00:50

00:50

This machine is widely used for the labeling of the round objects in such industrials as food, medicine, daily chemical and so on. It can work independently or by connecting to the production line. In addition, it is equipped with air-powered glue pump and label shortage warning device.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 01:17

01:17

The jam filling machine is suitable for sauce with particles within 10mm Main characteristics : 1.The machine adopts servo motor to control filling volume with high precision. 2. Customers will be able to set and change parameters via touch screen. 3. Filling nozzle and filling frame is controlled by cylinder 4. All the filling nozzles will filling at the same time. 5. All the filling nozzles adopt the most advanced setting and inject method. 6. This machine will alarm or automatically stop when happens unconventionality circs (such as account mistake, bottle missing ) 7. Customer can set up the total producing capacity on the PLC 8. With storage tank with stir, with a one set washing system (automatic clear water loading , and outlet of the unclear water , until all is clear) 9. bottle fiber inspection for counting and give signal for the machine (no enough bottles coming to the filling position , no filling. ) 10. Filling nozzle: The filling nozzle introduced is “closed preventing dropping filling nozzle” which can prevent dropping in a long time working. 11. This machine adopts Mitsubishi PLC program and Keyence photoelectricity sensor made in Japan, Airtac electromagnetism valve. 12 . GP5600 adopt number system to adjust filling capacity. It is easy and convenient to adjust, and only takes some minutes to change.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 00:53

00:53

Premade retort/spout pouch filling and sealing machine can insert the top spout .filling and sealing automatically . Features: 1. Pouch picking 2. Easy specification change 3. Needn't stop machine when supply pouches 4. Reduce filling time by half 5. Improved filling accuracy 6. Fill 2 products simultaneously 7. Ensure seal strength, no leakage 8. Even seal with good appearance 9. Higher adaptability of film material 10. Equipped with different metering device, it can realize packing different material such as powder, liquid, granule, sauce etc. 11. Compact design , easy to operate and maintain. Characteristics: 1) PLC control , English and man-machine interface, operating easy and simple maintain . 2) Advanced control system , no bag no filling and no sealing, reduce bag wasting. 3) Could fill powder, granule or liquid product by change filling device, stand up bag or flat bag are multi functional . 4) Whole safe door to protect operator safety . 5) Sanitary package for your product and perfect package appearance. 6) Easy and fast adjustment of change over, smooth performance and low noise Sensible safety device and no pollution during production to get Friendly working environment

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 01:38

01:38

Product Name AAAC、AAC&ACSR Reference Standard This product is produced with the standard of IEC 61089-1991 Applications Aerial transmission and distribution line, State Grid Project Performance Featured with convenient erection & maintenance, low cost of line construction, high transmission capacity, facilitate laying in special geographical condition such as across rivers and valleys, good conductivity and enough mechanical strength & tensile strength, pole distance could be increased and so on.

Wuxi Jiangnan Cable Co., Ltd., founded in 1985, is a National Key Hi-Tech. Enterprise, mainly manufacturing integrates wires and cables. By the end of 2015, With a floor space of more than 500,000 square meters, total built-up area of 350,000 square meters, and total assets worth above RMB 7 billion, the Company now has an employee size of 3,000-odd persons, of which, middle and high-level technical and managerial personnel with diploma of junior college or above make up more than 30 per cent of the Company’s total employees. In addition to boasting more than 1,400 sets (units) of China and the world first-class production and testing devices, the Company takes the lead in realizing whole-process dynamic monitoring and management over its logistics, capital flow, and human resources by virtue of its ERP network information management system, HER H.R. management system, and OA system, thus IT-based management in the Company comes true.

Contact Supplier 01:29

01:29

1.This stacker adopts a dual orifice control system and double linkage cylinder assembly to ensure a bi-directional motion of the piston rod. 2.The internal gantry is independent posts and connected to the fork with bolts.The piston rod moves up and down to elevate and descend the goods,without the help of the roller board to transmit. The external post is the supporting post,welded to the rack platform,which reduces the total height and weight. 3.The gate base is unfixed which allows a relative motion with the elevating of the rack and fork.When the fork(including the goods) rises to the platform height,the gate base withdraws and the rack rises to the platform with the cylinder in circulation.

Since the foundation, Shanghai Hytger Industry & Trade Co., Ltd. has striven to offer you high-class material handling solutions and high-class services. SHYGTER has specialized in manufacturing and selling forklift trucks, stackers, pallet trucks, loader trucks, container cranes, tire presses, dock ramps, aerial work platforms and other hydraulic equipment and their parts. After many years of successful development, SHYGER has grown to be a strong global supplier of material handling equipment and construction machinery. We can also provide forklift parts of other brands, such as TCM, LINDE, HELI, HYTSU, HANGCHA, BAOLI, JAC, DOOSAN and so on. Besides, we can offer OEM business to you according to your requirements. After great and constant efforts in recent years, we have had our own production bases and international trade company, set up a strict quality assurance system, built up a strong management framework and established a perfect after-sale service system. HYTGER has passed ISO9001, ISO14001, CE certifications. In addition, our products have passed the inspection of global markets and gained recognition from global customers! With a professional R&D team, well-trained workers and a strict quality control system, we are able to supply reliable and high-quality products to our esteemed customers all over the world with guaranteed delivery time. The annual output reaches 3000 units. Our products are popular with clients in over 50 countries and regions. HYTGER will continue to follow the spirit of "Innovation, Aggressiveness and Integrity" in the future. Meanwhile, we will strive to build a famous brand, follow the tenet of "globalization, specialization and environment protection" and offer high-class products and service to global customers!

Contact Supplier 01:07

01:07

Model PWM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-220 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-100 mm length 15-80 mm The suitable size of labeling objects Customized depends on client product Printer use air 5kg/cm ² Power(w) 600W Weight(kg) 200 Machine size 1800(L) 800 (W) 1300 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:05

01:05

Model PLM-S Driving Mode Servo motor Yield(pcs/min) 10-80(depends on product and label size) Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-150 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 850W Weight(kg) 360 Machine size 2300(L) 800 (W) 1500 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:08

00:08

Our production line including up decoiler and down decoiler, each decoiler has coil car, hydraulic station, decoiler body, our company has two type decoilers ,one has assist support device, the other do not has the assist support device. 1)The decoiler has two type. One type with assist support, the other without. 2)Two control type, one is using light switch ,the other is 3)Support design: The structure is more reliable than the hinged type frame, and 5Ton hydraulic can not working stable for a long time without this support design. 4)Coil drum: four pcs nest, provide 508mm and 610mm two size, when the coil inner diameters want to change into 610, can assembling the four arc plate and insure the hydraulic expand lock to insure the expand force. 5)Assistant supporter:during the production of PU continuous line, it needs to reduce the connection of steel coils, so the loading requirement of uncoiler is high. Meanwhile, in order to avoid the drooping of main shaft and off tracking of steel coil, uncoiler adopts assistant supporter to guarantee the loading of 10T coil without the deformation of main shaft. The assistant supporter of uncoiler adopts quick hinge type, operation is very convenient, so that the production line will not stop during the connection of steel coils’ends. 6)The assistant supporter of uncoiler adopts quick hinge type, operation is very convenient, so that the production line will not stop during the connection of steel coils’ends. 7)Above mentioned measures can guarantee the changing time of steel coil within 45 seconds; 8)Drive system:positive and negative rotation carry out the uncoiling and recoiling, the main shaft of uncoiler is driven by motor and reduction box to carry out the active uncoiling,and also used for recycling of unfinished production steel panel. When active uncoiling,the speed can be synchronous with production line, there is ultrasonic wave detecting for tracking the speed of main line, whole process is frequency conversion controlled; 9)Uncoiler has material pressing unit, which is fixed above with the angle 30-40°, avoid collision with up machine machine frame; 10)Lifting table:oil hydraulic motor drives lifting table move along the guide rail, the guide rail is lengthened to avoid collision of steel coil and up machine machine frame.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 04:46

04:46

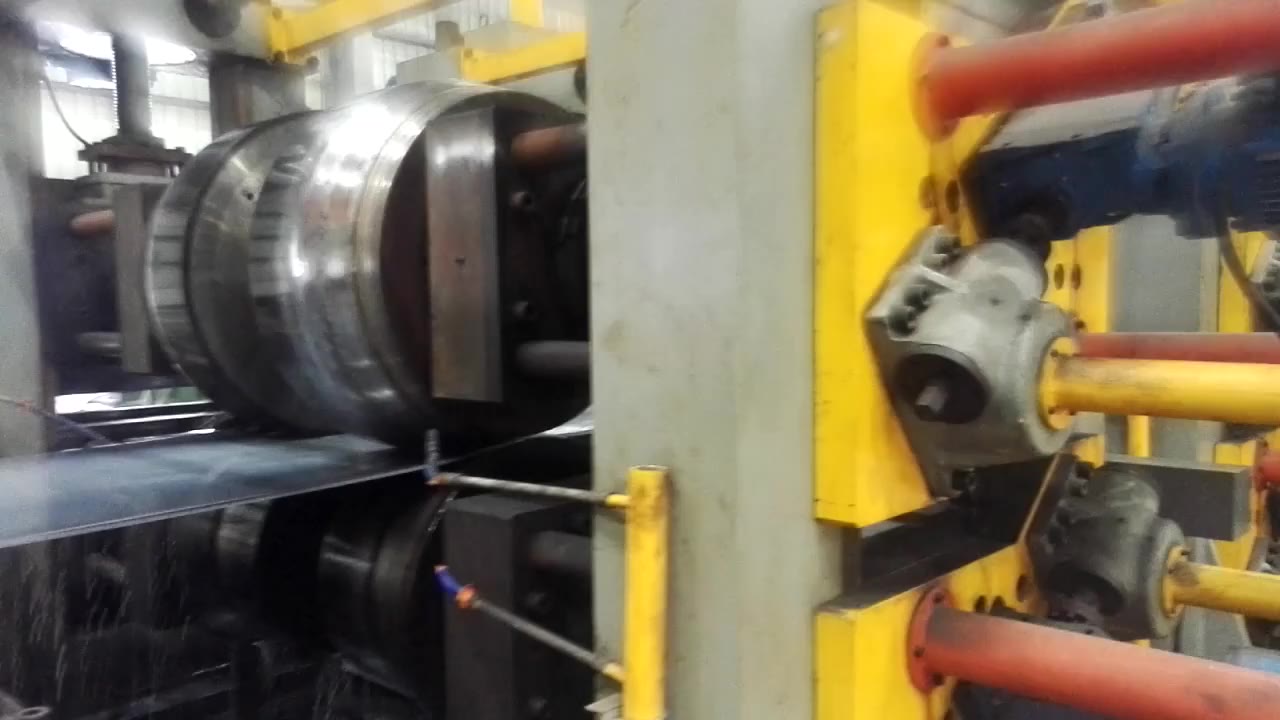

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” TDG Series Directly Forming to Square and Rectangular Tube Mill Only one set of rollers can be continuously produced within a certain range of rectangular steel pipe, using the international advanced multi-radius combination molding process and high-frequency welding, forming by multi-channel symmetrical bending. It can be divided into small side bending, boardside bending, free bending at closed side, high frequency welding, precision straightening, produce the exact size and good quality pipe after cut off. Characteristic: One set mold roller can produces a range of rectangular tubes. This machine has characteristics such as no replace spindle, no remove roller stand and quick change rollers. Save mold, save time. Four square corner deformation part which can save extra deformation process then save energy consumption and equipment load. Specification of Directly Forming to Square and Rectangular Tube Mill SPEC TDG600X600 TDG500X500 TDG400X400 - Material to be processed Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon - Type Square & Rectangular tube Square & Rectangular tube Square & Rectangular tube Square 300 x 300 – 600 x 600 mm 250 x 250 – 500 x 500 mm 180 x 180 – 400 x 400 mm Rectangular 300 x400 – 500 x 600 mm 250 x350 – 300 x 500 mm 180 x200 – 300 x 400 mm - Wall thickness 6.0 mm – 22.0 mm 5.0 mm – 18.0 mm 5.0 mm – 14.0 mm - Tube length 6.0 m - 24.0 m 6.0 m - 18.0 m 6.0 m - 12.0 m - Line Speed Max. 20m/min Min.12m/min Max. 24 m/min Max. 30 m/min - Welding Method Solid State High Frequency Welding Solid State High Frequency Welding Solid State High Frequency Welding - Forming Method Directly Forming to Square and Rectangular tube Directly Forming to Square and Rectangular Directly Forming to Square and Rectangular Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 00:31

00:31

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut to length line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” Our TAG series Alumnium High Precision Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation. Featured ERW Welded line for Aluminium Spacer Bar To meet the demand of aluminum spacer bar market,we also design High Frequency Welded line of Aluminium Spacer Bar for hollow glass that is based on 3003 aluminium the material .Adopt the technology roller forming and high frequency welding that does not destroy the molecular structure of raw material ,to ensure the molecular sieve activity,bending and filling without splitting. Our High frequency welding aluminum spacer bar production line has reached international standard .The finished alumium spacer bar have bright ,smooth surface with perfect single side and double line hole to ensure activity of desiccant.Strictly control of raw material procument and production of in order to guarantee to make sure the finished products no errors,no deformation and keep size precise. High Frequency welding for aluminium adopt one right angle connection technology to produce hollow glass without any joint parts,sealing effect is perfect that can avoid no leakage,Prolong the hollow galss working life. Advantage of ERW Welded line for Aluminium Spacer Bar Compare with ordinary aluminium bar,the high frequency welding have following advantage 1. Anti-rust,anti-corrosion, brighter surface. 2. The surface hole of aluminium bar is in unformity,,no deformation, good straighteness 3. High strength ,good toughness,the material can be bent continuously into aluminium frame in any angle by bending machine 4. Ensure the activity of molecular sieve and excellent adhension with all kinds of rubber. Aluminum Spacer Bar Products Spectification 1:1 Section Model Section Width(mm) Section Height(mm) Thickness (mm) Length(m/root) 6A 5.5 6.5 0.2-0.35 If more than 4m,we can sizing 8A 7.5 6.5 0.2-0.35 9A 8.5 6.5 0.23-0.35 10A 11.5 6.5 0.25-0.35 12A 11.5 6.5 0.25-0.35 15A 14.5 6.5 0.27-0.35 6.0 6.0 6.5 0.2-0.35 8.0 8.0 6.5 0.2-0.35 10.0 10.0 6.5 0.23-0.35 11.0 11.0 6.5 0.25-0.35 Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 00:52

00:52

Cleanroom air shower is a highly versatile partial purification device installed in the passage of clean room and non-clean room, used to reduce the pollution problems caused by entering and leaving the clean room. When people or goods need to enter the clean area, they must be sprayed and showered in this equipment. The clean air blown out can remove the dust carried by people or goods, and can effectively prevent or reduce dust from entering the clean area. The front and rear doors of the air shower are electronically interlocked and act as air locks to prevent un-purified air from entering the clean area.

Shanghai Marya Pharmaceutical Engineering & Project Co., Ltd is a professional Pharmaceutical EPC(Engineering Procurement Construction) supplier based in Shanghai. We mainly focus on the business of Pharmaceutical Turnkey Project, Pharmaceutical Machinery and Cleanroom Turnkey Project.

Contact Supplier 00:52

00:52

Hydrogen Peroxide Plasma Sterilizer is highly effective, non-toxic and harmless biological decontamination equipment, and has been widely used in the hospitals, medical clinics, laborataries, pharmaceutical factories for closed room and isolation space sterilizing. The hydrogen peroxide vapor sterilization equipment utilizes vaporized hydrogen peroxide to kill the spore, bacteria and virus at a normal temperature by forming a free -OH to attack cellular components, including lipids, proteins and DNA, finally to achieve complete sterilization requirements.

Shanghai Marya Pharmaceutical Engineering & Project Co., Ltd is a professional Pharmaceutical EPC(Engineering Procurement Construction) supplier based in Shanghai. We mainly focus on the business of Pharmaceutical Turnkey Project, Pharmaceutical Machinery and Cleanroom Turnkey Project.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery