01:43

01:43

The extrusion line can produce pressure water pipes ,drainage pipes ,industrial pipes and cables threading pipe. The screw structure for the corresponding designed to meet the processing of high filling material(Caco3) pipe requirements,according to the use of pipe,change molds and the corresponding auxiliary equipment,can be processed produce UPVC pipe ,C-PVC pipe ,foam core layer pipe,foam inside the Spiral hollow wall spiral pipe. Extruder SJZ-51/105 SJZ-55/110 SJZ-65/132 SJZ-80/156 SJZ-92/188 Pipe diameter GF-63 16-63 16-63 50-160 50-250 110-250 200-400 200-400 315-630 500-800 Mould(pipe/s) single double double single single single single single single single Downstream equipment GF-63 GF-63*2 GF-63*2 GF-160 GF-250 GF-250 GF-400 GF-400 GF-630 GF-800 Total power 60 70 91 85 86.5 114 131 212 220 240

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 00:46

00:46

311001 Aluminum alloy body pumping rod type hand nut riveter Product Characteristics Innovation of patented structure design.Labor saving more than 40% Delicate shape. Ergonomic handle Rapid loading and unloading nut structure Size: 14" (360mm) Nut size : M3 M4 M5 M6 M8 M10 M12 Material: Aluminum Alloy body Material of Handle: Plastic Length : 360mm (14') Weight 1152g Working stroke 7mm Customers Logo: Color Sticker / Printing Package: Color Box / Anti-thief Blister / Plastic Hang Card Plastic Hanger / Flag label Sample Time: Existing Items Sample time: 7- 10 days Delivery Time: Within 45-60 Days after Receiving the Deposit Payment Terms: T/T ,L/C

We (Landing tools). is one of the leading exporters of tools, hardware and householdware in China. we have built kinds of professional teams to support our operation. SALES TEAM, which has a exact grasp and understanding of clients' requirements. Make prompt, clear and complete replies according to different markets and quality requests of products. R&D TEAM has the full ability to organize and actualize preponderant production against the drawings and samples. PACKAGING & APPEARANCE DESIGN TEAM, in accordance with clients' requests, we supply the different appearances of products, color assortment, packaging design and making. SOURCING TEAM, which is familiar with the full range information in our field. We offer steady, highest cost-effective products. QC TEAM has established complete and comprehensive assessment system of suppliers Documentation team provide our clients with timely, secure and suitable mode of storage and transportation. Our goal is to supply Ideal Solutions for the full process. We will make our remaining efforts to meet and exceed the requirements of customers. We are ready to serve for every potential customers and sincerely looking forward to cooperate with you in the future.

Contact Supplier 00:31

00:31

The rock wool edge milling device: milling the rock wool edge to a section which can achieve the requirements of overlap joint. The two sides of the rockwool is milled by the shaping milling blade. We adopt five work station milling to ensure the quality, and it’s also convenient for different joint edge shapes. The milling cutter is installed on the cutter spindle, which is driven by motor. The milling direction is opposite with the conveying of rock wool. The position of milling cutters is set according to the size of the formed steel plate. There is also a cover piece out of cutters, and there is exhaust opening on the cover to protect the cutters.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:09

00:09

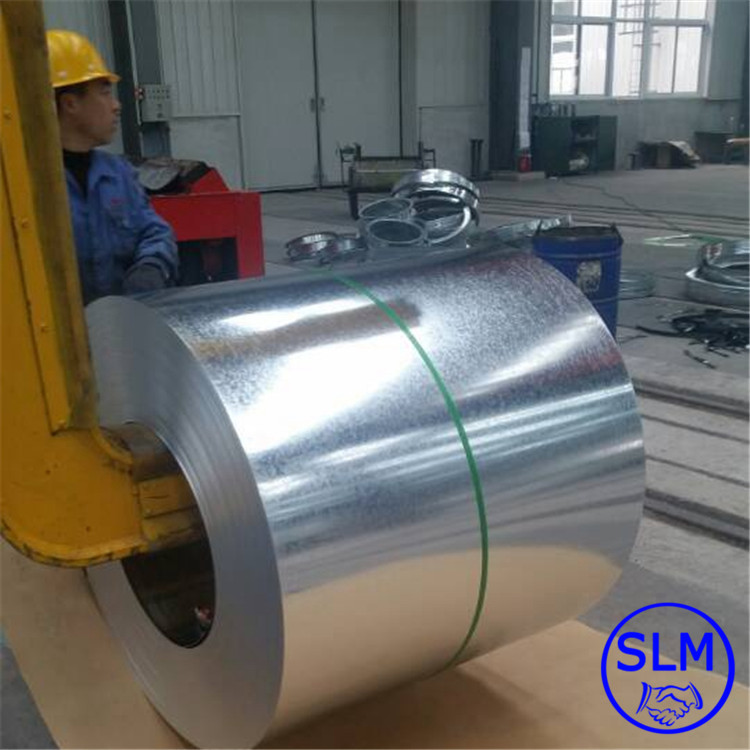

Thickness 0.14mm-3.0mm Width Prime.coil:1000mm,1219mm and 1250mm Slitting width: Minimum Width 4mm,7mm etc as your requirements. Length Cutting as your requirements,Minimum:200 mm length. Zinc Coating China Standard:30-600 G/cm 2 ASTM Standard:A40,A60,G60,G90,G1,G14,G16,G18,G21 JIS Standard: Z12,Z18,Z22,Z25,Z27,Z35,Z43,Z50,Z60 Spangle Small, regular or zero spangle Standard ASTM, AISI,JIS,DIN, GB etc. Material (most common) DX51D+Z,DX52D+Z,DX53D+Z,DX54D+Z,DX56D+Z DC51D+Z,DC51D+ZF,DC53D+Z,DC53D+Z,DC53D+ZF SGCC,JAC270D,MJAC270D Processing Pickling, cold rolling, annealing, degreasing, leveling, shear (transverse, longitudinal), Application Household Electric Appliances,Auto parts,Container plate etc. Coil Weight 3-8 tons normally Coil ID 508/610 mm Packing Simple package: Oil paper. Good package: Wooden box or steel box Payment T/T or L/C at sight Min order 1 ton

Shanghai Leading Metal Co., Ltd is Shanghai-based steel provider which has been focusing on the steel service for more than ten years. Our main business is construction-based steel commodities including coil, plate etc. We are especially experienced in Copper Steel ,Aluminum Steel and Steel Roofing Sheet . And our un-allocated inventory is 30,000 tons. There are 11 staff in the sales office, 67 workers in the warehouse, we are still developing and welcome more advice from you. A team (5 person with more average more than 5-year experienced) service for you.Save total cost is our advantage.

Contact Supplier 00:00

00:00

Parameter Weight 300Kg Dimension 1300*700*1400mm Power 220V/50Hz Motor 4.5Kw Filling Quantity 3-30ml/ 5-75ml or 30-200ml(Need change piston pump) Capacity 40-50 tubes/min Air Consumption <30 m³/min Tube size 9mm and 15mm Compressed Air 0.6-0.8Mpa Quantity Error <1%

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:50

00:50

Squared characteristics description: 1.Unmanned operation, automatic under cover and seal, in accordance with the artificial prices rising trend, the equipment will become the mainstream models; 2.Tanks not rotating sealing process design, to better products and body protection, machining accuracy is high, the sealing quality is better than the domestic similar products. 3.The production efficiency of the machine is semi-automatic sealing machine 2 ~ 3 times, and because of using automatic under cover and sealing device, save manpower cost at the same time, improve the production efficiency; 4.Suitable for all kinds of tinplate cans, aluminum cans, paper cans, etc all kinds of round specifications sealing cans, simple to operate, is the ideal equipment of food, beverage, pharmaceutical and other industries.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:35

00:35

Overview This machine is attached with 1 meters' length conveyer (non motivation).This series aluminum foil sealing continuous induction sealing machine utilizes electro magnetic induction principle to produce instant high heat to melt aluminum foil that then adheres to the bunghole, reaching the aim of wet-proof, leakage-proof, mildew-proof and extending preservation time. Now it is widely used as sealing package machine in industries such as medicines, pesticides, lubricant and cosmetics

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:39

00:39

Item CUSTOM MADE CARDBOARD PAPER CRAFT TUBE H.S. Code 4811900000 Material Kraft paper,Paper board, Art paper,Corrugated board,Coated paper, etc Size(L*W*H) Accept custom Color CMYK litho printing, Pantone color printing, Flexo printing and UV printing as your request Finish Processing Glossy/Matt Varnish, Glossy/Matt Lamination, Gold/Silver foil stamping, Spot UV, Embossed, etc. Usage Packaging, Shipping, etc. Samples fee Stock samples are free Lead time 5 working days for samples; 12 working days for mass production Advantage 100% manufactory with lots of advanced equipments QC Strict quality control under SGS, ISO9001 and Intertek. Certification BSCI, ISO9000/1400,BV TUV SGS FSC etc.

Coffe Packing was founded by a Packaging & Print expert, Mr. Lin, in 1986. Today, Coffe Packing, with a team of production, sales, R&D and superior service, has become one of the strongest Paper Packaging manufacturers in China. We have more than 100 advanced equipments, such as German MAN Roland R904-7B four-color, R9055 five-color offset press , Heidelberg speed master CP102 four color sheet-fed offset press, Japanese Roybi 754 four color offset press, five advanced 5-ply Corrugated Board Production Lines, automatic Printing Slotting/Die-cutting Machines, automatic folder gluer, UV Spot and Overall Coating Machine, film blowing machines etc.. With such modern production equipments and technology.

Contact Supplier 00:19

00:19

Specification G16-T3/13 Groove 3mm, Center to Center 16mm Surface Melamine / Woode Veneer / Painting / Fire resistance panel Core 1,MDF core, low formaldehyde with E1 standard 2,ECO core, which is low formaldehyde with E0 standard. 3,MGO core, which is high fire resistance level with A standard. 4,any required core materials could be replaced. Back Soundtex acoustic felt attached on the back of the panels. Noise Reduction Coefficient 0.7 Fireproof grade GB8624 2012 A / B1 Eco-protection grade E0 / E1 Installation aluminum keel and clips, wood frame, gun nail Certification BV,CE,SGS,ISO9001-2008 Test report Eco protction, sound absorption, flame retardant Model Type Specification NRC Punching Rate G8 M-T-2/6-8-15 0.9 2.5% G10 M-T-2/8-10-15 0.9 2% G16 M-T-2/14-16-15 0.9 1.3% G8 M-T-3/5-8-15 0.9 2.5% G16 M-T-3/13-16-15 0.9 2% G32 M-T-3/29-32-15 0.8 0.93% G32 M-T-4/28-32-15 0.8 1.24%

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier 01:03

01:03

The automatic carton one-piece wrap machine is a new type of automatic packaging equipment independently researched and developed by our company on the basis of foreign advanced technology. And the packaging form that the machine can provide, compared with the traditional packaging methods, has a distinctive feature. At present, most of the domestically produced products, such as bottled, boxed, and block-packed products, are generally packaged in corrugated boxes. This traditional packaging method has been accepted by the public. However, in addition to high-speed mass production of the beer industry, almost all medium and low-speed packaging areas, the carton packaging process is still the following production process: cardboard die-cutting → nail box → back cover → packing → sealing; using a carton wrap machine can Finished at once. Reduce the cost of equipment and equipment; greatly reduce the space occupied by equipment and raw materials and transportation conflicts at all levels; labor can be reduced by 7 to 9 people, labor management is more simplified; the appearance quality of packaging is flat and beautiful; Contact, tight and firm after wrapping; cardboard material can be reduced by about 20%. The application of automatic wrap-around machine to reduce labor intensity, reduce labor resources, reduce production processes, and its comprehensive performance indicators and economic benefits are superior. It has been accepted and widely recognized by the society and will be an upgrade and inevitable development trend of traditional packaging methods.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 02:25

02:25

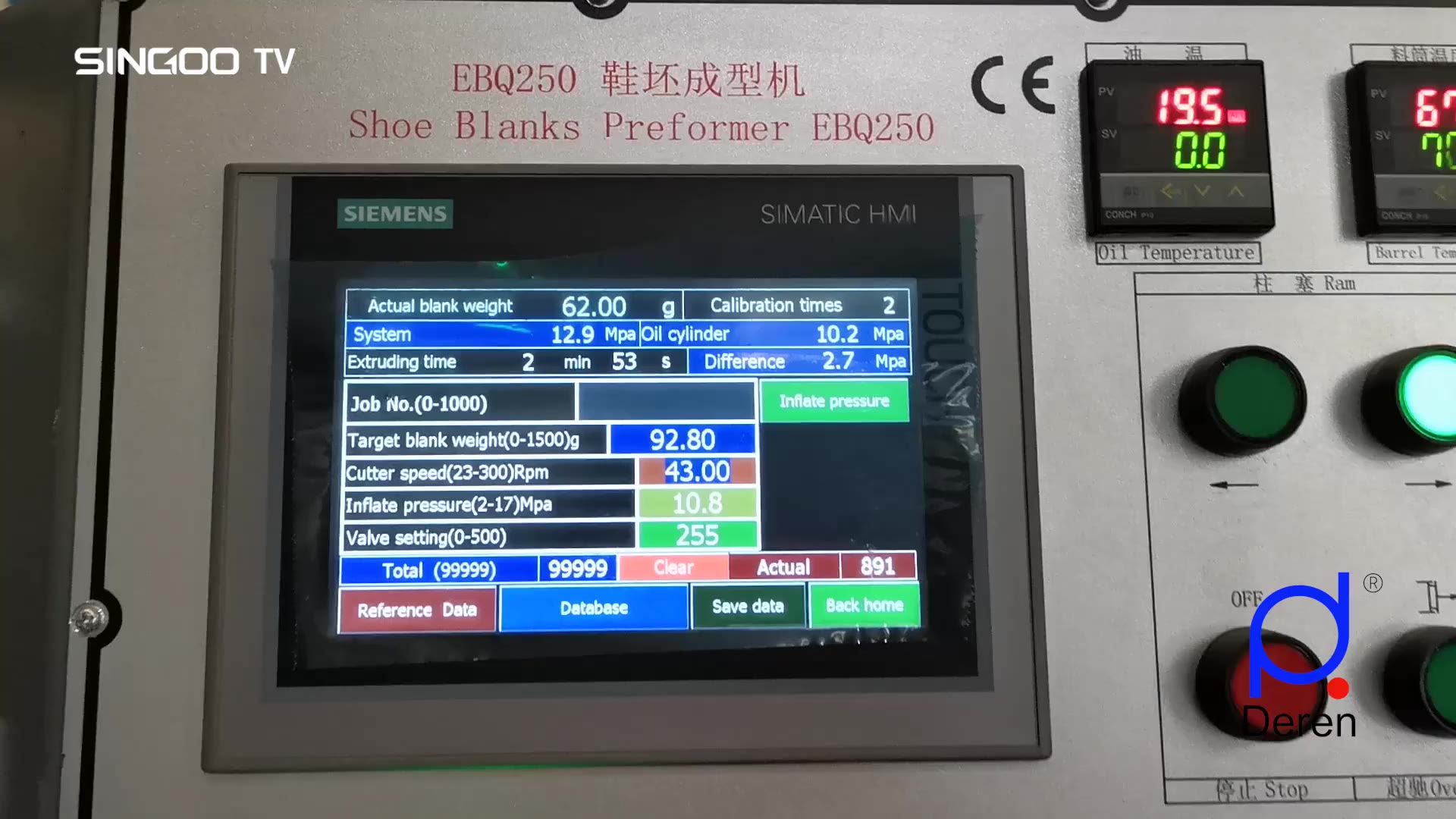

●PLC control system and touch screen operator interface. Color touch screen to input data and password protection. ●1000 products technics database available to connect anytime. ●Variable inverter controlled infinite speed regulation for cutter speed. ●Closed circuit feedback of electronic scale, one key automatic calibration of the weight of rubber blank. ●Reliable safety performance. There are interlocks when close ram head, the cutter rotates and ram moves forwards and retracts. ●Graphic and text display for failure point and cause ●Barrel adopts separated structure, Extended center, for easy cleaning. ●Reducing residual air in rubber blank by vacuum system. ●Stainless steel conveyer for reducing compound contamination. ●Accept high-end customization Technical Parameter Items Unit EBQ250 Barrel inside diameter mm 250 Max. extruding pressure MPa 17 Max. barrel temperature °C 95 Max. die diameter mm 300 Rubber weight range g 0.3~200 Rubber blank weight accuracy % ±1.0 Single feeding volume L 65 External dimension (L×W×H) m 5.08×1.25×1.64 Weight T 3.6

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 00:41

00:41

SPECIFICATIONS Battery Powered Cutting Tool Output: 5.5T Applicable for Wire Rope Wire Strands Round Bar Cables Cutting Capacity: Max Ø21mm (refer to bottom left table for details)Battery Voltage: 18V Battery Capacity: 4 Ah(Li-ion)Charging Time: 2 Hours Dimension: 117*77*383mm Weight: 2.9 kgs STANDARD ACCESSORIES Plastic Case: 1 pc Battery:2 pcs Charger: 1 pc Cutting Capacity OD(mm) Wire Rope 6*7 16 6*12 20 6*19 20 Round Bar Soft Cu Bar 20 Soft Al Bar 16 Soft Steel Bar 16 Re-Bar 13 Wire Strands Bare Cu Strands 20 Bare Al Strands 20 ACSR 21 1*7 Guy Steel Wire 15 1*19 Guy Steel Wire 16 Underground Cable 18 DESCRIPTIONS The ESG-20G is used to cut Wire Rope, Wire Strands, Round Bar and Cables, designed with: . Latch Type Rotatable Head. Guillotine Type Cutting Blades. Stick Type Compact Tool Body Trigger Switch Manual Retract Button . Auto- Retract Function . Quick Motor Stop Function . Powerful Motor .18V Li-lon Battery . LED illumination and indicator FEATURES Latch Type Head can be opened Guillotine Type Blades for less jam Stick Type Tool Body for light weight Two button control concept for easy operation by one hand Manually retract ram in case of need Automatically retract ram to original position when complete cutting Quickly stop motor if release switch Powerful motor ensure quick cutting Li-ion battery with high capacity and require short charging time LED illuminate work area & indicate battery capacity, working condition

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery