02:42

02:42

home use pellet grinder mill machine Where you can find everything you need by clicking here Product Description * Animal feed pellet making machine is equipped with enlarged and strengthened full stainless steel feeder and frequency-convertible and speed-adjustable controller with built-in high performance magnet; * Full stainless steel conditioner for good animal feed pellet making machine, sufficiently cook the materials so as to guarantee high quality of feed; * High-precision gear driving system of animal feed pellet making machine for overload protection with strong impact to ensure full load running and long lifespan; * High quality bearing and oil seal, and stable working; * High power flexible coupler with strong compensation displacement; * Fast and convenient positioning, loading and unloading of die. Die lift device can be supplied. * Suitable for producing all kinds of high quality animal feed pellet. FLow chart of animal feed pellet making line Certifications These certifications make us humble for producing quality products.

YuDa Machinery CO., LTD is located in the beautiful national AAAA level tourist area—Tianmu Lake along zhongguancun science and technology industrial park, Jiangsu. She is a professional high—tech enterprise engaged in grain and oil machinery, forage, fertilizer and feed machinery manufacturing. The company covers 34500 square meters, construction area of 27895 square meters, she gathers industry technical elite from Nanjing agricultural university, Jiangsu university and other scientific research institutions for technical cooperation. The company has passed national ISO9001: 2008 quality management system certification, European CE certification and SGS certification.

Contact Supplier 00:23

00:23

Features • 1/4 in (6.35 mm) end-porting • Low-cost, compact design • Spring check valves for superior priming in any mounting configuration • True-formed PTFE and Santoprene diaphragms for enhanced performance • External controller for optional remote operation Typical Applications • Supply pump for OEM applications • Printing ink supply • Wastewater chemical supply • Plating/surface finishing • Chemical dosing Typical Fluids Handled • Waterborne materials, some HHC’s • Paints, coatings, inks and dyes • Car wash chemicals • Laundry chemicals and detergents • Chemicals • Inks

Jianglang Technology Co., Ltd is a High-Tech Company and Green Factory which has been rewarded with the title of SRDI (Specialized, Refinement, Differential and Innovation). Established in the year of 2006, we’re one of the patent pilot units recognized by the Ministry of Industry and Information Technology. Its headquarter is located in Jinshan district of Shanghai. The company currently has 120 employees, with an annual output value of 100 million. It is a manufacturing enterprise with independent R&D and design capability and precision processing, mainly producing regulating valves and diaphragm pumps, etc. Presently the company has 143 patents, including 15 invention patents and 1 overseas patent. The annual production of valves and diaphragm pumps is more than 20,000 units, among which about 35 percent are exported to overseas market. The domestic market is mainly distributed in nuclear power, new energy, fine chemical, pharmaceutical, metallurgy, coating, shipbuilding, environmental protection, water treatment, etc. The company has a professional and excellent team to serve its clients.

Contact Supplier 01:48

01:48

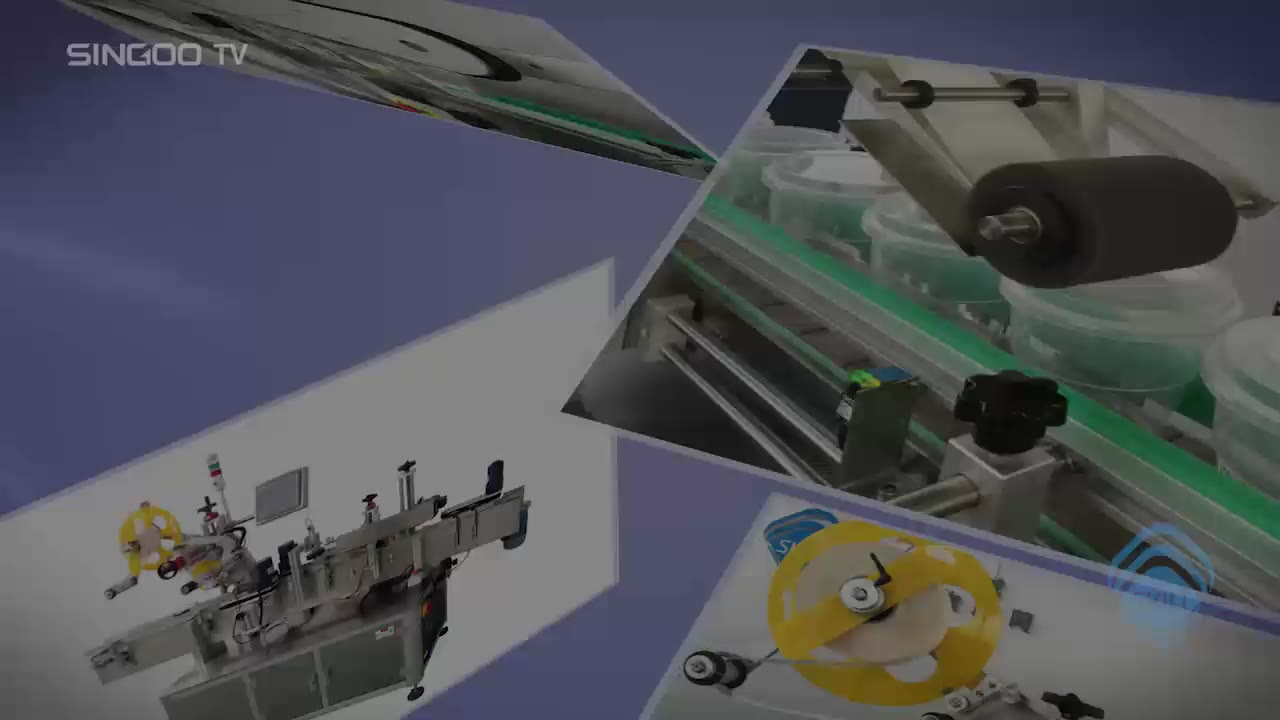

Model PWM-ALS104 Driving Mode Avery 104 Yield(pcs/min) 30-220 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-100 mm length 15-80 mm The suitable size of labeling objects Customized depends on client product Printer use air 5kg/cm ² Power(w) 600W Weight(kg) 200 Machine size 1800(L) 800 (W) 1300 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:10

00:10

Product name 316L Cold Rolled Stainless Steel Coil Specification Thickness: Cold Rolled: 0.3-3mm Hot Rolled: 3-120mm Width: 0-2000mm Length: 0-6000mm Customized sizes are accepted Standard ASME, ASTM, EN, BS, GB, DIN, JIS, etc Finish NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish and so on Material 201, 202, 304, 304L, 310S, 316, 316L, 410, 420, 430, 441, 800H, 904L Brand Name TISCO, Baosteel, LISCO, JISCO Place of Origin Foshan of China (Mainland) Technical treatment Cold Rolled, Hot Rolled MOQ 1 Metric Ton Port of Loading Shenzhen Terms of Delivery FOB, CFR, CIF, CNF, EXWORK Terms of Payment L/C, T/T (30% desipot) Packing Standard export sea-worthy packing Delivery time Within 7-15 days after recieve 30% desipot or as your requirement Stock In stock Chemical Elements Grade C ≤ Si ≤ Mn ≤ P ≤ S ≤ Ni Cr 201 0.12 0.75 7.00 0.045 0.045 1.00-1.28 13.70-15.70 202 0.15 1.00 2.25 0.045 0.045 4.07-4.17 14.00-16.00 301 0.15 1.00 2.00 0.045 0.03 6.00-8.00 16.00-18.00 302 0.15 1.00 2.00 0.045 0.03 8.00-10.00 17.00-19.00 304 0.035 0.75 2.00 0.045 0.03 8.00-13.00 18.00-20.00 309 0.15 0.75 2.00 0.045 0.03 12.00-15.00 22.00-24.00 309S 0.08 1.00 2.00 0.045 0.03 12.00-15.00 22.00-24.00 310S 0.08 1.50 2.00 0.045 0.03 19.00-22.00 24.00-26.00 316 0.08 1.00 2.00 0.045 0.03 10.00-14.00 16.00-18.00 316L 0.035 0.75 2.00 0.045 0.03 10.00-15.00 16.00-18.00 321 0.04-0.10 0.75 2.00 0.045 0.03 9.00-13.00 17.00-20.00 409 0.089 1.00 1.00 0.045 0.05 ≤0.06 10.50-11.75 410 0.15 0.75 1.00 0.045 0.03 ≤0.06 11.5-13.5 420 0.16-0.25 1.00 1.00 0.040 0.03 ≤0.06 12.00-14.00 430 0.12 0.75 1.00 0.045 0.03 ≤0.06 16.00-18.00 430A 0.06 0.05 0.05 0.030 0.50 ≤0.25 14.00-17.00 Grade C ≤ Si ≤ Mn ≤ P ≤ S ≤ Ni Cr Mo Cu 316L 0.03 1.00 2.00 0.035 0.03 23.0-25.0 18.0-20.0 3.0-4.0 4.0-5.0

Established in 2008, we devote ourselves into the business of stainless steel sheet,pipe,coil,etc. After fast and stable development, we are the very company with the most complete categories. The factory occupies a total area of 40,00 ㎡. Our main products are: 8K Mirror sheet, HL, NO.4 sheet. They are widely used in elevator decoration, Luxurious doors, outdoor projects, wall decoration, advertisement nameplates, furniture, kitchenware, sanitary ware, ceiling, corridor, hotel hall, shop facade and various stainless steel series.

Contact Supplier 00:44

00:44

Model UDPM-ALS104 Driving Mode German Avery 104 Yield(pcs/min) 20-100 Operating direction Left or Right Conveyor Speed(m/min) ≤35 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-160 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 01:13

01:13

Model DPM-SLM-A Driving Mode Servo motor Yield(pcs/min) 20-60 Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Label material Adhesive sticker, opaque or transparent label The inner diameter of label roll 76 mm The outer diameter of label roll 350 mm(max) The suitable size of label Width 15-160 mm length 15-300 mm The suitable size of labeling objects Can customized Printer use air 5kg/cm ² Voltage (In China) AC220V 50/60HZ Single phase (Can customized as client need)

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier 00:40

00:40

Foam Children's book made of by EVA. The eva thickness from 1mm to 5mm. Usually produce the foam children's book use the 3mm eva foam. This kind produce technique get the book become light but big size for children reading. The foam children's book produce technique is same as the board book, binding also is board book binding. The printing is colorful printing, most by the glossy varnish or the glossy lamination. The foam children's book have puzzle shape, board book style, the flap and find book style, touch and feel style, etc. We all hope the foam children's book become popular, because the materials is really good for children. The foam children's book Size: 21 x 23cm Pages: 10 pages Thickness: 24mm Materials: 300gsm card paper with glossy lamination, mounted on 3.0 mm EVA coated together, jigsaw puzzle style. MOQ: 3,000 piece Sample Cost: $100/title Sample Lead Time: 1 week produce the Castelo Dos Monstros Foam Children's Book Printing Mass production lead time: 10~15 days Loading Port: Shanghai, China Payment: 30% deposit + balance, by T/T Q: The special for the light book, right? A: Yes it is special for the light weight. Because the major materials is EVA / sponge, pressing EVA materials. One book could produce by many pages, and could be puzzle style. And the 3~5mm thickness EVA, the final book come out with very thick spine, seems a big book. The style book is loved by the children, parents, and publishing house.

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:50

00:50

Feeding and filming unit has the function of conveying steel panel, the plastic film can protect the surface of steel panel to avoid scratch. Filming device adopts air expanding roller to fix the film coil (inner diameter is ∮75mm); press roller and support roller are drum type with power, which is convenient and reliable. It has the adjusting at both left and right side for the film coil, which can guarantee the position accord with steel panel, so that the filming can be flat and without bubble & gauffer. The shaft for fixing film coiling block can rotate; left and right operation is convenient.The expanding roller pull out the production line via guide railway,clamping and replacement,and ensure the operation safe when continuous producing.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:45

00:45

Cooling system is one of the most important equipment of the sandwich panel production line. It is used for those panels which just come out from the double belt and the core parts of which are not completely solidified even still in a reaction. We do this is to avoid a series of problems caused by the non-uniform heat dissipating of the sandwich panel which stack immediately. The main beams of the cooling system are all processed by gantry, and connected by bolts positioning keys. Our company’s cooling bed has the characteristics of working smoothly and good rigidity, and can load the PU panels with thickness of 200mm. It adopts servo- control system to make three panels in and out at the same time to achieve the biggest utilization rate of the cooling bed. The panels move from transition roller path to the specified position of the up cooling bed roller table by rollers. The lift goes up, and the synchronous belt transfers panels to the bottom of fork, main shaft controls panel turning 90 degree. When panels move down, first the fork make the panels turn to the cooling roller path, then the moving mechanism transfer panels away from the fork, and convey them to next process through by transition roller path.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:00

00:00

Parameters (filling machine) Filling nozzle 1 head Quantitative filling (with pressurized barrel) Filling volume 2-10 ml Filling form Piston and vacuum pressure filling Filling speed 40 bottle per min Filling accuracy +/- 1mm Material tank / bottle table 25L / 600*300 mm length and width 2 pieces (input and output) Controller PLC+ touch screen Machine Filling nozzle tank, liquid contact material SUS 304 Medical silica gel pipe Air pressure pressure Flow quantity

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 04:12

04:12

Mobile crane, is to use Mobile chassis walk arm of the rotating crane. Mobile crane is installed in the lifting institutions add heavy axle tyres and composed of special chassis a kind of full rotary cranes, its upper structure and crawler crane basic same, in order to ensure the installation work time the stability of the body, crane with four retractable a leg. In flat on the ground can need not a leg up on small weight lifting and crane content low speed driving. It consists of getting on and off two parts. Get on the bus for lifting operation part, arm, with lifting me. luffing mechanism, the balance weight and turntable, etc.; Get off for supporting and walk part. On and off the bus with rotary bearing connection between. Hanging heavy usually takes a leg when put down, increase the bearing surface, and will the leveling of the fuselage, to ensure the stability of the crane. Compared with the crane the advantages are: between wider, good stability, automobile body, short turning radius small,can in 360 ° work within. But its down the road to the demand is higher, speed is slow, not suitable for car type on the soft ground in the muddy. The development trend of Mobile crane is: large-scale, high efficiency, safety, ease self-respect, and to further improve the performance and driving mobility lifting. Feature:

Jiangsu Zhendong Port Machinery Manufacture Co., Ltd is a leading Chinese port construction machinery manufacturer and exporter located in Suzhou,China. An hour's drive from Shanghai Airport. We have our own import and export rights and got ISO9000: 2008. ISO14001: 2004, OHSAS, SGS, CCS, BV, CE certifications and accept third party inspection, such as SGS etc. our clients also could come to visit our factory. We ZDPM Crane Machinery Group serving a broad range of customers all over the world to provide a complete set of advanced port lifting project, including Ship Floating crane, Deck fixed crane, Gantry crane, Bridge crane, Mobile wheeled crane, Container crane, Crane grab, Rail mounted hopper, Crane clamp, Machinery conveyor, and all its Accessories. Our clients include manufacturing and process industries, shipyards, ports and so on. China's leading mechanical research and design institute and famous university provides advanced technical support for us. We ZDPM Crane Machinery Group committed we not only supply high quality, in time delivery, reliable service, but also offer the most competitive prices. Welcome to visit China Jiangsu Zhengdong port machinery manufacturing factory.

Contact Supplier 01:57

01:57

Overview This detergent filling machine is specially made for all materials, such as tomato paste, water, gel, shampoo, oil olive oil,motor oil etc. The vegetable oil filling machine adopts piston pump and for filling. By adjusting the position pump, it can fill many kinds of the bottles in one filling machine, with quick speed and high precision.The detergent filling machine can fill different shapes of bottle such as circular, round, flat, square, etc. It is suitable for glass bottle and plastic bottle. The filling capacity can be adjustable, the filling volume can be varied from 100-5000ml by adjusting the piston pump. Characteristic: 1.Suitable filling material This detergent filling machine adopts piston pump, which is suitablefor all kind materials, with high filling speed and high filling precision.For filling corrosive, the position pumpwill be made by silicon rubber, Teflon, ceramics and other corrosion resistance materials. 2.Controlling system. The detergent filling machine adopts full-auto PLC and human-computer touch screen control system. For different volumes adjustment, we set several procedures, mode 1, mode 2, mode 3``` Operators do not need too much complicated adjustments, the filling machine can switch between the three models easily. 3.Different volume adjustment. By adjusting the piston pump, it also can fill all the liquid from 500-2500ml 4.Bottle position correct device. To ensure the bottles and filling nozzles are in the correct position, we add a special bottles position device to make the whole filling process smooth and stable. No bottle no filling. 5.Filling nozzles. The filling nozzles are specialized made: anti-drop. Also, the filling nozzles will come into the bottle bottom, and moving up slowly when filling. 6.Cleaning. The pump uses quick-fit removal Structure.It is easy cleaning and disinfection.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery