00:08

00:08

Stainless steel shot is delicately with the process of drawing, cutting, and conditioned etc. and with the appearance of brightness, restlessness and spherical beads (for cut wire shot, cylinders). And they are widely used for the surface preparation by peening and blasting on Copper, Aluminum, Zinc and stainless steel work pieces etc.. Thus the work can illustrate their metal color with sub-light effects and die casting restlessness after preparation. There is no need to adopting rust moving treatment by acid cleaning. Besides their abrasion resistance is 3-5 times as much than cast stainless steel shot, so the production could be cut down. Type Size:0.2mm-1.5mm Apply to equipment Stainless Steel Shots are typically used for the blasting machine with drum type, chain type, lifting hook type, crawler type, pass type, rotating table type, accumulation type, marching type and car type. Also can used for shot blast equipments, pretreatment of the production line, and sand blasting room. Package We can carry out woven bag packaging, ton bag packaging, wood tray packaging, plastic packing packaging and the like according to customer requirement

Shanghai Bosun Abrasive Co., Ltd. is a professional abrasive company, which can research, produce and sell all kinds of abrasive. The main products include all kinds of steel shot, steel grit, steel cut wire shot, stainless steel balls, aluminum balls, zinc balls, copper balls as well as the copper sand, brown corundum, black corundum and so on. The company has advanced equipment and technology, strong technology strength and perfect quality inspection methods. The products are strictly produced and tested according to relative standard, so it is trusted by our customers and be chosen as designated product by many companies which producing sand-blast equipment.

Contact Supplier 01:26

01:26

This automatic pouch packing line include empty pouch pagination machine, pouch packing machine , mutihead weighter , bucket conveyor , conveyor .

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 00:46

00:46

313001 Plastic body pumping rod type hand nut riveter Product Characteristics Innovation of patented structure design.Labor saving more than 40% Delicate shape. Ergonomic handle Rapid loading and unloading nut structure Size: 14" (360mm) Nut size : M3 M4 M5 M6 M8 M10 M12 Material: Plastc Material of Handle: Plastc Length : 360mm (14') Weight 1085g Working stroke 7mm Customers Logo: Color Sticker / Printing Package: Color Box / Anti-thief Blister / Plastic Hang Card Plastic Hanger / Flag label Sample Time: Existing Items Sample time: 7- 10 days Delivery Time: Within 45-60 Days after Receiving the Deposit Payment Terms: T/T ,L/C

We (Landing tools). is one of the leading exporters of tools, hardware and householdware in China. we have built kinds of professional teams to support our operation. SALES TEAM, which has a exact grasp and understanding of clients' requirements. Make prompt, clear and complete replies according to different markets and quality requests of products. R&D TEAM has the full ability to organize and actualize preponderant production against the drawings and samples. PACKAGING & APPEARANCE DESIGN TEAM, in accordance with clients' requests, we supply the different appearances of products, color assortment, packaging design and making. SOURCING TEAM, which is familiar with the full range information in our field. We offer steady, highest cost-effective products. QC TEAM has established complete and comprehensive assessment system of suppliers Documentation team provide our clients with timely, secure and suitable mode of storage and transportation. Our goal is to supply Ideal Solutions for the full process. We will make our remaining efforts to meet and exceed the requirements of customers. We are ready to serve for every potential customers and sincerely looking forward to cooperate with you in the future.

Contact Supplier 00:40

00:40

1. All mechanically operated design with all transmission mechanism in enclosed oil-bath thus ensures smooth, quite. Low noise. 2. Conveyer load lower top surface and turn table made of stainless steel for durability and ease in cleaning 3. The machine most suitable for small standard of bottles labeling in chemical Pharmaceutical food and beverage industries. 4. It is adopted the screw to separate the bottles and the function of labeling is more jarless.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Structure: Frame Filter Media Face net Water resistant cardboard Polyester/Polycotton Spot mesh, expanded mesh Product Features: -Self-supporting material -No metal, thus fully incinerable -Low pressure drop media Application: As prefilters for intake, exhaust and recirculating air systems, extending the operational lifetimes of the downstream fine filters.

Shanghai Thenow Purification Technology Co.,Ltd. Thenow was established in 2005, belonging to Thenow Group(Former name Apureda Group) as the wholly-owned subsidiary. Being a standard maker, Thenow Group is a global specialist in the development and production of filtering systems and solutions with 6 production units. As one of Thenow Group’s production units, Thenow Purification’s business is to provide customers with sustainable best in class air filtration products and services. We mainly focus on manufacturing air filters for industrial dedusting, gas turbine air inlet systems and HVAC systems.

Contact Supplier 00:00

00:00

Activated carbon has high efficiency in absorption and filtration. It features the filters with good air filtration performance: to filter all kinds of pollution particles, to remove various toxic organic gases, such as formaldehyde, hydrogen sulfide, ammonia, etc. Application: Laboratory,Air raid shelters,Medicines and chemicals industries.

Shanghai Thenow Purification Technology Co.,Ltd. Thenow was established in 2005, belonging to Thenow Group(Former name Apureda Group) as the wholly-owned subsidiary. Being a standard maker, Thenow Group is a global specialist in the development and production of filtering systems and solutions with 6 production units. As one of Thenow Group’s production units, Thenow Purification’s business is to provide customers with sustainable best in class air filtration products and services. We mainly focus on manufacturing air filters for industrial dedusting, gas turbine air inlet systems and HVAC systems.

Contact Supplier 00:00

00:00

Structure: Frame Filter Media Seperator Sealant Gasket Safe guard Aluminum/Galvanised steel/Stainless steel Fine fiber glass Aluminum Single componenet high temperature silicone caulk High temperature silicone sponge Aluminum mesh/None Product Features: -High temperature resistant -Large surface area, high dust holding capacity -Sturdy and moisture resistant construction, long life -Single header, double header and no headers models -Each filter element is tested before market release Application: -High temperature paint spray line -High clean food baking booth/ box/room -Use with high temperature equipment to kill the germ or virus, such as pharmaceutical factory -Ventilation systems with high fire resistant requirement and high temperature operating environment.

Shanghai Thenow Purification Technology Co.,Ltd. Thenow was established in 2005, belonging to Thenow Group(Former name Apureda Group) as the wholly-owned subsidiary. Being a standard maker, Thenow Group is a global specialist in the development and production of filtering systems and solutions with 6 production units. As one of Thenow Group’s production units, Thenow Purification’s business is to provide customers with sustainable best in class air filtration products and services. We mainly focus on manufacturing air filters for industrial dedusting, gas turbine air inlet systems and HVAC systems.

Contact Supplier 00:59

00:59

Soft ice cream machine LB-F22 Product feature: 1.All stainless steel 2.Low noise, energy saving and environmental protection 3.Real-time counting 4.The new LED screen, simple operation 5.Voltage, temperature, failure at a glance Specification: cooling method: Air-cooling Model LB-F22 Output 26-30L/H voltage 220V/50HZ Power 2400W Accumulator capacity 5.3L*2 Refrigerant capacity 2.0L*2 Dimensions /(L*W*H) After packing 725*650*835mm Size 665*540*735mm Operation panel LED display 1. Instant display voltage 2. Display the number of expected 3. Fault display 4. Molding ratio display 5. Display machine work phenomenon Weight net weight 100KG gross weight 108KG Material Stainless steel 304 Above models are 220V/50Hz/1Ph Testing condition:Ambient temp.21℃-25℃ Applications:

LANGTUO`S SOUL: With our products allow people to live more happily. LANGTUO`S TARGET: To be the first brand of national ice makers. LANGTUO`S MISSION: Let our products entered into thousands of families. LANGTUO`S CONCEPT:Explore Innovation True Simple Happy Langtuo Refrigeration Equipment Co.,Ltd. Was founded in 2007 that is a professional manufacturer which specialized in producing refrigeration equipment.At present,our company has two kinds of brands DIZHUO,LANGTUO. Langtuo products has gained the ISO9001:2008 and CE certificate. We own perfect management system, strong technical resources, advanced fabricating equipment and strict quality inspection process making our products best.Our annual production capacity can reach 50000 sets.We focused on producing all kinds of ice machines(Daily capacity from 55lbs. to 6600lbs.) which are widely used in ice plant, supermarket, restaurant, bar, hotel, hospital, drinking shop, convenient store, etc. For a long time, we keep "Honest, Creative, Human-oriented, Customer-first" as our business philosophy which gained good reputation by customers from all over the world !

Contact Supplier 00:35

00:35

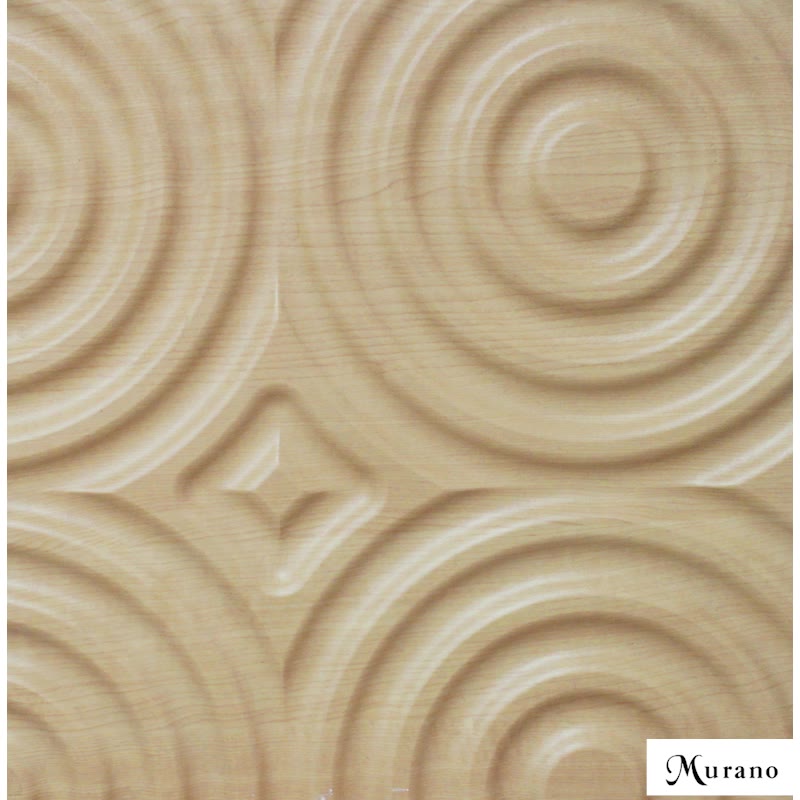

Introduction: Hollowing panel are made to the highest standards from high quality MDF with damp proof melamine backing to prevent warping once installed. The 3D carving is carried out on high tech computerized CNC router beds so that every panel matches perfectly when installed.All MDF panels come in primed and sanded smooth finish, making easy work to paint in your choice of color and paint finish. Specification: Material: MDF Dimension: 1220*2440mm Thickness: 15mm Finish:Painting Density:760kg/m³

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier 01:26

01:26

Large block ice machine(LRT-3T,LRT5T) Product features: 1. Block ice machine, the use of well-known domestic and international refrigeration brand accessories, the compressor standard for Germany Bitzer, refrigeration parts using Danfoss electrical control using Siemens or Schneider electrical components. 2. according to the user's local climatic conditions, on-site construction, tailor-made salt tank ice machine program, optimize the design of the refrigeration system to improve the operating efficiency of the system, energy efficiency in the industry increased by 5%. 3. Block ice machine refrigeration system, ice in the factory design, production, commissioning is completed, transported to the user site, according to the actual site to install the project. 4. block ice machine modular design. On-site maintenance is simple. Before and after the installation of the refrigeration system valves, user-friendly replacement of vulnerable parts, easy maintenance. 5. the device structure to withstand high load design, with high reliability, design life of 10 years. 6. according to the temperature of the salt water tank, automatically adjust the compressor load in order to achieve the effect of energy-saving operation, intelligent control of electronic control system to achieve the concept of man-machine integration Specification: Model Output BM-20T 20000kg/24h BM-3T 3000kg/24h BM-25T 25000kg/24h BM-4T 4000kg/24h BM-30T 30000kg/24h BM-5T 5000kg/24h BM-35T 35000kg/24h BM-6T 6000kg/24h BM-40T 40000kg/24h BM-8T 8000kg/24h BM-50T 50000kg/24h BM-10T 10000kg/24h BM-80T 80000kg/24h BM-15T 15000kg/24h BM-100T 100000kg/24h Weight of block ice Dimension of ice mould 5kg 80*150*500(mm) 75*145*500(mm) 10kg 210*100*600(mm) 195*95*600(mm) 15kg 190*115*860(mm) 185*110*800(mm) 20kg 280*115*860(mm) 275*110*800(mm) 25kg 300*120*880(mm) 295*115*820(mm) 30kg 350*120*880(mm) 345*115*820(mm) 50kg 400*130*1120(mm) 390*120*1020(mm) 100kg 514*214*1120(mm) 490*200*1020(mm) Above models are 380V/50Hz/3Ph Testing condition:Ambient temp. 25℃ Water temp. 21℃ Applications: 1. Widely used in cold storage refrigeration, meat cooling ice, frozen food refrigerated, frozen aquatic products, selling ice market, the seafood market, thinning preservation, flower transport, fishing port, seafood processing, rapid cooling and other fields place. 2. Operating conditions: water temperature 21 ℃, ambient temperature 25 ℃, evaporation temperature -15 ℃, condensation temperature 40 ℃. 3. Ice-making changes: the actual amount of ice due to water supply temperature and the impact of environmental temperature and timely changes. 4. Due to product technology is constantly updated, the data if there is change, reflected in the offer program. 5. Power supply standard: standard voltage is 3P ~ 50HZ ~ 380V, according to the global user requirements for the manufacture of electrical system 3P ~ 60HZ ~ 200V / 220V / 400 / 440V and other non-standard type

LANGTUO`S SOUL: With our products allow people to live more happily. LANGTUO`S TARGET: To be the first brand of national ice makers. LANGTUO`S MISSION: Let our products entered into thousands of families. LANGTUO`S CONCEPT:Explore Innovation True Simple Happy Langtuo Refrigeration Equipment Co.,Ltd. Was founded in 2007 that is a professional manufacturer which specialized in producing refrigeration equipment.At present,our company has two kinds of brands DIZHUO,LANGTUO. Langtuo products has gained the ISO9001:2008 and CE certificate. We own perfect management system, strong technical resources, advanced fabricating equipment and strict quality inspection process making our products best.Our annual production capacity can reach 50000 sets.We focused on producing all kinds of ice machines(Daily capacity from 55lbs. to 6600lbs.) which are widely used in ice plant, supermarket, restaurant, bar, hotel, hospital, drinking shop, convenient store, etc. For a long time, we keep "Honest, Creative, Human-oriented, Customer-first" as our business philosophy which gained good reputation by customers from all over the world !

Contact Supplier 00:43

00:43

Catalogue Download Feature • There is more than 40 dies could be chosen, And we accept OEM dies • Following format don’t include the terminals, Please check the ternimal type with our dies drawing. • Reduce 50% energy when crimping. • Precise crimping die sets And integral lock with self-releasing machanism ensure high-quality crimping effect after crimping repeatedly. • Accurate adjustment before ex works delivery. • Light And compact structure keep crimping effect. Parameters No. Model No. Terminals Type Crimping Capacity Size(mm)/Weight(kg) 1 LX-30J Insulated Terminals And Connector 0.5-1.5mm2/20-16AWG 2.5mm2 / 14AWG 4-6mm2 / 12-10AWG 230/0.6 2 LX-03C Insulated Terminals And Connector 0.5-1.5mm2/20-16AWG 2.5mm2 / 14AWG 4-6mm2 / 12-10AWG 230/0.6 3. LX-18C Insulated terminals And Connector 10-16mm2 / 8-6AWG 230/0.6 4 LX-10 Non Insulated Terminals 1.5-6mm2 /17-10AWG 230/0.6 5 LX-101 Non Insulated Terminals 1.0-10mm2 /17-10AWG 230/0.6 6 LX-336N Non Insulated Terminals 1.5-10mm2 /20-8AWG 230/0.6 7 LX-04WFL Cord End Sleeve And Wire Ferrules 0.5-6mm2 / 20-16AWG 230/0.6 8 LX-06WF Cord End Sleeve And Wire Ferrules 0.5-6mm2 / 20-16AWG 230/0.6 9 LX-16WF Cord End Sleeve And Wire Ferrules 6-16mm2 / 10-5AWG 230/0.6 10 LX-25WF Cord End Sleeve And Wire Ferrules 6-25mm2 / 10-3AWG 230/0.6 11 LX-35WF Cord End Sleeve And Wire Ferrules 10-35mm2 / 8-2AWG 230/0.6 12 LX-26TW Cord End Sleeve And Wire Ferrules 2*0.5-6mm2/2*20-10AWG 230/0.6 13 LX-06WF2C Cord End Sleeve And Insulated terminals 0.5-6mm2 /0.5-2.5mm2 20-10AWG/20-14AWG 230/0.6 14 LX-03B Non-insulated Receptacles And Tab 0.5-6mm2 / 20-10AWG 230/0.6 15 LX-103 Wire Joint 0.5-6mm2 /20-10AWG 230/0.6 16 LX-0506FL Insulated 90°Flag Terminals 4.8mm2 /6.3mm2 3AWG/6AWG 230/0.6 17 LX-07FL Insulated 90°Flag Terminals 0.5-1.25mm2 /1.5-2.5mm2 20-18AWG /16-14AWG 230/0.6 18 LX-02H Coaxial cable 6.5mm/5.4mm/1.72mm RG59/62 230/0.6 19 LX-05H Coaxial cable 8.1/6.5/5.4/2.6/1.72mm RG58/59/62 230/0.6 20 LX-336C Coaxial cable 1.73/5.41/8.10mm RG58/59/62/6 230/0.6 21 LX-336J Coaxial cable 1.07/1.72/1.98/3.25/3.84/4.52MM RG174,179,Fiber Optic 230/0.6 22 LX-457 Coaxial cable 11/8.2/5.4MM RG58/6 230/0.6 23 LX-157 Airlines of Truned contact plugs 0.5-6 mm2/20-10AWG 230/0.6 24 LX-158 Airlines of Truned contact plugs 2.5-4-6mm2/13-10AWG 230/0.6 25 LX-1060A Open nose Terminals 10A-60A 230/0.6 26 LX-0510A Open nose Terminals 5A-10A 230/0.6 Application Our cable crimper mainly used for electrical working, State Grid construction, underground cable construction, Building construction etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 00:47

00:47

Sanyyo Vibrating Feeder operates with a constant control feeding of material which, is widely used in metallurgy, coal mining mineral processing, building materials, chemicals, abrasives, water and other industries. Both of two type of vibrating Feeders have grated bars which shifts material into the primary crusher. The Feeder removes the non-stone type material automatically and allows smaller material to fall through the grated section to bypass the primary crusher and to enter into the secondary crusher directly, which greatly increases crushing capacity by the plant.

Pursue Perfection, Contribute to customer Shanghai Leiyou Complete Machinery Co.,Ltd. was founded in 1986. The company gradually turned into joint-stock enterprises, which produces large-sized crushing machinery and provides customers with perfect solution on its own, thanks to the fact that it initially focused on manufacture and research of wear-resistant material. Now the company covers an area of 80,000 square meters and three factories, is well equipped with modernized cutting plant, and has more than 500 people working in the plant. It has changed into an important manufacturer and exporter of crushing machinery, screening, Grinder, Ball mill, Diesel generator, Conveyor belt all over the world. The company mainly produces crushing and screening equipment, and has a product range of more than 300 models and about 30 categories, which included fixed, semi-mobile, portable crushing plant and sold thousands of machines annually. The capacity reached from 5tph to 1800tph for each complete plant. The company has set up offices in main cities across China, and technical service center in many countries around the world. In recent years, SANYYO exported to all over the world, such as Africa, Middle East, Asia, South America etc; over 60 Countries. Currently, the company in the process of conducting multilateral cooperation on product R&D and technical exchange, this is designed to take advantages from various sources for innovative activity to the degree to which the company is able to roll out a batch of models annually to secure advance in every aspect for its crushing machines. SANYYO is also staffed with well-experienced design engineers to facilitate on-site analysis for clients from various parts of the world, and to produce complete and perfect solutions. Our corporation insists on the idea of higher quality, higher innovation, better faith, better service, pursuing to satisfy our customers, improving and consummating the quality control and services system. Our corporation persists on Scientific outlook of development to increase and stabilize the values of SANYYO brand.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery