Glass Bottle IV Solution Production Line

1

Share

Features

Brief Introduction

Brief Introduction

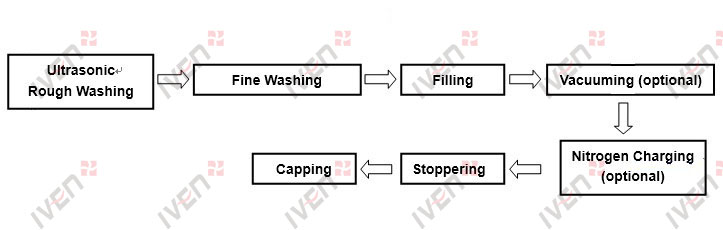

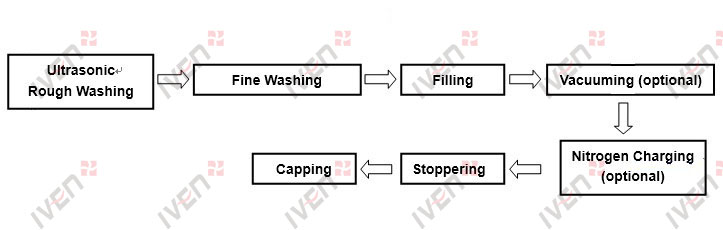

Glass bottle IV solution production line is mainly used for IV solution glass bottle of 50ml~500ml cleaning, filling, stoppering, capping etc. It can be used for the production of glucose, antibiotic, amino acid, fat emulsion, nutrient solution and biological agents and other liquids etc.

Main Features

1. Bottle washing machine adopts new design, rough cleaning adopts the same direction for bottle input and output, saving operators and machine space.

2. Bottle output from rough and fine washing machine adopts twice bottle receiving, avoiding bottle reversal and broken.

3. Bottle washing machine uses intermittent rinsing, avoiding cross contamination caused by continuous rinsing.

4. Bottle input adopts the combination of bottle hook and guide plate, making the bottle input reliable and no bottle reversal.

5. Washing water can be recycled and filtered, reduce water consumption.

6. Filling adopts time and constant current theory; filling quantity can be adjusted by computer with high accuracy.

7. No bottle no filling, can realize CIP/SIP.

Parameters

Glass bottle IV solution production line is mainly used for IV solution glass bottle of 50ml~500ml cleaning, filling, stoppering, capping etc. It can be used for the production of glucose, antibiotic, amino acid, fat emulsion, nutrient solution and biological agents and other liquids etc.

Main Features

1. Bottle washing machine adopts new design, rough cleaning adopts the same direction for bottle input and output, saving operators and machine space.

2. Bottle output from rough and fine washing machine adopts twice bottle receiving, avoiding bottle reversal and broken.

3. Bottle washing machine uses intermittent rinsing, avoiding cross contamination caused by continuous rinsing.

4. Bottle input adopts the combination of bottle hook and guide plate, making the bottle input reliable and no bottle reversal.

5. Washing water can be recycled and filtered, reduce water consumption.

6. Filling adopts time and constant current theory; filling quantity can be adjusted by computer with high accuracy.

7. No bottle no filling, can realize CIP/SIP.

Technical Parameters

| Main Items | Main Contents | |||

|---|---|---|---|---|

| Model | BPY50/500-120 | BPY50/500-200 | BPY50/500-300 | BPY50/500-600 |

| Applied Bottle Size | 50ml, 100ml, 250ml, 500ml | |||

| Production Capacity | 80-120 Bottle/min | 120-200 Bottle/min | 200-300 Bottle/min | 300-600 Bottle/min |

| Electric Capacity | 35KW | 37KW | 45KW | 55KW |

| Compressed Air Consumption | 4³/h (0.6MPa) | 5³/h (0.6MPa) | 6³/h (0.6MPa) | 7³/h (0.6MPa) |

| Water Consumption |

Tap water: 200ml/bottle Purified water: 80ml/bottle Injection water: 120ml/bottle 0.2MPa |

|||

| Overall Size(mm) | 17800×6000×2300 | 19000×6000×2300 | 24000×7000×2300 | 24000×7000×2300 |

TOP