01:13

01:13

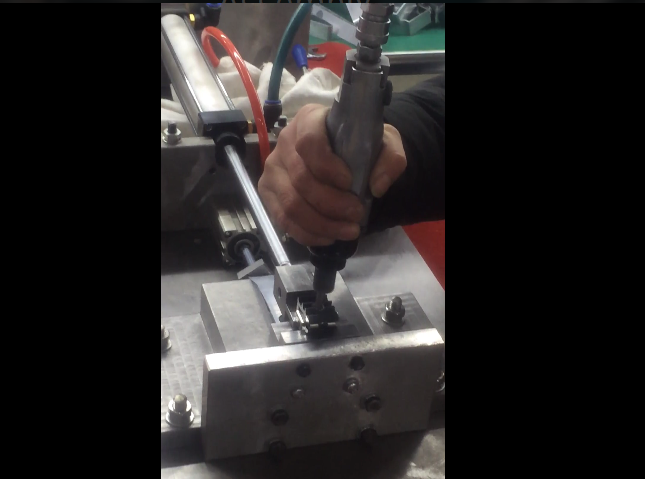

Starway provides Final assembly services with the components manufacture or outsourced by Starway. With the assembly services, we not only helps clients to save labor cost, shipping cost, but also and more important, it the assembly work verifies all the components manufacture or outsourced are correct. Starway takes charge of designing the assembly fixture, defining the assembly flow and quality control plan.

Starway Engineering & Manufacturing Co., LTD, founded in 2010 and located in west Shanghai, is focusing on providing one-stop solution for metal parts & products. We are committed to help clients realize the concepts and designs with support of our engineering and manufacturing advantages that includes projects made of processes as: Sheet metal fabrication CNC machinning Stamping & forming Aluminum extrusion Casting Assembly

Contact Supplier 01:56

01:56

These extrusion line consist of conical twin screw extruder, mould and related downstream equipment. Application: for furniture and construction material, advertisement plate, inside upholstering plate for carriage of ship/car/train. Type PVB-1400 PVCB-1700 Product width 1220mm 1600mm Product thickness 3-20mm 5-25mm Extruder type SJZ80/156 SJZ92/188 Max. extrusion capacity 400kg/h 600kg/h Main motor power 75kw 132kw

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 00:53

00:53

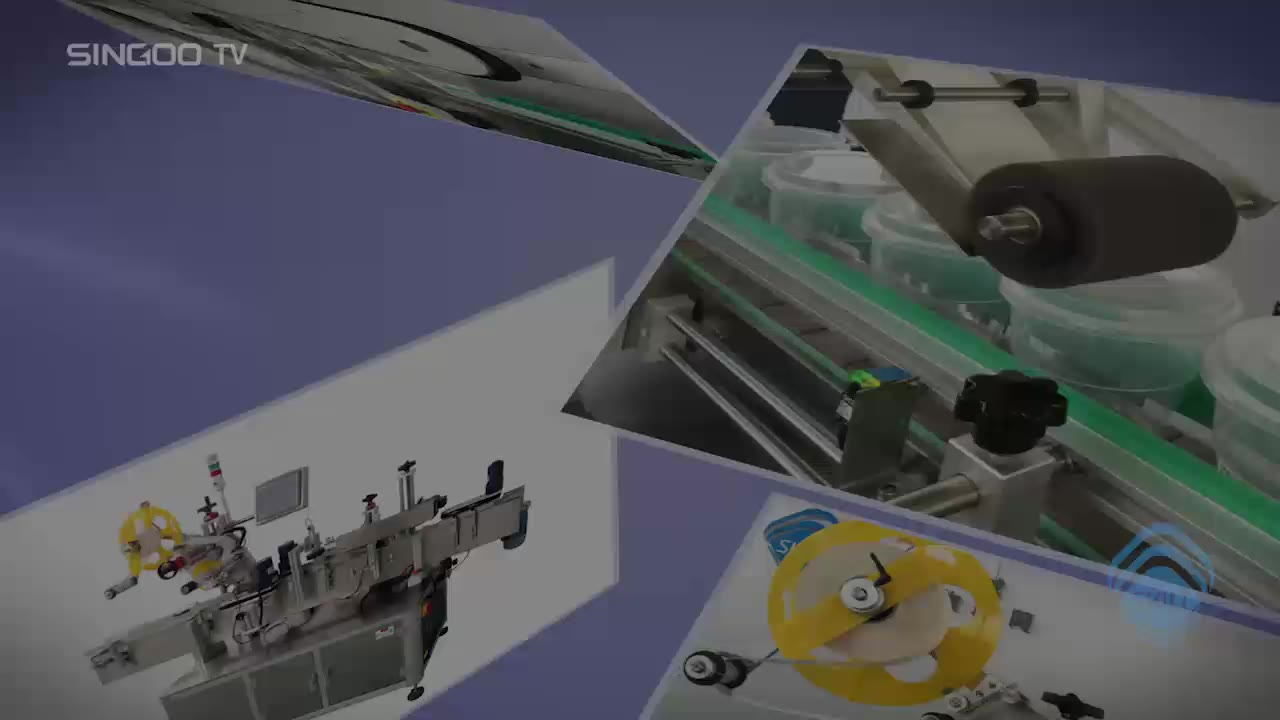

Model PWM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-220 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-100 mm length 15-80 mm The suitable size of labeling objects Customized depends on client product Printer use air 5kg/cm ² Power(w) 600W Weight(kg) 200 Machine size 1800(L) 800 (W) 1300 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:13

01:13

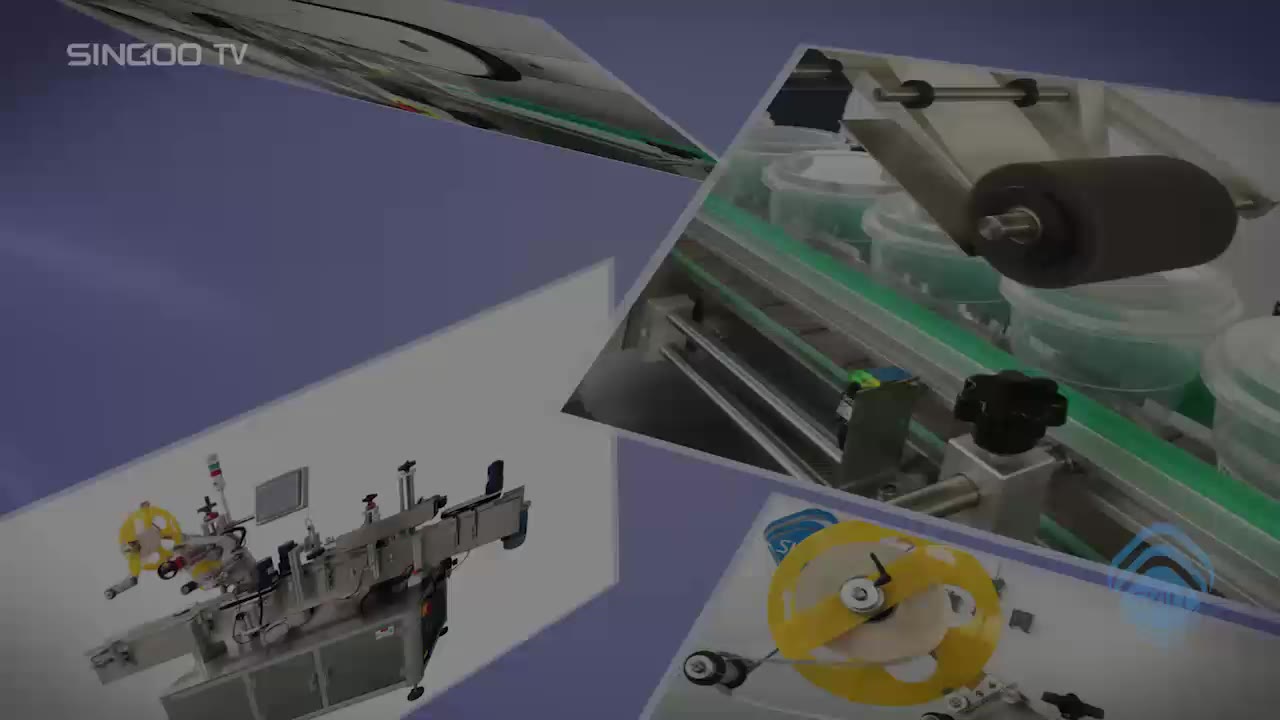

Model DPM-SLM-A Driving Mode Servo motor Yield(pcs/min) 20-100 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:13

01:13

Model DPM-SLM-A Driving Mode Servo motor Yield(pcs/min) 20-100 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-160 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 03:20

03:20

Parameters Unit GMC2560 Table size 2500*6000 Table load kg/m2 2000 T-slot size(width x nos.) mm 28*13 X travel mm 6500 Y travel mm 3300 Z travel mm 1000(1250 optional) Width passed the gantry mm 3100 Distance from spindle nose to table surface mm 200-1200(200-1450 optional) Spindle nose — ISO №50 Main motor power(cont/30min.) kW SIEMENS:30/41(optional 37/51) FANUC:30/37(optional 37/45) Max. Speed of spindle rpm 2000(3000、6000 optional) Cutting feed speed mm/min 1—5000 Rapid speed m/min 10 Type of tool magazine Mechanical arm Type of tool handle BT-50、JT-50 Magazine capability Mechanical arm 32(40、60 optional) Chain type - Max. Tool diameter mm φ125(adjacent:φ200) Max. Tool length mm 400 Max. Tool weight kg 20 Positioning accuracy mm Repetitive positioning accuracy mm Dimension mm 15300*6700*7020 Machine weight T 110 Attachment milling head Right angle milling head, universal milling head, extended milling head and special milling head. Optional parts Attachment milling head and integrity protective shield

COMPANY PROFILE Nantong Hangzhi Equipment Technology Co., Ltd. is a wholly owned subsidiary of AVIC Aviation High-technology Group Co., Ltd. In March 16, 2016, the company completed the renamed registration. Total assets of the company are RMB 330 million. Nantong Hangzhi Equipment Technology Co., Ltd was founded in 1956, Former Nantong Machine TOOL Works, Trademark include: “NANTONG”、“TONMAC”、“TONTEC”,It is one of six listed companies in Chinese machine tool industry. The company undertakes the aircraft in the original Department of AVIC HT’s machine tool business and AVIC Beijing Aeronautical manufacturing technology research Institute of high-end intelligent equipment and aviation equipment business. The main products are CNC milling machines, CNC lathes, Vertical machining center, Horizontal machining center, Gantry type vertical machining center and Aviation equipment, etc. The company employs more than 500 people, including nearly 150 professional, technical and engineering management staff. The company has domestic first-class production and processing equipment, which imports more than 130 sets of thin equipment, including Japan SNK five face machining center, Germany”s WARLDRICH precision guideway grinder, the United States CICINNATIE machining center, Switzerland DIXI coordinate boring machine, Zeiss coordinate measuring instrument and other world famous brand processing and testing equipment. The company independently developed machine tool products by a number of patents, which in the validity period of the invention patent 14, utility model patents 18. A number of key technologies like MCH63 precision horizontal machining center fill the gaps, accessing to the 2007 machine tool industry ten new product title, China Machinery Industry Science and Technology Progress Award. VMCL1100 vertical machining center series won the second prize of scientific and technological progress in Nantong City, Jiangsu Province, third prize of scientific and technological progress. Products are widely used in mold manufacturing, auto parts, wind energy nuclear power, marine ships, military aerospace, teaching and other fields. The company's sales network is throughout the South China, Zhejiang, Jiangsu, China and the West, North China, northeast and other regions, with a professional sales and after-sales team.

Contact Supplier 00:00

00:00

Lube oil, chemical material, industry oil, Detergent, bean oil, paint and other similar products. 1. Automatic bottle sensing system and filling 3. Filling error is control within 1‰ 5. Automatic filling volume correction system. 7. Can be equipped with cleaning system. Machine filling accuracy max is at 1‰, from 5l-30l volume, and it is gravity filling. This machine is mechanical transmission, controlled by servo motor, it is well developed machine, use life more than 15 years. Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL. we will take video for: 2. how to operate the machine 4. how to adjust machine to different bottle or material. you can also check video for:

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:00

00:00

A soft tube filling and sealing machine is mainly used for plastic tube filling and sealing. It has been widely used in the fields of pharmacy, cosmetic, food and chemical etc. This MIC-R60 auto soft tube filling & sealing machine is a 1 filling head filling machine with a heating gun. It has total 12 positions for filling and sealing. And materials such as paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste etc., are all applicable.

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 01:17

01:17

Filling head 6 heads Filling volume range 100ml-5L(according to customer different bottle volume customize the control filling volume cylinder) Production speed 1300-1500 Bph basis on100ml bottle Voltage 220v/380v Power 2.8kw Suitable bottle’s diameter Ф40mm-Ф250mm Filling error ≤±1‰ Work pressure 0.55Mpa-0.65Mpa Size 1840mm*1400mm*2500mm Weight 600kg Air consumption 0.9m^3/min

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:17

00:17

WH-PU-6-40 six-components continuous high pressure foaming machine adopts online mixing model , low pressure pre-mixing and high pressure collision . With the feature of low pressure high speed cutting mixing and high pressure collision , it is the best pentane foaming machine .These six components are :1) Poly 2) ISO 3) Fire retardant : TCPP 4) Catalyst :KatA 5) Catalyst katB 6) pentane foaming agent . Every component is individually metered. Driven by magnetic coupling and variable frequency motor , the high precision pump realize close-loop flow with accurate volume and quality flowmeter (catalyst and foaming agent). It can change output flow and mixing proportion automatically . This foaming machine work on line . Pentane is harder to dissolve in Poly than 141B, so we adopt pre-mixing of low pressure high speed cutting .Materials, including Poly .fire retardant. catalyst .foaming agent , are transported to separate moving mixer by separate meterting pump . In order to improve foaming effect and make the mixed polyether fully integrated to nuclear air, we adopt one set of high-precision gas metering device, which can make mix the air and integrated Poly fully after emulsifying and high speed shearing. The output mixed polyether and ISO will go through high precision and pressure metering unit. When they reach to150 bar, they will spray together and finish complete mixing. The total set of unit adopts human-computer interface, which can display working process, various technological parameter including component flow、mixing ratio、mixed model. All the data can be sated and amended on the operating panel. There are some signal communication interfaces between electrical controlling system and production line. Once the speed of double belt changes, various material flow of foaming machine also changes as same ratio simultaneously to keep the final panel quality and realize the double belt work automatically.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:21

00:21

Product Introduction Product name 201 Stainless Steel Sheet Specification Thickness: Cold rolled: 0.3-3mm; Hot Rolled: 3-120mm Width: 0-2000mm Length: 0-6000mm Customized sizes are accepted Standard ASME, ASTM, EN, BS, GB, DIN, JIS, etc Finish NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish and so on Material 201, 202, 304, 304L, 310S, 316, 316L, 410, 420, 430, 441, 800H, 904L Brand Name TISCO, Baosteel, LISCO, JISCO Place of Origin Jiangsu of China (Mainland) Technical treatment Cold Rolled, Hot Rolled MOQ 1 Metric Ton Port of Loading Shanghai or as your requirement Terms of Delivery FOB, CFR, CIF, CNF, EXWORK Terms of Payment L/C, T/T (30% deposit) Packing Standard export sea-worthy packing Delivery time Within 7-15 days after recieve 30% deposit or as your requirement Stock In stock Chemical Element Grade C ≤ Si ≤ Mn ≤ P ≤ S ≤ Ni Cr 201 0.12 0.75 7.00 0.045 0.045 1.00-1.28 13.70-15.70 Physical Property Grade YS (MPa) TS (MPa) Elongtion HRB 201 275 520 55 to 60% <183

Wuxi Ginlion Machinery CO., Ltd established in 2010,located in Wuxi Jiangsu Province. Our company mainly work on overseas sales business for special steel and stainless steel. Our products have obtained SGS, ISO9001:2000 approval certificate, QS-9000 : 1998 (American Vehicle Steel Quality System ) approval certificate, and API (American Petroleum Tube Production Quality System) approval certificate. The factory occupies a total area of 500,00 ㎡.Our own factory could also do cutting, bending and welding as your drawing! OEM is always welcomed! We appreciate your coming always!

Contact Supplier 01:22

01:22

Overview Automate bottle filling capping for small bottles , it is a high performance compact piston pump liquid filling machine and can be customized. We also can equip the peristaltic pump for filling. The system aseptically and precisely fills liquid to small bottles. An optional diving nozzle mechanism plunges the filling nozzles into the container for increased production speeds without splashing, and we can produce the different filing nozzles for your different speed requirement. Filling volumes are programmable and can be adjusted from the touch screen. Characteristics ● It is applicable to different-shaped bottles and plastic bottles: PP , PE , PVC ,glass bottle and mould bottle. ● The bottle-in and bottle-out has specialized structure .It doesn't drop bottles or nip bottles ● The part which touches the liquid medicine is made of SS304 stainless material completely, meeting the requirement of CE GMP. ● It can be connected with the bottle-washing machine and the label-attaching machine to form a complete set of produce line.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery