01:31

01:31

CNC Machining: It is mainly used for small or medium-size lot order production that requires fine surface, precise tolerance. Metal materials like steel, stainless steel or aluminum are suitable for this process. Starway is able to provide CNC machining services based on customers’ drawings or designs. CNC Machining Center: We have the CNC machining centers that are able to realize different manufacturing processes at high quality, precise tolerance. CNC Turning Machine: CNC lathe with universal tools to reach different features. CNC Milling Machine: Our milling machine work table is 1500*400mm max. Drilling Machine: We are able to provide drill Countersunk holes, Metric or imperial size threads. CNC Grinding Machine: It is used to manufacture products at high quality surface. EDM Wire Cutting Machine: It is used to cut thick plate with high quality cutting edge.

Starway Engineering & Manufacturing Co., LTD, founded in 2010 and located in west Shanghai, is focusing on providing one-stop solution for metal parts & products. We are committed to help clients realize the concepts and designs with support of our engineering and manufacturing advantages that includes projects made of processes as: Sheet metal fabrication CNC machinning Stamping & forming Aluminum extrusion Casting Assembly

Contact Supplier 01:58

01:58

Advantages: Low maintenance cost Easy operation Low break-down rate (servo structure) Product with high precision Characteristics: 1)The transmission of the main transmission system is carried out by either mean:1) Using a high-strength nylon-based flat transmission belt, in which the stress is even.2) Main motor directly connects to driving shaft. The operation is reliable and smooth, and the rolling mill system has the function of overload protection. 2)The stroke of the saddles is increased, the long-journey rolling is carried out by annular ring type roller, the rotation angle of the roller is changeable, the groove working section is lengthened, the length of deformation zone is increased, and therefore the uniformity of metal deformation in the rolling process is increased, the feed amount can be increased, and the quality of the finished pipe can be improved. 3)The rotary feed system is controlled with German Rexroth AC servo, wherein the feed amount is accurate, reliable and stepless adjustable, the deviation of feed amount is not more than 2%, the size of the rotation angle can be adjusted, the billet will be rotated and fed for two times in the same rolling process, and therefore the distribution of rolling force is even, the axial force is reduced significantly, the high-precision pipe with small deviation of the outer diameter and wall thickness can be obtained, and the yield is high. 4)Compared with side feeding, the rolling mill, which uses end feeding mode, reduces mandrel-removing device; moreover, the position of the mandrel in the deformation zone is accurate, length of mill is shortened, the mode is suitable for the rolling of long billet, and the working efficiency of the rolling mill is improved. 5)Function of loading, unloading, feeding and other procedures are controlled with PLC program,, and therefore the degree of automation is high. 6)The rolling pressure of machine is reduced by using a curve type core bar, and therefore the deformation of the billet metal is even and reasonable. 7)The main gears are provided with hardened tooth grinding process, by which the transmission is smooth, and the noise is low. 8)The main shaft and important gear are made of high-strength alloy steel. 9)The inner surface of the billet used is lubricated to improve the inner surface quality of the pipe, while prolonging the service life of the core bar. 10)The rolling machine uses annular ring type roller, curve type mandrel, as well as the rolling mode of dual rotation and dual feed, and therefore the correction ability to the billet of which the wall thickness is uneven is relatively strong. 11)The equipment has a mandrel fracture detection device, by which the equipment will be automatically stopped in case of the fracture of mandrel, and therefore the equipment can be protected well. 12)A number of patented technologies are applied to the equipment, such as floating type brake, and hydraulic locking nut of the rack. (The feed of the before dead center shall be determined according to the specific rolling condition)

Shanghai Pan Zhihua Machinery Manufacturing Co.,LTD is located on the third largest island of China municipal industrial park----No.898,San Sha Hong Road. Among the company’s 160 staffs them,25 people have high-level technical title.The total area of the factory is 38000 square meters,with standard workshop 19800 square meters.

Contact Supplier 01:16

01:16

Features: 1) Full-automatically Carton Erector 2) Vertical storage:the cartons can be added in line at any time without stopping the machine. 3) Folding and taping the bottom cover during delivery and without stopping. Finish adsorbing, forming, folding bottom cover and taping bottom in 3 seconds. More productive and more efficient. More productive and more efficient. 4) Suitable for different carton size and it can be manually adjust in 2 minutes. 5) Adopted international advanced technology, with imported parts and electrical components, this machine has a stable performance and long life-using. 6) Equipped with PLC system, saving labor and easy to operate.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 00:33

00:33

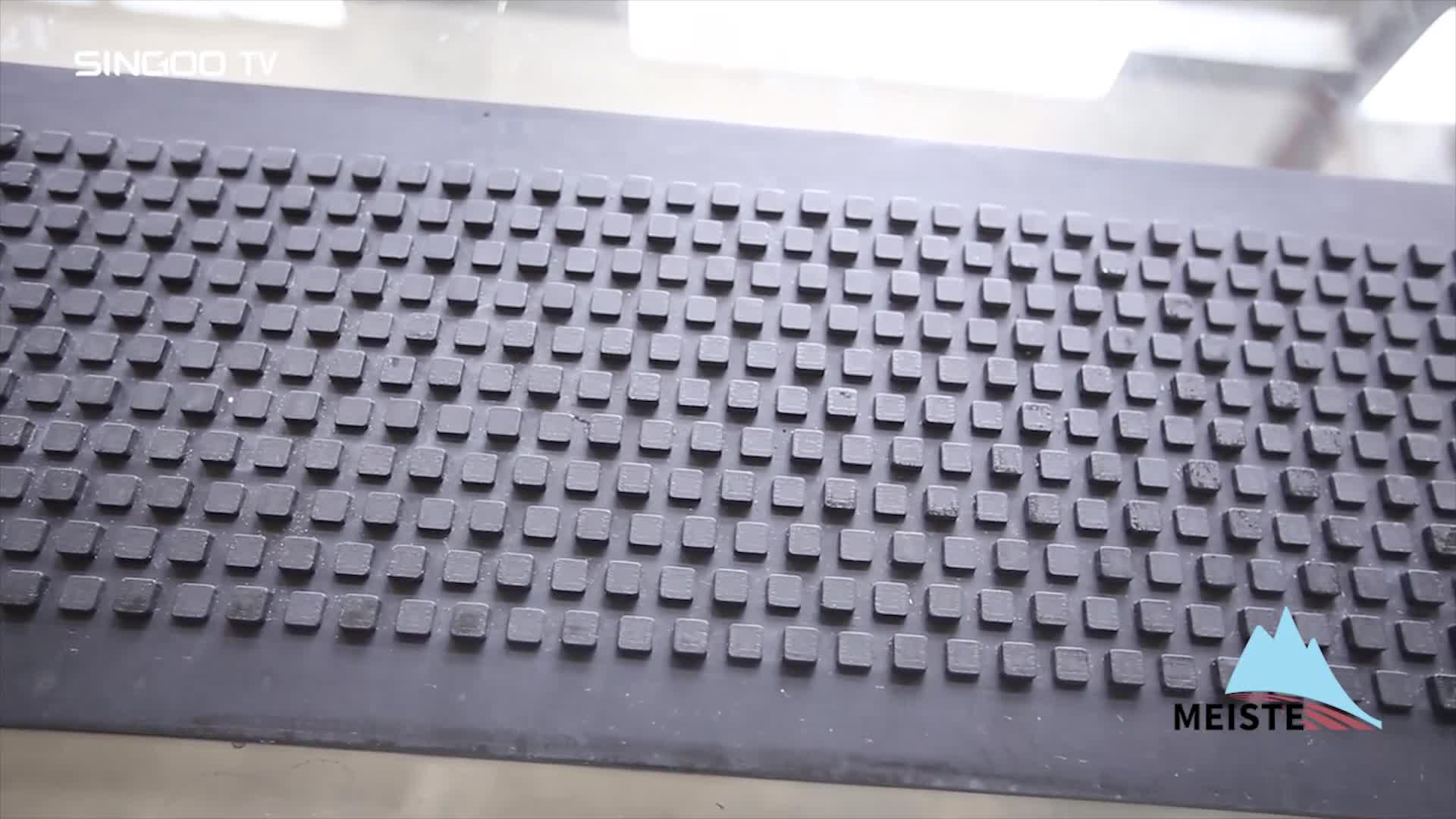

Our portable snow melting mats are specifically designed for you to create a safe, convenient and slip-resistant walkway for your family during the cold winter days. Snow melting mats could enable you to get a clean and safe passageway melting snow or ice automatically. The durable and effective melting system is undoubtedly the ideal alternative to the traditional way of snow and ice removal. Global Agents Wanted Click for more details Category Floor Cleaning/ Space Heating/ Roof Snow Melting/ Passageway Snow Melting/ Car Windshield Heating Pad Shipping

We are a professional Chinese manufacturer majoring in the production of snow melting mats efficient and convenient to save you out of the series of trouble like snow shoveling, salting and slipping.

Contact Supplier 00:44

00:44

Model XTHZ-10 Driving Mode Servo motor labeling methods The bottle is stand into, stand labeling, stand out Conveyor Speed(m/min) ≤50 Labeling Accuracy ±1.0mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The size of bottle Can customized The size of label Height 20-180 mm length 25-200 mm Printer to use air 5kg/cm ² Voltage AC220V 50/60HZ Single side (Can customized as buyer need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:21

00:21

Model PWM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-220 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-100 mm length 15-80 mm The suitable size of labeling objects Customized depends on client product Printer use air 5kg/cm ² Power(w) 600W Weight(kg) 200 Machine size 1800(L) 800 (W) 1300 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:37

00:37

Model SLM-A Driving Mode Servo motor Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized depends on client product Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:00

00:00

Self-centering feeding chuck, capable of round, square, rectangle and other kind of profiles’ clamping. And clamping force can be adjusted manually or automatic. Self-adjusting assisting chuck, the chuck could adjust itself according to the part program, so it perfectly fits the requirement of small batch production, for mass production just need one time adjustment. Position reconfigurable assisting chuck, under different cutting status, the program can auto configure the position of the assisting chuck, to minimize the residual length of the material to save custom cost. Material auto-alignment, auto aligning the material to the machine axis, avoid manual loading, which guarantee the safe operation and avoid collision between chuck and material. Real-time material supporting, CNC controlled material supporting axis will follow the contour of profile in real-time, to improve the machine accuracy, and can automated retract to avoid collision. Fully enveloped cutting zone with big fiber laser proofed watching window to guarantee the safety of the operator. Auto lubrication, equipped with auto-lubrication system to simplify ordinary maintenance procedure. Chuck system Self-centering feeding chuck, is capable for round, square, rectangle and other kind of profiles’ clamping automatically and the clamping force can be adjusted. Auto-focus Cutting Head The focus adjustment is motorized by an integrated capacitive distance sensor. Even with irregular tubes, the laser cutting process parameters will be kept constant during the entire production. CNC control A powerful CNC lies at the heart of the Lead Laser tube laser cutting performance. All important laser components are integrated in one single closed-loop control system mastering every single aspect of the laser cutting process at a microsecond-level cycle-time. Chuck system Auto-focus Cutting Head CNC control Application: All tubes such as rectangular, round tube and so on available for cutting such metal sheet as stainless steel, carbon steel, copper, brass, alloy steel, aluminum, gold, silver, titanium and so on. Widely used in the sheet metal processing, shipbuilding, automobile, rail transportation, agriculture machinery, advertising board ,kitchen utensils, machinery, elevator and so on.

As a professional and energetic enterprise in the sheet metal processing industry, Suzhou Lead Laser Technology Co., Ltd manufactures high performance of laser cutting machine and laser welding machine for various applications with two production facilities in China.

Contact Supplier 01:56

01:56

Description DL Sludge dehydrator SFC Sludge Dehydrator guide revolutionary technology in industry and municipal wastewater treatment sludge dewatering . Unique design of the Sludge Dehydrator allows 24 hr unattended operation 7 days per week, Simple process ,high efficiency ,power saving ,low investment make the SFC Sludge Dehydrator widely used in industry and municipal sludge dewatering replace any other kinds of dewatering unit plate fiter press, centrifuge , belt press and so on . Features * Simple process ,high efficiency ,power saving ,low investment * Programme setting makes the operation convenient and accurate * Exclusive flocculent helps with the dewatering performance * Accurate chemical preparation and dosage saves much operation cost Screw Press Superiority (SFC ) 1. Wide application range Exclusive pre-concentration design , applicable sludge concentration of 200mg/L~50000mg/L Due to innovation of the structure design .Highly suitable to various high and low concentration sludge most especially the oily ones. Widely application range including municipal sewage ,food wastewater,slaughter house ,printing and dyeing, oil chemical industry, paper making ,leather ,pharmacy and other different kinds of sludge dewatering. 2. Small foot print SFC Screw Press can be installed in places where placement would not be possible with other technology . What makes SFC Screw Press suitable to cutomers who are considering the replacement of existing sludge dewatering unit . 3. No blocking Due to the moving of the fixed rings and moving rings self -cleaning .The ubiquitous clogging is avoided .Handing oily sludge without trouble while separating the water from the sludge easily . Above all , no need large quantiry of flushing water and no odor ,no secondary pollution during the sludge dewatering process . 4. Running cost saving SFC Screw Press relles on the inner pressure of the filter chamber and the rotating speed is as slow as 2~4rpm. The average unit power consumption is only 0.1~0.01kwh/kg-DS(1/8 of Belt Filter Press and 1/20 of Centrifuge) . Greatly reduce the running cost of wastewater treatment system . 5. Fully automatic control SFC Screw Press equipped without device like filter clothes or filter pore that easy blocked .Operation so easily and can be set to operate automatically via the eletric control cabinet . 6. Super resistance to oily sludge Self-cleaning mechanism and stainless steel structure enables SFC Screw Press to be the ideal to dewater oily sludge ,which easily causes clogging and is difficult to treat wit other types of dewatering equipments . Application Field

Shanghai Fuchan Machinery Technology Co.,Ltd .Short of SFC is the Leading supplier of total solution and equipment of industrial and municipal wastewater applications. SFC design, engineer ,fabricate, assemble products market into the municipal wastewater and industrial wastewater segments. The company was founded in 2007 and has been owned by Jackson Wang. SFC headquartered is in shanghai , China. And manufacture center located in Environmental Town Jiangsu province.SFC is organized into a business unit structure to focus on four critical growth markets: Municipal Wastewater, Industrial Systems, After-sales Services, and International Market. SFC ensure the excellent quality products and customer service for our partners . ISO 9001:2008 and CE certified since 2007. SFC had won great fame both home and abroad in the business of water and wastewater.

Contact Supplier 00:44

00:44

Model XTHZ-10 Driving Mode Servo motor labeling methods The bottle is stand into, stand labeling, stand out Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The size of bottle Outer diameter 20-100mm, height 25-200mm The size of label Height 20-180 mm length 25-200 mm Printer to use air 5kg/cm ² Voltage AC220V 50/60HZ Single side (Can customized as buyer need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:38

00:38

Model DPM-SLM-A Driving Mode Servo motor Yield(pcs/min) 20-130 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-160 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:34

00:34

Brief Introduction YX toffee candy production line, combined manufacture with electromechanical program, great advantages of pneumatic system of depositing and demoulding, is an advanced equipment for producing various shapes and colors of toffee candy. single/double/stripped /center filled toffee candy can be made by the same machine. Toffee candy making process Sugar melting--Storage tank--Toffee candy cooker--Depositing and cooling--Packing The functions of each machine. 1) Sugar melting tank: heating sugar,water,milk and so on 2) Storage tank: storage and filting pure syrup. 3)Toffee candy cooker: jacket layer heating by steam, rotating speed-adjustable scraper, boiling the caramel 4)Deposting and Cooling: depositing the toffee syrup and cooling for demoulding 5) Packing machine: various packing machine available. Technical Parameters Model YX-150 YX-300 YX-450 YX-600 Power 20kw 30KW 40kw 50kw Compressed Air Consumption 0.5m³/min 0.6m³/min 0.6m³/min 0.7m³/min Compressed Air Pressure 0.4-0.6Mpa Steam Consumption 100-150kg/h 250-300kg/h 350-450kg/h 500-600kg/h Steam Pressure <0.6MPa Water Consumption 800L/H 1000L/H 1200L/H 1300L/H Dimension 18000×1200×2300mm 18000×1600×2300mm 20000×2000×2300mm 20000×2200×2300mm Weight 4200kg 5200kg 6200kg 7000kg Tips on the toffee candy production line: 1) The whole line equipped the international motor: ABB motor, Danfoss invertor, Mitsubishi PLC control, servo motor, copland AC, SS materials 2) Heating by steam 3) Essence and pigment pump installed with the machine. 4) Various shapes toffee candy can be produced by changing moulds 5) Candy size and weight effects the final output Pictures and final soft candy samples:

Shanghai Yixun Machinery Manufacturing Co., LTD is an experienced manufacturer integrated with design, manufacture, installment and service. The main products are cake machine, biscuit machine, candy machine and cookies machine in shanghai China. ISO and CE certificates we got 10 years ago, and the goods exported to120+ countries. Workshop tour is welcome.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery