01:03

01:03

Product name: Abrasive scouring pad sponge Material: High-quality abrasive which has very strong abrasive cleaning ability, rapid and effective in removing dirt and stains; Synthetic fiber which is constituted by non-woven fabric technology, forming open porous structure of the whole scouring pad; PU ordinary sponge which is very soft and strongly water-absorptive and can produce abundant bubbles. Product size: 35*63*110mm, can be made to order in light of customer’s requirement of sizes or shapes. Product packaging: Based on customer’s requirement. Product color: Yellow and green sponge is laminated onto blackish green scouring pad, colors can be adjusted according to Pantone card. Product’s functional diversity: 1.Strong ability of stain removing: It contains special abrasive particles with good quality, which can remove all kinds of stubborn stains. 2.Anti-bacteria: With a formula of anti-bacteria, it can effectively inhibit the breeding of bacteria and no odor will be engendered. 3.Diversified function: One side of scouring pad can remove dirt and the other side of sponge can produce bubbles. This is what we call double effect. This style is widely applied to the cleaning of the surface of hearth, sink, pot, bowl, ceramic tile and pottery.

Shanghai Kepu Industries Co., Ltd., situated in Fengxian District, the farthest of south Shanghai, has over 12,200 square meters of standardized workshop with about 120 employees. Its related factory Artek (Shaoxing) Co., Ltd., located in Shaoxing City(city of textile), Zhejiang Province, has more than 21,000 square meters of standardized workshop with around 350 employees.

Contact Supplier 03:50

03:50

The whole filling line will be with servo motor controlled bottle filling machine , capping machine and cap feeder ,labeling machine and so on Suitable for detergent , liquid soap , dish washer , hand washer and so on.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 01:19

01:19

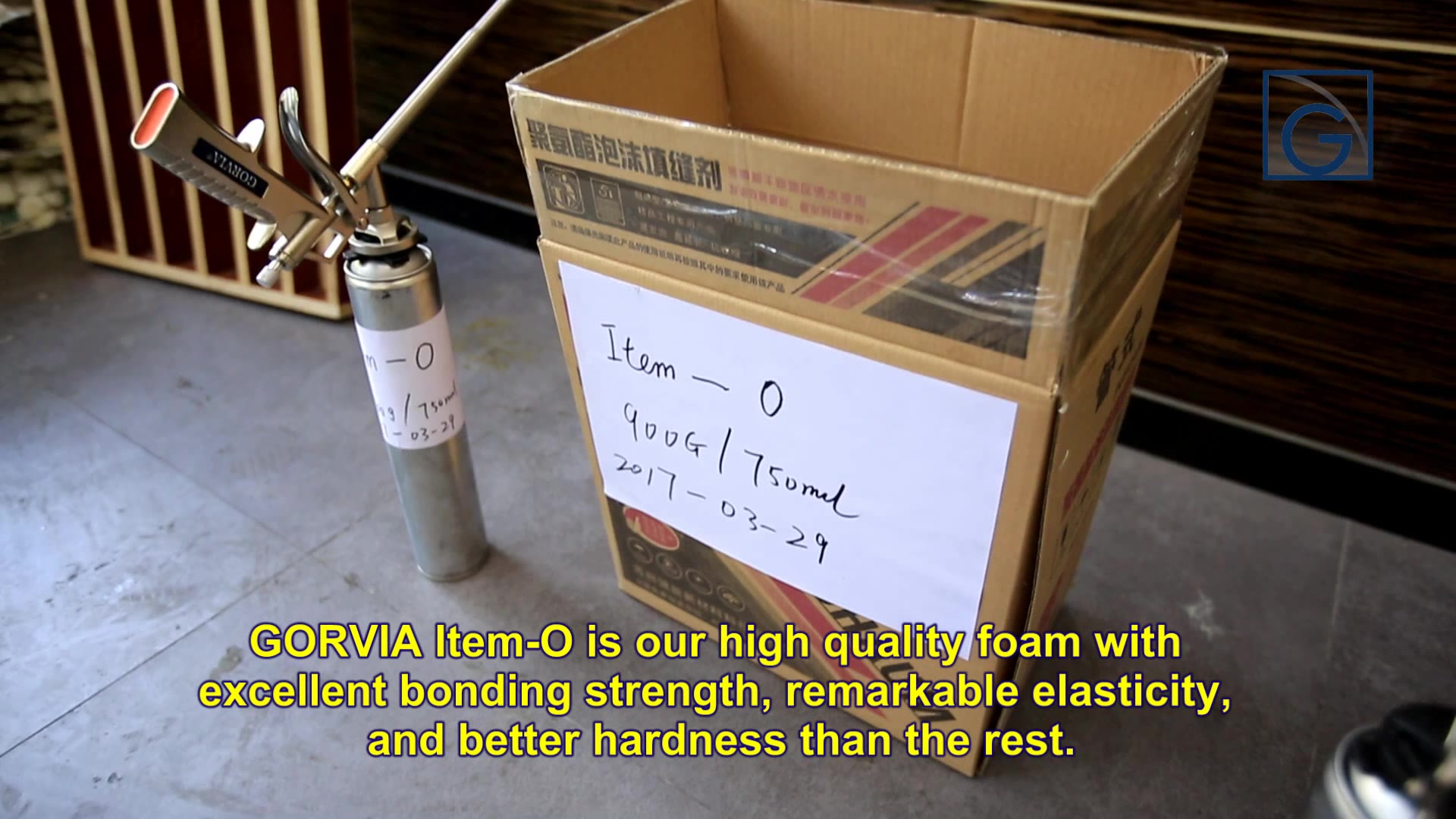

Tag: All-Season Use, High elastic foam, Dense cell structure, Shelf Life: 18 months Description: GF-series Item-O 750ML PU foam is an one component polyurthane foam used to seal gaps and crevices. The foam that dispenses from aerosol can is moisture cured and draws humidity from the air for cure. Product Features: Easy to use. Bonds to and seals most popular construction materials, wood, concrete, plaster, plumbing etc. Durable airtight seal-stops air infiltration, drafts and energy loss. High insulating value-saves energy and money. How To Use: 1. Shake can well to make the foam ready for use. 2. Clean the substrate and spray some water on it.. 3. Screw foam dispenser on tightly and turn the can upside down. 4. Vertical fill the gaps from the bottom upwards. 5. Foam is tack-free (surface drying) in 8 to 10 minutes in temperatures +18°C and +25°C; Higher temperatures will result in faster setup time. 6. Remove unwanted cured foam by cutting it with knife. Well done!

Gorcci International Limited is a high tech enterprise that is specialized in producing one-component spray polyurethane foam (PU foam), silicone sealant, PU sealant, no more nail, acrylic sealant, gasket maker and various types of glue, PU foam gun, cartridge caulking gun. Now we have been successfully exported to more than 50 countries. To meet different need from our valuable customers, we can also provide OEM and ODM service according to customer’s different requirements and samples.

Contact Supplier 02:50

02:50

Design Concept $ Process Description In order to ensure that the products in the use of the performance of good and lasting. We use strands of fine twisted and fine twisted bundles of fine level of oxygen free copper as a conductor, conform to DIN VDE 0295 grade 6, made of insulating PVC T12 conform to DIN VDE 0581 Part 1, PVC sheath TM2 conform to DIN VDE 0581 Part 1, and special structural design, mechanical and electrical properties can be calculated and simulated test using occasions. Reasonable structural design, strict material selection, excellent production and processing, strict quality control procedures to ensure that products in the practical application of good results. High soft of shielded twisted pair cable use: wood processing and packaging machinery, assembly line, automation equipment, CNC machine tools, machinery and equipment. Application This product is highly flexible characteristics, widely used for control cable and in bending requirements of the control unit, designed for use in continuous bending free movement without tension and forced movement of the towline system, while maintaining a flexible cable for mobile applications. Features Can be customized according to customer requirements color line core or coding line core. Good mechanical performance, high degree of flexibility. When used in the chain for the design life of 500 times of cyclic bending, validated and in practical use.

Founded in 2009, Shanghai Zhehong Robot Automation Co., Ltd. is located in Jiading district, Shanghai city. We specializes in cable harness and assembly processing, MPG hand wheel, CNC control panel, PLC distribution cabinet design and production, as well as CNC replacement part sales as a whole. We have a long-term cooperation with the major CNC machine manufacturers at home and abroad, providing technical services. We support FANUC, MITSUBISHI, SIEMENS, SYNTEC, LNC, LYNUC, KND etc. system.. After years of steady development, Zhehong Initially formed R & D, manufacturing, sales and service into one comprehensive pattern, with annual sales of more than 200 million RMB, number of employees more than 200, among them more than 30 R & D personnel, over 100 patented products, mold design more than 300 sets, the investment in R & D, production and testing equipment up to 300 million yuan. Our technical team with rich experience, their superb technology, efficient service won a wide range of customer trust.

Contact Supplier 02:04

02:04

Special rollers design, more precise and solid Solid Shaft diameter: 75 mm according to profile Mitsubishi PLC and converter Tool box and technical support

Young is in forming line since 1997. I have worked in three famous forming factory as senior technician. Young has gone to Portugal, the Czech Republic, Azerbaijan, Australia, India, Nigeria, Sudan , Kenya, America, Bolivia, Argentina….more than 20 countries to install machines and teach customers’ workers to operate machine. Therefore, Young knows machines very well. Now we build our factory Wuxi Jingshirui Machinery Co., Ltd. The first and important thing he do is to improve machine quality according to his experience. Quality is always our life.

Contact Supplier 01:20

01:20

Download how to choose the right filter housing Download catalogue for doctop filter High quality liquid filters pvdf material plastic water bag housing 1. Brief description of pvdf material plastic water bag housing pvdf material plastic water bag housing plastic pvdf for bag2#,1# ,5# easy for installation This one is most advance one in the world, it can be used widely in the sea water treatment and also the long time use no leakage problem. PVDF can against the temperature 150Deg. Its weight is around 26kg for one bag filter housing. With high quality control, our pvdf bag filter housing is very popular in end user market. 2. Types of pvdf material plastic water bag housing: 2# pvdf material plastic water bag housing 5# pvdf material plastic water bag housing 3. Features of pvdf material plastic water bag housing - simple and reasonable structure - good sealing - high water flow capacity - easy operation - positive sealing arrangement to avoid bypassing - high filtering fineness - easy replace 4. Apvdflications of pvdf material plastic water bag housing pvdf material plastic water bag housing in Paint Process water Filtration Plating Solutions Coatings Lubricants Solvents Hydraulic Fluids Ground Water Remediation Industrial Waste Water Treatment

Shanghai Sffiltech Co.,Ltd., based on the German technology, is the professional manufacturer and supplier of liquid filtration and separation products. Efiltech products include bag filter system, cartridge filter systems, pipe filters, self cleaning filters, auto back-flush self cleaning filter and other industrial filtration systems. They are widely used in electronics, semiconductor, chemical, pharmaceutical, food, beverages, paints, paper industry, automobile manufacturing, inks, resins, water treatment and other industrial fields. Sffiltech provide you affordable, reliable and efficient filtration solutions and perfect service. --Efiltech can provide various filters with international standard, such as American standard, Japanese standard, German standard etc. --All filters can be custom made according to customer drawings. --OEM is available Expect long term and good cooperation with all friends from all of the world.

Contact Supplier 00:00

00:00

Detailed informations(Products): 1. Feature: Filter cartridges with lugs can be installed from either the clean side or the dirty side.They are specially suitable for compact dust filter collectors. 2. Wide application: With plenty of filter media selection of high quality and many finishing treatments available, we can always provide proper filter cartridges for all kinds of operating environments. Structure: Item Material(Standard) Material(Alternative) Filter Media Cellulose/Synthetic fiber/ All kinds of H&V air filtration`s filter Nanofiber/Polyester fiber media selection Top cap/ Galvanized steel Stainless steel,Color-coated steel, Bottom cap recyclable plastic ABS (Open/Closed) Gasket EPDM Urethane/Silicone Inner Mesh Galvanized steel Stainless Steel,Color-coated steel, Recyclable PP Outside Straps/ Optional Glued or ultrasonic welded straps/ Outer Mesh Galvanized steel/Stainless Steel Finishing Treatment Teflon-coating,waterproofing,oilproofing,flame-retarding treatment, antistatic coating,etc Application: Widely used in sandblasting, welding fume, powder coating, and other kinds of dust collection applications. Also, we warmly welcome: -- End users or agents to find replacements here; -- Dust collector manufacturers to do customization.

Shanghai Thenow Purification Technology Co.,Ltd. Thenow was established in 2005, belonging to Thenow Group(Former name Apureda Group) as the wholly-owned subsidiary. Being a standard maker, Thenow Group is a global specialist in the development and production of filtering systems and solutions with 6 production units. As one of Thenow Group’s production units, Thenow Purification’s business is to provide customers with sustainable best in class air filtration products and services. We mainly focus on manufacturing air filters for industrial dedusting, gas turbine air inlet systems and HVAC systems.

Contact Supplier 00:27

00:27

Catalogue Download Feature • Cutting copper armored cable below 3*120 mm2, and aluminum armored cable max Φ75 mm. • For cutting aluminum cable, the max diameter could be according to blade available size. • Blades can be resharpened or exchanged. • Reliable ratchet mechanism and durable blade ensure superior cutting times. • Extensible handgrips are comfortable to hold. • Don't cut steel wires. • Supplied package: carrying bag. • Size: 420*205*50mm • Weight: 3.6 kg Parameters Model J75 Capacity (Max Range) copper armored cable 3*120 mm2 aluminum armored cable Φ75 mm Size 420*205*50mm Weight 3.6 kg Application Our cable cutter mainly used for electrical working, State Grid construction, underground cable construction, Building construction etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 00:35

00:35

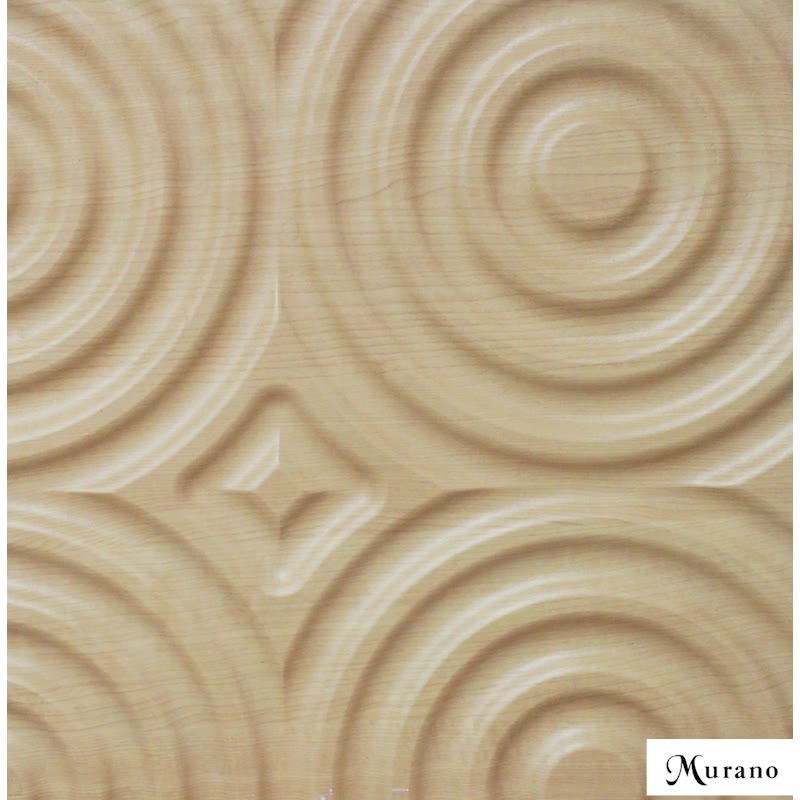

Introduction: MURANO 3D decorative panel are made to the highest standards from high quality MDF with damp proof melamine backing to prevent warping once installed. The 3D carving is carried out on high tech computerized CNC router beds so that every panel matches perfectly when installed. All MDF panels come in primed and sanded smooth finish, making easy work to paint in your choice of color and paint finish. Specification: Material: MDF Dimension: 300*450mm Thickness: 18mm Finish:Painting/PVC Backing: Melamine Film Density: 760kg/m³

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier 00:41

00:41

Feature • Flip-top latch type head • Head could be rotated 180 degree,For flexible operation in confined place. • Tools are set by double speed. Quick speed while dies have not connected with lug. Slow speed while dies touched lug. Two speed for save your labor and time. • Fitted with safety valve. Automatically relief working pressure when complete crimping. • Plastic case package is for easy carrying and well tool protection Parameters Model CPC-20AF Cutting Wire Type Cu/Al cable, wire rope, wire standard, round bar Cutting Capacity Max Φ20mm Output 5.5 T Length 380 mm Weight 3.2 kg Application Our hydraulic tools mainly used for electrical working, State Grid construction, underground cable construction, Building construction etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 01:07

01:07

Feature • Application width: 0.3-7.9mm • Application scope: Stainless steel cable ties • Material: Special Tool Steel • Automatically tensions and cut ties in one operation • Designed with ensure reduce efforts • Replacement ratchet set Parameters Model HS-600N Cable Tie Type Stainless steel cable ties Cable Tie Width 0.3mm- 7.9mm Length 178mm Weight 0.68 kg Application Our tools mainly used for cable ties cutting , Electric working, State Grid construction, underground cable construction, Building construction etc

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 00:00

00:00

soft tube filling and sealing machine is mainly used for plastic tube filling and sealing. It has been widely used in the fields of pharmacy, cosmetic, food and chemical etc. This MIC-R30 SEMI-auto soft tube filling & sealing machine is a simple operate sealing filling machine with inside heat and outside heat heads. It has total 8 positions for filling and sealing. And materials such as paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste etc., are all applicable.

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery