02:25

02:25

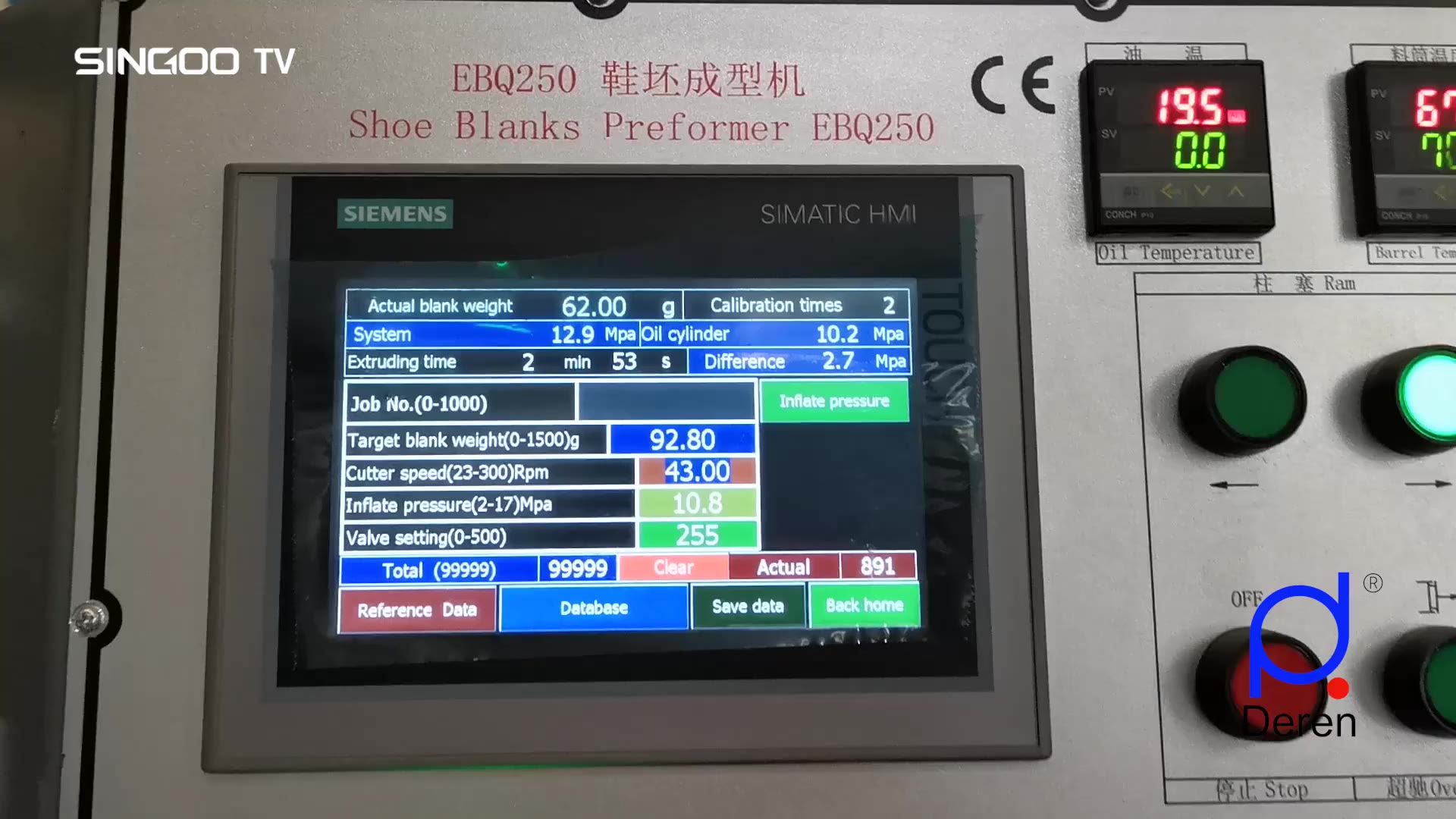

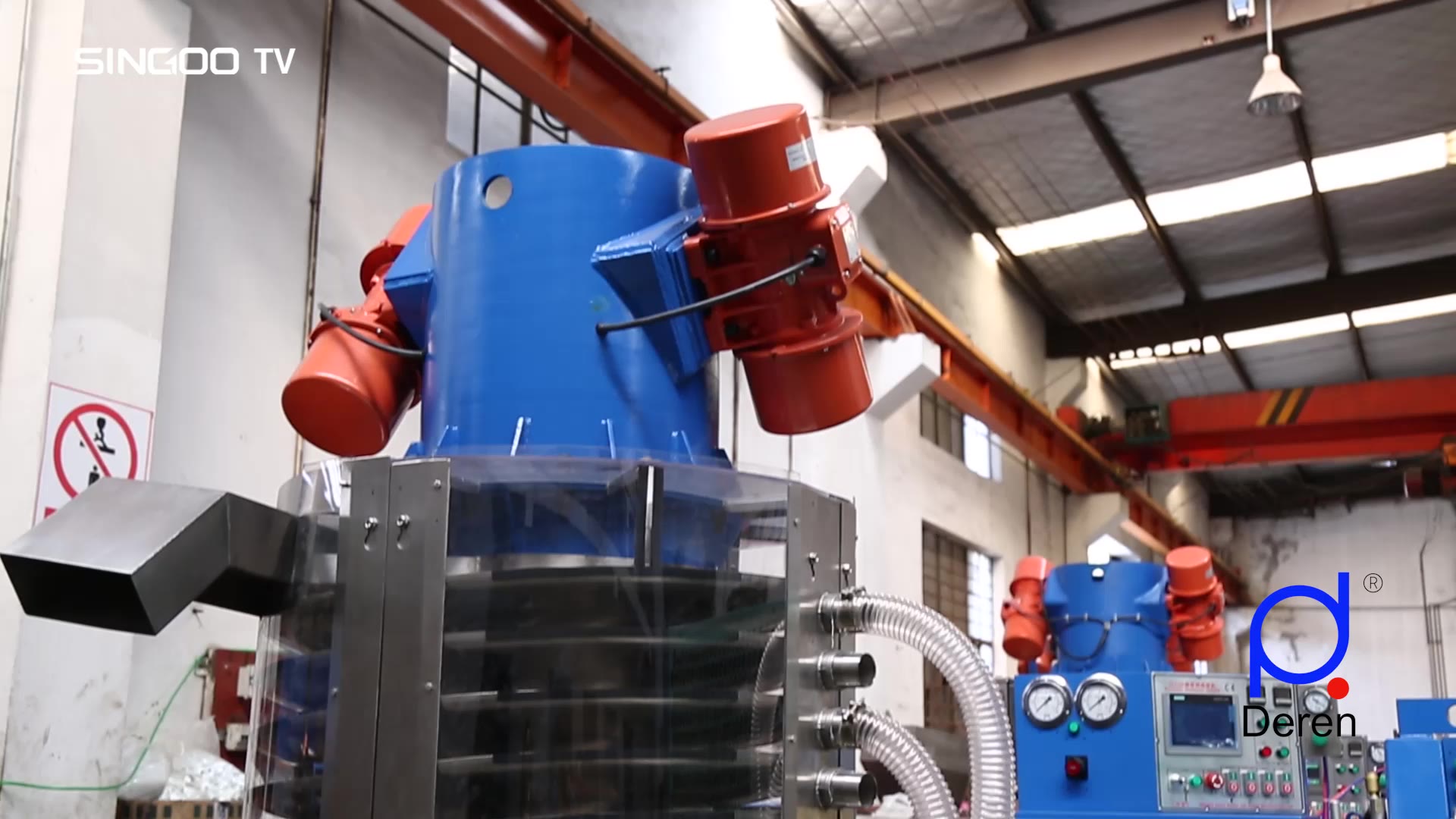

●PLC control system and touch screen operator interface. Color touch screen to input data and password protection. ●1000 products technics database available to connect anytime. ●Variable inverter controlled infinite speed regulation for cutter speed. ●Closed circuit feedback of electronic scale, one key automatic calibration of the weight of rubber blank. ●Reliable safety performance. There are interlocks when close ram head, the cutter rotates and ram moves forwards and retracts. ●Graphic and text display for failure point and cause ●Barrel adopts separated structure, Extended center, for easy cleaning. ●Reducing residual air in rubber blank by vacuum system. ●Stainless steel conveyer for reducing compound contamination. ●Accept high-end customization Technical Parameter Items Unit EBQ250 Barrel inside diameter mm 250 Max. extruding pressure MPa 17 Max. barrel temperature °C 95 Max. die diameter mm 300 Rubber weight range g 0.3~200 Rubber blank weight accuracy % ±1.0 Single feeding volume L 65 External dimension (L×W×H) m 5.08×1.25×1.64 Weight T 3.6

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 01:44

01:44

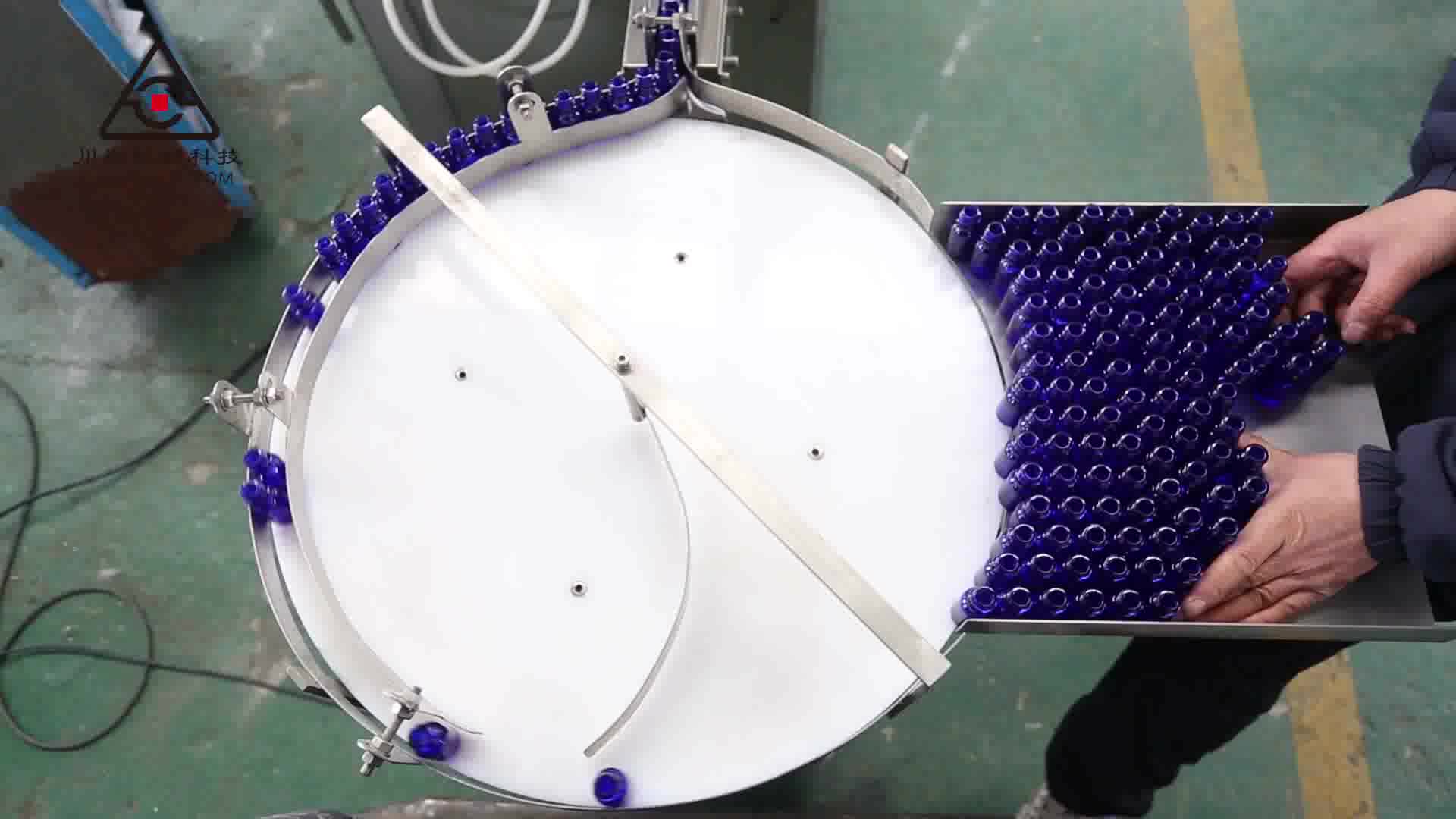

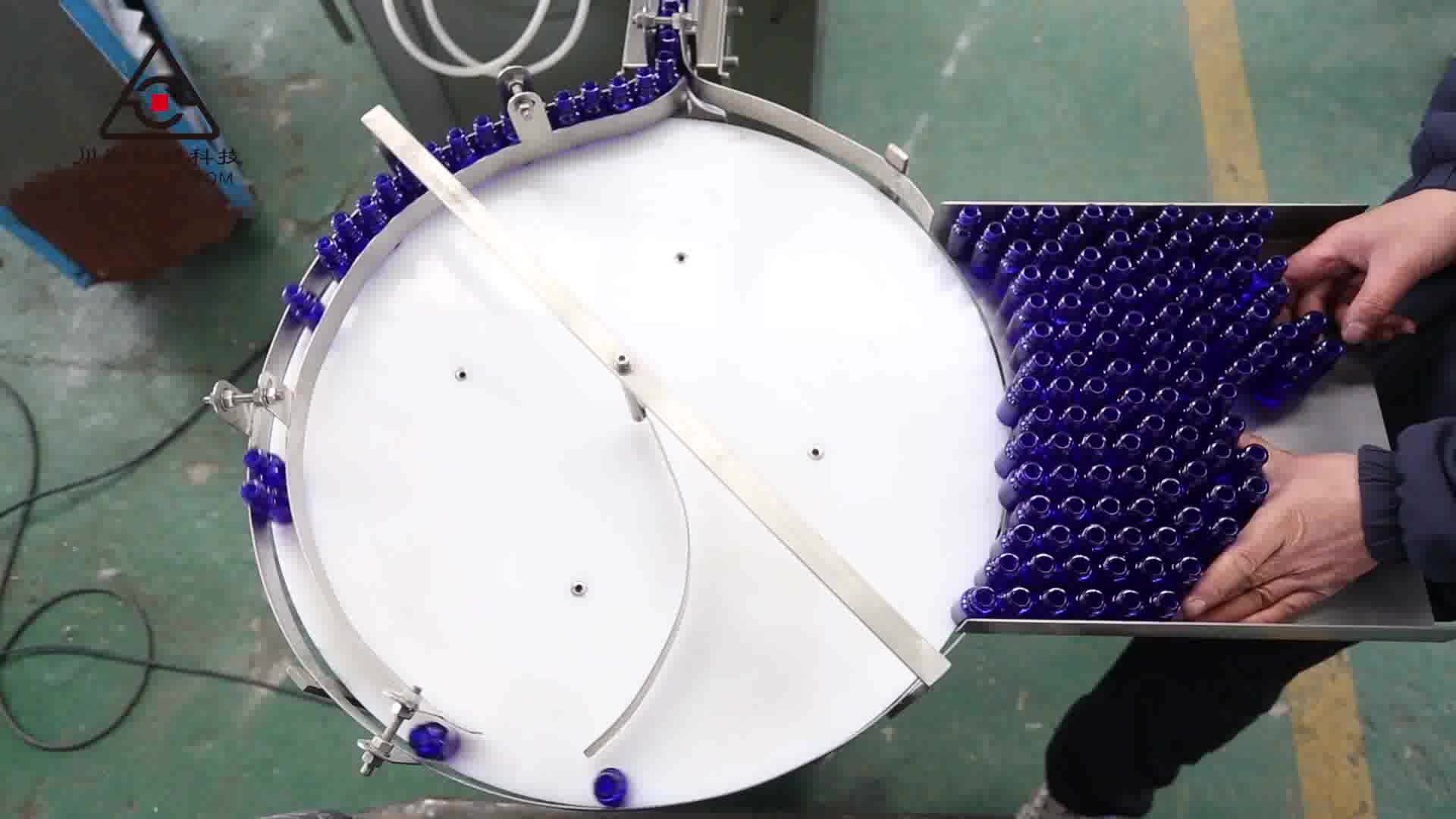

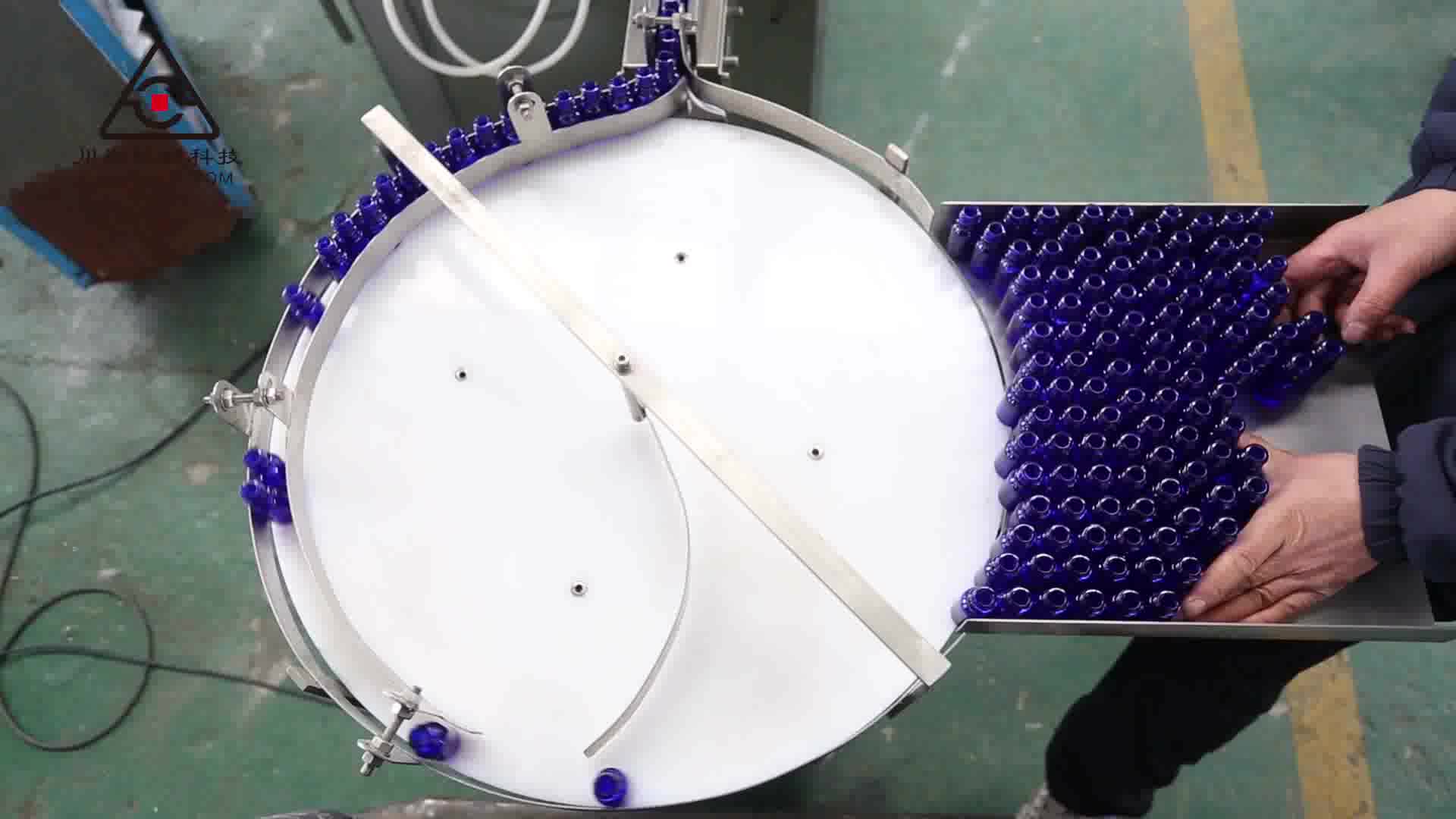

The utility model relates to an automatic molding filling machine for a plastic bottle of oral liquid, including a rack, feeding device and control system. Its characteristics are as follows: Described in the rack, in turn, is equipped with corresponding plastic molding equipment, filling equipment, the tail sealing device, cutting device and creasing device, described the feeding device, plastic molding equipment, filling equipment, sealing device, cutting device and creasing device connected with control system. The utility model has compact structure, realizes automatic operation, low manufacturing cost and high production efficiency. Instructions for installation of the filling machine for the first time film rolling forming oral liquid: 1. Stable air source of 0.5-0.7mpa is required. 2. The power supply of 220v-380v /50HZ is required to be 4.3kw. 3. The equipment shall be grounded. 4. Mould circulating cooling water. Instructions for the maintenance of the filling machine for the primary forming oral liquid of film rolling: 1. The equipment needs to be cleaned and maintained every day. 2. Add lubricating oil to all moving parts every day. 3. If there is any abnormality in the operation of the equipment, it shall be stopped for inspection. Operation instructions of the filling machine for the first time film rolling forming oral liquid: Instructions for the maintenance of the filling machine for the primary forming oral liquid of film rolling: 1. PLC control, stepless frequency conversion adjustment. 2. Seven jobs, including unwinding, plastic forming, filling, batch number printing, tail cutting, punching and cutting, etc., shall be completed automatically by the program. 3. Human-machine interface device, simple and clear operation. 4. The filling head shall not drip, drip, foam or overflow. 5. All the relevant parts in contact with the liquid medicine are made of high-quality stainless steel, meeting the GMP standard. 6. The main pneumatic components and the electrical appliances adopt imported parts. 7. The automatic filling system of electronic peristaltic pump and mechanical filling system are two kinds, and the accurate measurement error is small. Main technical parameters of the primary film roll forming oral liquid irrigation machine: The maximum molding depth is 12mm Impact times: 15-25 times/min Number of filling head 5 packaging materials PVC/PE or PET/PE (0.2-0.4) * 120mm Filling capacity: 1-50ml/ piece The total power supply is 4.5kw Voltage 220v, 380v three-phase /50Hz Weight (kg) 750kg External dimension: 2300 * 850 * 1400 (mm)

Shanghai Chuan Shang Machinery Technology Co., Ltd.is a scientific research, design, production, maintenance and sales of integrated technology enterprises.Its production facilities spread all over the country and are exported to the Americas, Europe, Africa, the Middle East and other parts of the world.It relies on expertise and mature technology in the field of automation.Due to the professional level and mature technology in the field of automation, the rapid rise in the field of filling and packaging equipment。

Contact Supplier 01:44

01:44

Brief introduction CSGX-30/100 Automatic Oral&sSyrup Filling&rotation (rolling) machine is built in the absorption of foreign advanced tecnology, based on independently developed by the company ,It is the domestic leading level. This machine is suitable for oral and syrup liquid filling&capping. Widely used in food, pharmaceutical, chemical industries and scientific research.Full compliance with the GMP requirements. Characteristic ◆Human-machine interface settings, an easy and intuitive, PLC control ◆Frequency control, the production rate be adjusted automatically count ◆No bottle no filling ◆High-precision cam meter control, precise positioning ◆SUS304 and 316L stainless steel, full compliance with GMP requirements Technical Parameters Filling volume 30-150ML Loading error ≤ ±1% Rotation (rolling) Cover pass rate ≥99% Production capacity 30-60 bottles / min 70-100 bottles / min Power 380V/50Hz Power 2.0 kw Net weight 600 kg Dimension 2000*1000*1500mm

Shanghai Chuan Shang Machinery Technology Co., Ltd.is a scientific research, design, production, maintenance and sales of integrated technology enterprises.Its production facilities spread all over the country and are exported to the Americas, Europe, Africa, the Middle East and other parts of the world.It relies on expertise and mature technology in the field of automation.Due to the professional level and mature technology in the field of automation, the rapid rise in the field of filling and packaging equipment。

Contact Supplier 01:44

01:44

Brief Introduction It’s just for 10-20ML oral filling&sealing, a major machine in production line for oral liquid, it main used in filling, capping placing and sealing of straight tube bottle. Tracking filling, cap automatically conveying by electromagnetic oscillator, three knifes centrifugal sealing (or screwing), no bottle no filling. Filling and sealing integrated in one machine, advanced design, compact structure and completely comply with requirement of GMP.this kind of machine . Characteristic ◆All elements is well know brand. ◆Direct viewing operation, no bottle nofilling, measuring accurate. ◆Three knifes centrifugal sealing, ensure firm and beauty. ◆The whole machine is designed according to the requirements of GMP Technical Parameters Model CS-4 10/20 Cutting dimension 10-20Ml Production 60-90 bottles/min Filling accuracy ≥99% Power Supply 380V 50Hz Damaged Rate ≥99% Power 1.5KW Weight 450KG Boundary dimension 1400 *1200*1600mm

Shanghai Chuan Shang Machinery Technology Co., Ltd.is a scientific research, design, production, maintenance and sales of integrated technology enterprises.Its production facilities spread all over the country and are exported to the Americas, Europe, Africa, the Middle East and other parts of the world.It relies on expertise and mature technology in the field of automation.Due to the professional level and mature technology in the field of automation, the rapid rise in the field of filling and packaging equipment。

Contact Supplier 02:01

02:01

This equipment is dedicated to the silicone conductive tube, conductive strip production. Basic principle is to use ram extruder to extrude rubber compound, and cured directly in the process of extrusion. Two equipments are extruding at the same time for conductive resin of different materials and double materials tube of non-conductive resin. This equipment adopts the ration accuracy control extrusion speed to ensure stable quality. Features: 1. Without staff supervision, extrusion speed absolute stable, ensure the quality stable. 2. Extrusion speed precision display can be corrected randomly. Classifications of four generations of ram extruder method Performance/model Extrusion speed adjustment method Extrusion speed advantages and disadvantages of display Products quality 1st generation Extrusion speed adjusted by extrusion pressure Rough display Extrusion speed is unstable with the increase of extrusion friction speed slow unstable, Most used currently 2nd generation Extrusion speed adjusted by hydraulic system flow Rough display Extrusion speed is relatively stable but accurate correction speed is more difficult Lack of stability, Most used currently 3rd generation Extrusion speed adjusted by hydraulic system flow Precise display Extrusion speed stability, such as error is to call the police. And precise adjustment Quailed, but need manual adjustment 4th generation Extrusion speed adjusted by hydraulic system flow Precise display and Automatic correction on extrusion speed Extrusion speed stability no need to adjust manually No defects Technical Parameter Item Unit JYZ80 JYZ100 Barrel inner diameter mm 80 100 Main power Kw 2 2 Curing unit power Kw 1.6 1.6 Max. extrusion pressure Mpa 35 35 Curing temperature ℃ 350 350 Extrusion precision % ±1.0 ±1.0 Single feed volume L 2 5 External dimension (L*W*H) m 1.75×0.76×1.7 2.9×1.2×1.7 Weight t 1.2 2.2 Cooling water flow L/min 10 10

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 02:30

02:30

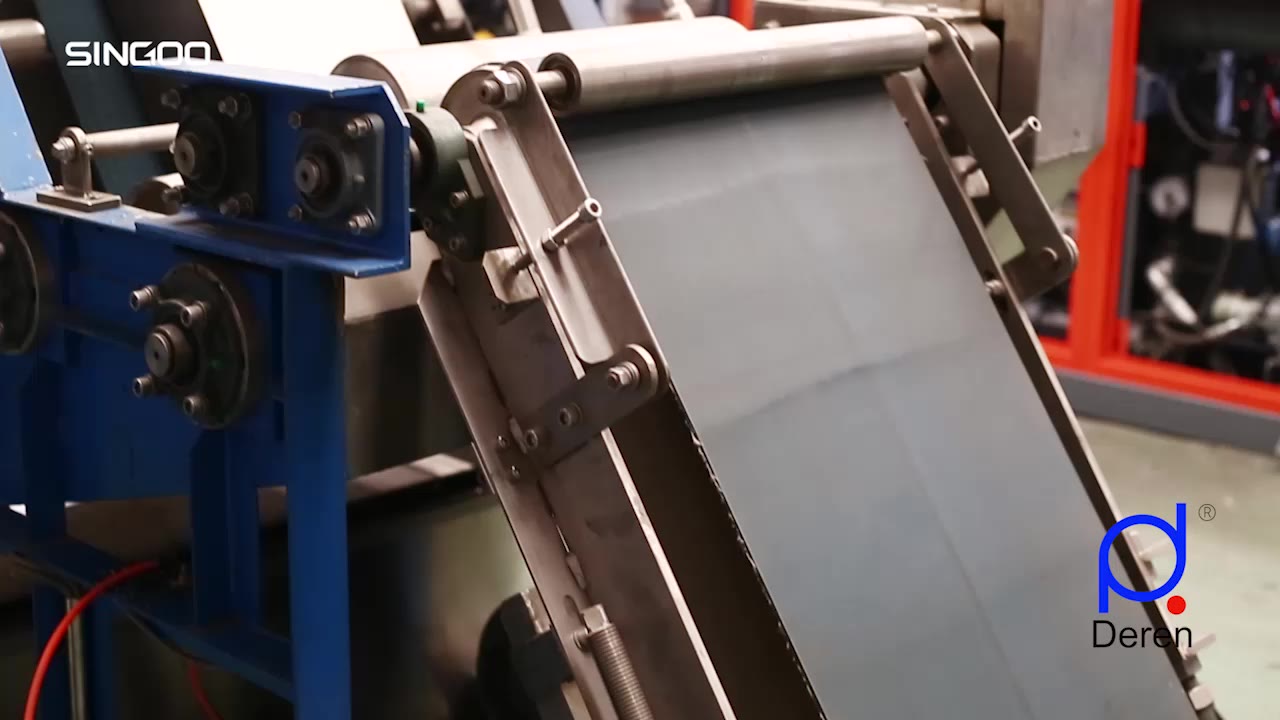

LSS-Q800 clean-up & auto-weighing water cooling conveyer is a downstream machine of precision preformer which is to cool, convey, dry, weigh and sort rubber compounds into charging-basket. Rubber compounds cut by precision preformer can be sorted into charging-baskets after dipped into water, conveyed, dried then delivered by cross belt conveyer. When the rubber compounds reach the set weight, the cross belt conveyer will stop running, the basket-pushed device will change this full charging-basket with an empty one automatically, and cross belt conveyer will run again to fulfill the functions of auto-weighing, automatic basket-sorting and automatic basket-changing. Meanwhile, full charging basket will be delivered to roller conveying line, and then operating personnel can deal with it. Water-dipping device facilitates to cool down the rubber compound and to avoid polluted by kinds of rubber chippings mutually. There is a charging-basket for remaining compounds which is easy to take out and clean up. When there is no rubber compound on the cooling conveyer, it will stop after 5 minutes’ automatic dry run. Technical Parameters: Conveying length: 1.5m Automatic basket-changing device will be customized as per charging-basket external dimension. 1.Water-dipping conveying net belt speed: 4~8m/min (infinite speed regulation) Conveying length: 1.5m 2.Slope conveying net belt speed: 3~6m/min (infinite speed regulation) Conveying length: 3.0m 3.Horizontal conveying net belt speed: 1.5~3m/min (infinite speed regulation) Conveying length: 4.0m 4.&=1.5mm stainless steel net belt, belt width: 300mm 5.Weight range for rubber compounds in charging-basket: 10~20kgs/basket(adjustable) customized accordingly if outside this range 6.Whole unit Max. Overall dimension (L*W*H) 9*2.4*2.1m 7.Weight: 1.0 T 8.Select matching charging-basket dimension: Charging-basket base L*W : (500~600)*(400~460)mm Charging-basket Height:150~170mm Automatic basket-changing device will be customized as per charging-basket external dimension. Mainframe Configuration: Program control system adopts MISUBISHI PLC, OMRON Photoelectric Sensors, Schneider breaker, SIEMENS AC Contactor, MISUBISHI Frequency Converter.

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 01:15

01:15

The water cooling conveyer is an auxiliary machine of the precision preformer to avoid stickiness and deformation of the rubber blanks. After cooling down with cooling water or cooling solution, and then with forcible cooling wind, the rubber blanks will become dry and stable. The feature of the machine is the running speed can be adjusted by the stainless steel net curtain during the whole process, to go with all the cutting speeds of the preformer. Technical Parameter Item Name Unit LSS650 LSS650P Sloping conveying Stainless steel Conveying width mm 450 450 Distance of blank conveying in water mm 700 1700 Speed of sloping conveying m/min 8.3 8.3 Volume of cooling wind m3/h 1620 1620 Speed of sloping conveying(Unadjustable) m/min 2.5 2.5 Sloping conveying (contacted with blank) is stainless steel Conveying width mm 380 380 Horizontal conveying(Adjustable) m/min 1.6~3.2 1.6~3.2 Layers 3 3 Whole unit (L×W×H)Water tank dimension m 1.46×0.8×0.27 2.46×0.8×0.27 Volume of cooling wind m3/h 10320 10320 (L×W×H) Overall dimension m 5.35×0.75×1.84 6.35×0.8×1.84 Total power KW 1.8 2.3 Weight T 1.2 1.8 1.This is an auxiliary machine of the precision preformer to avoid stickiness and deformation of the rubber blank. After cooling down with cooling water or cooling solution,and then with forcible cooling wind,the rubber blank will become dry and stable. 2.The part of the machine which directly contact rubber blanks is made of stainless steel. 3.Running speed can be adjusted. 4.Suitable for water cooling or the use of liquid release agent,and larger size products 5.The sink part uses the lever principle,easy separate the tank,in order to achieve rapid cleanup of the tank when replacing compound. 6.Optional: Chiller.

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 01:44

01:44

1.This is auxiliary machine of the precision preformer to avoid stickiness and deformation of the rubber blanks,the part of the machine which directly contact rubber blanks is made of stainless steel. 2.Small floor space,saving space 3.Suitable for liquid release agent,powder release agent or derect air -cooling. 4.Applicable to FKM,NBR,CR,EPDM and other rubber compounds,and granulation,bearing seals,oil seals,O-rings,Ling strips,Flakes of various kinds of blank. 5.Reasonble design,line hidden inside,connect all the parts of the machine with an aviation plug,easy to disassembly and installation. Technical Parameter Items Unit LSZ1050-L LSZ1200-L Groove diameter mm 1050 1200 Groove width mm 240 315 Groove height mm 1600 1600 Material running distance mm 35000 50000 Helical pitch mm 110 110 Width of inlet mm 650 650 Height of inlet (From the ground level)mm mm 300 300 Width of outlet mm 245 245 Height of outlet (From the ground level) mm 1650 650 Conveying Speed (adjustable) m/min 6~8 6-8 Motor power kw 0.75*2 1.1*2 Motor power for cooling fan kw 3.7 3.7 Wind inlet temp. Of refrigeration ℃ <8 <8 Power of dimension Kw 5~7 5-7 External Dimension (LXWXH) m 2.15*1.35*2.56 3*1.5*2.56 Total weight T 1.7 2.0

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 00:29

00:29

Vibrating Cooling Conveyor is an auxiliary machine of the precision preformer to avoid stickiness and deformation of the rubber blanks.The part of the machine which directly contact rubber blanks is made of stainless steel. Rubber blank travelles through vibrating method,avoid the stickiness and deformation,the long cooling stroke,max.travel stroke upto 50 meter,cool down fully and the dry effect is prominent. Operator can adjust the vibrating frequency manually,applied for the wide range of rubbr blanks. The material of machine unit is SUS304 stainless steel to avoid the corrosion, For small size rubber blanks, can be directly cooled down by wind; For the heavy weight and much heat rubber blanks, can be cooled by circulation water from external water tank to intensify the cooling effect of rubber blanks,especially with prominent effect for FKM,NBR,CR,EPDM, pelleting, bearing seals, oil seals, O-rings, rubber flakes etc. 1.This is auxiliary machine of the precision preformer to avoid stickiness and deformation of the rubber blanks,the part of the machine which directly contact rubber blanks is made of stainless steel. 2.Small floor space,saving space 3.Suitable for liquid release agent,powder release agent or derect air -cooling. 4.Applicable to FKM,NBR,CR,EPDM and other rubber compounds,and granulation,bearing seals,oil seals,O-rings,Ling strips,Flakes of various kinds of blank. 5.Reasonble design,line hidden inside,connect all the parts of the machine with an aviation plug,easy to disassembly and installation. Technical Parameter Items Unit LSZ1050 LSZ1200 Groove diameter mm 1050 1200 Groove width mm 240 400 Groove height mm 1600 1600 Material running distance mm 35000 50000 Helical pitch mm 110 110 Width of inlet mm 650 650 Height of inlet (From the ground level)mm mm 300 300 Width of outlet mm 245 245 Height of outlet (From the ground level) mm 1650 1650 Conveying Speed (adjustable) m/min 6~8 6~8 Motor power kw 0.75*2 3.7 Motor power for cooling fan kw 3.7 1.1*2 External Dimension (LXWXH) m 2.15*1.35*2.56 3*1.5*2.56 Total weight T 1.2 1.5

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 01:39

01:39

Structural features This unit has receiving and delivering, soaking and cooling, sheet hanging and cooling, hanging and conveying devices, etc. The receiving and delivering is driven by frequency conversion motor, the speed is adjustable. Soaking and cooling is through water pump to spray the cooling water (can add release agent) to the running rubber sheet; Hanging and conveying device is made up of cooling and delivering frame, hanging bar, link chain and guide rail for chain. Purpose LPX450 Hanging production line for cooling rubber sheet for rubber sheet is used to make mixing mill (screw machine) squeeze rubber sheet to cool and store. Technical Parameter Item Unit Specification Applicable rubber sheet specification mm >450 Receiving conveyer belt speed m/min 15~30 Rubber sheet hanging pole quantity pc 28 Max. height for rubber sheet hanging mm 1500 Cooling wind fan power kw 0.13kw×10 Max. power 3 phase kw 7 Soaking conveyer motor power kw 2.2 Soaking water pump power kw 0.75 Mixing motor power kw 0.4 Hanging motor power kw 2.2 External dimension (L*W*H) mm 7500×3300×2650 Total weight T 3.5

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 00:53

00:53

Traditional preform products (blanks) are produced by precision preform machines with fixed speed and precise plunger displacement control. The production process is not continuous. Because special mixers are needed to provide preheated and mixed rubber, and each batch must be re-fed, the labor intensity is considerable. Extrusion/gear pump technology was used in cold feed preform to improve the traditional rubber blank manufacturing technology. Strip cold rubber into the extruder feeding port automatically after plasticizing, preheating, and then sent to the entrance to the gear pump, the pump driven into the die, the die of the rotating cutter will cut into the required size, rubber in the system, the use of gear pump technology for extrusion efficiency and product precision provides important guarantee. Gear pump inside the rotor and bearings have been tested for many years proved very reliable, without frequent replacement. The control part of the system is a special PLC. Pressure sensors are installed at the inlet and outlet of the gear pump to ensure that the pressure at the inlet of the gear pump is maintained at a certain level. In addition, the extrusion speed can be controlled by adjusting the inlet pressure of the gear pump, so that the rubber compound can be injected into the gear pump stably under the required pressure conditions. Technical Description of DRL Series Cold Feed Rubber Precision Preformer 1 Cold Feed Precision Preformer is to cut the mixing rubber into the shape and weight required by customers. The weight accuracy of blank is controlled within ±1%. 2 PLC control, process parameter storage, direct data call instruction, easy operation. 3 The screw and barrel are electric disengaging from the structure, which can effectively reduce the labor intensity, facilitate the replacement of rubber and facilitate the cleaning. 4 Conveyor net cover and conveyor adopt stainless steel material to prevent rubber pollution. 5 Electronic scale closed circuit feedback, one key to calibrate the weight of rubber blank. 6 Equipment fault alarm and icon display fault location, regularly remind workers to spot check and calibrate the weight of the rubber blanks. 7 The machine head, cutting knife and other devices are interlocked, and all-round protection is provided to effectively avoid the occurrence of work-related injuries. 8 Searchlight with the machine head, easy to clean, to avoid the situation of bad cleaning corner. 9 The system pressure and extrusion pressure are displayed digitally on the touch screen. 10 When the new product is trial-produced, the PLC operation provides reference data to further simplify the operation process. 11 All machine heads are sealed with stainless steel to prevent rubber from spilling on the ground (polluting the environment, waste of rubber, etc.). 12 Continuous process and high production efficiency: DRL cold feeding preformer can input strip rubber uninterruptedly to produce high-precision blank, so it does not need to consume manpower to continuously add material.Because of continuous production, there is no unqualified rubber blank in the start-up and shutdown stages of hydraulic precision pre-forming machine, which reduces material loss and greatly improves production efficiency.Because of the continuous production, there is no unqualified rubber blank produced under the start-up and shutdown stages of hydraulic precision preformer, which reduces material loss and greatly improves production efficiency. Technical Parameter Items Unit DRL75 DRL90 DRL120 Screw diameter mm 75 90 120 Draw Ratio of Screw L/D 12:1 12:1 12:1 Screw rotation speed Rpm 6-60 6-60 6-60 Speed of gear pump Rpm 4-50 4-50 4-50 Cutter speed Rpm 23-400 23-400 23-400 Total power KW 45 55 75 Maximum extrusion pressure MPa 35 35 35 Temperature Controlled by Mould Temperature Machine °C 20-95 20-95 20-95 Max.die Diameter mm 80 125 190 Rubber blank weight range g 0.1-100 0.1-500 0.1-2000 Weight accuracy (99% compound) Percentage ≤±0.8% ≤±0.8% ≤±0.8% Filtration accuracy (99% rubber) Mesh ≤200 ≤200 ≤200 Max capacity kg/h 200 500 800 outline dimension (L×W×H) m 4.5×1.2×1.65 5.5×1.2×1.65 6.5×1.2×1.65 Machine weight t 3.5 4.8 8 Electronic Balance (Accuracy 0.01) g 300 300 300/1500 Head opening type WSAD WSAD WSAD Feeding type Cold/Hot Cold Cold Cold Electronic balance rack m 0.44×0.44×0.96 Distance between Cutter and Die mm Adjustable

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier 02:37

02:37

RS ram rubber strainer can strain various rubber compound, such as such as butadiene rubber, butyl rubber, fluorine rubber and silicon rubber and strain plastic and rubber mixture. The strain accuracy is up to 200 meshes. Compared to the screw type strainer, the compound has no temperature increase and no scorch in the whole straining process; it can strain the rubber compound after adding accelerant. It is with humanized design and easy operation, and less force to open ram head, with comprehensive safety control and impressive notice to ensure better security performance. Technical Parameter Items Unit RS150 RS200 RS250 RSH200 RSH250 Barrel inside diameter mm 150 200 250 200 250 Total power KW 14 14 17.5 17.5 17.5 Max. extruding pressure MPa 36.8 20.7 20.7 40 25/36 Max. barrel temperature °C 95 95 95 95 95 Single feeding volume L 12 25 60 25/40 60 Ouutput/h(98% of the compound type) Kg 100 200-400 300-600 300-600 500-800 Filtration Accuracy (95% of the compound type) Mesh(Max.) 300 250 250 300 300 External dimension(L×W×H) m 2.78×1.2×1.62 2.85×1.2×1.64 3.97×1.25×1.64 3.7×1.35×1.85 4.9×1.35×1.85 Weight t 2 2.17 3.2 4.1 4.5 1、Energy Conservation: More energy saving than the screw machine, the average power consumption per hour is about 7kw/h. 2、High Efficiency: The capacity of 300~900kg per hour. For example: for EPDM rubber, hardness of 60 Shore, and straining mesh size#100, then the capacity will be 600kg/h. 3、High Accuracy: with the ram to force through forward,the pressure of the standard equipment is up to 20MPa, and the high pressure equipment can reach 40MPa,It is mainly used of EPDM/NBR/FKM and other common rubber material, and maximum straining accuracy is up to mesh#300. The straining accuracy can reach mesh#500 for silicon rubber.This machine has higher straining accuracy. compared with the screw machine. 4、Stabilization: The ram push forward process is not heating-up compared with the screw extrusion,It is can adding vulcanizing agent and other rubber accelerant for straining,to stop rubber scorching of thing ever happening. 5、Convenient: The barrel adopts separated structure,center extended,It is easy to clean, easy to replace the rubber, no clean dead Angle; 6、Safety: Reliable control system and interlock device ,avoiding work injury. 7、PLC and touch screen control ,can store process parameter to make it convenient for extracting at any times ,and low requirement for the operators.

Shanghai Deren Rubber And Plastic Machinery Co., Ltd. specializes in the production of rubber precision preformer and cooling conveyor. more than 2600 foreign and domestic rubber products manufacturers and more than 20 domestic research institutes.Covering an area of 12000 square meters, relying on its strong economic and technical advantages, with its own development and striving for many years, constantly working on rubber precision preformer technology experience step by step, has a good reputation and influence in the rubber precision preformer industry. The product has series models, quality is excellent, own the largest global market share as rubber precision preformer professional manufacturer. From 2000 to 2015, make a golden brand " Deren " throughout the15 years.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery