab uses constant output pump and servo system. The flow of pump can change by itself according to working pressure. When the pressure reaches the max pressure, the flow is almost zero, so it can reduce the overflow, and reduce the temperature rise of oil. The opening and closing is controlled by valves or positive inversion motor which ensures the grab can positive inversion rotate frequently. The grab can be designed as half-close or full-open type with long teeth. The peels of the grab are particular, it is easy to grab scrap steel. The grab has six or eight peels, and each peel is driven by an oil cylinder, so the material won’t leak. The grab has tie-in on the grab and it is easy to connect to the crane. It can be used to load steel scrap whose piled density is below 3t/m3 Type and Size Volume (m3) (mm) Dimensions (kg) Empty Weight (KW) Power (s) Close time (Kg/cm2) Pressure (t) SWL A B C D Full open Half open Full close 380V 50Hz 440V 60Hz DYD5[1]2 1 1766 2626 2532 2093 1800 2000 2150 15 18.5 17 200 5 DYD8[1.5]3.2 1.5 1925 3462 3141 2730 3000 3200 3400 18.5 21 20 200 8 DYD10[2]4.2 2 2242 3565 3456 3147 4000 4200 4300 22 26 16 200 10 DYD16[3]5.5 3 2381 4184 3649 3155 5300 5500 5700 37 43 18 200 16 DYD20[4]7 4.0 2840 4505 3850 3282 6800 7000 7200 37 43 25 200 20 DYD25[5]9 5.0 3020 4807 4125 3027 8500 9000 9200 45 52 22 200 25 DYD30[6.5]9.8 6.5 3137 4983 4230 3700 9500 9800 10200 45 52 25 200 30 DYD35[8]12 8 3645 5513 4490 3850 11500 12000 12500 52 55 25 200 35 DYD40[12]16 12 4662 7188 4730 4590 15000 15500 16000 65 75 25 200 40 Note: 1.As the products have been improved, we will not advice another. 2.We can design and produce the grab according to user’s demand.

Shanghai Janus Grab Co., Ltd is a global reputed grab specialist, with more than 30 years experience in grabs design, R&D, and manufacturing. Highly educated professionals in steel structure, hydraulic and electric system make Janus grabs competitive in world-wide markets.

Contact Supplier 00:44

00:44

Principle It's a wet process milling equipment which can produce continuously, its working principle is the power delivered from high-speed rotor to milling medium and liquid product, through mutual colliding and laminating, ultrafine size can be achieved. Characteristics • High flux―technology imported from Germany: static centrifugal discharging devices, large discharge area with high output. • Double mechanical seal, lubricating liquid dissolves with material, safe and reliable. • Grinding area is made of special anti-wearing alloy ensuring long service life. • Cooling efficiency: segmented double helix waterway which is more advantageous to the energy exchange. Cooling efficiency is 2 times better than ordinary types. • Intelligent double mechanical seals: German mechanical seal technology, imported- fluorine sealing rings can resist different solvents. • Grinding efficiency: increased to more than 30% compared with regular models, the combination of the disperser can rapidly improve dispersion efficiency. The grinding medium can be superfine size to be more efficient. Product Advantages • Low energy consumption ratio, High cost-effective • With large and small belts to conveyor driving force from the motor the main shaft, it is easy to start. The grinding discs are specially designed to have higher effiency and lower electricconsumption. It is machine with higher performance-cost ratio among the grinding machines.Easy to clean and operate • The machine is with integrated on-spot control panel, easy to do operation. Following structures to make it is easy to clean the grinding chamber and the beads to produce materials with different color and varieties with beads collection hopper, the pulley gear device to make it easy for assemble and disassemble the grinding chamber and frame.Safe monitor, stable finished product • Grinding chamber is with cooling jackets. Input cooling water into the jacket when running to have good cooling result, normally the temperature increase will be within 10C. • The machine is with temperature and monitor control. With settable protection value to ensure the quality of the finished products. • Full specification, can be customized • Specifications ranges from 30L to 100L, which can be customized to be Exproof type. Grinding chambers made of Polyurethane or Zirconium are in option to ensure its anti-abrasiveness and alsoto prevent materials from metal pollution. Working Principle The delivery pump circulates the materials in the tank and the materials in the grinding chamber. The discs drive the grinding medium inside the grinding chamber to do irregular movements in all direction to put the materials under the. action of constant collision and friction. At same time, the materials are separated from the grinding medium by the sieve and keep circulating from the tank to the grinding chamber to obtain smaller particle size, narrower particle size range.

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier 06:10

06:10

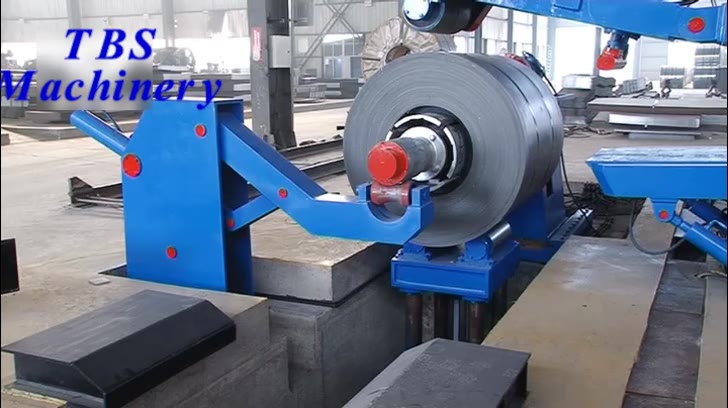

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” HR/pickling coil slitting line is used for coil with different specifications, through uncoiling-slitting-recoiling to needed width coil for the application of all kinds field.It is consists of uncoiler, feeder, pinch, pre-leveler, cropping shear, slitter, scrap winder and recoiler, etc. It is used for slitting the wide raw coil into narrow strips in order to prepare material for subsequent processes as milling, pipe welding, cold forming, punch forming, etc. Moreover, this line can also slit various non ferrous metal coils by changing slitting tools of different materials. This line is reasonable in layout, easy operation, high level of automation, high productivity . The machine performance has reached the international standard. This slitting line series coil thickness range can be from 1.0mm to 8.0mm and coil width can be from 900mm to 2000mm,all these size steel coils are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of Coil Slitting Line Model TMS6X2000 TMS8X2000 Coil Thickness(mm) 1.0-6.0 2.0-8.0 Coil Width(mm) 900-2000 900-2000 No. of Strips 2-10 2-8 Line Speed(m/min) 0-50 0-40 Coil Weight(T) 30 30 Finish Strip Width(mm) ≥50 ≥70 Occupied Area(m) 28X11 30X11 Power(kw) 320 340 Main Shaft Dia(mm) φ260 φ300

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 03:17

03:17

Brief Introduction YX Lollipo Production Line, confrms to the food GMP standard, is an advanced equipment for producing various shapes and colors of lollipop candy. Ideal equipment for continuous production of high quality single and double color lollipop candy. High-degree automation ensures of stale production and saves time, labor force and occupation to serve purpose of reducing the cost Lollipop candy making process Sugar melting--Storage tank-- Micro-film cooker --Depositing --Stick plug machine--Cooling tunnel--Packing The functions of each machine. 1) Sugar melting tank: heating sugar, glocose, water to 110 degrees. 2) Storage tank: storage the sugar syrup and and filting pure syrup. 3) Micro-film cooker: cooker the syrup again to 145 degrees for better taste, moisture is lower then 2%, suits for international standard. 4)Deposting and Cooling: depositing the sugar syrup into different candy mouds 5) Stick Plug machine: plug the stick into the lollipop moulds 6) Packing machine: various packing machine available. Technical Parameters Model YX-150 YX-300 YX-450 YX-600 Standard Output 150kg/h 300kg/h 450kg/h 600kg/h Max.Candy Weight over 4 gram Depositing Speed 40-45/min 40-45/min 40-45/min 40-45/min Steam Requirement 0.2m³/min, 0.4-0.6Mpa 0.2m³/min, 0.4-0.6Mpa 0.2m³/min, 0.4-0.6Mpa 0.2m³/min ,0.4-0.6Mpa Working Requirement Room Temperature: 20~25℃ Humidity: 55% Total Power 18kw/380V 27kw/380V 34kw/380V 38kw/380V Total Length 15m 17m 17m 20m Total Weight 3500kg 4000kg 4500kg 5000kg Tips on the lollipop candy production line: 1) The whole line equipped the international motor: ABB motor, Danfoss invertor, Mitsubishi PLC control, servo motor, SS materials 2) Heating by steam or electric 3) Essence and pigment pump installed with the machine. 4) Lollipop size and weight effects the final output 5) One/ two colors/center fillied lollipop candy can be made 6) 260 pieces candy moulds for the 150 type, 520 pieces for the 300 type Pictures and final hard Lollipop samples:

Shanghai Yixun Machinery Manufacturing Co., LTD is an experienced manufacturer integrated with design, manufacture, installment and service. The main products are cake machine, biscuit machine, candy machine and cookies machine in shanghai China. ISO and CE certificates we got 10 years ago, and the goods exported to120+ countries. Workshop tour is welcome.

Contact Supplier 00:41

00:41

Model DPM-DLM-SLM-A Driving Mode Servo motor Yield(pcs/min) 30-120 (depends on bottle and label size) Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Inner diameter of label roll 76 mm Outer diameter of label roll 350 mm(max) Suitable label size Width 15-150 mm length 15-250 mm Suitable labeling products size Can customized depends on client product Printer use air 5kg/cm ² Voltage (can customized) 110V/220V/380V Power(w) 1200W Weight(kg) 460 Machine size 3500(L) 1250 (W) 1300 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery