00:09

00:09

holesale tools / Mechanics tools / Tools / Basic tools / Hand tools / Measuring Tools / Measuring Tape For Workshop / Home work / Construction / Measuring Tools Auto Lock 562201 3m 5m 7.5m 8m reinforced hook heavy duty contractor Rubber Cover steel strip Measuring Tape Model: 3m(10ft)*16mm(5/8'') 5m(16ft)*19mm(3/4'') 7.5m(25ft)*25mm(1'') 8m(26ft)*25mm(1'') Material of Tape: Steel / Fiberglass Material of Case: Electroplate / ABS Finish of Blade: Yellow Coated / Nylon Coated Finish of Case: Rubber / Chrome Plated Thickness of Tape: 0.1-0.13mm Hook Common / Magnetic Application: Measuring Accuracy II Class Customers Logo: Color Sticker / Printing Package: Color Box / Anti-thief Blister / Plastic Hang Card Plastic Hanger / Flag label MOQ: 1200pcs Sample Time: 1) Existing Items Sample time: 7- 10 days 2) Customized items Sample time: Will check after receiving all details. Production Capacity: 100,000 Pieces / Month Delivery Time: Within 45-60 Days after Receiving the Deposit Payment Terms: T/T,L/C Model pcs/inner box pcs/carton L(cm) W(cm) H(cm) G.W/carton N.W/carton 3m(10ft)*16mm(5/8'') 12 120 43 36 34 20 19 5m(16ft)*19mm(3/4'') 12 120 46 39 36 24 23 7.5m(25ft)*25mm(1'') 6 60 44 35 32 24 23 8m(26ft)*25mm(1'') 6 60 45 37 33 24 23

We (Landing tools). is one of the leading exporters of tools, hardware and householdware in China. we have built kinds of professional teams to support our operation. SALES TEAM, which has a exact grasp and understanding of clients' requirements. Make prompt, clear and complete replies according to different markets and quality requests of products. R&D TEAM has the full ability to organize and actualize preponderant production against the drawings and samples. PACKAGING & APPEARANCE DESIGN TEAM, in accordance with clients' requests, we supply the different appearances of products, color assortment, packaging design and making. SOURCING TEAM, which is familiar with the full range information in our field. We offer steady, highest cost-effective products. QC TEAM has established complete and comprehensive assessment system of suppliers Documentation team provide our clients with timely, secure and suitable mode of storage and transportation. Our goal is to supply Ideal Solutions for the full process. We will make our remaining efforts to meet and exceed the requirements of customers. We are ready to serve for every potential customers and sincerely looking forward to cooperate with you in the future.

Contact Supplier 01:58

01:58

Advantages: Low maintenance cost Easy operation(One person can operate two devices) improved yield (improved by 20% to 30%) Low breakdown rate (servo structure) Product with high precision Characteristics : 1)The continuous feeding and rolling device is increased, and therefore the yield is increased by 20% at least. 2)The transmission of the main transmission system is carried out by either mean:1) Using a high-strength nylon-based flat transmission belt, in which the stress is even. 2) Main motor directly connects to driving shaft. The operation is reliable and smooth, and the rolling mill system has the function of overload protection. 3)The stroke of the saddles is increased, the long-journey rolling is carried out by annular ring type roller, the rotation angle of the roller is changeable, the groove working section is lengthened, the length of deformation zone is increased, and therefore the uniformity of metal deformation in the rolling process is increased, the feed amount can be increased, and the quality of the finished pipe can be improved. 4)The rotary feed system is controlled with German Rexroth AC servo, wherein the feed amount is accurate, reliable and stepless adjustable, the deviation of feed amount is not more than 2%, the size of the rotation angle can be adjusted, the billet will be rotated and fed for two times in the same rolling process, and therefore the distribution of rolling force is even, the axial force is reduced significantly, the high-precision pipe with small deviation of the outer diameter and wall thickness can be obtained, and the yield is high. 5)Compared with side feeding, the rolling mill, which uses end feeding mode, reduces mandrel-removing device; moreover, the position of the mandrel in the deformation zone is accurate, length of mill is shortened, the mode is suitable for the rolling of long billet, and the working efficiency of the rolling mill is improved. 6)Function of loading, unloading, feeding and other procedures are controlled with PLC program,, and therefore the degree of automation is high. 7)The rolling pressure of machine is reduced by using a curve type core bar, and therefore the deformation of the billet metal is even and reasonable. 8)The main gears are provided with hardened tooth grinding process, by which the transmission is smooth, and the noise is low. 9)The main shaft and important gear are made of high-strength alloy steel. 10)The inner surface of the billet used is lubricated to improve the inner surface quality of the pipe, while prolonging the service life of the core bar. 11)The rolling machine uses annular ring type roller, curve type mandrel, as well as the rolling mode of dual rotation and dual feed, and therefore the correction ability to the billet of which the wall thickness is uneven is relatively strong. 12)The equipment has a mandrel fracture detection device, by which the equipment will be automatically stopped in case of the fracture of mandrel, and therefore the equipment can be protected well. 13)A number of patented technologies are applied to the equipment, such as floating type brake, and hydraulic locking nut of the rack. (The feed of the before dead center shall be determined according to the specific rolling condition)

Shanghai Pan Zhihua Machinery Manufacturing Co.,LTD is located on the third largest island of China municipal industrial park----No.898,San Sha Hong Road. Among the company’s 160 staffs them,25 people have high-level technical title.The total area of the factory is 38000 square meters,with standard workshop 19800 square meters.

Contact Supplier 04:27

04:27

This system is adopted for recycling scraps and producing regeneration sponge. This production line is a good option for reducing the production cost and reasonably solving the unnecessary problems caused by the scraps and wasters. The regeneration sponge produced by our production line can meet the related quality standards. This production line can be operated independently or as the auxiliary equipment for sponge production line.

HiSuccess International Machinery Limited is expecting to cooperation with friends all over the world to protect our blue earth. Our staff is ready to provide you first-grade machinery with reliability, top technology and excellent service.

Contact Supplier 01:38

01:38

Product Name PVC Insulated Cable (Wire) Reference Standard PVC Insulated Cable (Wire) is manufactured according to the standards of IEC 60227-2007 and JB/T8734-2012 or BS, DIN, and ICEA up on repuest. Applications PVC Insulated Cable (Wire) is suitable for power intallation, fix wiring or flexible connection for electrical appliances with related voltage of 450/750V and below. Operating Characteristics Rated Voltage U0/U: 450/750V, 300/500V and 300/300V Max permissible Continuous Operating temperature of the conductor. 60227 IEC 07 (BV-90) ------ 90℃ 60227 IEC 08 (BV-90) ------ 90℃ 60227 IEC 56 (BV-90) ------ 90℃ 60227 IEC 57 (BV-90)------ 90℃ For other types ------------- 70℃ The ambient temperature under installation shall not be below 0℃. The bending radius of cable: D ≤ 25mm ------------- ≥ 4D D > 25mm ------------- ≥ 6D ( Diameter of the cable )

Wuxi Jiangnan Cable Co., Ltd., founded in 1985, is a National Key Hi-Tech. Enterprise, mainly manufacturing integrates wires and cables. By the end of 2015, With a floor space of more than 500,000 square meters, total built-up area of 350,000 square meters, and total assets worth above RMB 7 billion, the Company now has an employee size of 3,000-odd persons, of which, middle and high-level technical and managerial personnel with diploma of junior college or above make up more than 30 per cent of the Company’s total employees. In addition to boasting more than 1,400 sets (units) of China and the world first-class production and testing devices, the Company takes the lead in realizing whole-process dynamic monitoring and management over its logistics, capital flow, and human resources by virtue of its ERP network information management system, HER H.R. management system, and OA system, thus IT-based management in the Company comes true.

Contact Supplier 00:42

00:42

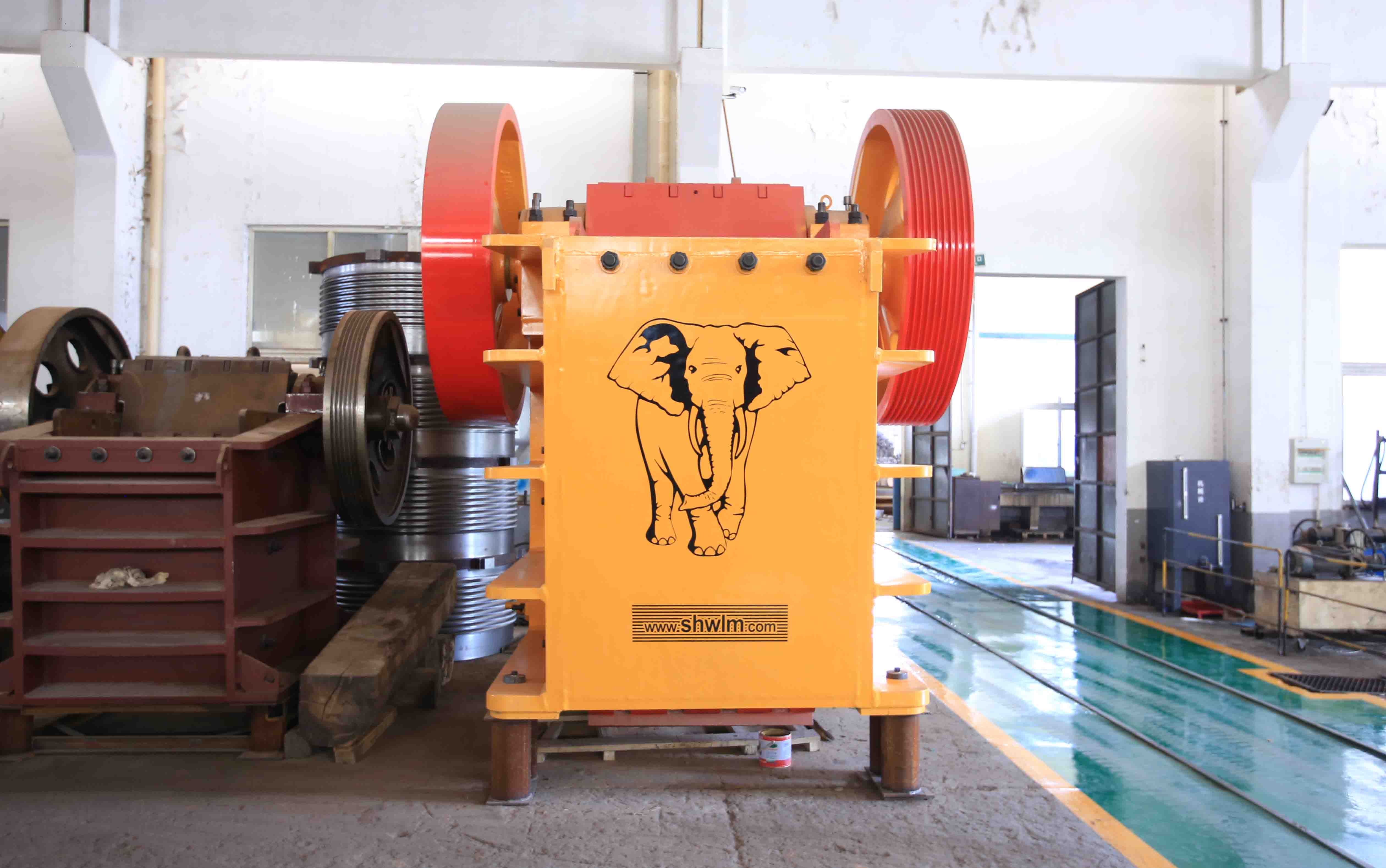

Oil bearings and labyrinth seals PEV Jaw Crushers are built with top quality oil bearings and seals. The lubrication system makes jaw crusher operation smooth. Hydraulic adjustment PEV Jaw Crushers are equipped with hydraulic adjustment system. It include hydraulic oil jacks, shim plates and other components. The hydraulic system easy and fast adjust the jaw mouth clearance, Saving operation time, improving work efficiency. Solid main frame All is with welded steel construction & stressed relieved Jaw Crusher main frame. Heavy duty reinforcement at major stress points. Safety of single toggle operation PEV Jaw Crushers perform crushing operations with force exerted from advancing and retreating motions of a swing jaw which is suspended from an eccentric shaft at the top while supported by toggle plate, seat & block at the bottom. These safety toggle plate, seat & block provide complete jaw protection from ensures a nip angle be properly maintained. Large crushing ratio production Since WHITE LAI Jaw Crushers have larger and deeper crushing chambers and the crushing angle is designed to be sharp, a very high crushing ratio can be achieved. For certain applications, a single toggle crusher can render both coarse and medium or medium and fine crushing quality.

Shanghai WHITE LAI Road and Bridge Machinery Co., Ltd is a renowned crushing and screening machinery equipment provider in China. We provide our clients with a whole series of crushing and screening machinery equipment, including hydraulic cone crusher, jaw crusher, impact crusher, vertical shaft impact crusher, vibrating screening and all complete set of stone crushing and sand making production lines. Our products had passed the quality system certification of ISO9001:2008, and the European CE certificate.

Contact Supplier 00:33

00:33

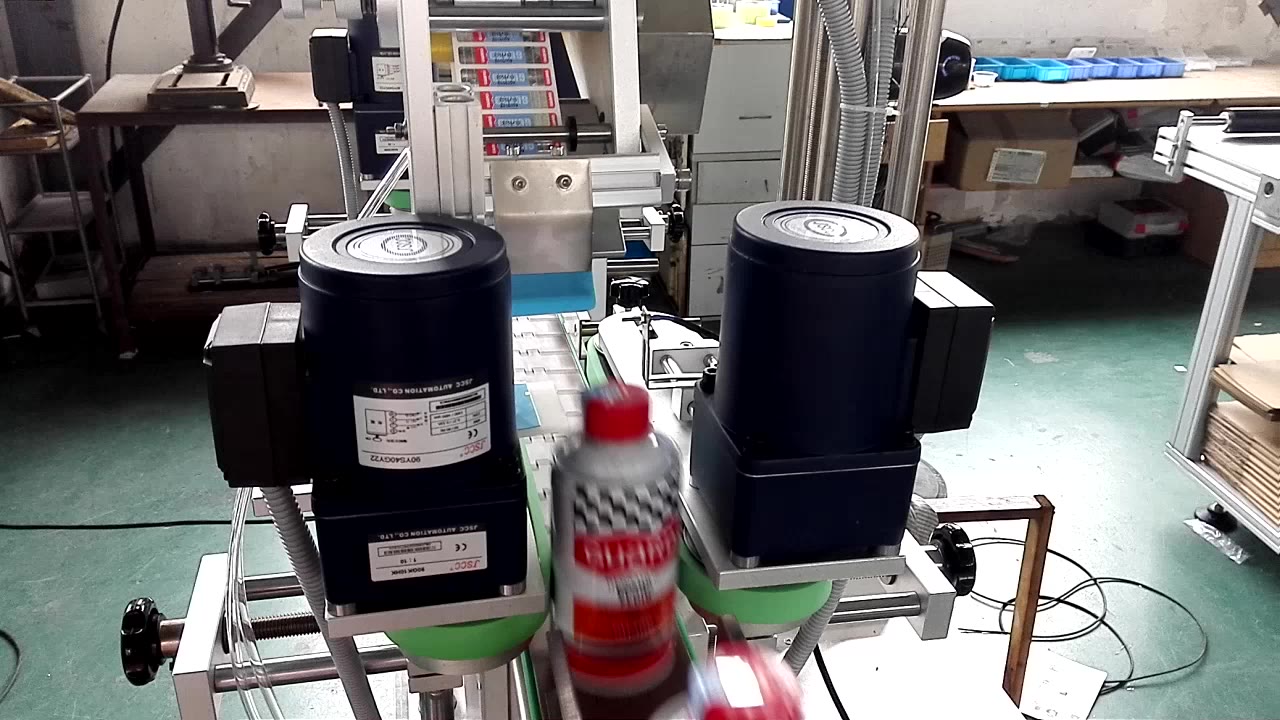

Model DPM-A Driving Mode Servo motor Yield(pcs/min) 30-150 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 1000W Weight(kg) 500 Machine size 2000(L) 1200 (W) 1600 (H) mm (machine size can made as client need )

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 02:11

02:11

Feature • It contain hydraulic punch driver. • With the help of hydraulic system, making holes by hand become fast and easy. • Die could be OEM. • With round dies MAP10-4, punching capacity can be reached 4” (MAP10-4 Dies sizes: 2 1/2”(Φ76.1mm), 3”(Φ88.9mm) , 3 1/2”(Φ102.8mm) 4”(Φ115.5mm) • Plastic case package for easy carrying and well tool protection. • Hole set include: 1*pump(CP-180),1*hydraulic ram,2*draw stud, 1*spacer,1*oil pipe,6*dies set. Parameters Model SKP-15 Stainless Steel plate Max thickness 1.6mm Mild steel plate Max thickness3.2mm Output 15 T Oil Capacity 55CC Working Pressure 600bar Ram Stroke 25 mm Weight 6.2kg Included Dies Set: Round Dies 1/2” (Φ21.8mm) , 3/4”(Φ27.6mm), 1”(Φ34.1mm), 1 1/4”(Φ42.7mm), 1 1/2”(Φ48.7mm), 2”(Φ60.2mm) Square Dies 32*32mm Application The knockout punching tools main work for switch board, distribution box and electrical working, State Grid construction, underground cable construction, Building construction etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 00:44

00:44

Apply for disperse and mill of small batch products.with characters ofmulti-function,easy operation and stable.It is widely use in science study and new product's development. Characteristics ●Multi-function,combine function of disperse,mill and mix in one machine. ●The disperser head it easy to dissemble and clean. ●Widely batch tackle scope. ●Digital disply and brainpower control.

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier 05:49

05:49

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” TDG Series Directly Forming to Square and Rectangular Tube Mill Only one set of rollers can be continuously produced within a certain range of rectangular steel pipe, using the international advanced multi-radius combination molding process and high-frequency welding, forming by multi-channel symmetrical bending. It can be divided into small side bending, boardside bending, free bending at closed side, high frequency welding, precision straightening, produce the exact size and good quality pipe after cut off. Characteristic: ·One set mold roller can produces a range of rectangular tubes. ·This machine has characteristics such as no replace spindle, no remove roller stand and quick change rollers. ·Save mold, save time. ·Four square corner deformation part which can save extra deformation process then save energy consumption and equipment load. Specification of Directly Forming to Square and Rectangular Tube Mill SPEC TDG120X120 TDG150X150 TDG200X200 - Material to be processed Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon - Type Square & Rectangular tube Square & Rectangular tube Square & Rectangular tube Square 60 x 60 – 120 x 120 mm 70 x 70 – 150 x 150 mm 80 x 80 – 200 x 200 mm Rectangular 60 x 80 –100 x 140 mm 60 x 80 –100 x 200 mm 80 x 100 –150 x 200 mm - Wall thickness 1.5 mm – 5.0 mm 2.0 mm – 6.0 mm 2.0 mm – 8.0 mm - Tube length 6.0 m - 12.0 m 6.0 m - 12.0 m 6.0 m - 12.0 m - Line Speed Max. 45m/min Max. 40 m/min Max. 40 m/min - Welding Method Solid State High Frequency Welding Solid State High Frequency Welding Solid State High Frequency Welding - Forming Method Directly Forming to Square and Rectangular tube Directly Forming to Square and Rectangular tube Directly Forming to Square and Rectangular tube Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 07:59

07:59

Brief Introduction For getting larger capacity and effective operation, adopting the latest abroad advanced technology, we developed this full automatic cake production line. Making cake process: Mixing--Oil sprayer --Forming--Baking--Demolding --Empty trays reuse-cooling--Filling--Sterilization--Packing. Each machine function: 1) Inflatable continous mixer: putting powder, eggs and so on into the tank, stirring enough dough for the whole line 2) Oil spray machine: spray oil before depositing for better taste and easier demolding 3) Cake forming machine: air cylinder, photoelectric tracking, PLC control, depositing dough accurately. 4)Tunnel baking oven: gas/electric tunnel oven available. 5)Demolding: sucking the cake from the trays to the cooling line. 6) Empty trays reuse: after demolding, the empty trays clean and recycle use. 7) Cooling line: natural cooling. 8) Cake filling machine: injecting chocolate syrup/cream/jam into the cake. 9) Sterilization: kill bacteria and microorganisms after filling for better cake quality. 10)Packing machine: various packing type available. 11) Nitrogen making machine and oil free compressor: inflate the nitrogen air into the packing bag for keeping the cake shelf life at least 6 months Tips on the whole line: Machines takes area: 100*10m Output: 500kg/h cake size:15-80g Tray size: 600*800mm Cake shapes depends on the cake trays Machine pictures and cake samples:

Shanghai Yixun Machinery Manufacturing Co., LTD is an experienced manufacturer integrated with design, manufacture, installment and service. The main products are cake machine, biscuit machine, candy machine and cookies machine in shanghai China. ISO and CE certificates we got 10 years ago, and the goods exported to120+ countries. Workshop tour is welcome.

Contact Supplier 04:03

04:03

Brief Introduction YX Hard Candy Production Line, confrms to the food GMP standard, is an advanced equipment for producing various shapes and colors of hard candy. ideal equipment for continuous production of high quality single and double color hard candy. High-degree automation ensures of stale production and saves time, labor force and occupation to serve purpose of reducing the cost Hard candy making process Sugar melting--Storage tank-- Micro-film cooker --Depositing and cooling--Packing The functions of each machine. 1) Sugar melting tank: heating sugar, glocose, water to 110 degrees. 2) Storage tank: storage the sugar syrup and and filting pure syrup. 3) Micro-film cooker: cooker the syrup again to 145 degrees for better taste, moisture is lower then 2%, suits for international standard. 4)Deposting and Cooling: depositing the sugar syrup into different candy mouds 5) Packing machine: various packing machine available. Technical Parameters Model YX-150 YX-300 YX-450 YX-600 Standard Output 150kg/h 300kg/h 450kg/h 600kg/h Max.Candy Weight over 4 gram Depositing Speed 40-45/min 40-45/min 40-45/min 40-45/min Steam Requirement 0.2m³/min, 0.4-0.6Mpa 0.2m³/min, 0.4-0.6Mpa 0.2m³/min, 0.4-0.6Mpa 0.2m³/min ,0.4-0.6Mpa Working Requirement Room Temperature: 20~25℃ Humidity: 55% Total Power 18kw/380V 27kw/380V 34kw/380V 38kw/380V Total Length 15m 17m 17m 20m Total Weight 3500kg 4000kg 4500kg 5000kg Tips on the hard candy production line: 1) The whole line equipped the international motor: ABB motor, Danfoss invertor, Mitsubishi PLC control, servo motor, SS materials 2) Heating by steam or electric 3) Essence and pigment pump installed with the machine. 4) Various shapes hard candy can be produced by changing moulds 5) Candy size and weight effects the final output 6) One/ two colors/center fillied hard candy can be made 7) 260 pieces candy moulds for the 150 type, 520 pieces for the 300 type Pictures and final hard candy samples:

Shanghai Yixun Machinery Manufacturing Co., LTD is an experienced manufacturer integrated with design, manufacture, installment and service. The main products are cake machine, biscuit machine, candy machine and cookies machine in shanghai China. ISO and CE certificates we got 10 years ago, and the goods exported to120+ countries. Workshop tour is welcome.

Contact Supplier 01:17

01:17

Every day, your manufacturing process produce loose scrap, like turnings, filings, chips and shavings, that takes up valuable space. To maintain a clean, safe workplace, our SBJ series metal briquetting press could help. Briquetting your scrap can reduce the volume as much as 90%, making scrap more economical to recycle or sell to foundries. It also help you to reclaim fluids, like oil, lubricants and other liquids. Jiangyin Metallurgy offers a number of press to meet your requirements. We offer free pressing tests using your materials. All SBJ systems can be automatic, allow for integration into existing lines. We also do fully customization for you, including conveying, crush, collecting, lifting and other accessory equipment. To find out more about our briquetting machines, email us to yj.oversea@gmail.com or call us at +86-18651010951 Parameters of Horizontal Briquetting press machine: Power: 37Kw*4 Pump:100SCY*2*4 Size of Briquette: Φ280*(~240) mm Density: ~4.1 t/m3 Weight of briquette: ~60 Kg Output in one shift: 64~80tons/8h Operation: Automatic Include: Storage hopper+ conveyor + Briquetter machine

The most experienced manufacturer of metal recycling equipment… Jiangyin Metallurgy Hydraulic Machinery factory (short name : Jiangyin Hydraulic) was originally set up in 1997 to manufacture and market briquetting press, metal balers, alligator shears, metal shears and other non ferrous scrap metal processing equipment. During the last two decade we have installed 3000 systems , build the entire quality controlling standards and cultivated an experienced technique&after sales tea.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery