Shanghai Chuan Shang Machinery Technology Co., Ltd.is a scientific research, design, production, maintenance and sales of integrated technology enterprises.Its production facilities spread all over the country and are exported to the Americas, Europe, Africa, the Middle East and other parts of the world.It relies on expertise and mature technology in the field of automation.Due to the professional level and mature technology in the field of automation, the rapid rise in the field of filling and packaging equipment。

-

Film roll forming oral liquid filling machine

The utility model relates to an automatic molding filling machine for a plastic bottle of oral liquid, including a rack, feeding device and control system. Its characteristics are as follows: Described in the rack, in turn, is equipped with corresponding plastic molding equipment, filling equipm

2 -

The automatic one-piece wrapping machine

Product Introduction The automatic one-piece wrapping machine is the latest independently-developed automatic machine, it is developed on the basis of foreign advanced technologies. This machine has the following distinctive features in packing methods compared to the traditional way.

- Contacter: 董方可经理

- Tel: 0086-021-59150868

- Fax: 0086-021-59155956-805

- Email: shchuanshang@126.com

-

Company Address:

no. 88, lane 919, jiaxin road, malu industrial park, jiading district, Shanghai

Film roll forming oral liquid filling machine

The utility model relates to an automatic molding filling machine for a plastic bottle of oral liquid, including a rack, feeding device and control system. Its characteristics are as follows:

Described in the rack, in turn, is equipped with corresponding plastic molding equipment, filling equipment, the tail sealing device, cutting device and creasing device, described the feeding device, plastic molding equipment, filling equipment, sealing device, cutting device and creasing device connected with control system. The utility model has compact structure, realizes automatic operation, low manufacturing cost and high production efficiency.

Instructions for installation of the filling machine for the first time film rolling forming oral liquid:

1. Stable air source of 0.5-0.7mpa is required.

2. The power supply of 220v-380v /50HZ is required to be 4.3kw.

3. The equipment shall be grounded.

4. Mould circulating cooling water.

Instructions for the maintenance of the filling machine for the primary forming oral liquid of film rolling:

1. The equipment needs to be cleaned and maintained every day.

2. Add lubricating oil to all moving parts every day.

3. If there is any abnormality in the operation of the equipment, it shall be stopped for inspection.

Operation instructions of the filling machine for the first time film rolling forming oral liquid:

Instructions for the maintenance of the filling machine for the primary forming oral liquid of film rolling:

1. PLC control, stepless frequency conversion adjustment.

2. Seven jobs, including unwinding, plastic forming, filling, batch number printing, tail cutting, punching and cutting, etc., shall be completed automatically by the program.

3. Human-machine interface device, simple and clear operation.

4. The filling head shall not drip, drip, foam or overflow.

5. All the relevant parts in contact with the liquid medicine are made of high-quality stainless steel, meeting the GMP standard.

6. The main pneumatic components and the electrical appliances adopt imported parts.

7. The automatic filling system of electronic peristaltic pump and mechanical filling system are two kinds, and the accurate measurement error is small.

Main technical parameters of the primary film roll forming oral liquid irrigation machine:

The maximum molding depth is 12mm

Impact times: 15-25 times/min

Number of filling head 5 packaging materials

PVC/PE or PET/PE (0.2-0.4) * 120mm

Filling capacity: 1-50ml/ piece

The total power supply is 4.5kw

Voltage 220v, 380v three-phase /50Hz

Weight (kg) 750kg

External dimension: 2300 * 850 * 1400 (mm)

Film roll forming oral liquid filling machine

The utility model relates to an automatic molding filling machine for a plastic bottle of oral liquid, including a rack, feeding device and control system. Its characteristics are as follows:

Described in the rack, in turn, is equipped with corresponding plastic molding equipment, filling equipment, the tail sealing device, cutting device and creasing device, described the feeding device, plastic molding equipment, filling equipment, sealing device, cutting device and creasing device connected with control system. The utility model has compact structure, realizes automatic operation, low manufacturing cost and high production efficiency.

Instructions for installation of the filling machine for the first time film rolling forming oral liquid:

1. Stable air source of 0.5-0.7mpa is required.

2. The power supply of 220v-380v /50HZ is required to be 4.3kw.

3. The equipment shall be grounded.

4. Mould circulating cooling water.

Instructions for the maintenance of the filling machine for the primary forming oral liquid of film rolling:

1. The equipment needs to be cleaned and maintained every day.

2. Add lubricating oil to all moving parts every day.

3. If there is any abnormality in the operation of the equipment, it shall be stopped for inspection.

Operation instructions of the filling machine for the first time film rolling forming oral liquid:

Instructions for the maintenance of the filling machine for the primary forming oral liquid of film rolling:

1. PLC control, stepless frequency conversion adjustment.

2. Seven jobs, including unwinding, plastic forming, filling, batch number printing, tail cutting, punching and cutting, etc., shall be completed automatically by the program.

3. Human-machine interface device, simple and clear operation.

4. The filling head shall not drip, drip, foam or overflow.

5. All the relevant parts in contact with the liquid medicine are made of high-quality stainless steel, meeting the GMP standard.

6. The main pneumatic components and the electrical appliances adopt imported parts.

7. The automatic filling system of electronic peristaltic pump and mechanical filling system are two kinds, and the accurate measurement error is small.

Main technical parameters of the primary film roll forming oral liquid irrigation machine:

The maximum molding depth is 12mm

Impact times: 15-25 times/min

Number of filling head 5 packaging materials

PVC/PE or PET/PE (0.2-0.4) * 120mm

Filling capacity: 1-50ml/ piece

The total power supply is 4.5kw

Voltage 220v, 380v three-phase /50Hz

Weight (kg) 750kg

External dimension: 2300 * 850 * 1400 (mm)

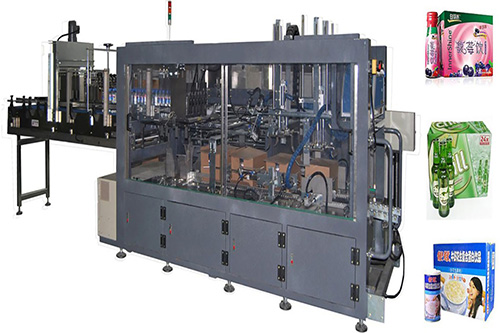

The automatic one-piece wrapping machine

Product Introduction

The automatic one-piece wrapping machine is the latest independently-developed automatic machine, it is developed on the basis of foreign advanced technologies. This machine has the following distinctive features in packing methods compared to the traditional way.

The machine features

●Arch-type structure that has the function of anti-vibration and excellent mechanical property.

●Excellent protection function for products. Such as damp-proof, heat- dissipation, easy-movement, etc.

●Low transportation cost, and easy implement of mechanization and automation of packing and transportation.

●Easy alteration of dimension and size, it can quickly adopt to packing of all kinds of products.

●Easy sealing and strapping, easy to automatic operation.

●Application to embellish and pressing of all types of cartons, it can easily resolve the issue of product protection and sales promotion.

●Easy recycling and reusing of waste cartons, fitting the environmental requirements.

●Application range can greatly expand through combination with various covers or damp-proof material.

●The nice packing effect improves the product grade and appearance.

In current domestic production, most of the regulate bottle, box and cube products adopt traditional corrugated case packing which has been widely accepted by public. Except for high-speed beer production in large scale, almost all of the mid and low-speed packing industry still adopt the following production process: cardboard die cutting→nailing→bottom sealing→packing→sealing. The wrapping machine can finish all the processes alone, greatly reduces the equipment quantity and costs, the space occupation, and transportation contradictions at all levels. The labor can reduce 7~9 persons, the labor management is more simply; the packing appearance is tidy and nice; there is no gap between the products in the carton, so after wrapping it is tight and firm; the cardboard material reduces about 20%.

Advantages: Reducing labor intensity and quantity, reducing production process, a more excellent comprehensive performance index and economic benefits, has been widely accepted by the society, is an upgradation of the traditional packing method and an inevitable development trend.

●Cost saving: Saves about 15% cardboard area compared with manual cardboard, reducing the carton cost by reducing raw material.

●Labor saving: Sucking, feeding, forming and folding are all automatically finished, which completely replace the manual processes of opening, packing and sealing.

●Environment-friendly: Traditional tape sealing is replaced by hot melt adhesive sealing, which meets the requirements of environment protection and sanitation, and the packing appearance is tidy and nice. This machine is an auxiliary equipment applies

●To beer and white wine production, it can finish the last packing procedure of the production line. What’ s more, it can also apply to packing of all kinds of carton-packed products, such as cigarette, soap, instant noodle, canned beverage, ink, jelly, etc.

技术参数

Model

CSGB -01

Power Supply

220V/380V 50/60HZ 8KW

Control Power

DC24V

Carton Application

L200-350*W300-450*H100-300mm

Nozzle Air Pressure

0.4Mpa

Packing Speed

12-15 Cartons/Minute;

Mid-speed type 15-20 Cartons/Minute

Adhesive Consumption

≤4g/Carton

Table Height

750±50mm

Adhesive Temperature

170℃±5℃

Air Source

6-7kg

Adhesive Curing Time

1.5S~2.5S

Dimension

6000*2200*1900mm(L*W*H)

Weight

2200kg

The automatic one-piece wrapping machine

Product Introduction

The automatic one-piece wrapping machine is the latest independently-developed automatic machine, it is developed on the basis of foreign advanced technologies. This machine has the following distinctive features in packing methods compared to the traditional way.

The machine features

●Arch-type structure that has the function of anti-vibration and excellent mechanical property.

●Excellent protection function for products. Such as damp-proof, heat- dissipation, easy-movement, etc.

●Low transportation cost, and easy implement of mechanization and automation of packing and transportation.

●Easy alteration of dimension and size, it can quickly adopt to packing of all kinds of products.

●Easy sealing and strapping, easy to automatic operation.

●Application to embellish and pressing of all types of cartons, it can easily resolve the issue of product protection and sales promotion.

●Easy recycling and reusing of waste cartons, fitting the environmental requirements.

●Application range can greatly expand through combination with various covers or damp-proof material.

●The nice packing effect improves the product grade and appearance.

In current domestic production, most of the regulate bottle, box and cube products adopt traditional corrugated case packing which has been widely accepted by public. Except for high-speed beer production in large scale, almost all of the mid and low-speed packing industry still adopt the following production process: cardboard die cutting→nailing→bottom sealing→packing→sealing. The wrapping machine can finish all the processes alone, greatly reduces the equipment quantity and costs, the space occupation, and transportation contradictions at all levels. The labor can reduce 7~9 persons, the labor management is more simply; the packing appearance is tidy and nice; there is no gap between the products in the carton, so after wrapping it is tight and firm; the cardboard material reduces about 20%.

Advantages: Reducing labor intensity and quantity, reducing production process, a more excellent comprehensive performance index and economic benefits, has been widely accepted by the society, is an upgradation of the traditional packing method and an inevitable development trend.

●Cost saving: Saves about 15% cardboard area compared with manual cardboard, reducing the carton cost by reducing raw material.

●Labor saving: Sucking, feeding, forming and folding are all automatically finished, which completely replace the manual processes of opening, packing and sealing.

●Environment-friendly: Traditional tape sealing is replaced by hot melt adhesive sealing, which meets the requirements of environment protection and sanitation, and the packing appearance is tidy and nice. This machine is an auxiliary equipment applies

●To beer and white wine production, it can finish the last packing procedure of the production line. What’ s more, it can also apply to packing of all kinds of carton-packed products, such as cigarette, soap, instant noodle, canned beverage, ink, jelly, etc.

技术参数

Model

CSGB -01

Power Supply

220V/380V 50/60HZ 8KW

Control Power

DC24V

Carton Application

L200-350*W300-450*H100-300mm

Nozzle Air Pressure

0.4Mpa

Packing Speed

12-15 Cartons/Minute;

Mid-speed type 15-20 Cartons/Minute

Adhesive Consumption

≤4g/Carton

Table Height

750±50mm

Adhesive Temperature

170℃±5℃

Air Source

6-7kg

Adhesive Curing Time

1.5S~2.5S

Dimension

6000*2200*1900mm(L*W*H)

Weight

2200kg

Automatic Cartoning Machine

The CS-280Z automatic cartoning machine is a high-technology carton packing equipment, it has been widely used for boxes packing in medicine, food, daily necessities, hardware, electronics, toys, auto. parts and other industries. With automatic goods feeding, box opening, goods encasing, box NO. Printing, box sealing and scrap rejecting, the machine can be easily operated and reduce labor costs for customers. The machine can work well as independent, and also can operate with other packing machines to be as a packing machine line.

Main performances and structure features

1.With automatic goods feeding, box opening, goods encasing, box NO. Printing, box sealing and scrap rejecting, the machine can be easily operated, running smoothly and low noisy.

2.With VFD speed controlling, tough screen and PLC controlling system, the machine must be high efficiency and energy saving.

3.With electrical appliances and pneumatic components of the world’s top brands, the machine will be more stable working performance.

4.With overload protection device, the machine can ensure itself and workers more safer.

5.With the automatic detection and tracking system, the machine will reject the non-goods or non-leaflet packages.

6.With the alarm system for mechanical defects, it will be much easier to maintain the machine.

7.According to customer’s requirement, the hot melt glue machine can be equipped to seal the boxes.

8.Running well as independent, the machine also can operate with the pillow packaging machine, labeling machine, heat-shrink packing machine or other machines to be as a packing machine line.

Automatic Cartoning Machine

The CS-280Z automatic cartoning machine is a high-technology carton packing equipment, it has been widely used for boxes packing in medicine, food, daily necessities, hardware, electronics, toys, auto. parts and other industries. With automatic goods feeding, box opening, goods encasing, box NO. Printing, box sealing and scrap rejecting, the machine can be easily operated and reduce labor costs for customers. The machine can work well as independent, and also can operate with other packing machines to be as a packing machine line.

Main performances and structure features

1.With automatic goods feeding, box opening, goods encasing, box NO. Printing, box sealing and scrap rejecting, the machine can be easily operated, running smoothly and low noisy.

2.With VFD speed controlling, tough screen and PLC controlling system, the machine must be high efficiency and energy saving.

3.With electrical appliances and pneumatic components of the world’s top brands, the machine will be more stable working performance.

4.With overload protection device, the machine can ensure itself and workers more safer.

5.With the automatic detection and tracking system, the machine will reject the non-goods or non-leaflet packages.

6.With the alarm system for mechanical defects, it will be much easier to maintain the machine.

7.According to customer’s requirement, the hot melt glue machine can be equipped to seal the boxes.

8.Running well as independent, the machine also can operate with the pillow packaging machine, labeling machine, heat-shrink packing machine or other machines to be as a packing machine line.

Automatic heat shrinkable film packaging machine (pure film)

Product Presentation

Chuangshang, since the development of China since the first heat shrinkable film packaging machine, heat shrinkable film packaging machine has more than ten years development course. Automatic heat shrinkable film packaging machine is a kind of continuous roll film, cut the length of the film, to the plastic film as required by the vacuum adsorption at the bottom of the slope to a group of container, the container will move on at the same time by the rotary rod plastic film package container, and overlap to a container at the end of the film super head of plastic film, and then wrapped in plastic containers are fed into the heating membrane channel, and finally form the membrane bag products automated packaging equipment. Including container feed, container groupings device, roller device, cutting film system, membrane transport and shrinkable film winding and thermal shrinkage furnace. Can packaging containers of different.

Packing Process

Technological Superiority

1、reducing investment cost

2、A faster return on investment

3、High quality and advanced equipment, USES the international general parts

4、Advanced pre-cut membrane device and energy saving heat shrinkable film channe

5、Reliable product channel input, bottle, film conveying system.

6、To expand production, reduce material waste, improve the yield

7、The application of equipment is flexible, high elasticity, easy to access, easy to operate

8、Bottle type synchronous adjustment and replacement is simple, save time

9、User friendly operation interface.

10、User friendly operation interface.

Automatic heat shrinkable film packaging machine (pure film)

Product Presentation

Chuangshang, since the development of China since the first heat shrinkable film packaging machine, heat shrinkable film packaging machine has more than ten years development course. Automatic heat shrinkable film packaging machine is a kind of continuous roll film, cut the length of the film, to the plastic film as required by the vacuum adsorption at the bottom of the slope to a group of container, the container will move on at the same time by the rotary rod plastic film package container, and overlap to a container at the end of the film super head of plastic film, and then wrapped in plastic containers are fed into the heating membrane channel, and finally form the membrane bag products automated packaging equipment. Including container feed, container groupings device, roller device, cutting film system, membrane transport and shrinkable film winding and thermal shrinkage furnace. Can packaging containers of different.

Packing Process

Technological Superiority

1、reducing investment cost

2、A faster return on investment

3、High quality and advanced equipment, USES the international general parts

4、Advanced pre-cut membrane device and energy saving heat shrinkable film channe

5、Reliable product channel input, bottle, film conveying system.

6、To expand production, reduce material waste, improve the yield

7、The application of equipment is flexible, high elasticity, easy to access, easy to operate

8、Bottle type synchronous adjustment and replacement is simple, save time

9、User friendly operation interface.

10、User friendly operation interface.