00:02

00:02

Steel cut wire shot is made with the process of drawing, cutting and conditioned etc. rigidly according to the standards of VDFI 8001/1994 and USA SAE2431. The particles of shot are uniformly size with the respective hardness of HV400-500, HV500-555, HV555-605, HV610-670, HV670-740 and more. And the granularity is distributed from 0.2mm to 3.0mm. The shapes of them are columnar and spherical with conditioned G1, G2, G3. Besides, their useful durability are ranged from 3500cycles to 9600 cycles. Type Apply to equipment Steel Cut wire Shots are typically used for the blasting machine with drum type, chain type, lifting hook type, crawler type, pass type, rotating table type, accumulation type, marching type and car type. Also can used for shot blast equipments, pretreatment of the production line, and sand blasting room. Package Our company can carry out woven bag packaging, ton bag packaging, wood tray packaging, plastic packing packaging and the like according to customer requirements. Advantage of Steel cut wire shot Compared with steel grit, you can get 30% reduction on cost. According to our experience, steel cut wire shot will turn into round shot after long-time use.bright appearance, no dust and long durability is the advantage of our steel cut wire shot. Shanghai Bosun Abrasive company is the earliest manufacturer of steel cut wire shot.

Shanghai Bosun Abrasive Co., Ltd. is a professional abrasive company, which can research, produce and sell all kinds of abrasive. The main products include all kinds of steel shot, steel grit, steel cut wire shot, stainless steel balls, aluminum balls, zinc balls, copper balls as well as the copper sand, brown corundum, black corundum and so on. The company has advanced equipment and technology, strong technology strength and perfect quality inspection methods. The products are strictly produced and tested according to relative standard, so it is trusted by our customers and be chosen as designated product by many companies which producing sand-blast equipment.

Contact Supplier 02:05

02:05

Imitation marble decorative sheet extrusion line adopts a special curing technology, to provide a mirror effect on the product surface, with a strong artistic appeal, can create a magical change, bright colors, the magnificent visual effects. Product saturation film surface, similar to ceramic stone transparent glass layer, it can achieve such as stone-like three-dimensional affect, with high hardness, impact resistance, acid-resistance, weathering-resistance, low coefficient of expansion, non-absorbent, good flatness and other advantages, and the exclusion of natural stone harmful substances and radiation elements, is an ideal new generation of green building materials. Specification: Extruder type 1220*2440MM Product thickness 1-4.5MM Max. extrusion capacity 350-450kg/h Main motor power 55KW

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact SupplierShanghai Neway Insourcing Co.,ltd is a trading and manufacturing company that located in Shanghai City, shorted name as NEWAY below. NEWAY started the exporting business from 2004. We focus on flexible heating technology for automotive and commercial application. In 2006, we owned carbon fiber heater factory as a shareholder that is certificated by TS16949.

Contact Supplier 01:12

01:12

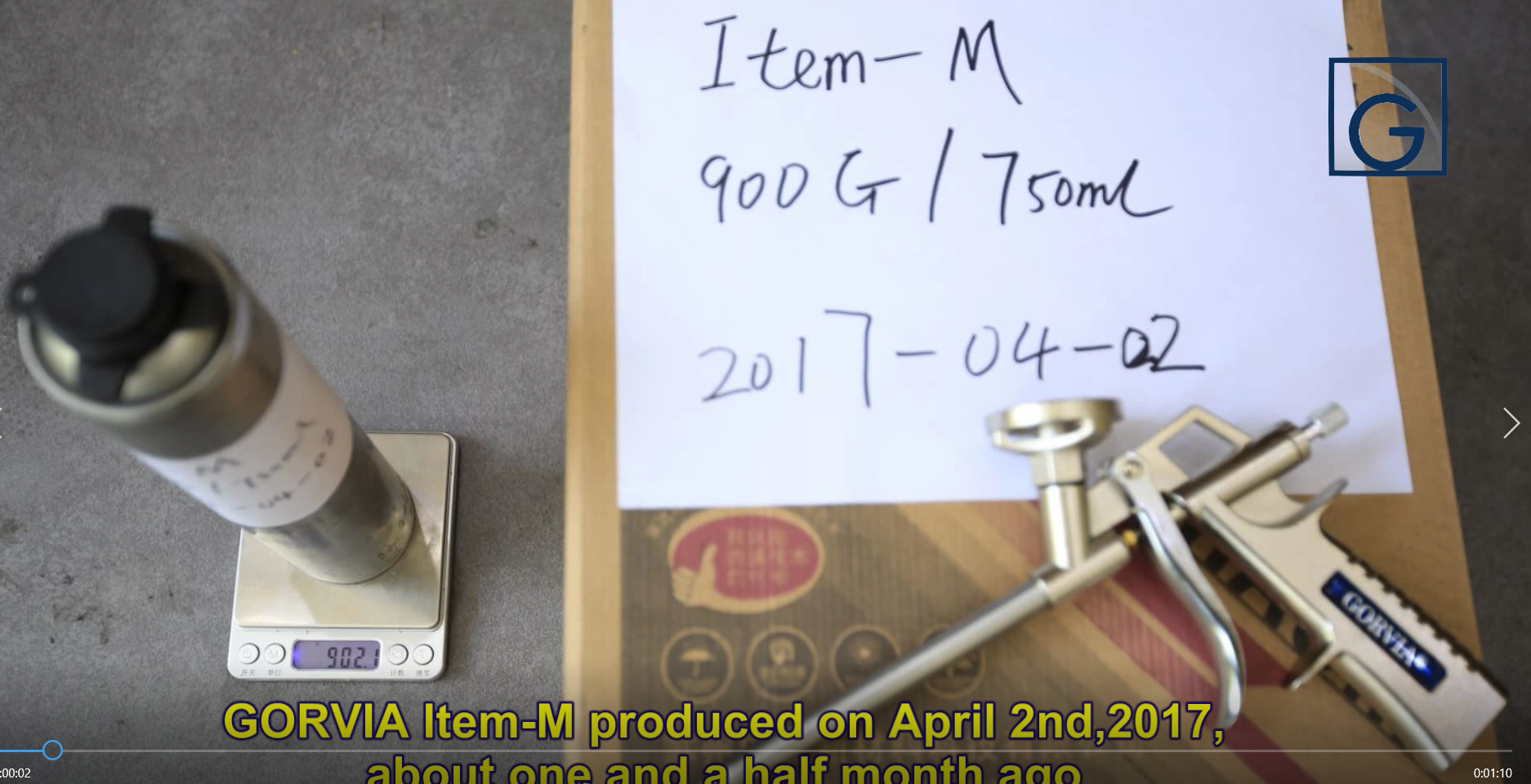

Tag: Utmost yield 65L, High elastic foam, All-Season use, Shelf Life: 18 months Description: GF-Series Item-M 750ML PU foam, which is based on moisture curing polyurethane, containing safety propellant, is used to seal gaps and crevices with very high expansion yield UP TO 65 LITERS, the post expansion is quite low to prevent deformation. The foam that dispenses from aerosol can is moisture cured and draws humidity from the air for cure. Product Features: Easy to use. Bonds to and seals most popular construction materials, wood, concrete, plaster, plumbing etc. Durable airtight seal-stops air infiltration, drafts and energy loss. High insulating value-saves energy and money. How To Use: 1. Shake can well to make the foam ready for use. 2. Clean the substrate and spray some water on it.. 3. Screw foam dispenser on tightly and turn the can upside down. 4. Vertical fill the gaps from the bottom upwards. 5. Foam is tack-free (surface drying) in 8 to 10 minutes in temperatures +18°C and +25°C; Higher temperatures will result in faster setup time. 6. Remove unwanted cured foam by cutting it with knife. Well done!

Gorcci International Limited is a high tech enterprise that is specialized in producing one-component spray polyurethane foam (PU foam), silicone sealant, PU sealant, no more nail, acrylic sealant, gasket maker and various types of glue, PU foam gun, cartridge caulking gun. Now we have been successfully exported to more than 50 countries. To meet different need from our valuable customers, we can also provide OEM and ODM service according to customer’s different requirements and samples.

Contact Supplier 01:18

01:18

Model DLM-ALS Driving Mode German Avery brand Yield(pcs/min) 20-150 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-160 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact SupplierShanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:00

00:00

Gantry type, double drive, people can get very close to the machine High-speed programmable focus-adjusting piercing mode Smart piercing system Fast cutting of thin sheet Edge-sharing cutting function, improve the material utlilzation and cutting efficiency Technique database, friendly human-machine interface, easy to operate Effective cutting of aluminum, brass and other high reflective material High photoelectric conversion rate, no consumption of gas, low cost with small size 15”touch controlling system, easy to operate Automatic exchanging table Aluminum Bridge Compared to traditional bridge, the light-weight aluminum bridge is 3 meters length,1.5 m span of working range. The operator can handle the problem quickly without entering the inside of the machine because of three-meter side opening. Cutting gas system Up to three types of assist gasses can be connected. Automatic gas selection valve will supply the right gas for each application. Extreme fast cutting gas supply system guarantees stable laser processing. Aluminum Bridge Cutting gas system Suction unit With improved suction system for fumes and smokes, scrap pieces and heavy dust fall through the cutting tables into separate boxes that can easily be taken away from the side of the machine. Laser source Germany famous IPG Laser source is with high performance, long stability. More than 100000 hours work-life of pumped diode Wide range of operating wavelengths, single-mode and multi-mode options Suction unit Laser source Application: Available for cutting such metal sheet as stainless steel, carbon steel, copper, brass, alloy steel, aluminum, gold, silver, titanium and so on. Widely used in the sheet metal processing, shipbuilding, automobile, rail transportation, agriculture machinery, advertising board ,kitchen utensils, machinery, elevator and so on.

As a professional and energetic enterprise in the sheet metal processing industry, Suzhou Lead Laser Technology Co., Ltd manufactures high performance of laser cutting machine and laser welding machine for various applications with two production facilities in China.

Contact Supplier 00:51

00:51

This machine adopts international advanced technology; cover the circle label on the pet bottle. And then hot shrinking to fix on the position which bottle body designated.This machine's structure is compact, and suitable for the production line of different direction and different height. The machinery part adopts combination designing of modularization, and makes the machine reasonable. The height adjustment adopts motor fluctuating; it is convenient to replace the material. The special cutter head designing, make the film-rolling cut more exactly and reliably.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 01:26

01:26

commercial ice cube machine(LB150S,LB175S,LB210S,LB300S) ◆Water-flow design,which the ice capacity can be increased 10% higher than other similar machines. ◆Anti-dust mesh design,which is removable and easy for cleaning. ◆Front air intake and exhaust,side for hot air spread,easy to clean,enhance the lifetime of machine. Product features: ◆Enhanced durable machine body and stainless steel material design. ◆Push-up door type; Space-saving body; Meeting the requirements of small space; Luxury and beauty. ◆Industry-leading copper-nickel evaporator; Shorter freeze and harvest cycle; Full capacity. ◆Using advanced noise reduction technology to make working noise reducing more than 15%. ◆Overall food-grade PE liner, through the European CE certification and Test Report . Specification Cooling method: Air-cooling Model Output/24h Ice store Power Dimensions/ (L*W*H) LB-150S 70kg 40kg 220V/490W 660*670*900mm LB-175S 80kg 40kg 220V/510W 660*670*900mm LB-210S 100kg 40kg 220V/750W 660*670*900mm LB-300S 130kg 40kg 220V/850W 660*670*900mm

LANGTUO`S SOUL: With our products allow people to live more happily. LANGTUO`S TARGET: To be the first brand of national ice makers. LANGTUO`S MISSION: Let our products entered into thousands of families. LANGTUO`S CONCEPT:Explore Innovation True Simple Happy Langtuo Refrigeration Equipment Co.,Ltd. Was founded in 2007 that is a professional manufacturer which specialized in producing refrigeration equipment.At present,our company has two kinds of brands DIZHUO,LANGTUO. Langtuo products has gained the ISO9001:2008 and CE certificate. We own perfect management system, strong technical resources, advanced fabricating equipment and strict quality inspection process making our products best.Our annual production capacity can reach 50000 sets.We focused on producing all kinds of ice machines(Daily capacity from 55lbs. to 6600lbs.) which are widely used in ice plant, supermarket, restaurant, bar, hotel, hospital, drinking shop, convenient store, etc. For a long time, we keep "Honest, Creative, Human-oriented, Customer-first" as our business philosophy which gained good reputation by customers from all over the world !

Contact Supplier 00:15

00:15

1. The whole forging parts with high rigidity and intensity. 2. Integrally processed, reduce the accumulating tolerance, high accuracy. 3. The bigger the diameter of roller is, the better the intensity is. 4. Surface carburizing, the surface hardness is high. 5. Wear-resisting, using life is long.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:00

00:00

Parameters (filling machine) Filling nozzle 1 head Quantitative filling (with pressurized barrel) Filling volume 2-10 ml Filling form Piston and vacuum pressure filling Filling speed 40 bottle per min Filling accuracy +/- 1mm Material tank / bottle table 25L / 600*300 mm length and width 2 pieces (input and output) Controller PLC+ touch screen Machine Filling nozzle tank, liquid contact material SUS 304 Medical silica gel pipe Air pressure pressure Flow quantity

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:49

00:49

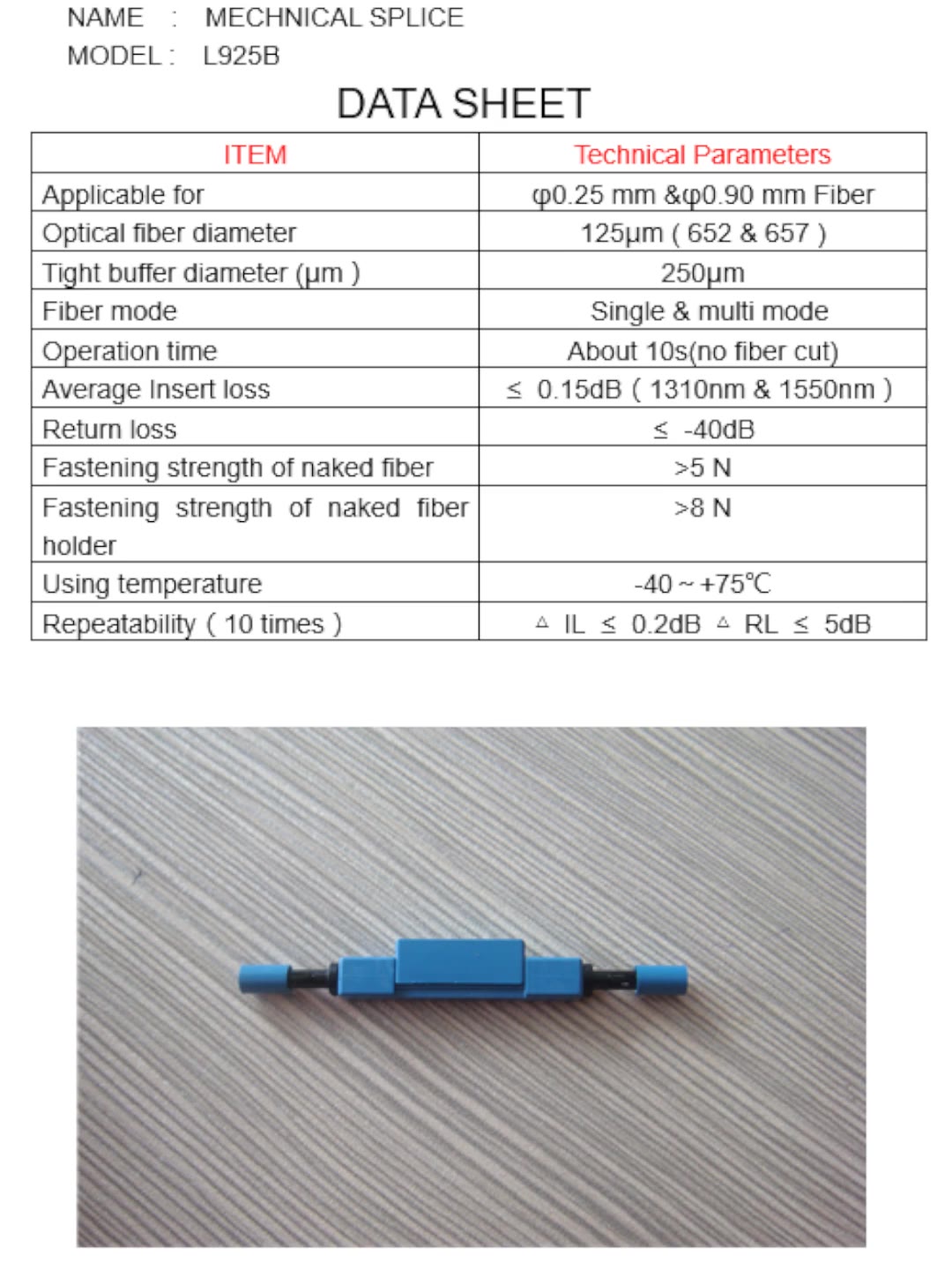

Fast connectors are specially designed for FTTx application. They can reduce operation time and connect the fibers or terminated fast. W-TEL provides Mechanical splice, Field connector, Filed Fusion Connector. Mechanical splicer Mechanical splicing maintains physical contact between mating fibers. Fiber can be spliced simply in this way in a very short time, a typical installation of W-TEL. Mechanical Splice takes less than two minutes. It can be used for 900/900µm ,250/250 µm, 250/900 µm fibers. W-TEL Mechanical splicer requires a few accessories to assemble. Features 1. No epoxy, no power 2. Outstanding optical performance 3. Best solution for emergency repairs and FTTX 4. Fits in industry-standard splice trays Item Specification Connection Loss ≤0.2dB (typical) 0.5dB(Max) Return Loss More than 40dB Dimensions L 40mm W 4mm H 4mm Applicable fiber Dia. 0.25mm and 0.9mm single fiber (SM/MM) Tensile Φ0.9 mm≥4N, Φ0.25 mm≥2N Durability ≥10 times Operation temperature -40℃~+80℃ Storage temperature -40℃~+80℃ Field connector In FTTH, optical drop cable should wind its way through the wall piping, and every house owns different requirement of cable length, traditional factory patch cord become very difficult to meet the FTTH. W-TEL filed connector can perfect fulfill the custom cable length, it can be installed in field, no epoxy, no power deed, it can be installed in 2 minutes. Insertion loss ≤0.3dB (typical) 0.5dB(Max) Return loss ≥40dB Material UL94-V0 Mechanical performance Tensile 30N △IL<0.3dB Durability 500times △IL<0.3dB Reassemble ≥5times Operating temperature -40℃~+80℃ Environment Storage temperature -40℃~+80℃ Operating humidity ≤85%(+30℃) Fusion Field Connector With a factory pre-polished ferrule, Fusion field connectors innovative field-termination process eliminates polishing, adhesives, and crimping in the field. Fusion field connector utilizes a fusion splicer to terminate the connector in the field, addressing return loss concerns present in analog optical networks. This advanced process ensure APC performance >60dB return loss. Fusion field connectors only require splicer with the fiber holder for installation. Features 1. Field installable 2. No adhesives, crimping or polishing 3. True apc performance 4. Compatible with most fusion splicers Connection Loss ≤0.25dB (typical) 0.4dB(Max) Return Loss ≥50dB/UPC, ≥60dB/APC Tensile Tight buffer fiber: 5N △IL<0.2db Drop cable: 30N △IL<0.2db Applicable fiber Cable, Φ2.0 indoor cable, Φ3.0 indoor cable Operation temperature -40℃~+70℃ Storage temperature -40℃~+80℃ Humidity ≤85%(+30℃)

Shanghai Warner Telecom is a global leader in the manufacture and supply of telecommunications equipment,network solution and energy saving system. As a science & technology innovative company, we are dealing with the R&D, manufacture, distribution and after-sales services of optical network communication equipment, optical fiber cable distribution products, telecom shelters and outdoor telecommunication cabinets with it's related power system ,control system ,cooling system ,battery system etc .Head of company located in shanghai ,3 branch factory : FTTX factory located in hebei with an area of more than 8,000 square meters, power control factory located in shenzhen and thermal control factory in suzhou . Warner has a well-established team of experts who can meet customers' specific needs accurately.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery

01:14

01:14

00:21

00:21