01:59

01:59

4-rope Dual Scoop grab is an efficient tool for loading and unloading sands, coal, mineral powder and bulk chemical fertilizer. The mechanical structure for opening & closing is succinct and original. It is easy to use and can work under any circumstances in order. The grab is equipped for the crane which has two hoisting drums and used for grabbing bulk materials. Now the grabs are widely used in ports, electricity, vessel, metallurgy, preservation and transportation, and are exported in batches. Using 3D Virtual Design, by Collision and Interference Checking and taking Dynamic Simulation Test, the products can be showed in the stage of design Intuitively, which can secure the product’s quality and outward appearance. By Simulating the various working conditions the bulk grab may service for, using ANSYS to strength check and Optimize the main parts of the equipment which make the weight distribution more reasonable, stress distribution more optimization and the service life longer. The 4-rope Dual Scoop Grab has 6 types as following:

Shanghai Janus Grab Co., Ltd is a global reputed grab specialist, with more than 30 years experience in grabs design, R&D, and manufacturing. Highly educated professionals in steel structure, hydraulic and electric system make Janus grabs competitive in world-wide markets.

Contact Supplier 01:35

01:35

The 4-rope scissors grab is a newly bulk grab, which is suitable to crane with two drum for loading and unloading iron ore, and, coal, bulk fertilizer, and so on. The characteristic of scissor grab is newly structure, convenient operation, and light dead weight, high loading ratio. When the grab loads the iron ore, its ratio is up to 1:2.5. The grab has short opening and closing stroke, it just need a half time for withdrawing out the closing rope, comparing with the grab with long pressing rod, which could improve the loading and unloading efficiency, and decrease abrasion of grab. Type and Size (t) SWL (m3) Volume (t) Dead Weight (mm) Dimensions (mm) Sheave Dia. (m) Use Height (mm) Steel Rope Dia. A B C D E CS16[4]5.5J 16 4 5.5 4325 4475 2675 4590 2000 Ø560 10 Ø26 CS20[5]6.6J 20 5 6.6 4845 5000 2885 5110 2200 Ø650 11.5 Ø28 CS25[6.5]8.3J 25 6.5 8.3 5450 5600 3200 5730 2350 Ø720 12.5 Ø32 CS32[8]11J 32 8 11 6140 6290 3400 6400 2600 Ø800 14.5 Ø36 CS40[10.2]13.5J 40 10.2 13.5 6920 7070 3660 7200 2750 Ø880 16 Ø40 CS52[13]17J 52 13 17 7785 7935 3965 8065 3000 Ø920 18 Ø44 CS63[16.5]21J 63 16.5 21 8600 8815 4300 8930 3300 Ø1120 20 Ø48 Note: 1.As the products have been improved, we will not advice another. 2.We can design and produce the grab according to user’s demand.

Shanghai Janus Grab Co., Ltd is a global reputed grab specialist, with more than 30 years experience in grabs design, R&D, and manufacturing. Highly educated professionals in steel structure, hydraulic and electric system make Janus grabs competitive in world-wide markets.

Contact SupplierShanghai Janus Grab Co., Ltd is a global reputed grab specialist, with more than 30 years experience in grabs design, R&D, and manufacturing. Highly educated professionals in steel structure, hydraulic and electric system make Janus grabs competitive in world-wide markets.

Contact Supplier 04:36

04:36

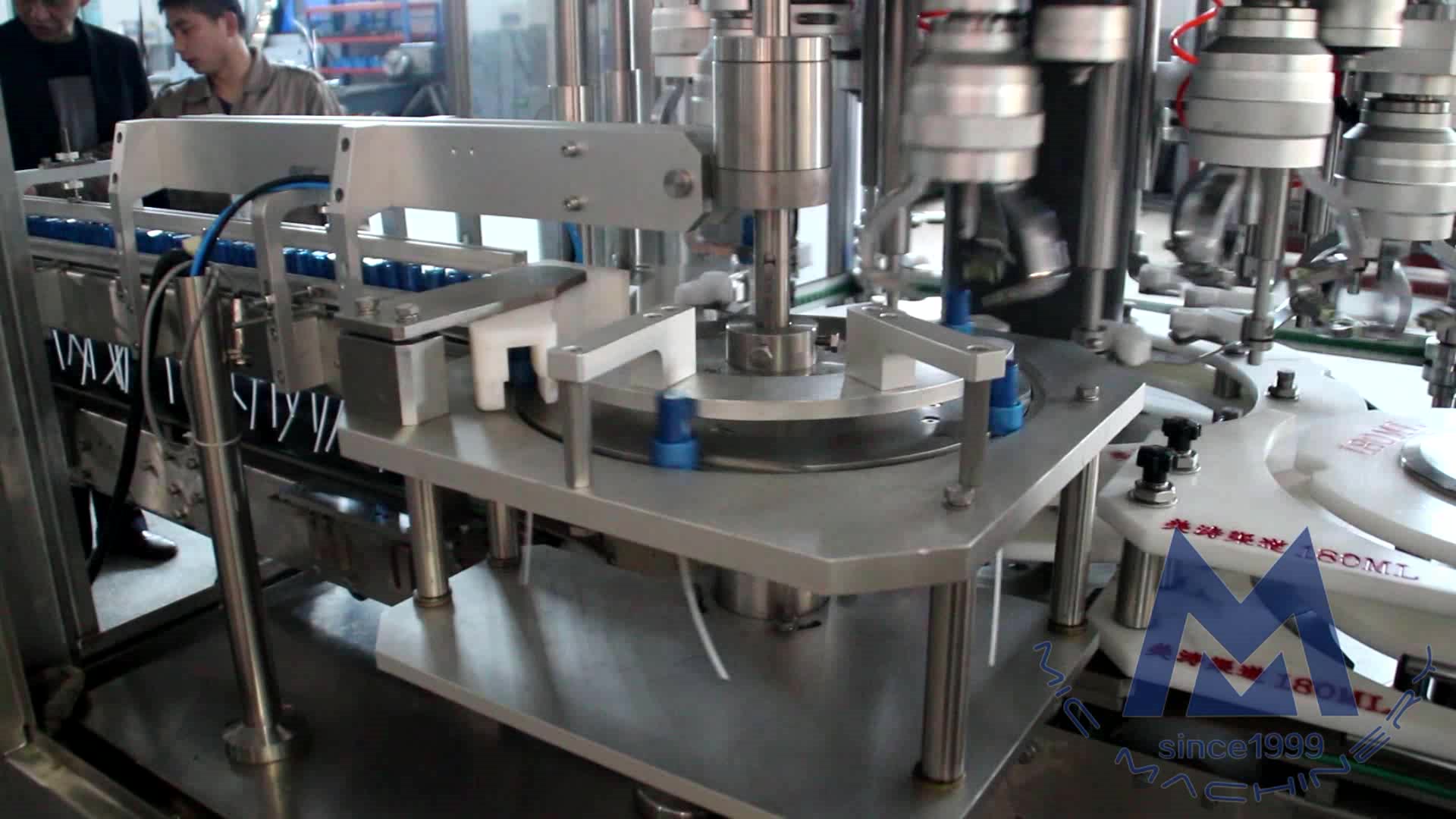

Put all caps into the cap vibrating plate, the cap along the loading cap tunnel placed in the bottle mouth ordered. Adjust the speed governor can change vibrating cap speed. After the cap be placed in the right position of the bottle mouth, use press cap head to press cap. This machine easy operation and adjustable easy.

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:38

00:38

This machine adopts PLC programmable control, In order to achieve data storage. Using electrical and pneumatic control machine running, high Stability. A positioning device, capping standard, Easy to operate. Reach GMP.

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 01:44

01:44

Heads 8 Piece Machine Size 2000*1600*2600mm Weight 4000kgs Cap Size Diameter 30mm, Length 250mm Speed 80 Piece above per min Torque Control +/-0.3Nm Capping Rate ≥98% (error from centre of bottle mould<1mm, height error<1mm) Voltage AC 380V 50Hz Machine Power 4Kw Need Air Supply 0.6Mpa clean air

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:44

00:44

Application area Suilable for printing ink, solvent ink, water-based ink, automobile paint, industrial coating, pigments, color paste, and nanometer materials. Characteristics • New design of pin-type grinding components, high grinding efficiency high output, and low energy consumption. • With smaller length/diameter ratio and higher energy density. • Using high flux static centrifugal separation sieve, large discharging area, grinding medium no contact with the sieve, no abrasion, with longer service life. • Grinding Barrel and grinding rotor adopt forced cooling system, with lower discharging temperature and no influence on sensitive materials. • Using top high quality wear-resisting alloy steel, reduce pollution to products. different materials are optional as per different products, such as stainless steel, high polymer materials, ceramics, etc. Product Advantages: •Novel structure, high stability •Strengthened frame with reasonable structure, steady operation and easy maintenance. Besides, nicer appearance with full of modern sense. •The main parts an out-sourced parts areinternationall renowned brands with higher stability and longer service life.Easy to clean, strong durability •Unique tri-pole mechanism design makes it easy to open for cleaning and replacing grinding chambers. •The grinding chamber, made of high wear-resistance alloy steel, is treated specially torealize higher wear resistance and longer service life. In addition, Burgmann Dual-end Mechanical Seal with self-lubricating system contributes directly to higher reliability and durability.Safe monitor, stable product •The machine is with triple cooling: internal, external, and end face, which ensures the grinding heat exchanged out in time. •The water temperature, material temperature, material pressure,water pressure, air pressure and other real-time monitoring and protection system ensure proper operation of the machine.Full specification, can be customized •Specifications ranges from 5L to 50L, which can be customized to be Exproof type. Working Principle The delivery pump circulates the materials in the tank and the materials in the grinding chamber. The main shaft in the grinding chamber is equipped with many pins with high anti-abrasiveness and hardness. The pins drive the grinding medium inside the grinding chamber to do irregular movements in all direction to put the materials underthe action of constant collision and friction. At same time, the materíals are separated from the grinding medium by the sieve and keep circulating from the tank to the grinding chamber to obtain smaller particle size, narrower particle size range.

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier 00:44

00:44

Characteristics ●This machine has stable structure ,ingenious design design and convenient operation. ●Cleaning、changing colour and replacing mill bead can be much easier. ●Non –vestigital design, it can solve the problem of material discharging better after milling. ●Hard alloy sticks, with proper redistribution, high-efficiency milling result can be obtained. ●Double cooling of inner rotor and outer jacket ensures effect of material cooling. ●Better lining of wear-resistant alloy, without pollution to materials. ●With less abrasion of milling media and cost.

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier 00:44

00:44

The lab sand mill is widely used in laboratory in different industry, such as painting, ink, pesticides, operating simply, using conveniently.

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier 00:44

00:44

Application area Mainly used in color paste and pesticide formulation. It's suit for medical laboratories, biological research, cosmetic and colleges laboratories. Applied in the field of dispersing and dissolving of liquid and liquid or solid and liquid with various viscosity levels. Characterstics • The structure of machine is designed according the principle of the sand mill, the experimental results can be enlarged and can could direct the production. • With frequency inverter,the machine could adjust speed according to the process characteristics of the material, could collect optimum parameters. • Such as temperature and pressure The parameters controlled by PLC ,can make ensure the safety of production and the equipment run fully to meet the technological requirements. • With imported diaphragm pump. • Fineness 100nm. • The whole structure is reasonable, running safety.

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier 00:44

00:44

Technique ∙The dissolver is a fast, high-capacity disperser with a wide range of speeds and high level of efficiency ∙Push-button speed control ∙Speed indicator and automatic speed reduction ∙The product is accelerated radially by the dispersion disk, deflected to the top and bottom at the tank wall and directed back to the dispersion disk through formation of a vortex ∙Shear forces around the circumference of the toothed disk result in highly efficient dispersion, good wetting and deagglomeration ∙For high-viscosity products, a tank wall scraping device can aid the mixing and dispersing process ∙Hydraulic lifting/lowering device ∙Push-button stroke adjustment ∙Adjustable tank clamping mechanism ∙Stainless steel shaft and dispersion disk; additional product-specific mixing tools available depending on the application ∙Manufactured in accordance with CE guidelines Options ∙Application-specific tank cover designs ∙Vacuum design ∙Scraping device for tank wall ∙Temperature sensor ∙Timer ∙Design for ceiling installation with hinged head ∙Various explosion protection ratings ∙Special tank clamping mechanisms ∙PLC-controlled units Advantage ∙ Easy handling which reduces costs and time ∙ Customized solutions on request ∙ A wide range of variously equipped versions available for highest process safety ∙ Various, easily exchangeable mixing tools to increase the efficiency ∙ Temperature measurement by wand or agitator shaft which increases the reliability of the production process ∙ Optimal positioning of the mixing tool via hydraulic lifting/lowering device ∙ Dissolver only starts When the vessel is correctly positioned ∙ At the lowest possible speed ∙ Two-handed operation for lifting/lowering of the tank cover (optional design) ∙ Automatic switch-off, if the toothed disks are lifted above the level of the tank ∙ Protection against accidental contact with the rotating shaft ∙ Bellows serving as dust protection for the shaft

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier 00:44

00:44

Applicable industry: The two-shaft mixing disperser is applicable to the chemical industry, such as printing ink, paint, coating and pigment, etc. Function: This machine is suitable for product dispersing, mixing, blending and other production processes. Operating principle: The disperser is not only able to disperse the materials with low fineness requirement but also blend them into final products directly. Disperser's sawtooth-shaped dispersing impeller intensely stires the paste in the vessel while rotating at high speed. The material particles become finer particulates during strong impact and shearing force. The mixing impeller blade is fabricated according to the size of material tank in order to fully disperse the materials inside the tank and meet production process requirements. Tips: You can raise processing amount, equipment form, size requirements or the property of the materials you need to process. Sower's sales engineers will provide you with the solutions to your satisfaction. Characteristics 1. More sufficient processing of the materials 2. Hydraulic lift ensures stability and reliability 3. Large power with stronger processing ability 4. Two-shaft mixing form 5. With CE & ISO 9001:2015 qualifications

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery

00:21

00:21