01:14

01:14

NEWAY heating products could also apply to many commercial projects. Heating leather sofa in winter time, heating gloves or vest,heating door mat and etc. All applications will give you better comfortable and luxury feeling.

Shanghai Neway Insourcing Co.,ltd is a trading and manufacturing company that located in Shanghai City, shorted name as NEWAY below. NEWAY started the exporting business from 2004. We focus on flexible heating technology for automotive and commercial application. In 2006, we owned carbon fiber heater factory as a shareholder that is certificated by TS16949.

Contact Supplier 00:35

00:35

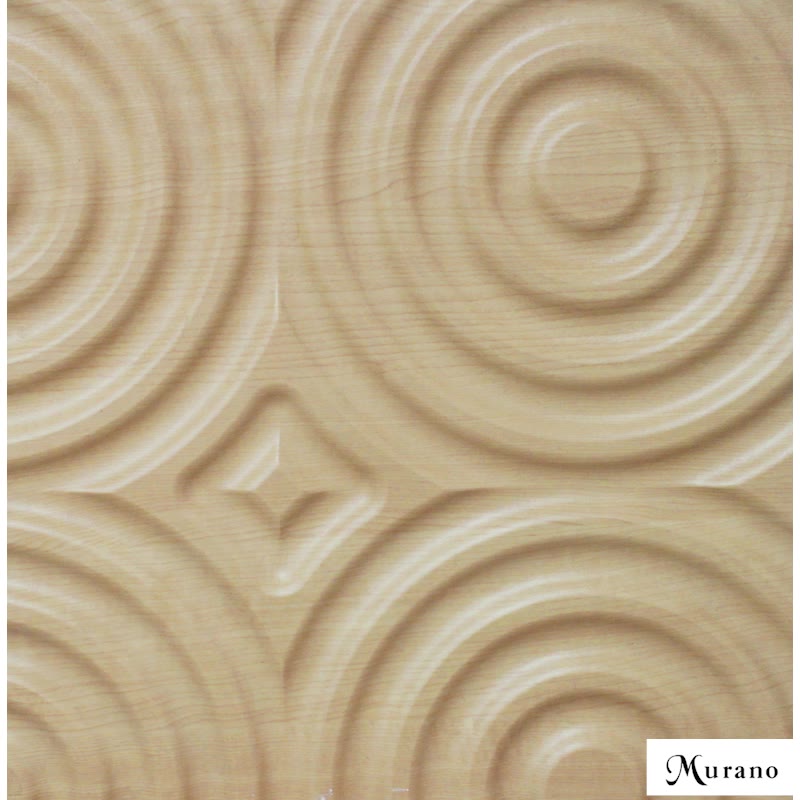

Introduction: MURANO 3D decorative panels are made to the highest standards from high quality MDF with damp proof melamine backing to prevent warping once installed. The 3D carving is carried out on high tech computerized CNC router beds so that every panel matches perfectly when installed. All MDF panels come in primed and sanded smooth finish, making easy work to paint in your choice of color and paint finish. Specification: Material: MDF Dimension: 1200 x 2400mm Thickness: 18mm Finish: Painting/PVC Backing: Melamine Film Density: 60kg/m³

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier 00:19

00:19

Specification G32-T3/29 Groove 3mm, Center to Center 32mm Surface Melamine / Wood Veneer / Painting / Fire resistance panel Core 1,MDF core, low formaldehyde with E1 standard 2,ECO core, which is low formaldehyde with E0 standard. 3,MGO core, which is high fire resistance level with A standard. 4,any required core materials could be replaced. Back Soundtex acoustic felt attached on the back of the panels. Noise Reduction Coefficient 0.7 Fireproof grade GB8624 2012 A / B1 Eco-protection grade E0 / E1 Installation aluminum keel and clips, wood frame, gun nail Certification BV,CE,SGS,ISO9001-2008 Test report Eco protection, sound absorption, flame retardant Model Type Specification NRC Punching Rate G8 M-T-2/6-8-15 0.9 2.5% G10 M-T-2/8-10-15 0.9 2% G16 M-T-2/14-16-15 0.9 1.3% G8 M-T-3/5-8-15 0.9 2.5% G16 M-T-3/13-16-15 0.9 2% G32 M-T-3/29-32-15 0.8 0.93% G32 M-T-4/28-32-15 0.8 1.24%

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier 01:12

01:12

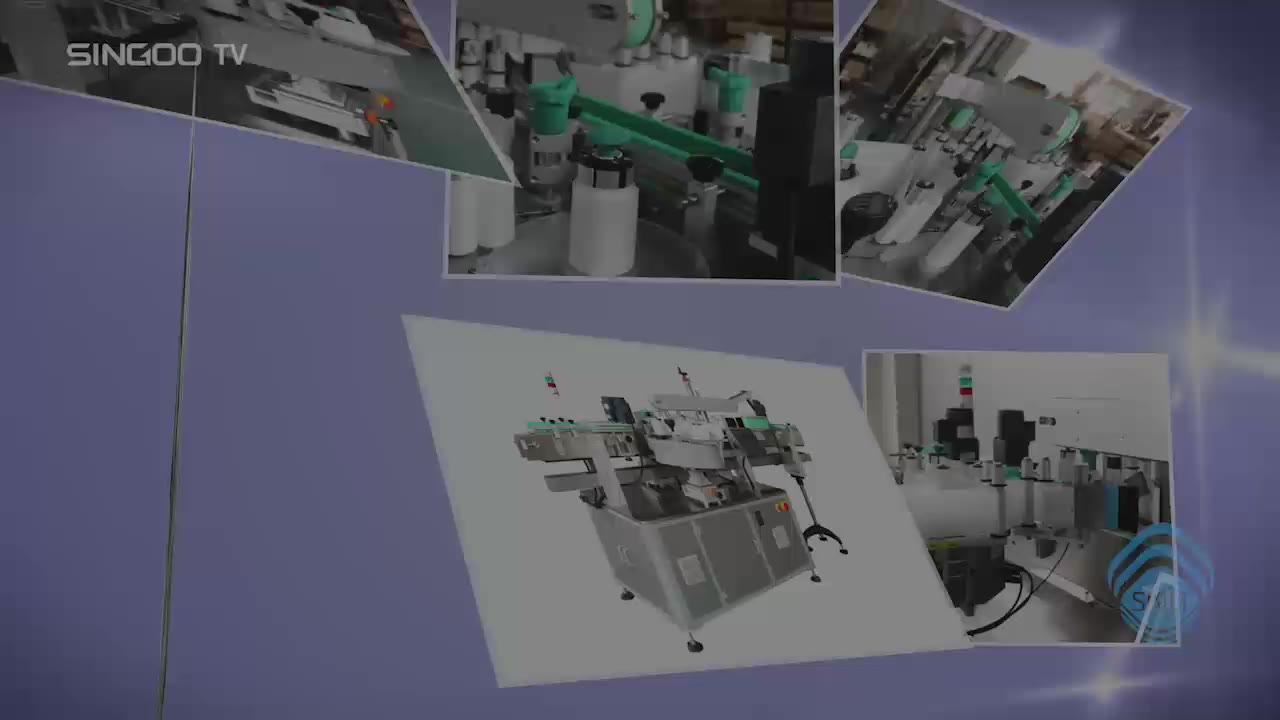

Model PLM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-180(depends on product and label size) Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-150 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 550W Weight(kg) 260 Machine size 1800(L) 800 (W) 1500 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:18

01:18

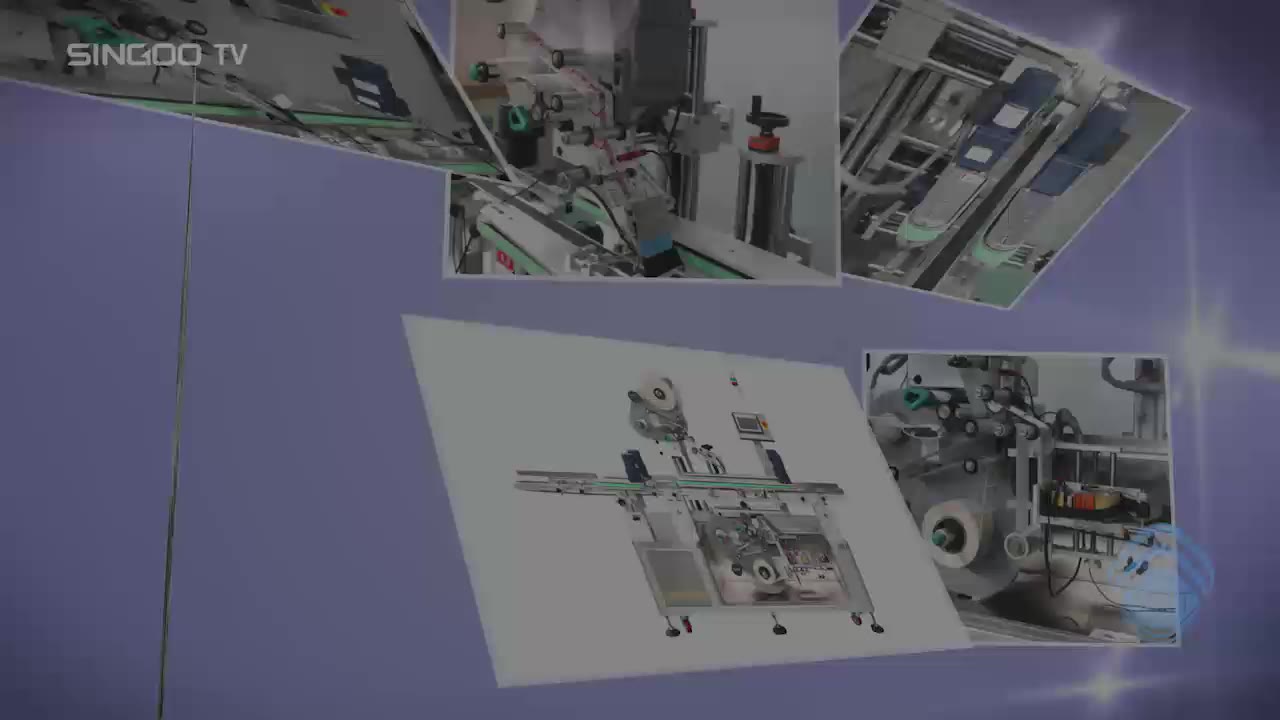

Model DLM-ALS104 Driving Mode German Avery Yield(pcs/min) 20-180 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-160 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:44

00:44

Model UDPM-ALS104 Driving Mode German Avery 104 Yield(pcs/min) 20-100 Operating direction Left or Right Conveyor Speed(m/min) ≤35 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-160 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:05

01:05

Model SLM-S Driving Mode Servo motor Yield(pcs/min) 10-80(depends on product and label size) Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-200 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 850W Weight(kg) 360 Machine size 2300(L) 800 (W) 1500 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 02:01

02:01

This equipment is dedicated to the silicone conductive tube, conductive strip production. Basic principle is to use ram extruder to extrude rubber compound, and cured directly in the process of extrusion. Two equipments are extruding at the same time for conductive resin of different materials and double materials tube of non-conductive resin. This equipment adopts the ration accuracy control extrusion speed to ensure stable quality. Features: 1. Without staff supervision, extrusion speed absolute stable, ensure the quality stable. 2. Extrusion speed precision display can be corrected randomly. Classifications of four generations of ram extruder method Performance/model Extrusion speed adjustment method Extrusion speed advantages and disadvantages of display Products quality 1st generation Extrusion speed adjusted by extrusion pressure Rough display Extrusion speed is unstable with the increase of extrusion friction speed slow unstable, Most used currently 2nd generation Extrusion speed adjusted by hydraulic system flow Rough display Extrusion speed is relatively stable but accurate correction speed is more difficult Lack of stability, Most used currently 3rd generation Extrusion speed adjusted by hydraulic system flow Precise display Extrusion speed stability, such as error is to call the police. And precise adjustment Quailed, but need manual adjustment 4th generation Extrusion speed adjusted by hydraulic system flow Precise display and Automatic correction on extrusion speed Extrusion speed stability no need to adjust manually No defects Technical Parameter Item Unit JYZ80 JYZ100 Barrel inner diameter mm 80 100 Main power Kw 2 2 Curing unit power Kw 1.6 1.6 Max. extrusion pressure Mpa 35 35 Curing temperature ℃ 350 350 Extrusion precision % ±1.0 ±1.0 Single feed volume L 2 5 External dimension (L*W*H) m 1.75×0.76×1.7 2.9×1.2×1.7 Weight t 1.2 2.2 Cooling water flow L/min 10 10

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 01:13

01:13

Feature • Stripping both insulation and semiconductor layer of cable from Φ40 mm to Φ90 mm. • Stripping thickness could be adjusted. • Don’t keep the knives reach CU/AL core during stripping. • Blades can be resharpened or exchanged. • Product supplied with plastic box. • Size: 510*150*90 mm • Weight: 2.47 kg Parameters Model BX-90 Stripping Capacity Stripping both insulation and semiconductor layer of cable from Φ40 mm to Φ90 mm. Size 290*80*55 mm Weight 0.69 kg Application Our cable tools mainly used for electrical working, State Grid construction, underground cable construction, Building construction etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 00:00

00:00

This glue filling sealing machine is suitable for: This machine function is: 2. Automatic tube logo marking 4. Automatic tube loading device 6. Automatic counting and tube outlet 8. Can be equipped different tanks and mixers Machine filling accuracy max is at 0.1-0.5g, from 3ml-150ml with different pump. The sealing divider speed reaches 35 piece per min, compare to other usually company, we can really do 35 piece per min, not just design theory. Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL. we will take video for: 2. how to operate the machine 4. how to adjust machine to different bottle or material. you can also check video for:

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:15

00:15

Overview Automate bottle filling capping for small bottles , it is a high performance compact piston pump liquid filling machine and can be customized. We also can equip the peristaltic pump for filling. The system aseptically and precisely fills liquid to small bottles. An optional diving nozzle mechanism plunges the filling nozzles into the container for increased production speeds without splashing, and we can produce the different filing nozzles for your different speed requirement. Filling volumes are programmable and can be adjusted from the touch screen. Characteristics ● It is applicable to different-shaped bottles and plastic bottles: PP , PE , PVC ,glass bottle and mould bottle. ● The bottle-in and bottle-out has specialized structure .It doesn't drop bottles or nip bottles ● The part which touches the liquid medicine is made of SS304 stainless material completely, meeting the requirement of CE GMP. ● It can be connected with the bottle-washing machine and the label-attaching machine to form a complete set of produce line. After sale service (1) Long life service (2) One year warranty (3) Offering free parts for one year . (4) Engnieers available to service machinery overseas

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:52

00:52

1.Chemical, powder, organic solvent production, operating room, machine room, special place ground system; 2.Computer,electronic, microelectronic, precision instrument manufacturing, precision machinery manufacturing,telecommunication,communiation,printing,military industry,aerospace and other enterprise workshop grounds.

Shanghai Marya Pharmaceutical Engineering & Project Co., Ltd is a professional Pharmaceutical EPC(Engineering Procurement Construction) supplier based in Shanghai. We mainly focus on the business of Pharmaceutical Turnkey Project, Pharmaceutical Machinery and Cleanroom Turnkey Project.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery