01:02

01:02

50HZ(1500RPM)-3Phase 400V/230V(1phase 230v) Genset Model Power(KW/KVA) Engine FUEL TANK Data Download Continuous Standby Kubota Control SKW8.3-1P 6/7.5 6.6/8.3 D1105-BG Mech BASK TANK Download SKW10.6-1P 7.7/9.6 8.5/10.6 D1105-BG Mech Download SKW14-1P 10/12.5 11/14 V1505-BG Mech Download SKW16.5-1P 12/15 13.2/16.5 D1703-BG Mech Download SKW22.5-1P 16/20 18/22.5 V2203-BG Mech Download SKW25-1P 18/23 20/25 V2003-T-BG Mech Download SKW32.5-1P 24/30 26/32.5 V3300-BG Mech Download SKW40-1P 29/36 32/40 V3300-T-BG Mech Download SKW11 8/10 8.8/11 D1105-BG Mech Download SKW14 10/12.5 11/14 V1505-BG Mech Download SKW16.5 12/15 13.2/16.5 D1703-BG Mech Download SKW22.5 16/20 18/22.5 V2203-BG Mech Download SKW25 18/23 20/25 V2003-T-BG Mech Download SKW32.5 24/30 26/32.5 V3300-BG Mech Download SKW40 29/36 32/40 V3300-T-BG Mech Download 60HZ(1800RPM)-3Phase 220V/127V(1phase 220v) Genset Model Power(KW/KVA) Engine FUEL TANK Data Download Continuous Standby Kubota Control SKW8.8X-1P 6.4/8 7/8.75 D1105-BG Mech BASK TANK Download SKW12.8X-1P 9.3/11.6 10.2/12.8 D1105-BG Mech Download SKW16.5X-1P 12/15 13.2/16.5 V1505-BG Mech Download SKW20X-1P 14.5/18 16/20 D1703-BG Mech Download SKW22X-1P 16/20 17.6/22 V2203-BG Mech Download SKW26.5X-1P 19.3/24 21.2/26.5 V2203-BG Mech Download SKW30X-1P 22/27 24.2/30 V2003-T-BG Mech Download SKW40.4X-1P 29.4/37 32.3/40.4 V3300-BG Mech Download SKW49X-1P 35.4/44 39/49 V3300-T-BG Mech Download SKW9.5X 7/8.75 7.6/9.5 D1105-BG Mech Download SKW13.2X 9.6/12 10.6/13.2 D1105-BG Mech Download SKW16.5X 12/15 13.2/16.5 V1505-BG Mech Download SKW20X 14.5/18 16/20 D1703-BG Mech Download SKW22X 16/20 17.6/22 V2203-BG Mech Download SKW26.5X 19.3/24 21.2/26.5 V2203-BG Mech Download SKW30X 22/27 24.2/30 V2003-T-BG Mech Download SKW40.4X 29.4/37 32.3/40.4 V3300-BG Mech Download SKW49X 35.4/44 39/49 V3300-T-BG Mech Download

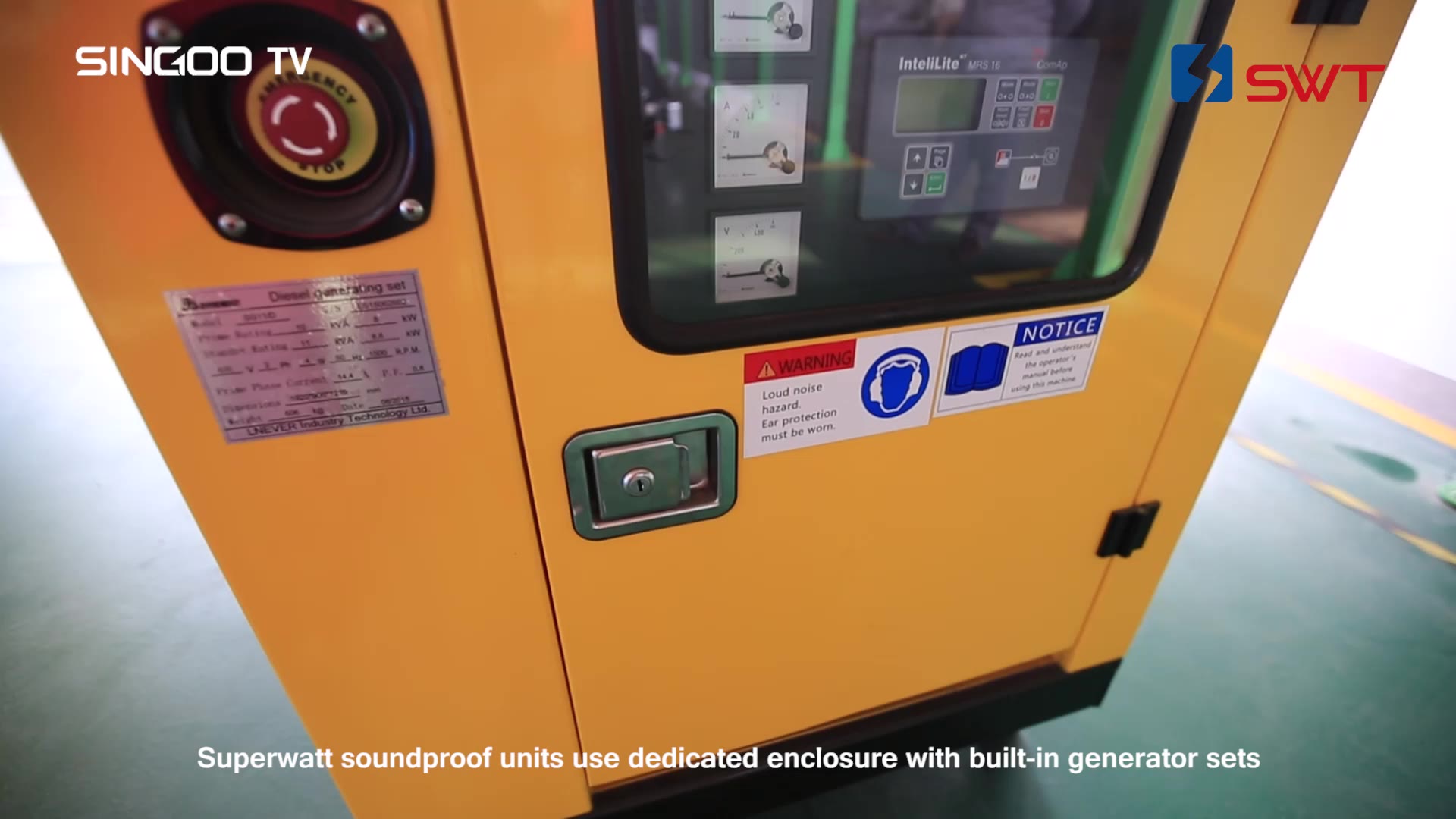

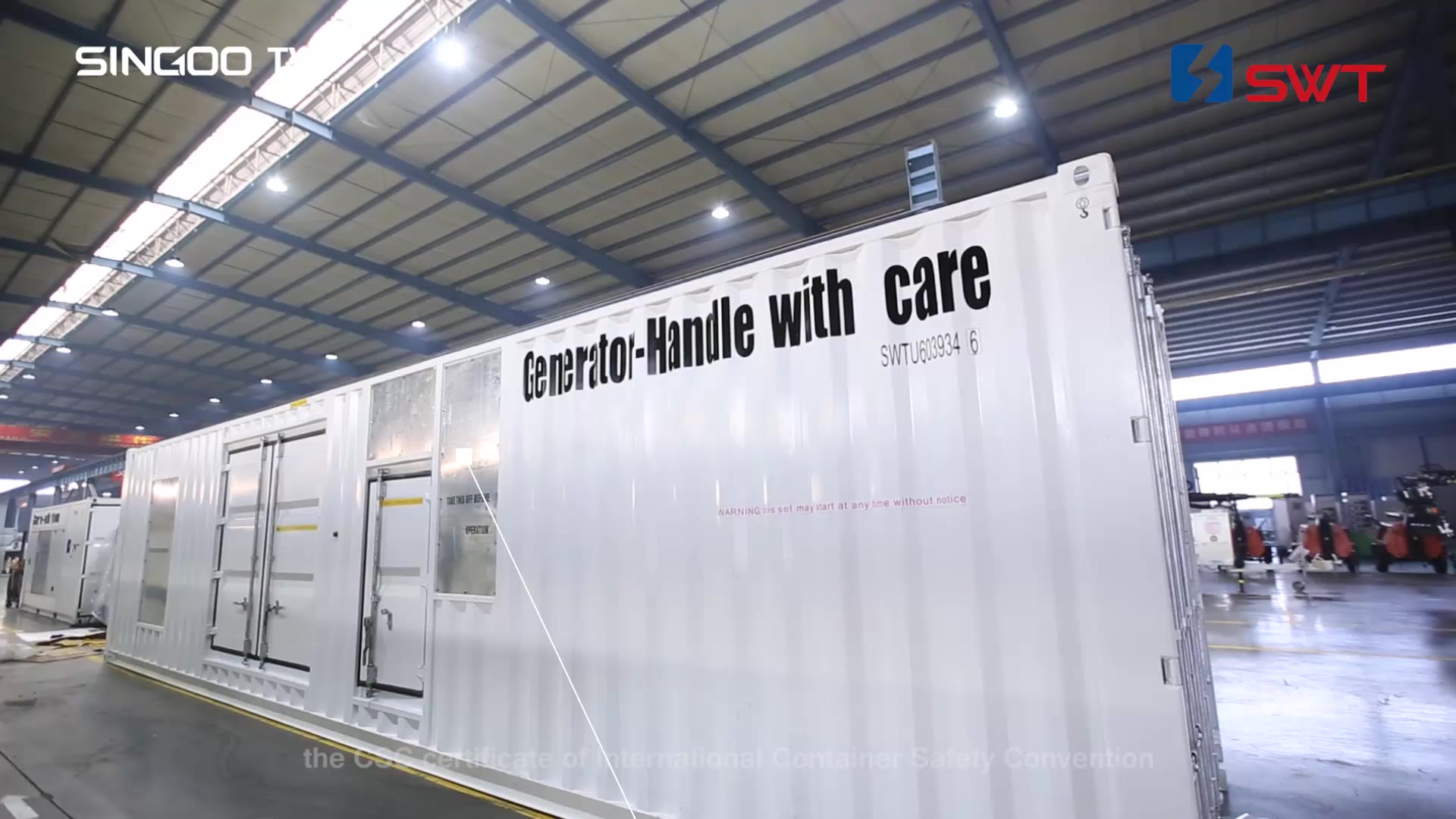

SWT, the pioneer of power equipment manufacturer in China, was established in 1993. After continuous development for over 25 years, we have been an outstanding manufacturer and professional integrated solution provider of power plants or equipment in the world. Meanwhile, our products cover diesel generators, mobile lighting tower, gas generator sets. We have gathered more than a decade of researching experience of Mobile Lighting Tower before we invent the first LED lighting tower and became a technology leader of this kind products in the world. We invested to develop Vehicle Power Station and Gas Generator Sets in recent years, to achieve good reputation with excellent quality and performance.

Contact Supplier 01:29

01:29

50HZ(1500RPM)-3Phase 400V/230V Genset Model Power(KW/KVA) Engine FUEK TANK Data Download Prime Standby Perkins Control SPW33 24/30 26.4/33 1103A-33G Mech BASK TANK Download SPW50 36/45 40/50 1103A-33TG1 Mech Download SPW67 49/61 53/67 1103A-33TG2 Mech Download SPW227 165/206 182/227 1506A-E88TAG1 ECM Download SPW265 190/238 212/265 1506A-E88TAG2 ECM Download SPW275 200/250 220/275 1506A-E88TAG3 ECM Download SPW308 224/280 246/308 1506A-E88TAG4 ECM Download SPW350 255/319 280/350 1506A-E88TAG5 ECM Download SPW400 280/350 320/400 2206C-E13TAG2 ECM NONE TANK Download SPW450 320/400 360/450 2206C-E13TAG3 ECM Download SPW500 360/450 400/500 2506C-E15TAG1 ECM Download SPW565 412/515 452/565 2506C-E15TAG2 ECM Download SPW680 495/619 544/680 2806C-E18TAG1A ECM Download SPW725 535/670 580/725 2806A-E18TAG2 ECM Download SPW825 600/750 660/825 4006-23TAG2A Electric Download SPW880 640/800 704/880 4006-23TAG3A Electric Download SPW1006 732/915 805/1006 4008TAG1A Electric Download SPW1128 820/1025 902/1128 4008TAG2A Electric Download SPW1250 906/1133 1000/1250 4008-30TAG3 Electric Download SPW1395 1012/1265 1116/1395 4012-46TWG2A Electric Download SPW1520 1105/1382 1216/1520 4012-46TWG3A Electric Download SPW1650 1200/1500 1320/1650 4012-46TAG2A Electric Download SPW1910 1388/1735 1528/1910 4012-46TAG3A Electric Download SPW2037 1480/1850 1630/2037 4016TAG1A Electric Download SPW2033 1505/1881 1626/2033 4016-61TRG1 Electric Download SPW2275 1656/2070 1820/2275 4016TAG2A Electric Download SPW2234 1626/2031 1788/2234 4016-61TRG2 Electric Download SPW2515 1810/2263 2012/2515 4016-61TRG3 Electric Download

SWT, the pioneer of power equipment manufacturer in China, was established in 1993. After continuous development for over 25 years, we have been an outstanding manufacturer and professional integrated solution provider of power plants or equipment in the world. Meanwhile, our products cover diesel generators, mobile lighting tower, gas generator sets. We have gathered more than a decade of researching experience of Mobile Lighting Tower before we invent the first LED lighting tower and became a technology leader of this kind products in the world. We invested to develop Vehicle Power Station and Gas Generator Sets in recent years, to achieve good reputation with excellent quality and performance.

Contact Supplier 00:00

00:00

Filling head 20 heads Filling volume range 200ml-2500ml Production speed ≤4000 Bph basis on1L bottle Voltage 220V/380V Power 3.0Kw Suitable bottle’s diameter Ф40mm-Ф100mm Filling error ≤±3‰ Work pressure 0.55Mpa-0.65Mpa Size 2800mm × 1400mm× 2500mm Weight 1000 kg

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:00

00:00

Filling head 20 heads Filling volume range 200ml-2500ml Production speed ≤4000 Bph basis on1L bottle Voltage 220V/380V Power 3.0Kw Suitable bottle’s diameter Ф40mm-Ф100mm Filling error ≤±3‰ Work pressure 0.55Mpa-0.65Mpa Size 2800mm × 1400mm× 2500mm Weight 1000 kg

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:00

00:00

Filling head 8 heads Filling volume range 50-1000ml(Use 1000ml piston cylinder) Production speed ≤1800 Bph basis on 1000ml bottle Voltage 220v/380v Power 3kw Suitable bottle’s diameter Ф40mm-Ф100mm Filling error ≤±1‰ Work pressure 0.55Mpa-0.65Mpa Size 2000mm × 1400mm× 2500mm Weight 1000kg

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:15

00:15

Certificate ISO 9001 Standard EN & JIS & ASTM & GB Substrate Hot-dip Galvanized Steel Hot-dip Alum-zinc Coated Steel Electrical Galvanized Steel Cold Rolled Steel Color Any color in RAL Thickness 0.12~2.0mm OR Customized Width 600~1250 OR Customized Painting Thickness Top paint Back paint Max Min Max Min 30μ 13~15μ 20μ 5~7μ Protective Film Polyester (PE) Silicon Modified Polyester (SMP) High-durability Polyester (HDP) Polyvinylidene Fluoride (PVDF) Surface Treatment Chromated / Oiled / Anti-finger Tolerance Thickness +/-0.05 mm Width +5/-2 mm Total quantity +/-10% Zinc coating +/-10% Tensile Strength >300mpa Packing Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, wit Payment T/T 30% in advance,70% balance after received B/L copy Alibaba Assurance Min order 1 Ton

Shanghai Leading Metal Co., Ltd is Shanghai-based steel provider which has been focusing on the steel service for more than ten years. Our main business is construction-based steel commodities including coil, plate etc. We are especially experienced in Copper Steel ,Aluminum Steel and Steel Roofing Sheet . And our un-allocated inventory is 30,000 tons. There are 11 staff in the sales office, 67 workers in the warehouse, we are still developing and welcome more advice from you. A team (5 person with more average more than 5-year experienced) service for you.Save total cost is our advantage.

Contact Supplier 01:15

01:15

Product description 1.The mineral water filling machine has three functions for bottle rinsing, filling and capping, which are composed in one body of the machine . The whole process is full automatic. 2. This machine is used in filling mineral water, drinking water, flavor water, etc. in bottles made of polyester and plastics . 3. The filling packaging operation is faster and more stable because the micro pressure filling operation of the new type is adopted . There the output and benefit of the machine is higher than the machinery of the same specifications . 4. PLC control, full automatic working . 5. Touch-screen control panel, easy operation. 6. Singel positional adjustable central transmission post, more stable lable transmission . 7. Screw rod of separate bottle: stable transportation of bottles. 8. Label control sensor shelf: original creation tail surface and sensor are combined to improce the precision of cutting the material .

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:43

00:43

Overview The rolling capping machine can cap different sizes and shapes of lids, the capping height of the machine can be adjusted to fit your machine. The machine is made of stainless steel of 304, meeting with CE standard and GMP standard, can be used in food, medicine. It can be connected with filling machine and labeling machine. The machine adopts PLC control, it’s easy operate. Characteristics 1 It is applicable to different-shaped bottles and plastic bottles: PP , PE , PVC ,glass bottle and mould bottle. The bottle-in and bottle-out has specialized structure. 2 PLC control , simple and easy to operate. And sample to operate, to adjust the filing capacity. Measure accurately, make the whole machine stable and high-speed 3 Use touch screen control system, make operation simple, practical and efficient; 4 The medicine is made of 304 stainless material completely or medical grade silicone tube , meeting the requirement of GMP. 5 It can be connected with the filling machine and the label-attaching machine to form a complete set of produce line.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:27

00:27

Overview The rolling capping machine can cap different sizes and shapes of lids, the capping height of the machine can be adjusted to fit your machine. The machine is made of stainless steel of 304, meeting with CE standard and GMP standard, can be used in food, medicine. It can be connected with filling machine and labeling machine. The machine adopts PLC control, it’s easy operate. Characteristics 1 It is applicable to different-shaped bottles and plastic bottles: PP , PE , PVC ,glass bottle and mould bottle. The bottle-in and bottle-out has specialized structure. 2 PLC control , simple and easy to operate. And sample to operate, to adjust the filing capacity. Measure accurately, make the whole machine stable and high-speed 3 Use touch screen control system, make operation simple, practical and efficient; 4 The medicine is made of 304 stainless material completely or medical grade silicone tube , meeting the requirement of GMP. 5 It can be connected with the filling machine and the label-attaching machine to form a complete set of produce line.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:39

00:39

Overview This Top supplier self adhesive semi automatic labeling machine sticker labeling machine for bottle in factory price is suitable for labeling all kinds of regular or irregular containers,such as round bottles,square bottles and flat bottles,it can label Double or Single label,which is high speed and high precision.Built in microchip storing different job setting makes fast and easy changeover.This Customized OEM collamat labeling machie 6600 conveyor speed bottling filling machine with automatic grade is ideal for cylindrical container with diameter from 30mm–100mm(above size could be customized made). Characteristics The default setting is “No bottle feed - stop label supply". Brush label system adapts to different bottle models. Change label or bottle types conversion without tools. Adopt mature PLC control system technology,make the whole machine stable and high-speed. Adopt touch screen control system,make operation simple,practical and efficient. Advanced pneumatic code system technology,make the printed letter clear,fast and stable. Wide labeling application,adapt to various sizes of round bottles. Roll extrusion bottle,so that the labels attached more solid The tolerance of label length is controlled within 1 mm. Production line is optional before or after the machine,also collection turntable is optional for collection,sorting and packaging Main material is made of stainless steel equipment and advanced aluminum alloy manufacturing,comply with GMP requirement

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:27

00:27

This machine is used for rinsing glass &plastic bottle by clean compressed air, which enters into the bottle,rinses the intemal of bottle and then is absorbed out from another exit.Since the machine is fully closed,the powder, dust,water drops or impurities in bottle or on the wall of bottle can be blown away. The development and manufacture of the equipment fills in the gap in the market. With continuous improvement fo several years, this kind of equipment has been launched in mass and obtained above 90% of domestic market shares. It has the several patent in china.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:39

00:39

Item Custom brown paper tube with black logo H.S. Code 4811900000 Material Kraft paper,Paper board, Art paper,Corrugated board,Coated paper, etc Size(L*W*H) Accept custom Color CMYK litho printing, Pantone color printing, Flexo printing and UV printing as your request Finish Processing Glossy/Matt Varnish, Glossy/Matt Lamination, Gold/Silver foil stamping, Spot UV, Embossed, etc. Usage Packaging, Shipping, etc. Samples fee Stock samples are free Lead time 5 working days for samples; 12 working days for mass production Advantage 100% manufactory with lots of advanced equipments QC Strict quality control under SGS, ISO9001 and Intertek. Certification BSCI, ISO9000/1400,BV TUV SGS FSC etc.

Coffe Packing was founded by a Packaging & Print expert, Mr. Lin, in 1986. Today, Coffe Packing, with a team of production, sales, R&D and superior service, has become one of the strongest Paper Packaging manufacturers in China. We have more than 100 advanced equipments, such as German MAN Roland R904-7B four-color, R9055 five-color offset press , Heidelberg speed master CP102 four color sheet-fed offset press, Japanese Roybi 754 four color offset press, five advanced 5-ply Corrugated Board Production Lines, automatic Printing Slotting/Die-cutting Machines, automatic folder gluer, UV Spot and Overall Coating Machine, film blowing machines etc.. With such modern production equipments and technology.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery