01:02

01:02

Model SLM-A Driving Mode Servo motor Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized depends on client product Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:48

00:48

Model PLM-DS Driving Mode servo motor Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-110 mm length 15-150 mm The suitable size of labeling objects Can customized depends on client product Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:13

01:13

Model DPM-SLM-A Driving Mode Servo motor Yield(pcs/min) 20-100 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:00

00:00

Detailed informations(Products): 1. Feature: High dust loading capacity, Optimized flow conditions, Can be acted replacements for many brands to clean your air perfectly; 2. Suitable for all kinds of operating environments: There are plenty of filter media options at hand, thus we can provide filter cartridges for various industries and dust types even abrasive, toxic and explosive dust. Item Material(Standard) Material(Alternative) Filter Media Cellulose/Synthetic fiber/ All kinds of H&V air filtration`s filter Nanofiber/Polyester fiber media selection Top cap/ Galvanized steel Stainless steel,Color-coated steel/ Bottom cap recyclable plastic ABS (Open/Closed) Gasket EPDM Urethane/Silicone Inner Mesh Galvanized steel Stainless Steel, Color-coated steel/ Recyclable PP Outer Mesh Galvanized steel with Stainless Steel, Color-coated steel hotmelt glue Finishing Treatment Teflon-coating,waterproofing,oilproofing,flame-retarding treatment, antistatic coating,etc Comprehensive advantages(Company): 1. One of the biggest filter manufacturers in China; 2. H&V`s biggest customer in China; 3. Our vast experience and state-of-the-art laboratories enable us to provide customization; 4. Welcome you to our factory and you will be convinced by our advanced workmanship and big scale. Applications: Industrial air filtraton of dut and fumes in many industries: Metallurgy, Cement, Woodworking, Chemicals Powder coating, Plasma/laser cutting, Sandblasting, Textiles, Welding and Casting, Food&Beverage, Aerospace. We warmly welcome: -- End users or agents to find replacements here; -- Dust collector manufacturers to do customization.

Shanghai Thenow Purification Technology Co.,Ltd. Thenow was established in 2005, belonging to Thenow Group(Former name Apureda Group) as the wholly-owned subsidiary. Being a standard maker, Thenow Group is a global specialist in the development and production of filtering systems and solutions with 6 production units. As one of Thenow Group’s production units, Thenow Purification’s business is to provide customers with sustainable best in class air filtration products and services. We mainly focus on manufacturing air filters for industrial dedusting, gas turbine air inlet systems and HVAC systems.

Contact Supplier 01:47

01:47

Jiangyin Metallurgy Hydraulic baling presses are applied in steel mills, recycling plants, ferrous and non-ferrous smelting industries to press scrap metal (steel, copper, aluminum, stainless steel, discarded automobiles, etc.) into acceptable furnace charges in shapes of cuboids, cylinders and octagons. There are cutting blades on all three sides of the loading box so that oversized sheets and sections can be handled with ease. The metal recycling baler is built for speed, with hard wear plates in the bale box, a return-line filter which reduces wear and tear on hydraulic components. The combined features of YD metal baler result in a low-cost, reliable and effective machine. To find out more about our briquetting machines, email us to yj.oversea@gmail.com or call us at +86-18651010951 Parameter Value Name YDF-250A Main cylinder pressure 2500kn Side cylinder pressure 950kn*2 Door cylinder pressure 950kn Lock-door cylinder pressure 200kn*2 Turn-out bale cylinder pressure 200kn System working pressure High 25Mpa, low 16Mpa Host overall dimensions 6300*3200*3150mm (L*W*H) Density ≥2t/m3 Press box size 2000*1200*1000mm Bale size 450*450mm Bale weight 180~370kg Output in one shift 20~32t/8h Machine weight About 20ton Motor Model Y225L-4 Rated power 30kw Rated speed 1470r/min Power specs 380V, 50HZ (changeable) Pump Model 160YCY14-1B Nominal displacement 160ml/r Rated pressure 31.5Mpa Control system Manual operation Delivery One 40HC container could load one set

The most experienced manufacturer of metal recycling equipment… Jiangyin Metallurgy Hydraulic Machinery factory (short name : Jiangyin Hydraulic) was originally set up in 1997 to manufacture and market briquetting press, metal balers, alligator shears, metal shears and other non ferrous scrap metal processing equipment. During the last two decade we have installed 3000 systems , build the entire quality controlling standards and cultivated an experienced technique&after sales tea.

Contact Supplier 01:30

01:30

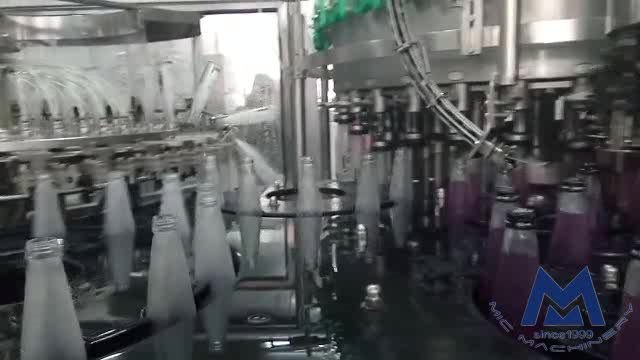

MIC 24-18-6 It is applicable for glass bottle filling capping machine for whisky, alcohol drinks and spirit. (if need hot filling temperature at 85-90 degree) Adopt products: whisky ,alcohol drinks, spirit, chivas, liquor, vodka, vinegar, soy sauce etc liquid products. Machine working principle: 1. Negative pressure filling(slightly), controled by pressure, accuracy is +/-1%,liquid level difference is not more than 4-5mm(cause bottle has difference when it produced). easy adjustmeant on liquid level. 2. Glass bottle capping machine is qualified for Chinese capping standard, and no air leakage at all, machine capping rate is 99.5%. 3. About oxygen content, we have device nitrogen filling for replace air. 4. About gems sterilizing, we could use bottle invertor for the cap, and pasteurization for juice, hot filling for can. and sterilizing tunnel (with cooling spray) for second steilizing and cool off. 3. Aluminum cap and crown cap are ok problem working on our capping machine(different capping head), We use our own technical drawing and own processing machine, to make sure our capping head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Nitrogen filling machine 7> CIP cleaning system 8> Pasteurization, inventor and sterilizing tunnel. 9> Glass bottle air washing machine Related machines are: Glass bottle filling machine, glass bottle capper, glass bottling companies, bottle filling machine, bottle equiment, bottle filling, bottle filling capping machine, bottle filler, bottle capper, bottle capping machine, crown bottle capper, bottle capping machine price, Whisky filling capping machine, vodka filling capping machine, liquor filling machine, spirit filling machine. Lately news for shipment: →We sold one to King of Thailand on June 16,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:07

01:07

Model PWM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-220 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-100 mm length 15-80 mm The suitable size of labeling objects Customized depends on client product Printer use air 5kg/cm ² Power(w) 600W Weight(kg) 200 Machine size 1800(L) 800 (W) 1300 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:02

01:02

Feature • Stripping both insulation and semiconductor layer of cable from Φ25 mm to Φ65 mm. • Stripping thickness could be adjusted. • Don’t keep the knives reach CU/AL core during stripping. • Blades can be resharpened or exchanged. • Size: 290*120*75 mm • Weight: 1.4 kg Parameters Model KBX-65 Stripping Capacity The both insulation and semiconductor layer of cable from Φ25 mm to Φ65 mm. Size 290*120*75 mm Weight 1.4 kg Application Our cable tools mainly used for electrical working, State Grid construction, underground cable construction, Building construction etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 01:08

01:08

Feature • Dies sets could matched with hydraulic tools. • With high quality for tools steel. • Dies could be OEM. • Package: with plastic carrying case. Parameters Model MAP-60 Stainless Steel plate Max thickness 2.0mm Mild steel plate Max thickness 3.0mm Weight 2.8kg Included Dies Set: Round Dies 1/2” (Φ21.8mm) , 3/4”(Φ27.6mm), 1”(Φ34.1mm), 1 1/4”(Φ42.7mm), 1 1/2”(Φ48.7mm), 2”(Φ60.2mm) Application The knockout punching tools main work for switch board, distribution box and electrical working, State Grid construction, underground cable construction, Building construction etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 00:00

00:00

This glue filling sealing machine is suitable for: super glue, glue 502, cyanoacrylate adhesive AB glue, gel glue and other similar products. This machine function is: 1. Automatic tube clamping and sealing 2. Automatic tube logo marking 3. Automatic filling for glue 4. No tubes no fill and date printing 5. Automatic counting and tube outlet 6. Can be customized for different tube or liquid 7. Can be equipped different tanks and mixers This machine filling system is made for specially for glue, easy clean and changes, it is a practical machine for glue production, 24 hours runs none stops, hardly have machine break down once well adjusted. Machine filling accuracy max is at 0.1-0.5g, from 3ml-150ml with different pump. This machine is mechanical transmission, logo marking has only 0.3 degree error, normally in china market is 1 degree, you can choose how to fold your tubes by show your ideal pictures. The sealing divider speed reaches 35 piece per min, compare to other usually company, we can really do 35 piece per min, not just design theory. This machine is guaranteed for one year and you can extent your guarantee easily by discuss with our sales. Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL. About the machine use problem, after the sales, we will take video for: 1. how to connect the power 2. how to operate the machine 3. how to maintain the machine and how often to do it 4. how to adjust machine to different bottle or material. Thank you for the reading this article, you can also check for: → Our machine application ← → Our machine lately export news ←

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:42

00:42

Features 1. Dual frequency conversion control, instant bag length setting and cutting without film feeding test run, saving time and packing film. 2. Man-machine interface, convenient and quick parameter setting. 3. Fault self-diagnosis function, clear failure display. 4.High sensitivity photoelectric tracking system, digital setup for positioning and precisely cutting and sealing. 5. Independent PID temperature control, apply for different types of packing materials. 6.Positioned stop function, not stick to knife and not waste packing film. 7.Simple driving system, stable performance, convenient maintenance. 8.All controls are achieved by software, good for function adjusting and upgrading. Applications This packing machine is suitable for packing regular shape products in box or in trays such as biscuit, popping-rice-cake, custard cake, chocolate, bread, instant noodle, moon cake, walnut biscuit, cookies biscuit and so on. Optional Devices 1.Coding Device 2. Line Sealing Wheel 3. Moire Terminal Sealing Mold 4 Extra Big Screen Parameters: Model YX-280 YX-320 YX-280A YX-280B YX-280C YX-280D YX-320A YX-320B Film Width Max.280mm Max.240mm Max.180mm Max.350mm Bag Length 90~220/150~330mm 65~190/120~280mm 90~220mm 50~115/45~90mm 65~190/120~280mm 90~220/150-330mm Bag Width 50~140mm 30~110mm 30~80mm 50-160mm Product Height Max.40mm Max.40mm Max.55mm Max.35mm Max.40mm Max.60mm Rewind Diameter Max.280mm Max.320mm Packing Speed 50~250 packs/min 40~280packs/min 60~350packs/min 40~230packs/min Voltage 220V/380V 50HZ/60HZ Machine Size (L)3770×(W)720 ×(H)1450 mm (L)4000×(W)950 ×(H)1450 mm Machine Weight 400kg 500kg Packing Samples:

Shanghai Yixun Machinery Manufacturing Co., LTD is an experienced manufacturer integrated with design, manufacture, installment and service. The main products are cake machine, biscuit machine, candy machine and cookies machine in shanghai China. ISO and CE certificates we got 10 years ago, and the goods exported to120+ countries. Workshop tour is welcome.

Contact Supplier 02:01

02:01

Brief Introduction YX Die Type Toffee Candy Production Line, the traditional toffee candy making machine, High-degree automation ensures of stale production and saves time, labor force and occupation to serve purpose of reducing the cost Toffee candy making process Sugar melting--Storage tank-- Toffee cooker --Cooling table--Extruder--Jam pump--Rope sizer--Forming--Swing conveyor and cooling tunnle --Packing The functions of each machine. 1) Sugar melting tank: heating raw materials. 2) Storage tank: storage the sugar syrup and and filting pure syrup. 3)Toffee candy cooker: jacket layer heating by steam, rotating speed-adjustable scraper, boiling the caramel 4) Cooling Table: cooling the toffee candy syrup, jacket layer 5) Extruder: 4 or 6 heads extruding the toffee candy dough at the same time. 6) Jam Pump: filling the insde gam or chocolate syrup. 7) Rope Sizer: pull the centerfilled candy dough more even and smooth 8)Forming machine: Chain type forming mouds inside, die forming the final toffee candy. 9) Swing and cooling machine: seperate and cooling final toffee candy into the cooling tunnel 10) Packing machine: various packing machine available. Technical Parameters Output 200~300kg/h Speed 1000-1200Pc/min Max.Candy Weight As per candy size Min.Candy Weight 3g Steam Pressure 0.5~0.7MPa Steam Consumption 250~400kg/h Cooling System Requirement Room Temperature: 20~25℃ Humidity: 40-45% Power 50kw/380V Length 25m Gross Weight 5000kg Tips on the toffee candy production line: 1) The whole line equipped the international motor: ABB motor, Danfoss invertor, SS materials 2) Heating by steam 3) Various shapes toffee candy can be produced by changing moulds 4) Toffee candy size and weight effects the final output 5) One/ two colors/center fillied toffee candy can be made Pictures and final toffee candy samples:

Shanghai Yixun Machinery Manufacturing Co., LTD is an experienced manufacturer integrated with design, manufacture, installment and service. The main products are cake machine, biscuit machine, candy machine and cookies machine in shanghai China. ISO and CE certificates we got 10 years ago, and the goods exported to120+ countries. Workshop tour is welcome.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery