00:56

00:56

RFID Blocking Card is the size of a credit card that is designed to protect personal information stored on credit cards, debit cards, smart cards, RFID driver’s licenses and any other RFID Cards from e-pickpocket thieves using handheld RFID scanners. The Scanner Guard Card is half as thick as a standard credit card so it will not increase the size of your wallet. It is very flexible and durable.

When the Smart Card industry kicked off in mainland China 20 years ago, RFIDHY were at the forefront. In 1995, we began by producing plastic magnetic cards. We are the first supplier of magnetic cards as the ticket for AFC (Automatic Fare Collection) system for Shanghai Metro No1 line. Our products line covered Plastic card, Smart cards, Contactless cards, RFID inlay and RFID products tags with growing of technology and applications in this area. Our experience is not only in RFID products R & D, but also system and solution design, and system integration manufactures, but also development. Our success in oversea market was apparent – from the first client in Spain in Europe in 2005, and expanded to hundreds of clients covering up to 100 countries and regions in several years.

Contact Supplier 01:31

01:31

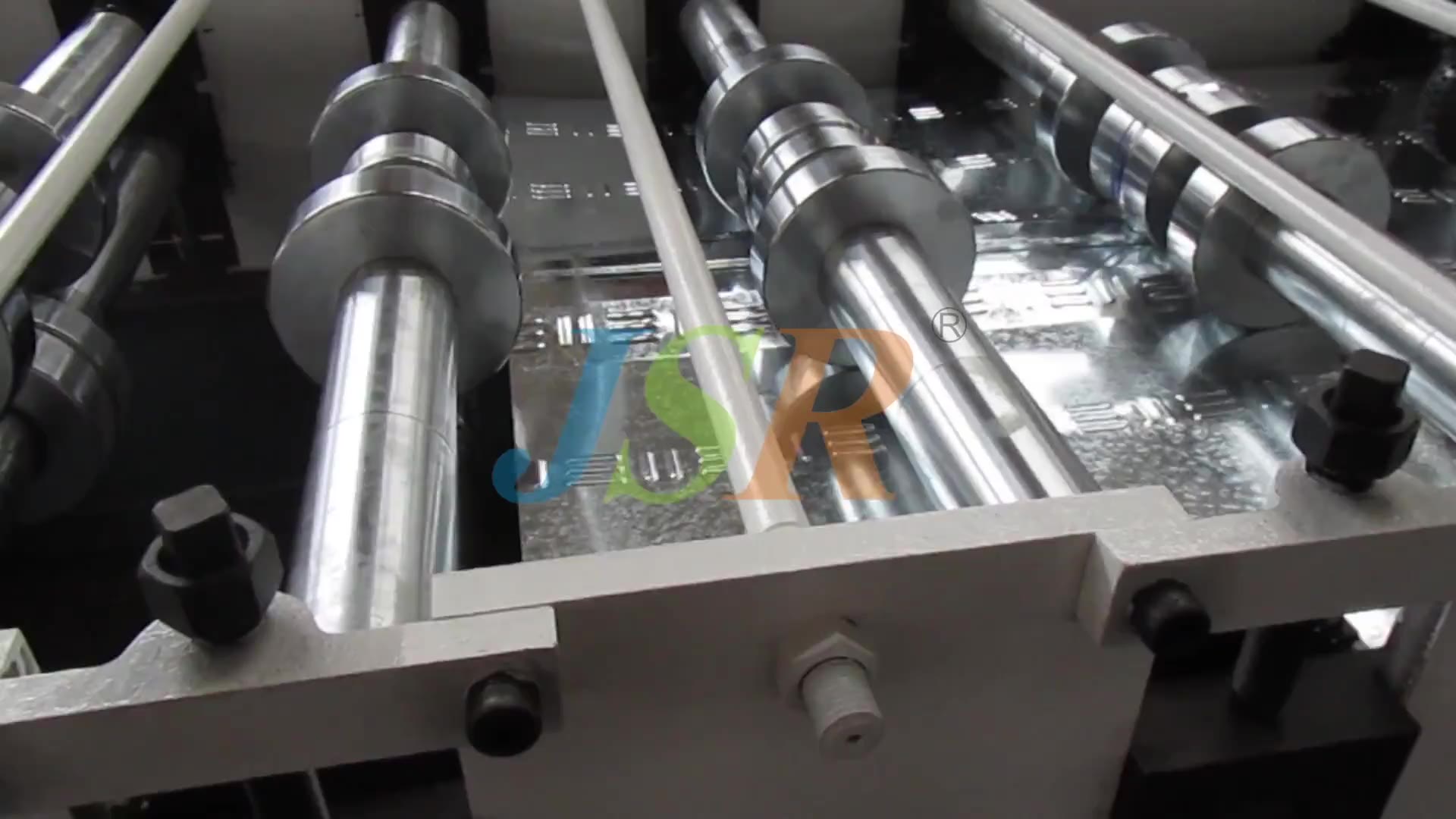

Solid shaft diameter 85 mm or more according to design Wall thickness 20mm Mitsubishi PLC and converter Tool box and technical support

Young is in forming line since 1997. I have worked in three famous forming factory as senior technician. Young has gone to Portugal, the Czech Republic, Azerbaijan, Australia, India, Nigeria, Sudan , Kenya, America, Bolivia, Argentina….more than 20 countries to install machines and teach customers’ workers to operate machine. Therefore, Young knows machines very well. Now we build our factory Wuxi Jingshirui Machinery Co., Ltd. The first and important thing he do is to improve machine quality according to his experience. Quality is always our life.

Contact Supplier 00:53

00:53

Traditional preform products (blanks) are produced by precision preform machines with fixed speed and precise plunger displacement control. The production process is not continuous. Because special mixers are needed to provide preheated and mixed rubber, and each batch must be re-fed, the labor intensity is considerable. Extrusion/gear pump technology was used in cold feed preform to improve the traditional rubber blank manufacturing technology. Strip cold rubber into the extruder feeding port automatically after plasticizing, preheating, and then sent to the entrance to the gear pump, the pump driven into the die, the die of the rotating cutter will cut into the required size, rubber in the system, the use of gear pump technology for extrusion efficiency and product precision provides important guarantee. Gear pump inside the rotor and bearings have been tested for many years proved very reliable, without frequent replacement. The control part of the system is a special PLC. Pressure sensors are installed at the inlet and outlet of the gear pump to ensure that the pressure at the inlet of the gear pump is maintained at a certain level. In addition, the extrusion speed can be controlled by adjusting the inlet pressure of the gear pump, so that the rubber compound can be injected into the gear pump stably under the required pressure conditions. Technical Description of DRL Series Cold Feed Rubber Precision Preformer 1 Cold Feed Precision Preformer is to cut the mixing rubber into the shape and weight required by customers. The weight accuracy of blank is controlled within ±1%. 2 PLC control, process parameter storage, direct data call instruction, easy operation. 3 The screw and barrel are electric disengaging from the structure, which can effectively reduce the labor intensity, facilitate the replacement of rubber and facilitate the cleaning. 4 Conveyor net cover and conveyor adopt stainless steel material to prevent rubber pollution. 5 Electronic scale closed circuit feedback, one key to calibrate the weight of rubber blank. 6 Equipment fault alarm and icon display fault location, regularly remind workers to spot check and calibrate the weight of the rubber blanks. 7 The machine head, cutting knife and other devices are interlocked, and all-round protection is provided to effectively avoid the occurrence of work-related injuries. 8 Searchlight with the machine head, easy to clean, to avoid the situation of bad cleaning corner. 9 The system pressure and extrusion pressure are displayed digitally on the touch screen. 10 When the new product is trial-produced, the PLC operation provides reference data to further simplify the operation process. 11 All machine heads are sealed with stainless steel to prevent rubber from spilling on the ground (polluting the environment, waste of rubber, etc.). 12 Continuous process and high production efficiency: DRL cold feeding preformer can input strip rubber uninterruptedly to produce high-precision blank, so it does not need to consume manpower to continuously add material.Because of continuous production, there is no unqualified rubber blank in the start-up and shutdown stages of hydraulic precision pre-forming machine, which reduces material loss and greatly improves production efficiency.Because of the continuous production, there is no unqualified rubber blank produced under the start-up and shutdown stages of hydraulic precision preformer, which reduces material loss and greatly improves production efficiency. Technical Parameter Items Unit DRL75 DRL90 DRL120 Screw diameter mm 75 90 120 Draw Ratio of Screw L/D 12:1 12:1 12:1 Screw rotation speed Rpm 6-60 6-60 6-60 Speed of gear pump Rpm 4-50 4-50 4-50 Cutter speed Rpm 23-400 23-400 23-400 Total power KW 45 55 75 Maximum extrusion pressure MPa 35 35 35 Temperature Controlled by Mould Temperature Machine °C 20-95 20-95 20-95 Max.die Diameter mm 80 125 190 Rubber blank weight range g 0.1-100 0.1-500 0.1-2000 Weight accuracy (99% compound) Percentage ≤±0.8% ≤±0.8% ≤±0.8% Filtration accuracy (99% rubber) Mesh ≤200 ≤200 ≤200 Max capacity kg/h 200 500 800 outline dimension (L×W×H) m 4.5×1.2×1.65 5.5×1.2×1.65 6.5×1.2×1.65 Machine weight t 3.5 4.8 8 Electronic Balance (Accuracy 0.01) g 300 300 300/1500 Head opening type WSAD WSAD WSAD Feeding type Cold/Hot Cold Cold Cold Electronic balance rack m 0.44×0.44×0.96 Distance between Cutter and Die mm Adjustable

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 00:18

00:18

00:56

00:56

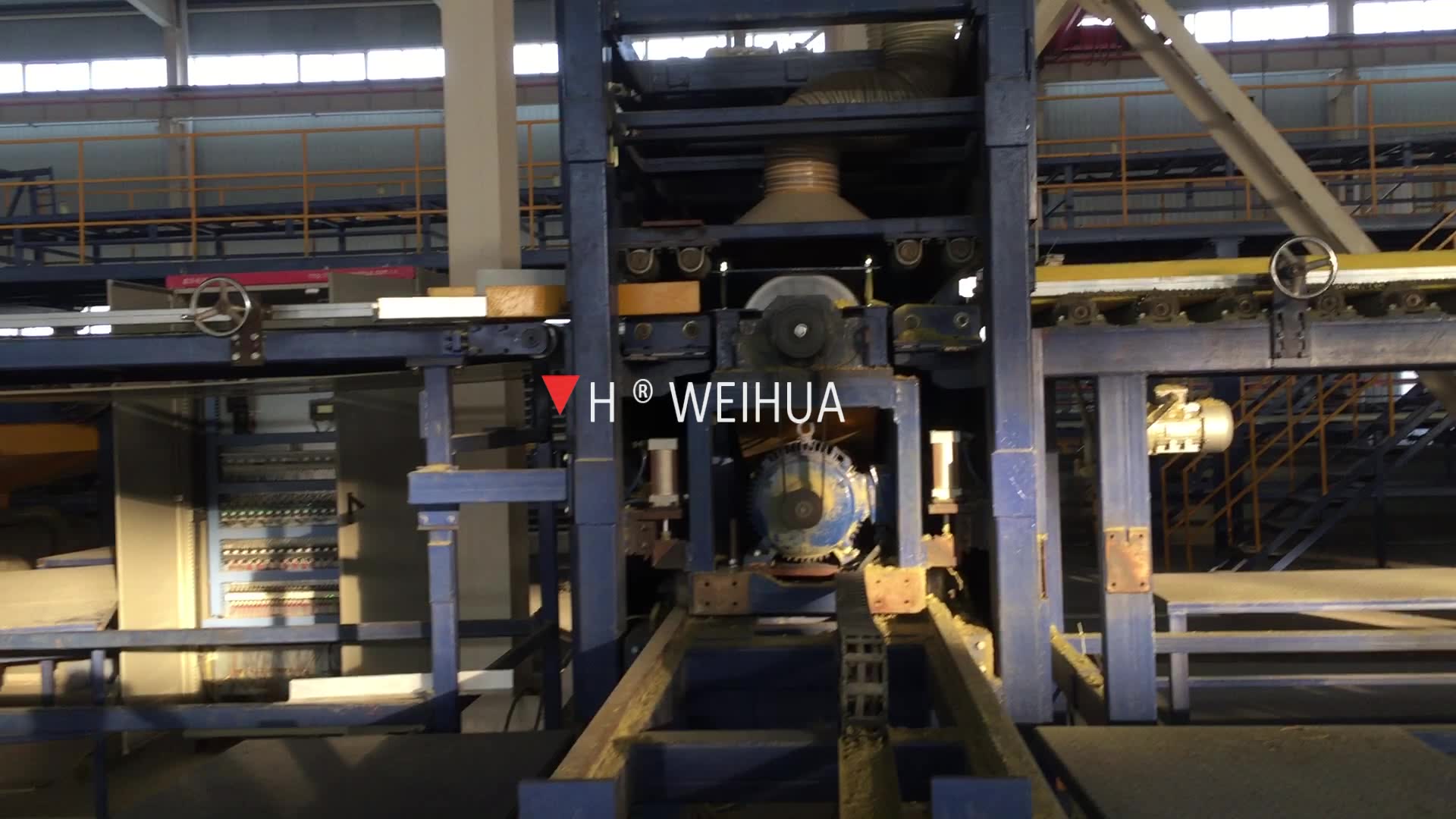

In July,2012, Weihua provided the whole set of flexible surface sandwich panel line to Nanjing Hongbaoli Co., Ltd., which has multiterm of top-level patent technology, such as side seal of sandwich panel, up & down surface material deviation correction centering and detecting, surface material connection and energy-saving of double-belt conveyor. The width of sandwich panel output from double belt conveyor is 1203mm (without side trimming), base on two shift daily output, every year can save the PU material of about 1.5 million, especially double belt conveyor whose heat preservation system can save 30% energy consumption for customer. The correction device of soft substrate decoiler is one of the core part of the whole production line. It can decoil smoothly for soft substrates such as kraft paper、asphalt fabric、cement mortar paper & fabric、aluminium foil and so on and then supply to double-belt conveyor to solidify.The keypoint of the correction device is to solve the problem of non-centring and correct the deflection.The precision can be controled within 2mm. This device lays the foundation for saving more material when side seal for double belt conveyor.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:20

00:20

The function of rock wool slitting machine is to cut the rock wool block into corresponding width to meet the dimension of the final composite panel. In addition, it lays the foundation for the turning over and interface arrangement. Through conveying roller and positional guiding, the rock wool enters into the slitting machine. The slitting blade is designed with high-precision. The cutter is manufactured according to different thickness, that is to say, each thickness is matched with one set of cutter. When change different standard, hydraulic cylinder will push the cutter out and guide rail conveys the cutter. The position of cutter is locked by locating pin to materialize shock-proof and high precision cutting. It lays the foundation for the high-quality panels as the width of rock wool is consistent.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:23

00:23

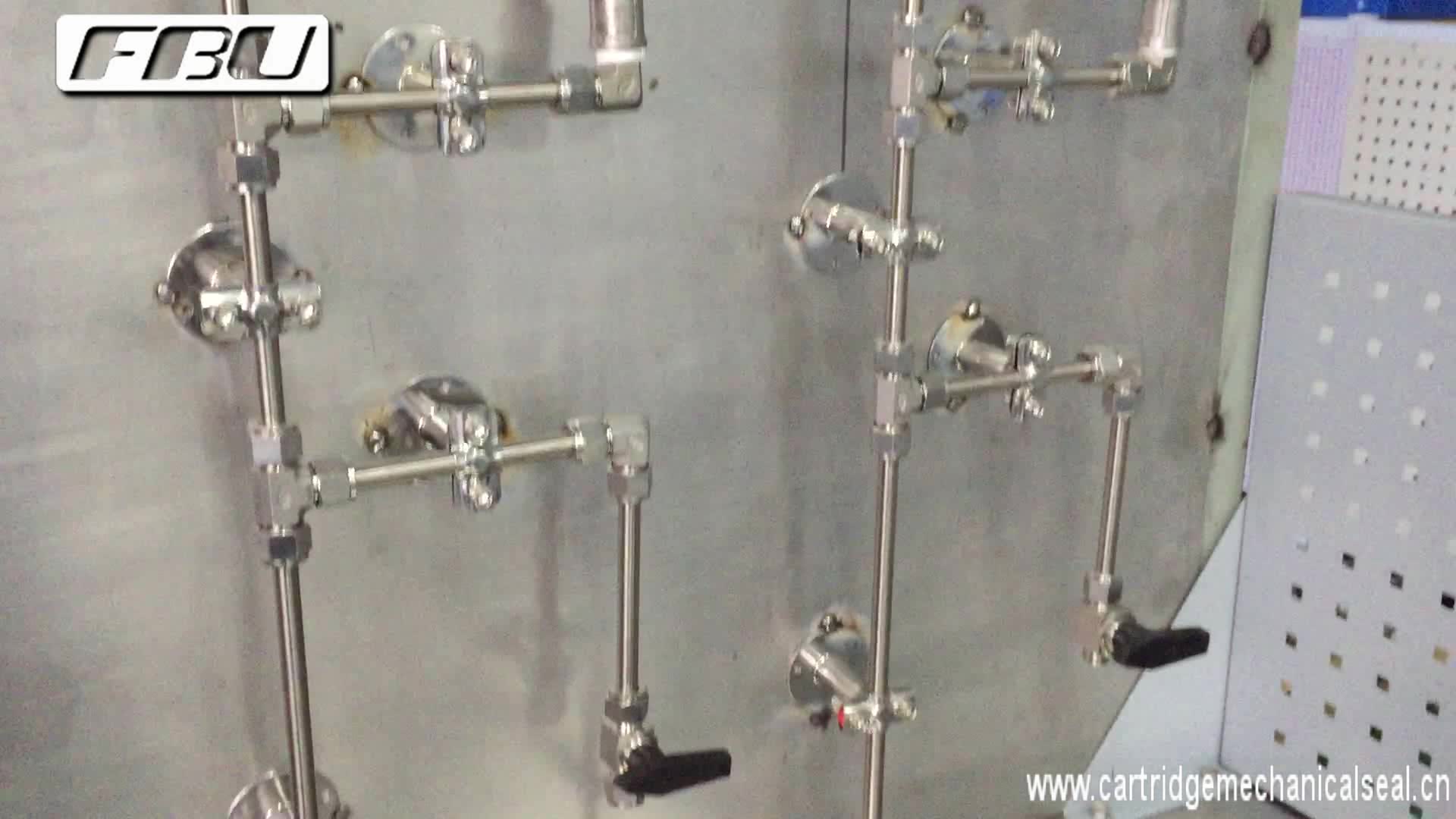

Double cartridge seal 2650 to Safematic SAF pressure screen. size 50mm, 70mm, 90mm, 110mm,130mm, 140mm. FBU was established in 2007, with FBU trademark and is constantly developing series of cartridge seals conforming to standards of ISO , ANSI, DIN, and API ,which are widely used in industry such as chemical processing, paper & pulp, Iron Mine, marine and food processing. Our core business is cartridge mechanical seals and seal supporting system, FBU can design, manufacture, and recondition mechanical seals as per ISO 9001:2008 LRQA assessed management. Choose FBU, find us to save your Time and Money. How we do our jobs ??? Want to know more about us, kindly feel at free to sale@fbuseals.com

FBU was established in 2007, with FBU trademark and is constantly developing series of cartridge seals conforming to standards of ISO , ANSI, DIN, and API ,which are widely used in industry such as chemical processing, paper & pulp, Iron Mine, marine and food processing. Our core business is cartridge mechanical seals, FBU can design, manufacture, and recondition mechanical seals as per ISO 9001:2008 LRQA assessed management.

Contact Supplier 00:13

00:13

Overview Automate bottle filling capping for small bottles , it is a high performance compact piston pump liquid filling machine and can be customized. We also can equip the peristaltic pump for filling. The system aseptically and precisely fills liquid to small bottles. An optional diving nozzle mechanism plunges the filling nozzles into the container for increased production speeds without splashing, and we can produce the different filing nozzles for your different speed requirement. Filling volumes are programmable and can be adjusted from the touch screen. Descriptions This machine is the matching product for various kinds of bottle packaging equipment and can automatically delivery the bottles into the conveying belt of the equipment, thus assuring the normal work of the bottle packaging equipments. The machine is applicable for small mass production. To the mass production, please select Automatic Bottle Distributing Machine. The machine completely meets the GMP standard.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:28

00:28

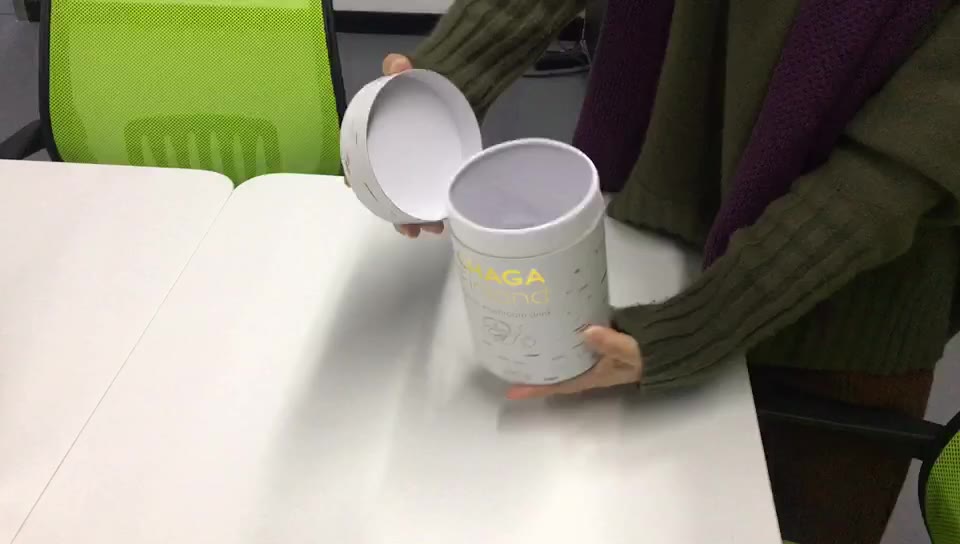

Item Custom size and printing paper tubes for tea H.S. Code 4811900000 Material Kraft paper,Paper board, Art paper,Corrugated board,Coated paper, etc Size(L*W*H) Accept custom Color CMYK litho printing, Pantone color printing, Flexo printing and UV printing as your request Finish Processing Glossy/Matt Varnish, Glossy/Matt Lamination, Gold/Silver foil stamping, Spot UV, Embossed, etc. Usage Packaging, Shipping, etc. Samples fee Stock samples are free Lead time 5 working days for samples; 12 working days for mass production Advantage 100% manufactory with lots of advanced equipments QC Strict quality control under SGS, ISO9001 and Intertek. Certification BSCI, ISO9000/1400,BV TUV SGS FSC etc.

Coffe Packing was founded by a Packaging & Print expert, Mr. Lin, in 1986. Today, Coffe Packing, with a team of production, sales, R&D and superior service, has become one of the strongest Paper Packaging manufacturers in China. We have more than 100 advanced equipments, such as German MAN Roland R904-7B four-color, R9055 five-color offset press , Heidelberg speed master CP102 four color sheet-fed offset press, Japanese Roybi 754 four color offset press, five advanced 5-ply Corrugated Board Production Lines, automatic Printing Slotting/Die-cutting Machines, automatic folder gluer, UV Spot and Overall Coating Machine, film blowing machines etc.. With such modern production equipments and technology.

Contact Supplier 02:56

02:56

Spider-hand-boxing robots are ideal for applications that need to move objects quickly and accurately from one place to another. The system is extremely accurate, and the robot only selects intact objects and ignores defective objects (such as cookies, chocolates, pills, etc.). The structure is very simple and consists of only a few components, which is why its uptime is longer than a hard automation solution. The robot has the fastest operation speed. Designed for quick pick and place, it can perform 130 pick-ups per minute with a corresponding cycle time of 0.4 seconds. With a maximum acceleration of 10g, the spider hand is the fastest robot in the world. The robot has a duty cycle of up to 150 cycles per minute. The payload of the picker can be up to 20kg. The robot is available in stainless steel and is suitable for use in environments where environmental cleanliness is critical. Stainless steel spider hand robots are ideal for use in the food, pharmaceutical, medical, and electronics industries. The robot is top mounted, does not occupy indoor area, and is easy to integrate. The spider hand robot is the most flexible robot solution for high-speed pick and place applications. The replacement fixture can be used for high-speed sorting and high-speed packing of various lighter products such as soft bags, cartons, fruits, cakes, milk, ice cream, parts, and electronic products.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 00:15

00:15

DESCRIPTION: 1.Outside Dimension :6000mm*4500mm*1800mm 2.Body frame :Partners extruded aluminum 3.Voltage :AC220V,50Hz/60Hz 4.Power consumption :13.5kw 5.Capacity : 70000-90000pcs/day 6.FPY :> 96% 7.Utilization : > 98% 8.Request person :1 person TECHNICAL PARAMETERS:

Shanghai Shouda Packaging Machinery & Material Co., Ltd. is a professional manufacturer of automatic packaging machineries & automatic filling and packing production line for liquid, gel, aerosol

Contact Supplier 00:42

00:42

Thread Specification Metric, PG Thread Product Material Nylon PA6 with silicone rubber seal Color Black, can be customized Working Temperature -40°C-105°C, short time 120°C Fireproof Level UL94 V0 Features The four bumps on the cap will interlock with the main body groove which can effectively solve the damage caused by vibration convolution. The eight claw on the top will cling to the corrugated shape to strengthen the tensile strength. Besides, the wave shape design of the seal reinforces the watertight protection level. 1, Choose the corresponding connector and the corrugated tube. 3, Insert the conduit inside the connector. 5, To disconnect, just screw the cap to the same direction and same indicating sound will be heard again.

Jiaxing Sheng Yang Eletcric Co., Ltd. located in Jiaxing Nanhu District which is very convenient in transportation. Since its inception in 1999, the company has been committed to wiring product development, production and sales. We believe that only dedicated, professional, can provide customers with better products and services. We have been doing this, the future, will also have been adhering to this attitude go. Since 2008, SHENG YANG cable gland products have leaded an industry sales record for eight consecutive years. Participated in well-known construction projects many times. Core philosophy: people-oriented, quality assurance, continuous innovation, abide commitments.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery