00:06

00:06

Air discharge direction Performance ranges Cooling capacity: from 268 to 1478 kw Air volume: from 74478 to 366798 m3/h Sound pressure level: from 64 to 73 dB A(10m) Air cooled condensers:customized on demand High efficiency heat exchanger Capacity designs for maximizing the heat transfer relative to the energy consumption of the fan. Tube and tube coupling design for low pressure drop in the coil on the media sides(maximum 100KPa at water designing condition). Our thermodynamic and aerodynamic designing software is long year tested and proved in Germany Fan Only choose low specific energy consumption fans. Fan nozzle designs for maximum air flow and air throw. Our fans from the world`s leading manufacturer are practically proved to be reliable in operation and long lasting. Motor: protection class IP 54 and insulation class F. Voltage:400V/3N/50Hz Air separator for each fan. Testing Heat exchangers are supplied clean and tested at a pressure of 30 bars Options Coil design refrigerant: R414A, R407C. Multiple circuits. Sub-cooling circuits. Stainless steel or aluminum casing. Coated aluminum or copper fins and anti-corrosion expoxy fin. Explosion ploof motor. Customized fin spacing.

Venttech is a company engaged in refrigeration equipment development, design, production, sales and installation of high-tech enterprises. In the early 21st century, Venttech set up factory in Shanghai and adopt foreign advanced technology. Venttech has more than 15 years experience in developing refrigeration equipment such as water chillers, cooling towers and dry coolers. Till now, our refrigeration equipments have exported to more than 30 countries.

Contact Supplier 00:25

00:25

Products Features 1. Twin screw compressor brand is employed, with high efficiency, low noise level, less wearing and long operation time. 2.Four stage volume control or 0%-100% automatic regulation. 3.Use PLC microcomputer control from Germany SIEMENS. LCD touch screen, both English and Chinese human-machina intertace. 4.Complete breakdown protection: high and low pressure protection, air discharge protection, oil level protection, water flow protection, reverse and lack phase protection, chilled water anti-freezing protection, cooling water overheat protection. 5.Wider range of varibale chilled water temperature to meet the low temperature industrial requirements. Product options 1.Salt water evaporator 2.Stepless energy regulation 3.Pump/Cooling tower control 4.Special power supply 5.Remote communication connector Product specfication Refrigerant: R22/R407C Evaporator max water pressure drop: 1.0Mpa Evaporator: fouling factor 0.018m2.℃/KW Condenser: fouling factor 0.044m2.℃/KW Power supply: 380V/3P/50Hz Allowable voltage fluctuate: ±5% Allowable frequency fluctuate: ±2% Compressor Select semi-closed 5:6 asymmetric twin-screw compressor from world-renowned brand. The possibility of shaft seal leakage is zero. Using a rotating exhaust design, the lastest development of the fourth generation line, optimize the circumference speed, excellent design of gear so that the unit has higher compression efficiency. Motor chamber compression chamber integrally cast, high precision. Double pressure compensated rotor housing, very strong, no expansion even in the state of high pressure, and it effectively reduces the noise. Heat exchanger The condenser and evaporator of this series unit adopts shell and tube heat exchanger, using new high efficient heat exchanger structure. Heat exchanger adopts the most advanced and effcient heat exchanger tube bundle with unique geometric characteristics and enhanced tube nucleate boiling required vaporization core, strengthen the fluid in the tube and delay perturbationat the same time, the water side fouling, heat transfer enhanment, the inside wall in order to get the best performace, comparade to the previous design, the unique design of the heat transfer efficiency is increased by 30%. Evaporator evapotation tube with inner grooved on outer concave tooth enhanced heat transfer technology, condenser tube with inner grooved cutter teeth technology, improves the evaporator and condenser heat transfer efficiency and the evaporation temperature, and improve the energy efficiency ratio for the unit. PLC A good Chinese-English interactive interface is to achieve automatic control function before the LCD display real-time statues of the machine work, precise monitoring unit operating at optimun state, the touch pannel sealed, waterproof, dustproof, corrosion-resistant, long-key life. Equipped with cooling pumps, cooling water pumps and cooling tower fan interlock control function. Application Chemical, chemical fiber, plastic, oil, food, pharmaceutical, military, printing, painting, electroplating, electronics and other industries

Venttech is a company engaged in refrigeration equipment development, design, production, sales and installation of high-tech enterprises. In the early 21st century, Venttech set up factory in Shanghai and adopt foreign advanced technology. Venttech has more than 15 years experience in developing refrigeration equipment such as water chillers, cooling towers and dry coolers. Till now, our refrigeration equipments have exported to more than 30 countries.

Contact Supplier 00:17

00:17

Products Features 1. Twin screw compressor brand is employed, with high efficiency, low noise level, less wearing and long operation time. 2.Four stage volume control or 0%-100% automatic regulation. 3.Use PLC microcomputer control from Germany SIEMENS. LCD touch screen, both English and Chinese human-machina intertace. 4.Perfect breakdown protection: high and low pressure protection, air discharge protection, oil level protection, water flow protection, reverse and lack phase protection, chilled water anti-freezing protection, cooling water overheat protection. Product options 1.Salt water evaporator 2.Stepless energy regulation 3.Whole heat recovery/partial heat recovery 4.Pump control 5.Special power supply 6.Remote communication connector Product specfication Refrigerant: R22/R407C Evaporator max water pressure drop: 1.0Mpa Evaporator: fouling factor 0.018m2.℃/KW Power supply: 380V/3P/50Hz Allowable voltage fluctuate: ±5% Allowable frequency fluctuate: ±2% The unit uses high efficiency heat exchanger with advanced, unique shape design and systems. Units can be installed directly on the roof, or other well-ventilated place outdoors, without a separate room, space saving construction. Compact shape, appearance, unit uses “W” type coil design, space utilization, small unit size, in order to adapt to the outdoor weather conditions to ensure that the unit has a good operating results during the life cycle. Friendy choose to use environmentally R407C, R134A or R410A refrigerant ect. There may be change of the dimensions without pre notice. For accurate you are welcome to ask us for installing drawing.

Venttech is a company engaged in refrigeration equipment development, design, production, sales and installation of high-tech enterprises. In the early 21st century, Venttech set up factory in Shanghai and adopt foreign advanced technology. Venttech has more than 15 years experience in developing refrigeration equipment such as water chillers, cooling towers and dry coolers. Till now, our refrigeration equipments have exported to more than 30 countries.

Contact Supplier 00:34

00:34

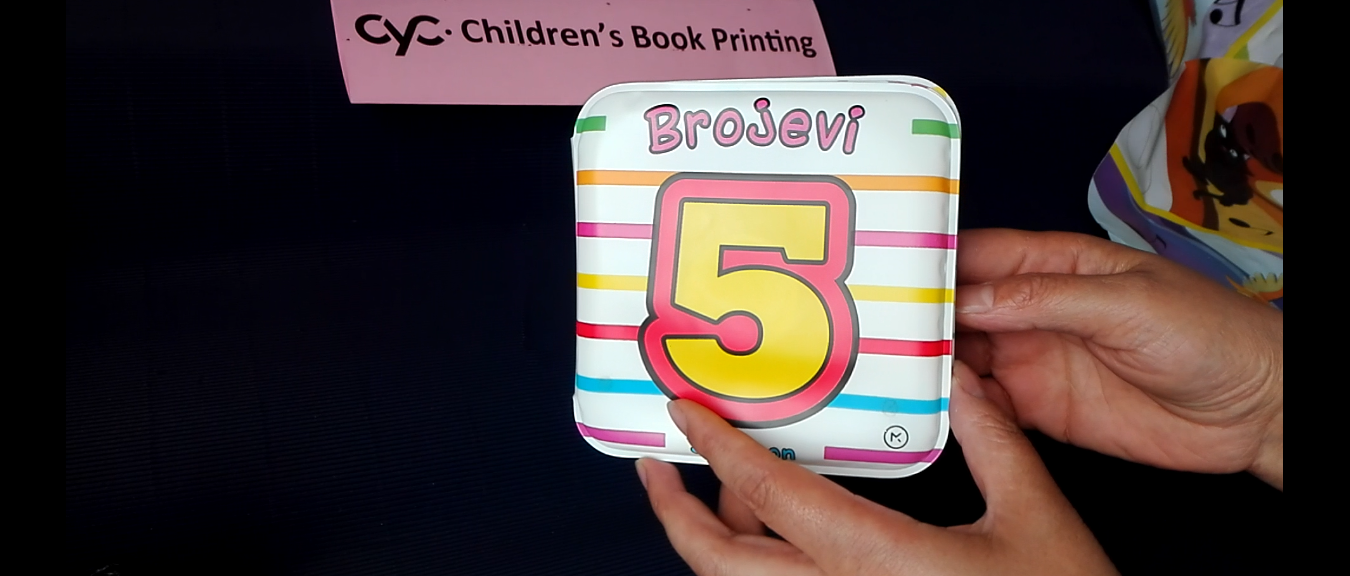

CYC children's book printing is willing to become China's first brand of Bath book. We produce those category bath books print, bath book, rainbow fish bath book, baby bath books, bath books for babies, bath time books, bath books for toddlers, baby bath book, bath time book, the pigeon needs a bath book, a bathing ape book, bath spa booking, book bath. If you could not find your book size, pls email to caroline@childbookprinting.com, or skype cycpackinfo, whatapp: +86-13585530707. Q: Is the bath book print have big market? A: which is really difficult to say. It depend on each publishing house's consideration, if they have full range of the children's book, they will consider the bath book print. Because it will be part of their production range. Size 13 x 13cm Page 8 pages Materials 100% recycle PEVA + Sponge Package pp bag + headercard + master carton MOQ 3000 copies / title Approx Unit Price $0.45~1.10 Sample Cost $125 ~ $250 Sample Lead Time 15 days Mass Production Lead Time 30~45 days Shipping Term FOB Shanghai, China / CIF destination Port Payment Term T/T, T/T+L/C Welcome your custom bath books inquiry coming.

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:40

00:40

The deep blue dolphin made by the vinyl toys, soft, suitable for babies. All the materials is new and clear with the safety test. The shape could work by your design to custom produce. The dolphin MOQ is 5,000 pcs, mold charge for the dolphin vinyl toy take 20~30 days finishing. As long as you have the custom design, pls contact with Caroline@childbookprinting.com. Q1: You are sale the Dolphin Toys of Kids Book Making separate? or Combine with the book making? A: Normal condition, we sales the dolphin toys with book. However if you only need the dolphin, we could also provide. Q2: We feel the Dolphin Toys of Kids Book Making is good sales in the market? A: You are right! The kids and parent more love such book with toys, because they could reach the story and playing the story. Size 89 x 58mm Materials rubber Weight 32g/pc Printing one color MOQ for such materials 5,000 piece Sample cost mold charge $450 Sample lead time 25 days Mass production lead time 15~25 days Safety Guanartee Could pass the testing of the CE, and EN71, and Child Toy Testing

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:32

00:32

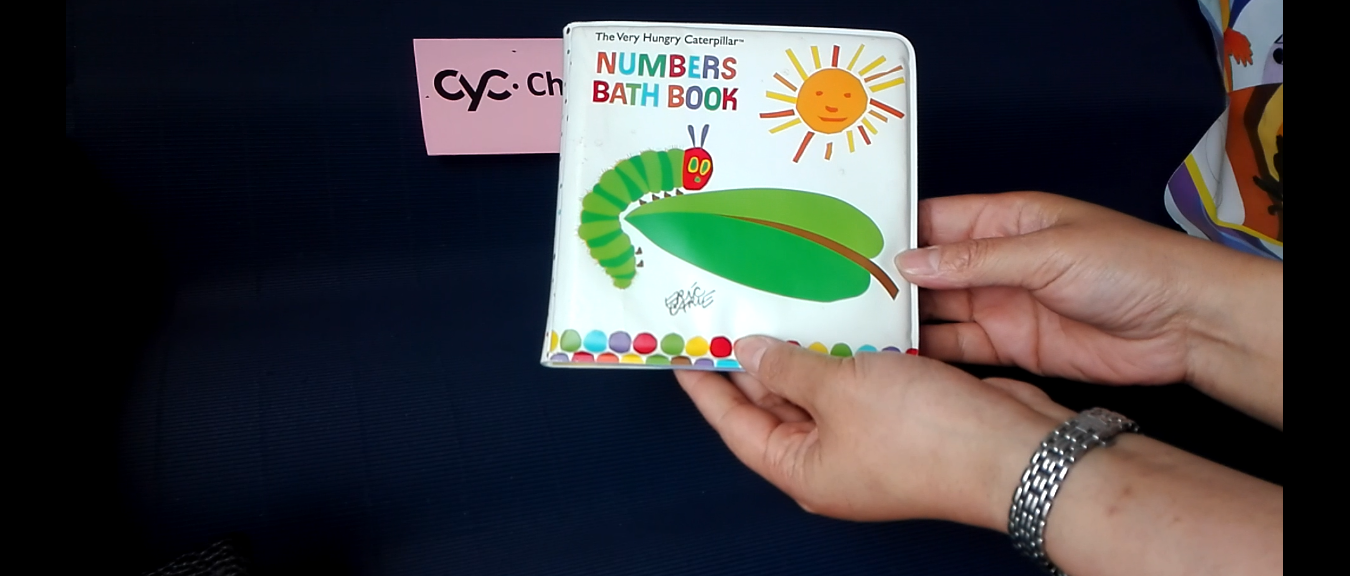

The Hunger Caterpillar Strip Book is a very famous book in the children's reading world. The book illustrate by the Cartier the famous children cartoon drawer. Produce by the strip book could give you more good version on review each cartoon. We also produce the long strip book of the car, the train, the animal, the sea star, etc. Welcome you custom inquiry on the Strip book, pls email to Caroline@childbookprinting.com. Thanks. The cyc children's book also have the cloth book, the baby book, the fabric book, the bath book, the waterproof pvc book, the floating book, the bath time book, etc, under producing. Q: It is the famous Hunger Caterpillar Large Print Children Books? A: Yes, it is the Hunger Caterpillar series. This time they adopt the soft PEVA materials. Q: How many quantity of the MOQ to produce the Hunger Caterpillar Large Print Childrens Books? A: usually by 3000 copies per title Hunger Caterpillar Hunger Caterpillar Large Print Childrens Books. Of course bigger quantity, the price is lower. Book Size 15 x 15 cm Page 8 pages Materials 100% recycle PEVA + Sponge Cartoon Size 95 x 18mm Cartoon Function corresponding with the story of the bath book Package each put into polybag with header card MOQ 3000 copies / title Approx Unit Price $0.6~1.10 Sample Cost $125 ~ $250 Sample Lead Time 15 days Mass Production Lead Time 30~45 days Shipping Term FOB Shanghai, China / CIF destination Port Payment Term T/T, T/T+L/C

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:18

00:18

840001 Professional Angle Grinder 115MM Application. Plastic,Cutting Disc. Dia.: 115mm Dia of hole :22mm Spindle diameter 14mm Rated Voltage : 230V Rated Frequency 50Hz Input power 810W No-load Speed 11000/min Accessories: 1pair carbon brush & 1pc wrench & 1pc grinder disc Cable 2M VDE Certificate CE/GS/EMC/ROHS/FFU GOOD Package: Color Label / Color Box Sample Time: 3 days Delivery Time: Within 35 Days after Receiving the Deposit Payment Terms: T/T ,L/C

We (Landing tools). is one of the leading exporters of tools, hardware and householdware in China. we have built kinds of professional teams to support our operation. SALES TEAM, which has a exact grasp and understanding of clients' requirements. Make prompt, clear and complete replies according to different markets and quality requests of products. R&D TEAM has the full ability to organize and actualize preponderant production against the drawings and samples. PACKAGING & APPEARANCE DESIGN TEAM, in accordance with clients' requests, we supply the different appearances of products, color assortment, packaging design and making. SOURCING TEAM, which is familiar with the full range information in our field. We offer steady, highest cost-effective products. QC TEAM has established complete and comprehensive assessment system of suppliers Documentation team provide our clients with timely, secure and suitable mode of storage and transportation. Our goal is to supply Ideal Solutions for the full process. We will make our remaining efforts to meet and exceed the requirements of customers. We are ready to serve for every potential customers and sincerely looking forward to cooperate with you in the future.

Contact Supplier 01:16

01:16

DOPOM is a product with a great balance of characteristics,making it suitable for many industrial and model building applications.In recent years,there is a growing demand for low-distortion material with good workability for precision machining and large workplaces,and for automated production of multiple pieces.By optimizing the molding and anneal-ing processes,DOPOM has successfully developed a low distortion material DOPOM ‘super’ that has extremely low distortion.It is recommended as material for product with strict dimensional accuracy and automated process. PERFORMANCE CHARACTERISTICS: · Well rounded balance of three major aspects:material properties,cost and machinability. · Good chemical resistance to organic solvents ad alkaline substances,but will be oermeated by strong acids. · There are wide range of lineup from rod with 3 mm-250mm(including centerless and super) diameters to sheet and plate with 0.2mm-100mm thickness. · Deformation is about 1/4 of conventional products. · Heat-dependent dimensional change in thickness and length almost zero at temperatures up to 140°C. · Low rate of dimensional change and shape deformation during cutting allows shorter cutting times.

DOTOQ is a privately owned China business focused on the application of thermoplastic materials in engineering.Established in 2015 and with three branches, Dotoq is now the leading supplier of engineering thermoplastics in stock shapes and components in China. DOTOQ, through its strong network of International and China Engineering Partners, stays at the "leading edge" of product and technology in its field. DOTOQ Comprises Three Focused Areas of Business:Complementing its engineering materials, Dotoq has important partnering relationships that enhance distribution and provide "Technical Centres" alongside its own facilities, for machining, design and application advice to support your needs. Commitment across the business is to developing close and sustainable relationships with customer partners through Service, Quality Products, Quality Practice and a high level of Technical Support.

Contact Supplier 00:00

00:00

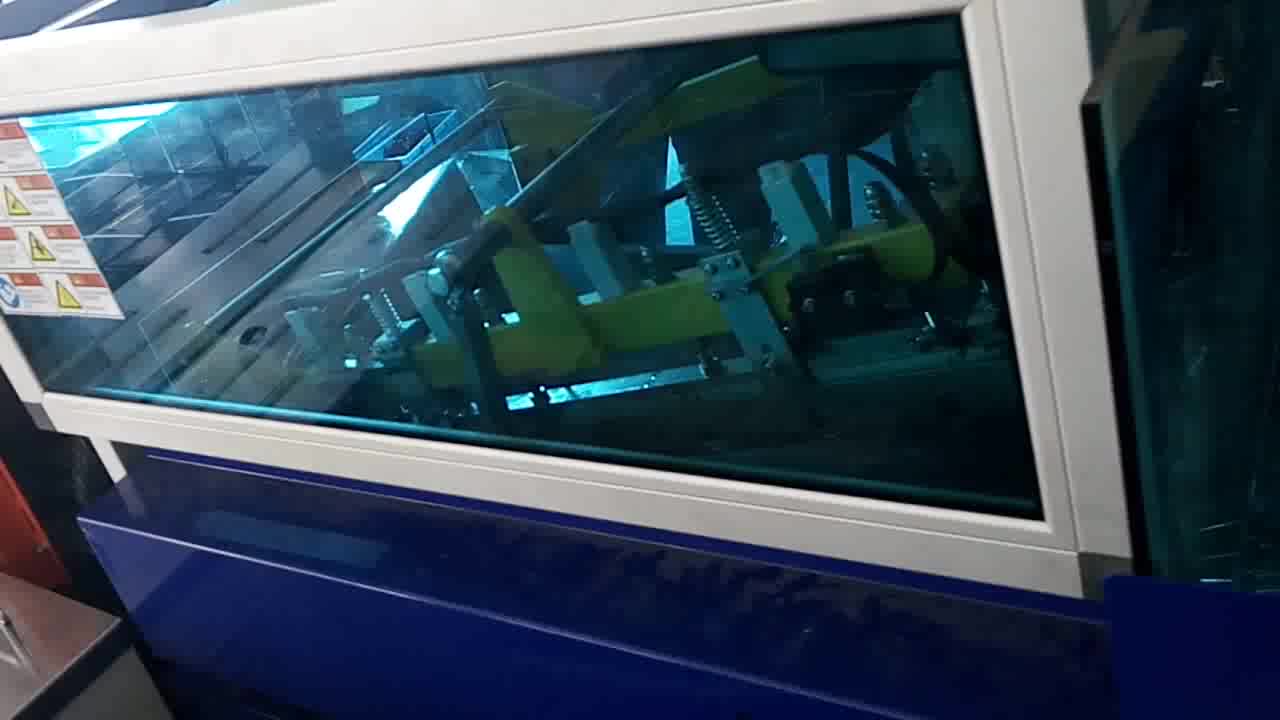

Brief Introduction XGF PP Bottle LVP Wash-Fill-Seal Machine has three sections, ionic air washing or ionic air plus water washing, constant pressure filling, and hot melting sealing. It can automatically finish the processes of bottle feeding, bottle entering, bottle reversing by manipulator, ionic air reversely blowing and washing, bottle conveying, fixed volume filling, cap sorting, cap feeding, simultaneously heating cap and bottleneck, air eliminating, hot melting sealing, bottle conveying out etc. It is mainly applied to the washing, filling and sealing production for PP plastic soft and hard bottle large volume parenteral, like glucose infusion, sodium chloride infusion, sodium chloride and dextrose injection, metronidazole injection etc. Main Features 1. Compact integrated design of wash-fill-seal with smaller production area 2. Applicable to any round or flat IV solution bottles with different shapes 3. Voice alarm when fault, and machine halt 4. PLV control, all operation data can be set, changed and kept on file 5. CIP/SIP on line

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:41

00:41

Brief Introduction GZ-SS400-FI injection stretch blow molding machine has 4 stations of injection moulding, temperature controlling, stretching & blowing, and product demoulding, the products it produces get one-step formed from raw material to finished products. It can produce many kinds of containers, like IV solution bottle, oral liquid bottle, liquid medicine bottle, tablet bottle, capsule bottle, LED lamp cover, cosmetics bottle, detergent bottle, collutory bottle, milk bottle, condiment container, salad dressing container, drinking water bottle and etc. Main Features 1.Need no reheating, reducing molding cycle and energy consumption. 2.Avoid possible pollution from preform station to blow station. 3.Easy replacement of the mold. 4.Apply to many kinds of materials: PC, PET, PP, HDPE, PS etc. 5.Apply to different container shapes: round, non-round, wild-mouth bottle, oval.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 02:08

02:08

Description Unit Travel X travel mm 1300 Y travel mm 650 Z travel mm 710 Distance between spindle nose and worktable surface mm 120-830 Distance from worktable center to column surface mm 355-1005 Worktable Table area mm 630*1600 Max. loads kg 1500 T-slot width mm 5×18H8×100 Spindle Max. spindle speed rpm 6000 Angle of spindle taper - BT-50 Feed rate X/Y/Z rapid speed m/min 15/15/12 Max. cutting feedrate m/min 5 Automatic Tool Changing System manipulator Qty. Of tools pcs 24 Tool changing time sec 2.9 Max. tool length mm 400 Max. tool diameter/Adjacent no tool mm φ110/φ200 Max. tool weight kg 15 Motor Spindle motor kw 15/18.5 X/Y/Z axis motor kw 4/4/7 Cooling pump motor w 0.4+1.5 Precision(SN precision according to standard JB/T8772.4-1998) Positioning accuracy mm X:0.026,Y/Z:0.018 Repetitive positioning accuracy mm X:0.013,Y/Z:0.01 Machine Dimension Overall height of machine mm 3020 Floor area(L×W) mm 3740×3440 Weight kg 12000 Power supply kw 40

COMPANY PROFILE Nantong Hangzhi Equipment Technology Co., Ltd. is a wholly owned subsidiary of AVIC Aviation High-technology Group Co., Ltd. In March 16, 2016, the company completed the renamed registration. Total assets of the company are RMB 330 million. Nantong Hangzhi Equipment Technology Co., Ltd was founded in 1956, Former Nantong Machine TOOL Works, Trademark include: “NANTONG”、“TONMAC”、“TONTEC”,It is one of six listed companies in Chinese machine tool industry. The company undertakes the aircraft in the original Department of AVIC HT’s machine tool business and AVIC Beijing Aeronautical manufacturing technology research Institute of high-end intelligent equipment and aviation equipment business. The main products are CNC milling machines, CNC lathes, Vertical machining center, Horizontal machining center, Gantry type vertical machining center and Aviation equipment, etc. The company employs more than 500 people, including nearly 150 professional, technical and engineering management staff. The company has domestic first-class production and processing equipment, which imports more than 130 sets of thin equipment, including Japan SNK five face machining center, Germany”s WARLDRICH precision guideway grinder, the United States CICINNATIE machining center, Switzerland DIXI coordinate boring machine, Zeiss coordinate measuring instrument and other world famous brand processing and testing equipment. The company independently developed machine tool products by a number of patents, which in the validity period of the invention patent 14, utility model patents 18. A number of key technologies like MCH63 precision horizontal machining center fill the gaps, accessing to the 2007 machine tool industry ten new product title, China Machinery Industry Science and Technology Progress Award. VMCL1100 vertical machining center series won the second prize of scientific and technological progress in Nantong City, Jiangsu Province, third prize of scientific and technological progress. Products are widely used in mold manufacturing, auto parts, wind energy nuclear power, marine ships, military aerospace, teaching and other fields. The company's sales network is throughout the South China, Zhejiang, Jiangsu, China and the West, North China, northeast and other regions, with a professional sales and after-sales team.

Contact Supplier 02:08

02:08

Description Unit Travel X travel mm 1650 Y travel mm 850 Z travel mm 710 Distance between spindle nose and worktable surface mm 150-860 Distance from worktable center to column guide surface mm 440-1290 Worktable Table area mm 800×1850 Max. loads kg 3000 T-slot width mm 6×18H8 Spindle Max. spindle speed rpm 6000 Angle of spindle taper - BT-50 Feed rate X/Y/Z rapid speed m/min 15/15/12 Max. cutting feedrate m/min 5 Automatic Tool Changing System manipulator Qty. Of tools pcs 24 Tool changing time sec 2.9 Max. tool length mm 400 Max. tool diameter/ Adjacent no tool mm 110/φ200 Max. tool weight kg 15 Motor Spindle motor kw 15/18.5 X/Y/Z axis motor kw 7 Cooling pump motor w 0.75+1.5 Precision(SN precision according to standard JB/T8772.4-1998) Positioning accuracy mm X:0.042,Y:0.032,Z:0.025 Repetitive positioning accuracy mm X:0.020,Y:0.018,Z:0.015 Machine Dimension Overall height of machine mm 3390 Floor area(L×W) mm 4500×3890 Weight kg 17000 Power supply kw 50

COMPANY PROFILE Nantong Hangzhi Equipment Technology Co., Ltd. is a wholly owned subsidiary of AVIC Aviation High-technology Group Co., Ltd. In March 16, 2016, the company completed the renamed registration. Total assets of the company are RMB 330 million. Nantong Hangzhi Equipment Technology Co., Ltd was founded in 1956, Former Nantong Machine TOOL Works, Trademark include: “NANTONG”、“TONMAC”、“TONTEC”,It is one of six listed companies in Chinese machine tool industry. The company undertakes the aircraft in the original Department of AVIC HT’s machine tool business and AVIC Beijing Aeronautical manufacturing technology research Institute of high-end intelligent equipment and aviation equipment business. The main products are CNC milling machines, CNC lathes, Vertical machining center, Horizontal machining center, Gantry type vertical machining center and Aviation equipment, etc. The company employs more than 500 people, including nearly 150 professional, technical and engineering management staff. The company has domestic first-class production and processing equipment, which imports more than 130 sets of thin equipment, including Japan SNK five face machining center, Germany”s WARLDRICH precision guideway grinder, the United States CICINNATIE machining center, Switzerland DIXI coordinate boring machine, Zeiss coordinate measuring instrument and other world famous brand processing and testing equipment. The company independently developed machine tool products by a number of patents, which in the validity period of the invention patent 14, utility model patents 18. A number of key technologies like MCH63 precision horizontal machining center fill the gaps, accessing to the 2007 machine tool industry ten new product title, China Machinery Industry Science and Technology Progress Award. VMCL1100 vertical machining center series won the second prize of scientific and technological progress in Nantong City, Jiangsu Province, third prize of scientific and technological progress. Products are widely used in mold manufacturing, auto parts, wind energy nuclear power, marine ships, military aerospace, teaching and other fields. The company's sales network is throughout the South China, Zhejiang, Jiangsu, China and the West, North China, northeast and other regions, with a professional sales and after-sales team.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery