01:16

01:16

Automatic piston filling machine is a volume type liquid filling machine which suitable for many products , such as honey , mayonnaise,cream ,grease and so on . Main characteristics 1. One year Guarantee. 2 .One year free spare parts will be shipped with the machine. 3 .We can help install the production line or machine , the customer need to provide the room, board, round tickets and pay $60/day to our technician. 4..These machines are easy to maintain and clean, no special tools are required. 5 .Accuracy: ± 0.3%. (for 1000ml) 6 .Two servo motor control 7 .CE approved and production comply with GMP standard .

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 01:16

01:16

Horizontal duplex pouch packing machine can automatic finish bag forming, filling, easy tear notch making, print date, finished bag discharged. Reclosable zipper, nitrogen flushing, hole punching are optional. Characteristics: 1) PLC control, English and man-machine interface, operating easy and simple maintain . 2) Bagging, sealing and filling is relatively independent of the system 3) Could fill powder, granule or liquid product by change filling device,two or even more products are nice with one machine. 4) Digital temperature controller for vertical and horizontal sealing, intuitive and accurate. 5) Sanitary package for your product and perfect package appearance. 6) Easy and fast adjustment of change over, smooth performance and low noise Sensible safety device and no pollution during production to get Friendly working environment

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 00:08

00:08

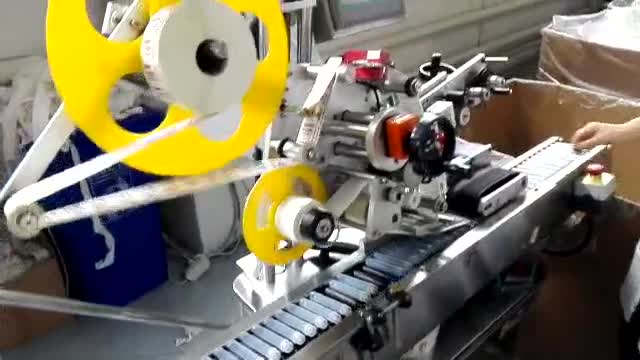

Model PWM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-220 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-100 mm length 15-80 mm The suitable size of labeling objects Customized depends on client product Printer use air 5kg/cm ² Power(w) 600W Weight(kg) 200 Machine size 1800(L) 800 (W) 1300 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:18

01:18

Model DLM-ALS104 Driving Mode German Avery 104 Yield(pcs/min) 20-200 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-110 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:24

00:24

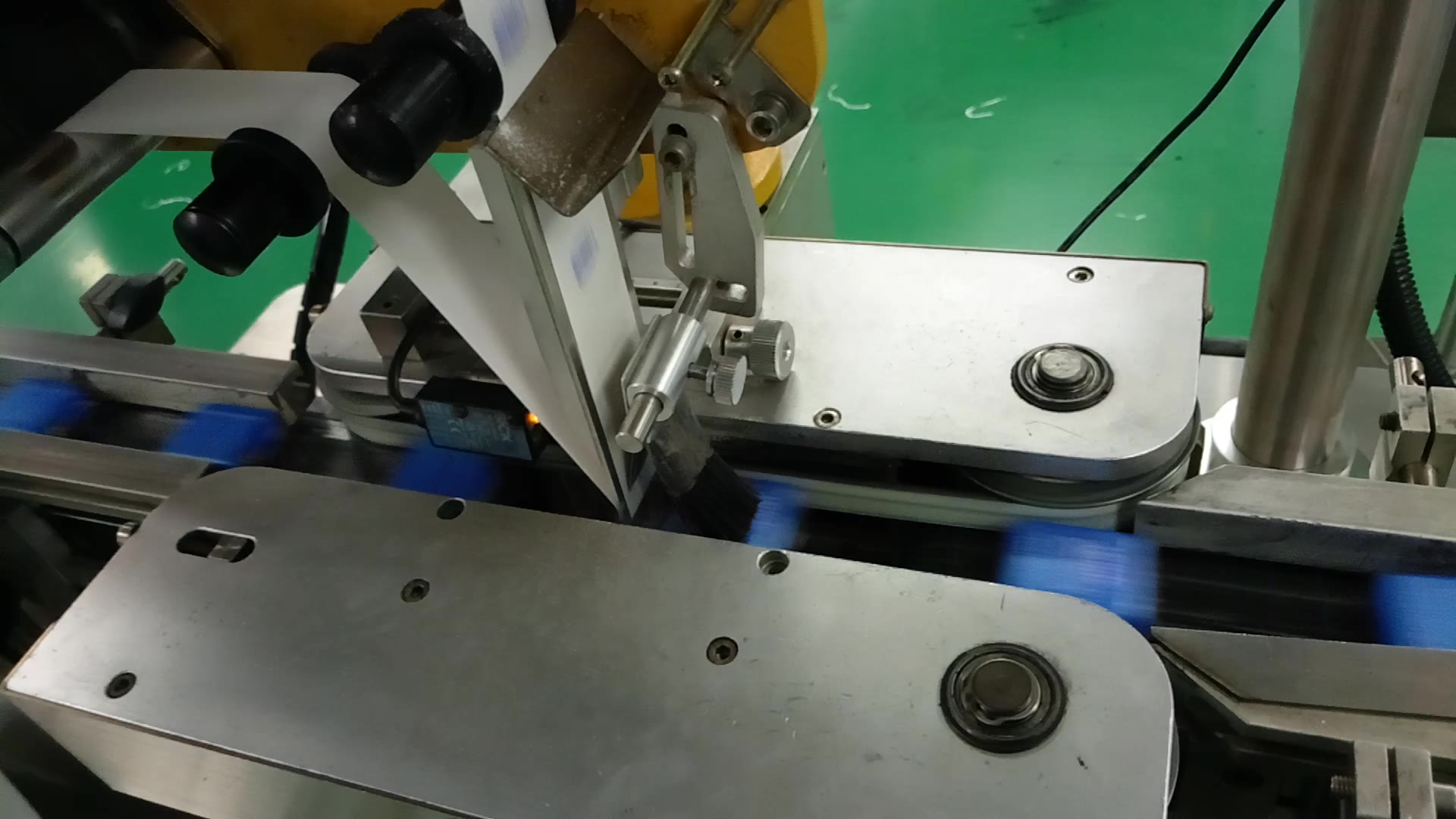

The Process of dental floss Packaging line ( pls ref the video for each step) ① The big dental floss roll to the small rolls 30m first on the winding machine; ② Workers put dental floss roll in the box by hand, then put the already packaged box on the conveyor and delivery to the box labeling machine; ③ After labeling progress , box go on delivery on the conveyor to the printer device part, printing date and batch number on box body one by one. The Industrial blower dry the ink after printing. Drawing

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:00

00:00

Excalibur 4020 Laser Cutting is an all-purpose gantry type flying optics laser cutting machine. Shuttle table in the front of the machine close to the operator access to the cutting head for full overview in production CNC control with virtually unlimited program memory 23" touch screen operator panel with Lead Laser Suite graphical user interface 23" monitor with 4 cameras inside the working area CE certified safety light curtain around the shuttle table Automatic cutting head height sensor system with capacitive distance sensor On-board data base with cutting and piercing parameters for all materials and thickness On-line correction of cutting and piercing parameters during processing Lead Laser Suite This windows based on software platform for laser cutting machines offering a modern graphical user interface for all the laser machine's functions and features, where the operator can manage manipulate in an intuitive way the laser cutting jobs and programs. Database Manager The parameters of all cutting and piercing technologies for every material and thickness are present on-board and can be managed in this dedicated page. Default values for all common applications are stored for reference in the Lead Laser database. Lead Laser Suite Database Manager Low inertia motors Integrated gears and high-precision rack and pinions High-performance dynamics Motion digital servo drives for X-axis gantry, Y- and Z-axis Procutter cutting head Auto-focus cutting head for fiber-delivered laser source Internal sensors detect possible problems before result in bad processing Automatic cutting head height sensor system with capacitive distance sensor Equipped with fast auto-focus axis to adjust the focus point dynamically. Excellent surface quality Low inertia motors Procutter cutting head Shuttle table Perfect level lifting of 2 cutting tables with 1800kg of material each The shuttle table in the front of the machine close to the operator access to the cutting head, with full overview of all the steps in the production Suction unit With improved suction system for fumes and smokes, scrap pieces and heavy dust fall through the cutting tables into separate boxes that can easily be taken away from the side of the machine. Shuttle table Suction unit Application: Available for cutting such metal sheet as stainless steel, carbon steel, copper, brass, alloy steel, aluminum, gold, silver, titanium and so on. Widely used in the sheet metal processing, shipbuilding, automobile, rail transportation, agriculture machinery, advertising board ,kitchen utensils, machinery, elevator and so on.

As a professional and energetic enterprise in the sheet metal processing industry, Suzhou Lead Laser Technology Co., Ltd manufactures high performance of laser cutting machine and laser welding machine for various applications with two production facilities in China.

Contact Supplier 00:00

00:00

The machine has a robust and rigid design that guarantees repeatable high precision cutting results Both the working tables move in and out of the machine simultaneously, decreasing dramatically the time of the table change cycle and increasing the productivity of the machine. New sheets get faster in and cut sheets get faster out of the machine. The machine features a completely closed cabin and offers safe and ergonomic operation. The large eye-safe windows allow an optimal overview of the entire working area of the machine. The light-weight aluminum bridge assures accurate cutting results even under high-dynamic axis movements. A long vertical stroke of the cutting head gives additional freedom in the cutting application: pre-formed sheets, tubes, profiles, etc. can easily be put on the cutting table and are in reach of the cutting head. The machine lay-out is symmetric when it comes to the maintenance access from the sides: either side can be put close to a wall while having all the necessary reach to maintenance points on the opposite side. Laser source Germany famous IPG Laser source is with high performance, long stability. More than 100000 hours work-life of pumped diode Wide range of operating wavelengths, single-mode and multi-mode options Cutting Head Manual or Auto-focus is for your option, the manual auto –focus head equipped for fiber-delivered laser sources of maximum 2kW output power. More than high power higher power lasers (>2kW), the fully automatic focus cutting head is recommended. Laser source Cutting Head Shuttle table Full-automatic and completely integrated with the safety light curtain system to protect the operator The cycle time is extremely fast because the tables are not moving vertically at any time. The cutting tables come into the machine at different heights, well within reach of the long Z-axis stroke. Suction unit With improved suction system for fumes and smokes, scrap pieces and heavy dust fall through the cutting tables into separate boxes that can easily be taken away from the side of the machine. Shuttle table Suction unit Application: Available for cutting such metal sheet as stainless steel, carbon steel, copper, brass, alloy steel, aluminum, gold, silver, titanium and so on. Widely used in the sheet metal processing, shipbuilding, automobile, rail transportation, agriculture machinery, advertising board ,kitchen utensils, machinery, elevator and so on.

As a professional and energetic enterprise in the sheet metal processing industry, Suzhou Lead Laser Technology Co., Ltd manufactures high performance of laser cutting machine and laser welding machine for various applications with two production facilities in China.

Contact Supplier 00:09

00:09

Product name Stainless Steel plate Specification Thickness: Cold rolled: 0.3-3mm; Hot Rolled: 3-120mm Width: 0-2000mm Length: 0-6000mm Customized sizes are accepted Standard ASME, ASTM, EN, BS, GB, DIN, JIS, etc Finish NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish and so on Material 201, 202, 304, 304L, 310S, 316, 316L, 410, 420, 430, 441, 800H, 904L Brand Name TISCO, Baosteel, LISCO, JISCO Place of Origin Shanxi of China (Mainland) Technical treatment Cold Rolled, Hot Rolled MOQ 1 Metric Ton Port of Loading Shenzhen Terms of Delivery FOB, CFR, CIF, CNF, EXWORK Terms of Payment L/C, T/T (30% deposit) Packing Standard export sea-worthy packing Delivery time Within 7-15 days after recieve 30% deposit or as your requirement Stock In stock Chemical Element Grade C ≤ Si ≤ Mn ≤ P ≤ S ≤ Ni Cr 201 0.12 0.75 7.00 0.045 0.045 1.00-1.28 13.70-15.70 Physical proprety Grad YS (MPa) TS (MPa) Elongtion HRB 201 275 520 55 to 60% <183

Established in 2008, we devote ourselves into the business of stainless steel sheet,pipe,coil,etc. After fast and stable development, we are the very company with the most complete categories. The factory occupies a total area of 40,00 ㎡. Our main products are: 8K Mirror sheet, HL, NO.4 sheet. They are widely used in elevator decoration, Luxurious doors, outdoor projects, wall decoration, advertisement nameplates, furniture, kitchenware, sanitary ware, ceiling, corridor, hotel hall, shop facade and various stainless steel series.

Contact Supplier 01:19

01:19

Model ELM-S Driving Mode Servo motor Yield(pcs/min) 10-60 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 3000W Weight(kg) 500 Machine size 4000(L) 1500 (W) 1600 (H) mm (machine size can made as client need )

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact SupplierShanghai Janus Grab Co., Ltd is a global reputed grab specialist, with more than 30 years experience in grabs design, R&D, and manufacturing. Highly educated professionals in steel structure, hydraulic and electric system make Janus grabs competitive in world-wide markets.

Contact Supplier 00:44

00:44

BPF-H conversion dispersing machine is the latest model which is designed according to actual need in production, mainly used in preproduction experiment of liquid sizing agent such as paint, coating, dye, plastic, foodstuff, etc. It can provide right data for mass production, also used in small-lot production. It can disperse 5 to 80 litres. Characteristics ●Frequency speed control, digital display. ●Container is fastened with belt to ensure safety. ●Hand-operated lifting, handle conveniently.

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier 05:12

05:12

Major Characteristics 1. Claw structure, obtained many patent on technology, suitable for caps with the function of liquid diversion and inserters 2. PLC controlled, integrated cap sorting, sending, grasping, inserting 3. Automatic inlet cap and bottle position-setting and orientation, adjustable torque control 4. Gentle manipulation, no scratch and injury to caps and containers 5. Easy changeovers, one line capable of several products 6. Connected with filling machine and labeling machine easily 7. Module structure, manipulate on the touch screen, easy maintenance 8. Suitable for containers made of PET/PP/PE/HDPE and so on 9. Production capacity can achieve 4000-8000b/h, higher speed can be customized 10. Applicable in detergent, shampoo, shower gel, hand cleaning gel, laundry detergent and many other daily chemical products.

Huituo is a leading manufacturer of intelligent packing machinery, focus on providing customized filling and capping solution. Our vision is “helping customer realize brand dream”, which pushes us continuously improving, including servo intelligent capping machine and other equipment that have reached the international leading level.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery

00:21

00:21