00:42

00:42

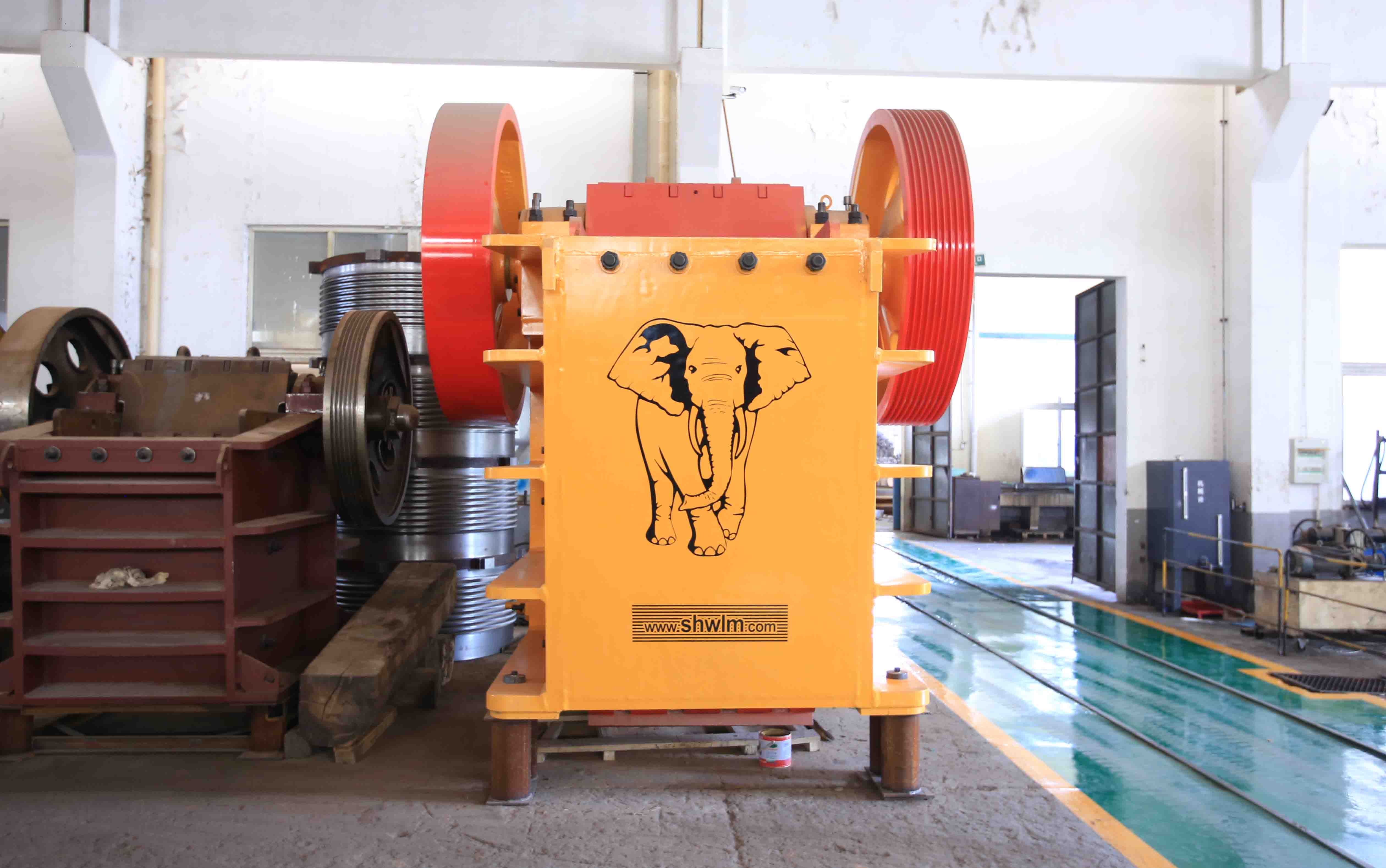

Oil bearings and labyrinth seals PEV Jaw Crushers are built with top quality oil bearings and seals. The lubrication system makes jaw crusher operation smooth. Hydraulic adjustment PEV Jaw Crushers are equipped with hydraulic adjustment system. It include hydraulic oil jacks, shim plates and other components. The hydraulic system easy and fast adjust the jaw mouth clearance, Saving operation time, improving work efficiency. Solid main frame All is with welded steel construction & stressed relieved Jaw Crusher main frame. Heavy duty reinforcement at major stress points. Safety of single toggle operation PEV Jaw Crushers perform crushing operations with force exerted from advancing and retreating motions of a swing jaw which is suspended from an eccentric shaft at the top while supported by toggle plate, seat & block at the bottom. These safety toggle plate, seat & block provide complete jaw protection from ensures a nip angle be properly maintained. Large crushing ratio production Since WHITE LAI Jaw Crushers have larger and deeper crushing chambers and the crushing angle is designed to be sharp, a very high crushing ratio can be achieved. For certain applications, a single toggle crusher can render both coarse and medium or medium and fine crushing quality.

Shanghai WHITE LAI Road and Bridge Machinery Co., Ltd is a renowned crushing and screening machinery equipment provider in China. We provide our clients with a whole series of crushing and screening machinery equipment, including hydraulic cone crusher, jaw crusher, impact crusher, vertical shaft impact crusher, vibrating screening and all complete set of stone crushing and sand making production lines. Our products had passed the quality system certification of ISO9001:2008, and the European CE certificate.

Contact Supplier 00:54

00:54

High strength and firm structure The main body of the cone crusher a box shaped cast steel structure, whose high load areas are reinforced by hard steel. Finite element design WL series high efficiency cone crusher is designed with the help of modern CAD technology. All series models have gone through the FEM technology analysis, which ensures all stress levels inside within appropriate range and guarantees the high strength structure and stable performance of WL series high efficiency cone crusher. High reliability and practicability originates from excellent design High efficiency compound cone crusher adopts tapered roller bearing to replace the old style horizontal shaft copper sleeve at both ends of the horizontal drive shaft and thus largely improves its rotation speed. Dust proof ring is assembled between the mantle cone and the seat liner. The maze O-ring is full of lubrication oil. The dust proof ring is supported by the spring in the seat liner so as to prevent dust from entering. The machine adopts electric automatic lubrication system that connects the main motor. If the pressure is insufficient or the temperature is too high, the main motor stops immediately to prevent the main engine from damage. The machine is installed with hydraulic pressure adjustment device so as to quickly adjust the discharge mouth size and clear the crushing chamber and therefore reduce the time of machine hault. High capacity,low cost and easy Our machine's fine crushing chamber shape increases the effective crushing surface. The machine has the capacity to process larger feed size, increases 1/3 production capacity comparing with other cone crushers and can produce fine particles and cubic products. The mantle core and the crushing chambre are processed by digital control CNC machine, which makes the replacement of wearing plates quick and easy, eliminates the need to fill epoxide resin and improves the operational efficiency. Traditional cone crusher with the ancient crushing chamber structure, has limited crushing surfaces, low production and produces more elongated and flaky particles content. Epoxide resin needs to be filled between the mantle cone the crushing surface, which makes the replacement difficult, increases the failure rate and machine halt time and causes unstable performance of the machine. Less downtime Using the Hydraulic Pressure Chamber Clearing mean the WL Series cone crushers can pass tramp iron that would stall many competitors’ crushers. Using the Hydraulic Pressure Adjustment Device setting adjustment with the adjustment under load capability makes it easy to balance the crushing circuit and optimize crusher productivity. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. WHITE LAI cone crushers are widely used in mines and quarries around the world and have earned a reputation for being tough and reliable. Two main types of cone crushers are available: the Standard type for coarse crushing. the short head type for fine crushing. These two crusher types are designed for secondary or tertiary crushing of highly abrasive materials in ether fixed or mobile plants.

Shanghai WHITE LAI Road and Bridge Machinery Co., Ltd is a renowned crushing and screening machinery equipment provider in China. We provide our clients with a whole series of crushing and screening machinery equipment, including hydraulic cone crusher, jaw crusher, impact crusher, vertical shaft impact crusher, vibrating screening and all complete set of stone crushing and sand making production lines. Our products had passed the quality system certification of ISO9001:2008, and the European CE certificate.

Contact Supplier 01:00

01:00

Jaw Plates WHITE LAI replacement crusher jaws are engineered to last longer and crush more efficiently, while reducing wear and tear on the crusher. The crusher jaws produce better quality rock more consistently than standard original equipment jaws, while reducing the need for re-screening and re-crushing. WHITE LAI offers a full range of options for all popular jaw crushers, including various tooth designs, curves and alloys. WHITE LAI's crusher jaws give you: ● Machined surfaces for a consistent fit with less hassle and downtime ● Large selection of tooth and curve configurations for optimum performance in any application ● Unsurpassed alloys for extended wear life and lower cost per ton Mantles & Concaves WHITE LAI supplies replacement wear parts to fit all major cone crusher models, including the new high-horsepower crushers. WHITE LAI cone crusher wear parts are engineered to maximize production by retaining the feed opening throughout the part’s lifespan, and balancing the mantle and bowl liner wear. Cone parts can be custom fit to match any application. WHITE LAI’s cone crusher wear parts give you: ● Custom configuration ensures consistent production ● Long-lasting manganese steel and durable parts increase crusher uptime ● Precise fitting distributes stresses across the frame for less wear and tear on the equipment Gripper Slot Bowl Liner The WHITE LAI gripper slot bowl liner is specifically engineered to permit oversized rock to enter the chamber and keep the feed opening clear. The ribbed mantle helps begin the crushing process higher up in the chamber for cobblestone and river rock material that is typically difficult to grab. The result is more even wear and improved production. Main Frame Cone Crusher Liners WHITE LAI also fabricates Main Frame Liners and inserts that provide an economical alternative to OEM parts. Our selection of WHITE LAI plates and chromium carbide overlay plate offers a wider choice to address wear protection. Magotteaux Blow bar Xwin® Martensitic Steel is a standard MMC (Metal Matrix Composit) solution which was first developed to recycle building waste; it has now been used for many years and is hence renowned on the market. Combining the high wear resistance of the ceramic compound with a high chrome white iron increases the lifetime while keeping the physical parameters of the required matrix. Against white iron solutions, which are breakable, the use of Xwin® Martensitic solutions reduces the risk of breakage of the blow bars to its lowest level according to applications. Key Benefits: ● Increase the lifetime of blow bars(from 80 up to 120%) ● Reduced maintenance ● Maintained original wear profile ● Improved productivity VSI Wear Table WHITE LAI S series VSI crusher wear parts are cast from premium chrome white iron alloys 35S and 33F-MC for maximum abrasion resistance. Careful production control ensure that parts wear uniformly. In addition, weight is maintained to a very close tolerance to minimize vibration. WHITE LAI offers high quality throw shoes and anvils for S series VSI crushers,also offers such VSI accessories as rim liners, lid liners, table liners, feed tubes, feed discs and pedestal liners. Key product features include: ● Material: high manganese steel, high Chromium or 45 carbon steel; Depending on the specific conditions, all wear parts can be ordered as high manganese steel, high chrome cast iron or Cr-Mo alloy steel. ● Process: polished and rust-resistant as per your requests.

Shanghai WHITE LAI Road and Bridge Machinery Co., Ltd is a renowned crushing and screening machinery equipment provider in China. We provide our clients with a whole series of crushing and screening machinery equipment, including hydraulic cone crusher, jaw crusher, impact crusher, vertical shaft impact crusher, vibrating screening and all complete set of stone crushing and sand making production lines. Our products had passed the quality system certification of ISO9001:2008, and the European CE certificate.

Contact Supplier 00:00

00:00

Brief Introduction FE Non-PVC soft bag IV solution production line is the latest production line with most advanced technology. It can automatically finish film feeding, printing, bag making, filling and sealing in one machine. This LVP FFS line can be used to automatically fill 50-5000ml general solution, special solution, dialysis solution, Parenteral nutrition, Antibiotics, Irrigation and Disinfectant solution etc. FE can supply you different PP bag design with single boat type port, single/double hard ports, double soft tube ports etc. Main features: 1.100% film utilization: No waste edge between bags, reducing both material and energy consumption. 2.Special IV bag design: each bag saves 10mm film than others. 3.Reliable heating and welding system: Leakage rate less than 0.03%. 4.Quick changeover: 0.5-1 hour to switch from one size to another. 5.Stable transmission system: only needs 1 control system, 1 HMI and 1 operator. 6.Safe filling nozzle: No solution overflows, no particles generation. 7.Auto faulty rejection system detected by the machine. 8.Production line length is reduced by 1/3, both workshop and air conditioning and cleaning area are reduced by 1/3, greatly reducing the initial investment and future running cost. 9.Simple structure, more stable and reliable performance.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:34

00:34

Brief Introduction CPP series bottle blowing machine is with high production automatically blowing for IV bottle and other PP bottles, includes stations of preform loading, preform heating, preform delivering, blowing, bottle taking out. The blown bottles are suitable for filling glucose infusion, sodium chloride infusion, glucose and sodium chloride injection, metronidazole injection etc. Main Features 1.Different performs loading, no need to change any spare parts 2.Fully servo electric control 3.Piston type high pressure mold lock, improving blown bottle quality 4.Stable power output, ensure bottle uniform thickness 5.Max production capacity 12000 bottles per hour

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:00

00:00

Main application This unit is made up of CLQ Ultrasonic Vertical Washing Machine, RSM Sterilizing & Drying Machine and KGYX Filling & Sealing Machine. Divided into three working areas of washing, sterilizing & drying and filling & sealing. It can be either used in-line or in the form of three single machines. Can automatically finish the processes of water spaying, ultrasonic wave washing, compressed air blowing, recycling water flushing, compressed air blowing, fresh high-temperature sterilizing, cooling, bottle-collating, filling, cap-collating, stopppering, panel mounting and so on for vials. Can be equipped with Servo-motor , more stability and accuracy.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:41

00:41

Reverse osmosis is the eighties developed a membrane separation technology, which mainly use the semipermeable membrane permeation principle, to give it a certain way by applying a pressure on the natural infiltration direction against the force of the water in the concentrated solution dilute the solution to penetrate this way is called reverse osmosis. By the components of the device is reverse osmosis reverse osmosis unit. One, two reverse osmosis + EDI preparation (purified water process characteristics) 1 Suitable for raw water salinity compared Height regions; 2 product water conductivity is better; 3 one-time investment of less; 4 lower operating costs; 5.Stability.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:00

00:00

Brief Introduction XGF PP Bottle LVP Wash-Fill-Seal Machine has three sections, ionic air washing or ionic air plus water washing, constant pressure filling, and hot melting sealing. It can automatically finish the processes of bottle feeding, bottle entering, bottle reversing by manipulator, ionic air reversely blowing and washing, bottle conveying, fixed volume filling, cap sorting, cap feeding, simultaneously heating cap and bottleneck, air eliminating, hot melting sealing, bottle conveying out etc. It is mainly applied to the washing, filling and sealing production for PP plastic soft and hard bottle large volume parenteral, like glucose infusion, sodium chloride infusion, sodium chloride and dextrose injection, metronidazole injection etc. Main Features 1. Compact integrated design of wash-fill-seal with smaller production area 2. Applicable to any round or flat IV solution bottles with different shapes 3. Voice alarm when fault, and machine halt 4. PLV control, all operation data can be set, changed and kept on file 5. CIP/SIP on line

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:41

00:41

Brief Introduction GZ-SS400-FI injection stretch blow molding machine has 4 stations of injection moulding, temperature controlling, stretching & blowing, and product demoulding, the products it produces get one-step formed from raw material to finished products. It can produce many kinds of containers, like IV solution bottle, oral liquid bottle, liquid medicine bottle, tablet bottle, capsule bottle, LED lamp cover, cosmetics bottle, detergent bottle, collutory bottle, milk bottle, condiment container, salad dressing container, drinking water bottle and etc. Main Features 1.Need no reheating, reducing molding cycle and energy consumption. 2.Avoid possible pollution from preform station to blow station. 3.Easy replacement of the mold. 4.Apply to many kinds of materials: PC, PET, PP, HDPE, PS etc. 5.Apply to different container shapes: round, non-round, wild-mouth bottle, oval.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:00

00:00

Brief Introduction Glass bottle IV solution production line is mainly used for IV solution glass bottle of 50ml~500ml cleaning, filling, stoppering, capping etc. It can be used for the production of glucose, antibiotic, amino acid, fat emulsion, nutrient solution and biological agents and other liquids etc. Main Features 1. Bottle washing machine adopts new design, rough cleaning adopts the same direction for bottle input and output, saving operators and machine space. 2. Bottle output from rough and fine washing machine adopts twice bottle receiving, avoiding bottle reversal and broken. 3. Bottle washing machine uses intermittent rinsing, avoiding cross contamination caused by continuous rinsing. 4. Bottle input adopts the combination of bottle hook and guide plate, making the bottle input reliable and no bottle reversal. 5. Washing water can be recycled and filtered, reduce water consumption. 6. Filling adopts time and constant current theory; filling quantity can be adjusted by computer with high accuracy. 7. No bottle no filling, can realize CIP/SIP.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:34

00:34

Brief Introduction GZ-SS400-TI injection stretch blow molding machine has 3 stations of injection, stretching & blowing, and products demoulding, the products it produces get one-step formed from raw material to finished products. It can produce many kinds of containers, like IV solution bottle, oral liquid bottle, liquid medicine bottle, tablet bottle, capsule bottle, LED lamp cover, cosmetics bottle, detergent bottle, collutory bottle, milk bottle, condiment container, salad dressing container, drinking water bottle and etc. Main Features 1.Need no heating, reducing molding cycle and energy consumption. 2.Avoid possible pollution from preform station to blow station. 3.Easy replacement of the mold. 4.Apply to many kinds of materials: PC, PET, PP, HDPE, PS etc. 5.Apply to different container shapes: round, non-round, wild-mouth bottle, oval.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:00

00:00

Brief introduction & Advantage The whole production line equips with brand new online aseptic assembly and semi-finished product online inspection technology that achieve better stability, more accuracy and reliability so as to guarantee the machine keeps long term and high efficiency operation. The whole production line includes tube loading, atomization dosing, drying, stoppering & capping, vacuuming, tray loading, and etc. Easy & safe operation with individual PLC touch screen control, only need 2 workers can run the whole line well. Compared with other manufacturers, our equipment has unique features, including overall dimension is half smaller, higher automation & stability, lower fault rate and maintenance cost, and etc. Production Procedures Schematic Diagram Aseptic Environment: equipped with clean laminar flow hood and adopt with high-powered fan and HEPA, it can be operated in long term under high static pressure and keep low noise. The space cleanness can up to class 10,000 (can be optional), which is the exclusive technology in China. Tube loading: adopting with automatic tube loading technology, loading the tube into clamps automatically with detector for no tube or inverse direction tube. The machine apply for any kind of label tubes and solve the defect of the avo label broken of traditional tube loading machine from other manufacturers. Atomization Dosing: The machine adopts with a set of 5 FMI precision ceramic metering pump and 1 set of five conjoined of micro - ceramic injection pump that can dose separately for biochemical tube and anticoagulant tube (EDTA salts, heparin salt); Another set of metering pump is dosing for sodium citrate tubes. Dosing volume controlled by PLC touch screen(see parameter), the error rate is ≦ 5%, and detect for no dosing tubes during the dosing process. Compared with other companies’ machine rely on stable air supply for dosing, our technology of dosing volume will not be influenced by any factors. 3 sets of dosing system meet all kinds of blood collection tubes production, that is the exclusive and advanced technology in China. Drying: Adopting with six sets of dust-free PTC heating dryer to make the inner of products with zero pollution so as to improve the drying effect and production efficiency. Compared with traditional heating method, our machine solves the problem of temperature instability and pollution. Online Stoppering & Capping: finish the combination of stopper & cap online quickly and efficiently (apply for both type: upward and downward), and avoid the nonuniform vacuum degree when dose the tubes after the combination of stopper and cap and it may cause the stopper not seal well against tube. Detect for cap and rubber stopper and avoid the possibility of no stopper or no cap.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery