00:40

00:40

This is one set of EVA letters and numbers for kids playing and learning, which is the necessary tools for the kids. The 36 Bath Letters and Numbers content A to Z, 26 letters, and 0 to 9, 10 numbers, total 26 pieces. Help develop the children's mind, let them know the words of the letters. And 36 Bath Letters and Numbers are fun in playing, could paste to the bath tub, the wall, the door, the refrigerator, anywhere you love. The letters and the numbers thickness is 5mm eva foam. The behind is the magnet. All the materials is safety for the children and the baby. The cyc children's book printing also provide the eva foam book, the eva cartoon shape book, the eva foam picture book, the eva educational book, the eva discovery book, etc. Welcome your custom inquiry, pls email to caroline@childbookprinting.com, thank you! The finishing size is is 23 x 18cm Weight: 360g Materials: 5mm pressing EVA materials, all is safety guarantee. Such Childrens Book Maker 36 Bath Letters And Numbers learning tools is loved by the children, parents, publishing and toys company. MOQ: 5,000 sets Sample Cost: $100/title Sample Lead Time: 1 week Mass production lead time: 10~15 days Loading Port: Shanghai, China Payment: 30% deposit + balance, by T/T

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:00

00:00

Filling head 6 heads Filling volume range 100ml-5L(according to customer different bottle volume customize the control filling volume cylinder) Production speed 1300-1500 Bph basis on100ml bottle Voltage 220v/380v Power 2.8kw Suitable bottle’s diameter Ф40mm-Ф250mm Filling error ≤±1‰ Work pressure 0.55Mpa-0.65Mpa Size 1840mm*1400mm*2500mm Weight 600kg Air consumption 0.9m^3/min

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:11

00:11

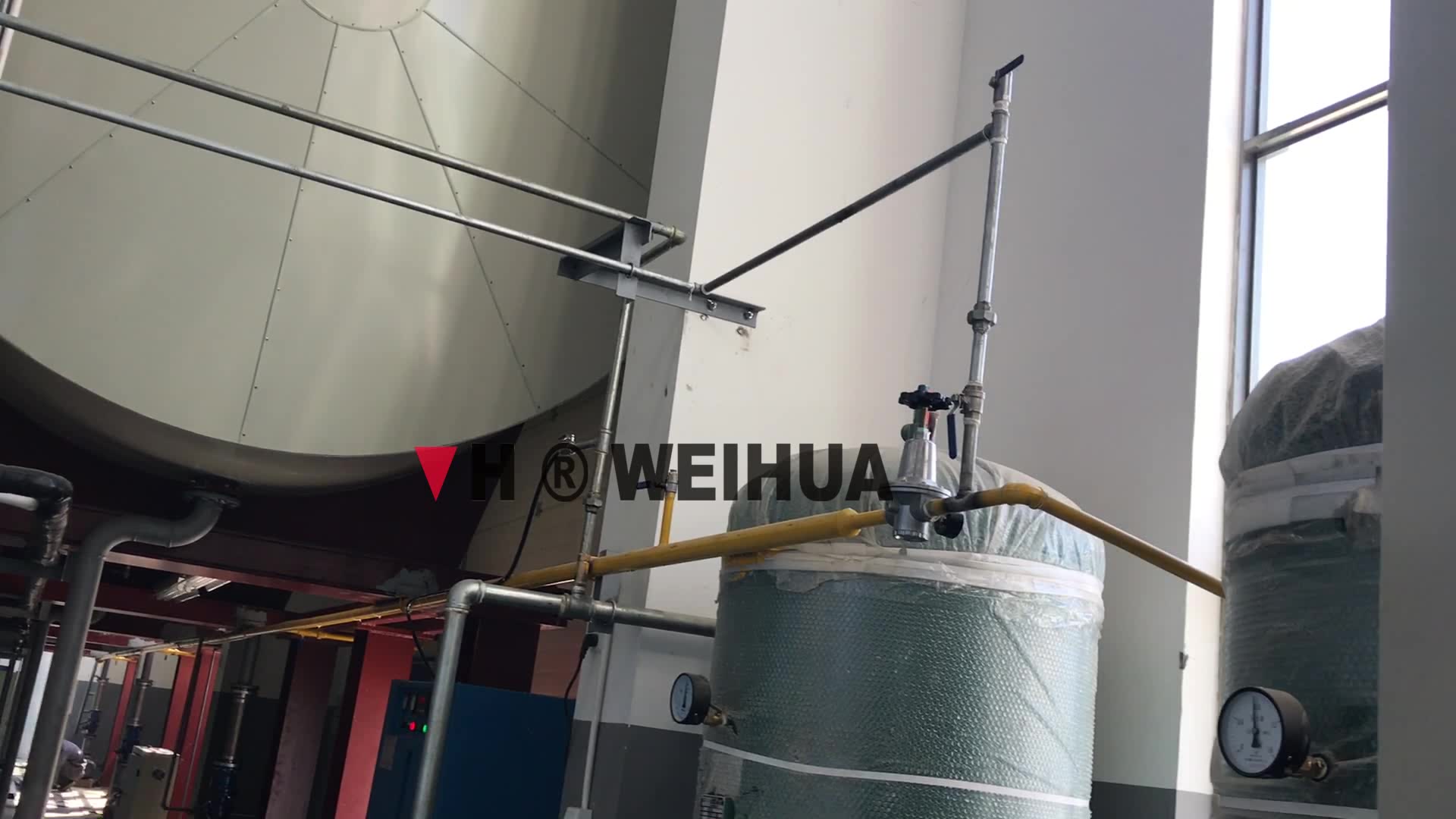

The tank car outside can supply the raw material which can deduce the cost. The chemical storage system has many advantages such as high precision by continuous injecting, material mixing uniform, stable performance, convenient operation, high production efficiency, etc. The tank car outside can supply the raw material which can deduce the cost. Material storage tank, cycling supply, heat exchange, temperature control unit, pipeline system, electronic control system

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:26

00:26

Cyclopentane storage system is mainly used for storing cyclopentane which is unloaded from tank truck and then feeding the material to foaming machine automatically. The design, operation and safety of the system strictly conforms to the TUV standard.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 01:01

01:01

4HVL/P Basic Model 4HVL/P4000 Dimensions Length 3420mm (11’2’’) Width 2800 mm(9’2’’) Height 2460mm (8’1’’) Full extending height 8.84m (29’) Gross weight 1410kg (3110 lb) Engine Engine model D1105 (KUBOTA) Speed(rpm) 1500/1800 Number of cylinders 3 Engine characters 4 cycles,Watercooled diesel Combustion System E-TVS Engine aspiration Naturally aspirated Emission level Regular Alternator Standard configuration SPARKS Frequency(Hz) 50/60 Rating voltage (V,AC) 230/240-120 VAC Alternator insulation Class H Alternator protection grade IP23 Mast & Lights Type of Lights Regular metal halide Light’s fixture Rectagle(GEWISS) Luminous flux 110000 LM/light Number & power of lights 4x1000W Number of mast sections 7 Mast extension Hydraulic Mast rotation Manually, max. 330° lockable Light bar tilt 12VDC Electric linear actuator Trailer Trailer suspension & axle with brakes Leaf springs & single axle with mechanical brakes Tow bar Retractable & adjustable supporting wheel tow bar Stabilizing legs & number 4 pcs extendable bar with manually retractable jacks 4 pcs hydraulic pivot legs Wheel’s rim size & tires 16" rim with regular tires Tow adapter 2" or 50 mm ball adapter Tail light Tail light kit Max towing speed 100km/h (62 mph) Additional Features Fuel tank Type Double wall sub-fueltank Fuel tank capacity 120 liters (31 US gallons) Operating hours with full fuel 84 hours Wires & electric components Regular Generator controller DSE 702AS Max. against wind 20 m/s (45 mph) Acoustic pressure 72dB(A) at 7 meters away Standard colour SWT orange trunk, black or galvanized all of the steel components Max. # of units loading in 40’ high container (Some components would be detached) 7 Basic Model 4HVL/P6000 4HVL/P1200 Dimensions Length 3420mm (11’2’’) Width 2800 mm(9’2’’) Height 2460mm (8’1’’) Full extending height 8.84m (29’) Gross weight 1410kg (3110 lb) 1360kg (3000 lb) Engine Engine model D1105 (KUBOTA) Z482 (KUBOTA) Speed(rpm) 1500/1800 3000/3600 Number of cylinders 3 2 Engine characters 4 cycles,Watercooled diesel Combustion System E-TVS Engine aspiration Naturally aspirated Emission level Regular Alternator Standard configuration SPARKS Frequency(Hz) 50/60 Rating voltage (V,AC) 230/240-120 VAC Alternator insulation Class H Alternator protection grade IP24 Mast & Lights Type of Lights Double-end metal halide LED Light’s fixture Oval Rectagle Luminous flux 162000 LM/light 39000 LM/light Number & power of lights 4x1500W 4x300W Number of mast sections 7 Mast extension Hydraulic Mast rotation Manually, max. 330° lockable Light bar tilt 12VDC Electric linear actuator Trailer Trailer suspension & axle with brakes Leaf springs & single axle with mechanical brakes Tow bar Retractable & adjustable supporting wheel tow bar Stabilizing legs & number 4 pcs extendable bar with manually retractable jacks 4 pcs hydraulic pivot legs 4 pcs extendable bar with manually retractable jacks 4 pcs hydraulic pivot legs Wheel’s rim size & tires 16" rim with regular tires 14" rim with regular tires Tow adapter 2" or 50 mm ball adapter Tail light Tail light kit Max towing speed 100km/h (62 mph) Additional Features Fuel tank Type Double wall sub-fueltank Fuel tank capacity 120 liters (31 US gallons) Operating hours with full fuel 56 hours Wires & electric components Regular Generator controller DSE 702AS Max. against wind 20 m/s (45 mph) Acoustic pressure 72dB(A) at 7 meters away Standard colour SWT orange trunk, black or galvanized all of the steel components Max. # of units loading in 40’ high container (Some components would be detached) 7

SWT, the pioneer of power equipment manufacturer in China, was established in 1993. After continuous development for over 25 years, we have been an outstanding manufacturer and professional integrated solution provider of power plants or equipment in the world. Meanwhile, our products cover diesel generators, mobile lighting tower, gas generator sets. We have gathered more than a decade of researching experience of Mobile Lighting Tower before we invent the first LED lighting tower and became a technology leader of this kind products in the world. We invested to develop Vehicle Power Station and Gas Generator Sets in recent years, to achieve good reputation with excellent quality and performance.

Contact Supplier 00:00

00:00

Suitable filling volume 10-20ml Production speed 40-60 bottles/min Filling accuracy ≤±1% Voltage 220V/50Hz Capping rate ≥99% Stoppering rate ≥99% Air source 1.3 m3/h 0.4-0.8Mpa Power 1kw Machine weight 450kg Size 2400*1650*1820mm

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:00

00:00

Factory MIC Machinery Co., Ltd Device Name 250L Emulsifying Machine Working ability Design volume: 250L Working volume:200L Minimum operating volume: 80L Material Contact Parts: 304 stainless steel thickness: 4mm Interlayer: 304 stainless steel thickness: 4mm Outer layer: 3 04 stainless steel thickness: 3mm Weight 1200kg Size 2600mm×1900mm×2500-3500 mm Service life 10 years Stirring Fixed paddle stirring, PE blade Scraping Homogenizer Power: 4KW Motor speed: 2800r/min Particle size: 0.2-0.6um Uncapping Electric lift Heating Electric heating Discharge Tilt pot discharge and bottom valve discharge Process parameters Working pressure: -0.09MPa Flimsy parts 1 year renewal except artificial Warranty period 1 year

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:28

00:28

Item CUSTOM MADE CARDBOARD PAPER CRAFT TUBE H.S. Code 4811900000 Material Kraft paper,Paper board, Art paper,Corrugated board,Coated paper, etc Size(L*W*H) Accept custom Color CMYK litho printing, Pantone color printing, Flexo printing and UV printing as your request Finish Processing Glossy/Matt Varnish, Glossy/Matt Lamination, Gold/Silver foil stamping, Spot UV, Embossed, etc. Usage Packaging, Shipping, etc. Samples fee Stock samples are free Lead time 5 working days for samples; 12 working days for mass production Advantage 100% manufactory with lots of advanced equipments QC Strict quality control under SGS, ISO9001 and Intertek. Certification BSCI, ISO9000/1400,BV TUV SGS FSC etc.

Coffe Packing was founded by a Packaging & Print expert, Mr. Lin, in 1986. Today, Coffe Packing, with a team of production, sales, R&D and superior service, has become one of the strongest Paper Packaging manufacturers in China. We have more than 100 advanced equipments, such as German MAN Roland R904-7B four-color, R9055 five-color offset press , Heidelberg speed master CP102 four color sheet-fed offset press, Japanese Roybi 754 four color offset press, five advanced 5-ply Corrugated Board Production Lines, automatic Printing Slotting/Die-cutting Machines, automatic folder gluer, UV Spot and Overall Coating Machine, film blowing machines etc.. With such modern production equipments and technology.

Contact SupplierSpeedtek is specialized in production of home electronic and furniture lighting more than 15 years . With the relocation to Dongguan, our goal was to strengthen our product development. So far we have launched new products such as USB operated vests and shoe dryers, USB chargers, bluetooth headphones beanies, in-car DAB devices, DAB earmuffs, sport camera beanies and bluetooth work lamps. All of them received very good market response because of their high level of innovation and design. Our focus market includes European, American and Oceanian countries, with most OEM and ODM clients from the a.m. markets. We proudly announce our own brand new production plant with modern testing facilities, well-equipped production lines, skilled workers and an experienced R&D team. All of our products retain the latest internationally recognized certificates incl. GS, CE, S, BS, UL, CETL, SAA etc. We apply the newest technology and offer you professional products, which possess characteristics like smart controls, energy-saving solutions, modern lifestyle designs, convenient innovations, and much more. If you are interested in any of our products or have any inquiries, please do not hesitate to contact us. You are sincerely welcome to visit our factory or meet us at various trade fairs.

Contact Supplier 00:18

00:18

Overview This piston pump filling machine is specially made for all viscous materials, such as peanut butter, honey, tomato paste, jam etc. The machine adopts piston pump and for filling. By adjusting the servo motor, it can fill all of the bottles in one filling machine, with quick speed and high precision. The machine adopts full-auto PLC and human-computer touch screen control system. For different volumes adjustment are no problem. All the touch production material is stainless steel 304. Characteristics 1 use good quality components and parts. 2 all design with rich experience 15 years. 3 humanization design concept to machine 4 Whole machine meet GMP standard. 5 All spare parts are meet client requires

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 01:30

01:30

Overview The rolling capping machine can cap different sizes and shapes of lids, the capping height of the machine can be adjusted to fit your machine. The machine is made of stainless steel of 304, meeting with CE standard and GMP standard, can be used in food, medicine. It can be connected with filling machine and labeling machine. The machine adopts PLC control, it’s easy operate. Characteristics 1 It is applicable to different-shaped bottles and plastic bottles: PP , PE , PVC ,glass bottle and mould bottle. The bottle-in and bottle-out has specialized structure. 2 PLC control , simple and easy to operate. And sample to operate, to adjust the filing capacity. Measure accurately, make the whole machine stable and high-speed 3 Use touch screen control system, make operation simple, practical and efficient; 4 The medicine is made of 304 stainless material completely or medical grade silicone tube , meeting the requirement of GMP. 5 It can be connected with the filling machine and the label-attaching machine to form a complete set of produce line.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:26

00:26

Item customized paper gift packaging box H.S. Code 4819100000 Material Kraft paper,Paper board, Art paper,Corrugated board,Coated paper, etc Size(L*W*H) Accept custom Color CMYK litho printing, Pantone color printing, Flexo printing and UV printing as your request Finish Processing Glossy/Matt Varnish, Glossy/Matt Lamination, Gold/Silver foil stamping, Spot UV, Embossed, etc. Usage Packaging, Shipping, etc. Samples fee Stock samples are free Lead time 5 working days for samples; 12 working days for mass production Advantage 100% manufactory with lots of advanced equipments QC Strict quality control under SGS, ISO9001 and Intertek. Certification BSCI, ISO9000/1400,BV TUV SGS FSC etc.

Coffe Packing was founded by a Packaging & Print expert, Mr. Lin, in 1986. Today, Coffe Packing, with a team of production, sales, R&D and superior service, has become one of the strongest Paper Packaging manufacturers in China. We have more than 100 advanced equipments, such as German MAN Roland R904-7B four-color, R9055 five-color offset press , Heidelberg speed master CP102 four color sheet-fed offset press, Japanese Roybi 754 four color offset press, five advanced 5-ply Corrugated Board Production Lines, automatic Printing Slotting/Die-cutting Machines, automatic folder gluer, UV Spot and Overall Coating Machine, film blowing machines etc.. With such modern production equipments and technology.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery

01:24

01:24