00:49

00:49

This machine is used for the surface labeling of the round, square and flat objects in such industries as medicine, daily chemical, food, and cultural supplies and so on. It can paste three labels at a time. One label covers three sides of the bottle

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 04:22

04:22

The whole filling line is with servo motor controlled bottle filling machine , capping machine and cap feeder ,labeling machine ,and so on. Main characteristics 1. The machine adopts servo motor to control filling volume with high precision. 2. Customers will be able to set and change parameters via touch screen. 3. Filling nozzle and filling frame is controlled by cylinder 4. This machine will alarm or automatically stop when happens unconventionality circs (such as account mistake, bottle missing ) 5. Not enough bottles coming to the filling position , no filling.

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 01:14

01:14

1. NEWAY produce carbon , carbon split and wire pads 2. NEWAY pad use high-quality Japanese company carbon fiber elements . They are approx. 10 times longer than the filaments in conventional seat heaters. 3.The quick and even heating provide by professionally SHNIC pads . 4. 9*18inch /23*46cm or 11*18inch/27*46cm regular size and customer required size and designs are available 5. Automatic temperature control is provided by a thermostat integral to the pad element 6. Silver conductive line technology will come with stable heating performance and non-risk of burning out. 7. Different pattern designs from machine line production could provide varied power supply. 8.The perfect compliment to a leather interior that will give you a feeling of pure luxury. 9. FLAME RETARDANT NON-WOVEN FABRIC material that certificated by SGS. Picture

Shanghai Neway Insourcing Co.,ltd is a trading and manufacturing company that located in Shanghai City, shorted name as NEWAY below. NEWAY started the exporting business from 2004. We focus on flexible heating technology for automotive and commercial application. In 2006, we owned carbon fiber heater factory as a shareholder that is certificated by TS16949.

Contact Supplier 00:38

00:38

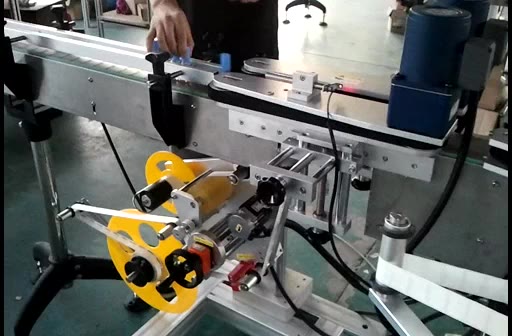

Model PM-DPM-S Driving Mode Servo motor Yield(pcs/min) 30-100 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-300 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need) Power(w) 1000W Weight(kg) 500 Machine size 3000(L) 1200 (W) 1600 (H) mm (machine size can made as client need )

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:18

01:18

Model DLM-ALS104 Driving Mode German Avery 104 Yield(pcs/min) 20-150 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-110 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:00

01:00

Model DLM-BLM-A Driving Mode Servo motor Yield(pcs/min) 20-100 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-200 mm length 15-200 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:53

00:53

Model BFM-ALS104 Driving Mode German Avery brand Yield(pcs/min) 20-120 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-80 mm length 15-100 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:40

00:40

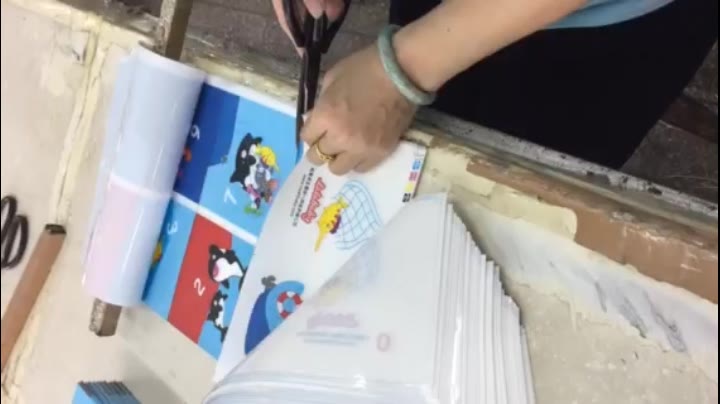

CYC Children's book printing company are willing become the first brand of baby book in China. Now we the eva foam book, foam book, board book, children's book & baby book. If you could not find yours printing book, pls contact us email caroline@kidbookprinting.com, or skype cycpackinfo or whatsapp +86-13585530707. Here is the wipe off book's specification, Size: 18 x 16cm Pages: 12 pages Thickness: 22mm Materials: 300gsm card paper with glossy lamination, mounted on 3.5mm EVA Accessories: a erasable pen Function: learning, reading, writing good in the function of school book MOQ: 3,000 piece Sample Cost: $100/title Sample Lead Time: 1 week finishing the Eva Book Print for Children With Erasable Pen. Mass production lead time: 10~15 days Loading Port: Shanghai, China Payment: 30% deposit + balance, by T/T

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 01:08

01:08

SANYYO PE/PEX series jaw crushers are based on a forward-looking idea of making our users enjoy great variety-both casting and welded frame construction. The design offers owners the highest possible fatigue strength, excellent reliability and numerous mounting possibilities. This, combined with special high-quality cast steel components and very durable wear parts, means exceptionally high crusher availability, cost-efficient crushing and low cost per ton.

Pursue Perfection, Contribute to customer Shanghai Leiyou Complete Machinery Co.,Ltd. was founded in 1986. The company gradually turned into joint-stock enterprises, which produces large-sized crushing machinery and provides customers with perfect solution on its own, thanks to the fact that it initially focused on manufacture and research of wear-resistant material. Now the company covers an area of 80,000 square meters and three factories, is well equipped with modernized cutting plant, and has more than 500 people working in the plant. It has changed into an important manufacturer and exporter of crushing machinery, screening, Grinder, Ball mill, Diesel generator, Conveyor belt all over the world. The company mainly produces crushing and screening equipment, and has a product range of more than 300 models and about 30 categories, which included fixed, semi-mobile, portable crushing plant and sold thousands of machines annually. The capacity reached from 5tph to 1800tph for each complete plant. The company has set up offices in main cities across China, and technical service center in many countries around the world. In recent years, SANYYO exported to all over the world, such as Africa, Middle East, Asia, South America etc; over 60 Countries. Currently, the company in the process of conducting multilateral cooperation on product R&D and technical exchange, this is designed to take advantages from various sources for innovative activity to the degree to which the company is able to roll out a batch of models annually to secure advance in every aspect for its crushing machines. SANYYO is also staffed with well-experienced design engineers to facilitate on-site analysis for clients from various parts of the world, and to produce complete and perfect solutions. Our corporation insists on the idea of higher quality, higher innovation, better faith, better service, pursuing to satisfy our customers, improving and consummating the quality control and services system. Our corporation persists on Scientific outlook of development to increase and stabilize the values of SANYYO brand.

Contact Supplier 00:50

00:50

Roll forming machine is very important, it is used for forming outer panel, which will influence the surface quality of sandwich panel. This is one core part of the whole production line, which is one of important steps for guaranteeing the high-quality sandwich panel. The numbers of stations in roll forming machine is designed by adopting the German software COPRA in theory and then tested in practice. All the rollers after finish machining are coated by chrome which has a good adhesion by slow plating technology. The rollers are processed in numerical control machining centre in one step and grinded in the mirror grinder to improve the smooth finish. This kind of roller treatment can reduce the inner stress release and guarantee the flatness of panels during the forming period. The roll forming machine adopts the two-head type which have two sets of rollers in each side. One more profile will be formed by exchanging the former position. Roller adopts high-grade steel with thorough heat treatment and accurate processing by CNC machine tool, surface coated with chrome to increase degree of finish and hardness, so that can increase the using life. Small corrugated roller is very important, if up and down roller caity is misfit, the height of small corrugated panel on the surface is not the same, which will cause the phenomenon of refraction no uniform or even destroy the surface quality of steel panel. The roller adopts integral structure, a process in the large CNC machine with high rigidity, high intensity and high accuracy. If want to increase roof panel forming machine(optional), can adopt integral type machine frame, whose machine base and forming machine base is separate, so that can produce more profiles in future.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 01:48

01:48

Product description 1.The mineral water filling machine has three functions for bottle rinsing, filling and capping, which are composed in one body of the machine . The whole process is full automatic. 2. This machine is used in filling mineral water, drinking water, flavor water, etc. in bottles made of polyester and plastics . 3. The filling packaging operation is faster and more stable because the micro pressure filling operation of the new type is adopted . There the output and benefit of the machine is higher than the machinery of the same specifications . 4. PLC control, full automatic working . 5. Touch-screen control panel, easy operation. 6. Singel positional adjustable central transmission post, more stable lable transmission . 7. Screw rod of separate bottle: stable transportation of bottles. 8. Label control sensor shelf: original creation tail surface and sensor are combined to improce the precision of cutting the material .

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 01:03

01:03

Equipment technical parameters: 1.This set of automatic weighing and packing system This machine can do the work of bag-making, weighting, filling, filling the nitrogen, date coding, and bag-cutting. It is suitable for packing power and granule material such as milk tea, monosodium glutamate, solid beverage, sugar, grape sugar, coffee, feedstuff, solid medicine, powder type additive, and dye, etc. 2.Main performance and functional characteristics 1.Equipped with safety protection, comply with firm’s safety management requirements. 2.Use intelligent temperature controller to have accurate temperature, which ensures the artistic and neat seal. 3.Use PLC Servo System and pneumatic control system and super touch screen to compose the drive control center which maximize the whole machine’s control precision ,reliability and intelligentized level. 4.Touch screen can store the technical parameters of various kinds of products ,it is unnecessary to reset while products changing. 5. With error indicating system , which help to handle the trouble immediately. 6. Make pillow bags and hanging bags in terms of customers’ different requirements.

Shanghai kunbu packaging Machinery Co.,Ltd .Is collection of research and development , manufacturing ,sale and service in the integration of automatic packaging machinery .We Specialized in Snacks food , biscuit ,powder , nut ,liquid , paste and frozen food ,agricultural chemical products and automatic packaging conveyor system .Our machines are exported to Europe, America, Southeast Asia, the Middle East, Russia and the surrounding more than and 50 countries .

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery