01:13

01:13

Model DPM-SLM-A Driving Mode Servo motor Yield(pcs/min) 20-100 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-160 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 02:30

02:30

LSS-Q800 clean-up & auto-weighing water cooling conveyer is a downstream machine of precision preformer which is to cool, convey, dry, weigh and sort rubber compounds into charging-basket. Rubber compounds cut by precision preformer can be sorted into charging-baskets after dipped into water, conveyed, dried then delivered by cross belt conveyer. When the rubber compounds reach the set weight, the cross belt conveyer will stop running, the basket-pushed device will change this full charging-basket with an empty one automatically, and cross belt conveyer will run again to fulfill the functions of auto-weighing, automatic basket-sorting and automatic basket-changing. Meanwhile, full charging basket will be delivered to roller conveying line, and then operating personnel can deal with it. Water-dipping device facilitates to cool down the rubber compound and to avoid polluted by kinds of rubber chippings mutually. There is a charging-basket for remaining compounds which is easy to take out and clean up. When there is no rubber compound on the cooling conveyer, it will stop after 5 minutes’ automatic dry run. Technical Parameters: Conveying length: 1.5m Automatic basket-changing device will be customized as per charging-basket external dimension. 1.Water-dipping conveying net belt speed: 4~8m/min (infinite speed regulation) Conveying length: 1.5m 2.Slope conveying net belt speed: 3~6m/min (infinite speed regulation) Conveying length: 3.0m 3.Horizontal conveying net belt speed: 1.5~3m/min (infinite speed regulation) Conveying length: 4.0m 4.&=1.5mm stainless steel net belt, belt width: 300mm 5.Weight range for rubber compounds in charging-basket: 10~20kgs/basket(adjustable) customized accordingly if outside this range 6.Whole unit Max. Overall dimension (L*W*H) 9*2.4*2.1m 7.Weight: 1.0 T 8.Select matching charging-basket dimension: Charging-basket base L*W : (500~600)*(400~460)mm Charging-basket Height:150~170mm Automatic basket-changing device will be customized as per charging-basket external dimension. Mainframe Configuration: Program control system adopts MISUBISHI PLC, OMRON Photoelectric Sensors, Schneider breaker, SIEMENS AC Contactor, MISUBISHI Frequency Converter.

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 00:39

00:39

Feature • Hexagon crimping type for cable lug,wire clamp,pipe with hexagon dies or other dies for crimper • Dies could be OEM as per different terminals sizes, like round is welcome too. • C shape head design for convenient operation. • Head could be rotated 180 degree. For flexible operation in confined place. • Tools are set by double speed. Quick speed while dies have not connected with lug, Slow speed while dies touched lug. Two speed for save your labor and time. • Fitted with safety valve. When pressure reach to limited max pressure,s afety-value will release pressure automatically, which prevent over pressure. • Standard dies:16 25 35 50 70 95 120 150 185 240 mm² • Plastic case package is for easy carrying and well tool protection Parameters Model HP-240C Terminal Type Cable Lug or Connector Crimping Capacity 16 25 35 50 70 95 120 150 185 240 mm² Output 12 T Ram Stroke 25 mm Length 505mm Weight 4.8kg Application Our hydraulic tools mainly used for electrical working, State Grid construction, underground cable construction, Building construction etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 00:38

00:38

Feature • Flip-top latch type head • Head could be rotated 180 degree .For flexible operation in confined place. • Tools are set by double speed. Quick speed while dies have not connected with lug. Slow speed while dies touched lug. Two speed for save your labor and time. • Fitted with safety valve. Automatically relief working pressure when complete crimping. • Plastic case package is for easy carrying and well tool protection Parameters Model CPC-20A Cutting Wire Type Cu/Al cable, wire rope, wire standard. Cutting Capacity Max Φ20mm Output 5.5 T Length 420 mm Weight 3.14 kg Application Our hydraulic tools mainly used for electrical working, State Grid construction, underground cable construction, Building construction etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 02:08

02:08

Description Unit Travel X travel mm 600 Y travel mm 410 Z travel mm 510 Distance between spindle nose and worktable surface mm 150-660 Distance from table center to stand column surface mm 215-625 Worktable Table area mm 400×800 Max. loads kg 700 T-slot width mm 3×18H8 Spindle Max. spindle speed rpm 8000 Angle of spindle taper - BT-40 Feed rate X/Y/Z rapid speed m/min 15/15/15 Max. cutting feedrate m/min 5 Automatic Tool Changing System Hat type Qty. Of tools pcs 16 Tool changing time sec 7sec Max. tool length mm 350 Max. tool diameter mm 180(adjacent without tools) Max. tool weight kg 6 Motor Spindle motor kw 5.5/7.5 X/Y/Z axis motor kw 3 Cooling pump motor w 0.4+0.9 Precision(SN precision according to standard JB/T8772.4-1998) Positioning accuracy mm X/Z:0.015,Y:0.014 Repetitive positioning accuracy mm X/Z:0.009, Y:0.008 Machine Dimension Overall height of machine mm 2550 Floor area(L×W) mm 2500×2630 Weight kg 5500 Power supply kw 18

COMPANY PROFILE Nantong Hangzhi Equipment Technology Co., Ltd. is a wholly owned subsidiary of AVIC Aviation High-technology Group Co., Ltd. In March 16, 2016, the company completed the renamed registration. Total assets of the company are RMB 330 million. Nantong Hangzhi Equipment Technology Co., Ltd was founded in 1956, Former Nantong Machine TOOL Works, Trademark include: “NANTONG”、“TONMAC”、“TONTEC”,It is one of six listed companies in Chinese machine tool industry. The company undertakes the aircraft in the original Department of AVIC HT’s machine tool business and AVIC Beijing Aeronautical manufacturing technology research Institute of high-end intelligent equipment and aviation equipment business. The main products are CNC milling machines, CNC lathes, Vertical machining center, Horizontal machining center, Gantry type vertical machining center and Aviation equipment, etc. The company employs more than 500 people, including nearly 150 professional, technical and engineering management staff. The company has domestic first-class production and processing equipment, which imports more than 130 sets of thin equipment, including Japan SNK five face machining center, Germany”s WARLDRICH precision guideway grinder, the United States CICINNATIE machining center, Switzerland DIXI coordinate boring machine, Zeiss coordinate measuring instrument and other world famous brand processing and testing equipment. The company independently developed machine tool products by a number of patents, which in the validity period of the invention patent 14, utility model patents 18. A number of key technologies like MCH63 precision horizontal machining center fill the gaps, accessing to the 2007 machine tool industry ten new product title, China Machinery Industry Science and Technology Progress Award. VMCL1100 vertical machining center series won the second prize of scientific and technological progress in Nantong City, Jiangsu Province, third prize of scientific and technological progress. Products are widely used in mold manufacturing, auto parts, wind energy nuclear power, marine ships, military aerospace, teaching and other fields. The company's sales network is throughout the South China, Zhejiang, Jiangsu, China and the West, North China, northeast and other regions, with a professional sales and after-sales team.

Contact Supplier 00:00

00:00

This type filler is best suited for the paste and semi-paste product. such as heavy sauce, salsa, salad dressing, cosmetic cream, heavy shampoo, gel, paste cleaner and waxes, adhesive, heavy oil and lubricant .This machine is made to meet food-grade.It is automatically controlled by computer (PLC) and touch screen control panels. Advance structure, highly reliable, low noise, wide regulating range and high filling speed The material storing tank of the machine has been specially added the churn-dasher, it can churn up and fill at the same step. All the parts touching the material are made of advanced SS,also applied to GMP standard requirement.

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:00

00:00

Vacuum emulsifying machine consists of vacuum homogeneous emulsifying machine, heating system, mixing system, vacuum system, electric lifting system, operation control cabinet, piping system(oil tank and water tank optional). It is the most suitable equipment to produce mayonnaise and other paste or cream . Body Material: Inner wall: stainless steel 316 Jacket and outer layer: stainless steel 304 Both inner and outer are polished and handled by special light treatment. Pot Capacity: Primary Pot: 120L (working volume: 100L) Oil Tank: 40L Water Tank: 60L

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:00

00:00

This machine is suitable for a variety of materials 50-100ML flat bottles . The high precision cam provides a regular plate positioning on the plug cover; acceleration cam provide lifting screw head, constant torque rotary cover; measuring and filling of piston pump; touch screen control. No bottle no filling and don't upload the plug and outer cap . The advantages of accurate positioning, stable transmission, protection of the bottle cap, measurement accuracy and simple operation, etc.

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:00

00:00

Filling head 12 heads Minimum filling capacity 100ml Production speed ≤4000 Bph basis on 500ml bottle Voltage 220V/380V Power 1Kw Suitable bottle's diameter Ф40mm-Ф100mm Filling error ≤±1% Work pressure 0.55Mpa-0.65Mpa Size 2000mm × 1300mm× 2200mm Weight 700 kg

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:40

00:40

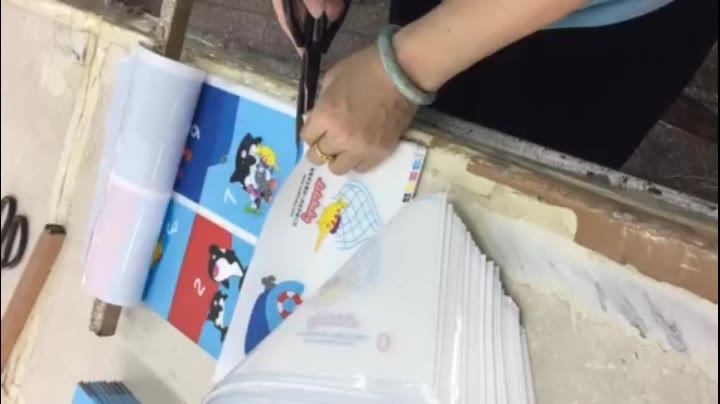

This baby bath book produce by the high density foam. Outside is 0.2mm PEVA, inside is 5mm foam. Which get the book image strong and thick. we warm welcome your baby bath book inquiry come. Here is the baby bath books size and price, Size 145 x145mm Materials 0.2mm PEVA outside, inside is 5mm foam Printing offset full color printing Packing polybag with printed 4C header card MOQ 3,000 copies per title Price: US$0.6~0.9/copies depend on your quantity

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:39

00:39

Item Custom paper tube with gold foil stamping logo H.S. Code 4811900000 Material Kraft paper,Paper board, Art paper,Corrugated board,Coated paper, etc Size(L*W*H) Accept custom Color CMYK litho printing, Pantone color printing, Flexo printing and UV printing as your request Finish Processing Glossy/Matt Varnish, Glossy/Matt Lamination, Gold/Silver foil stamping, Spot UV, Embossed, etc. Usage Packaging, Shipping, etc. Samples fee Stock samples are free Lead time 5 working days for samples; 12 working days for mass production Advantage 100% manufactory with lots of advanced equipments QC Strict quality control under SGS, ISO9001 and Intertek. Certification BSCI, ISO9000/1400,BV TUV SGS FSC etc.

Coffe Packing was founded by a Packaging & Print expert, Mr. Lin, in 1986. Today, Coffe Packing, with a team of production, sales, R&D and superior service, has become one of the strongest Paper Packaging manufacturers in China. We have more than 100 advanced equipments, such as German MAN Roland R904-7B four-color, R9055 five-color offset press , Heidelberg speed master CP102 four color sheet-fed offset press, Japanese Roybi 754 four color offset press, five advanced 5-ply Corrugated Board Production Lines, automatic Printing Slotting/Die-cutting Machines, automatic folder gluer, UV Spot and Overall Coating Machine, film blowing machines etc.. With such modern production equipments and technology.

Contact Supplier 00:02

00:02

Machine list Machine list 3 ton passive de-coiler 1 set Main roll forming machine 1 set Punching device 1 set Cutting device 2 sets PLC Control box 1 unit Hydraulic station 1 unit Out table 2 units Safety cover 1 unit Parameter Items Specifications Remarks Material of coil Thickness 0.27-1mm galvanized steel De-coiler Weight 3 ton manual Forming system Rolling Speed 0-10m/min Embossing At sides Roller Stations About 13 stations forming Roller Material Cr40 Steel with quenching Shaft Material 45# Steel Diameter 60mm shaft Motor Power 7.5 kw Hydraulic cutting Power 4 kw Cutting system Material of cutting CR12 with quench treatment Hardness HRC58-62 Tolerance +-1.5mm Cutting blade 1 set of cutting blade Electrical control system Electric Source 380V, 60HZ,3 phase Control System PLC Weight About 3 tons Way Of Drive 1 inch single chain Size of machine Length 5500mm* Width 600mm* Height 800m Machine picture Product

We have high technological background, advanced production equipment, strict inspection,matured after-sales work and thoughtful service.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery