02:11

02:11

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut to length line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” Our TZG series High Precision Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation. This high precision tube mill series with excellent design, selected high precision durable roller under strictly quenching , high performance cutting saw, complete machine body with heat treatment, accurate fabrication, precise assembly. The machine performance has reached the international ERW welded tube standard. This tube mill series outer diameter range can be from Φ7mm to Φ 50.8mm and wall thickness of 0.2~2.0mm,all these size tubes are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of High precision series tube mill line Model Tube O.D.(mm) Wall Thickness(mm) Speed(m/min) H.F. power(Kw) Main motor(Kw) TZG-12 φ7-16 0.2-0.5 30-100 60 15 TZG-16 φ8-25 0.3-1.0 30-90 60 22 TZG-25 φ8-30 0.4-1.3 30-90 100 37 TZG-28 φ10-38 0.5-1.5 30-80 100 45 TZG-32 φ13-50.8 0.6-2.0 20-90 100 75 Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 04:17

04:17

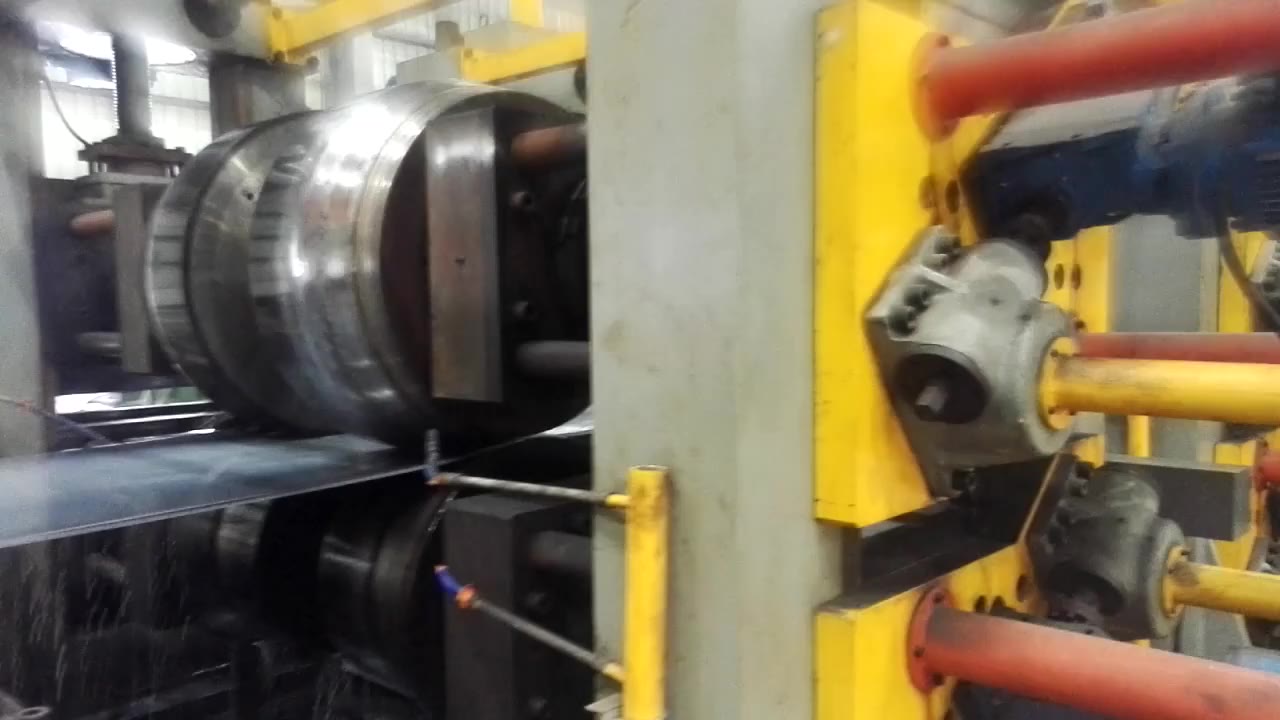

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut to length line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” Our TZG series ERW/API Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation. This ERW/API tube mill series with excellent design, selected high precision durable roller under strictly quenching , high performance cutting saw, complete machine body with heat treatment, accurate fabrication, precise assembly. The machine performance has reached the international ERW welded tube standard. This tube mill series outer diameter range can be from Φ140mm to Φ 630mm and wall thickness of 4.0~22.0mm,all these size tubes are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of ERW/API Welded tube mill line Model Tube O.D.(mm) Wall Thickness(mm) Speed(m/min) H.F. power(Kw) TZG-325 φ140-325 4.0-12.7 12-35 800 TZG-508 φ165-508 6.0-20.0 10-30 1000 TZG-630 φ273-630 6.0-22.0 6-20 1200 Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 05:49

05:49

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” TDG Series Directly Forming to Square and Rectangular Tube Mill Only one set of rollers can be continuously produced within a certain range of rectangular steel pipe, using the international advanced multi-radius combination molding process and high-frequency welding, forming by multi-channel symmetrical bending. It can be divided into small side bending, boardside bending, free bending at closed side, high frequency welding, precision straightening, produce the exact size and good quality pipe after cut off. Characteristic: ·One set mold roller can produces a range of rectangular tubes. ·This machine has characteristics such as no replace spindle, no remove roller stand and quick change rollers. ·Save mold, save time. ·Four square corner deformation part which can save extra deformation process then save energy consumption and equipment load. Specification of Directly Forming to Square and Rectangular Tube Mill SPEC TDG120X120 TDG150X150 TDG200X200 - Material to be processed Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon - Type Square & Rectangular tube Square & Rectangular tube Square & Rectangular tube Square 60 x 60 – 120 x 120 mm 70 x 70 – 150 x 150 mm 80 x 80 – 200 x 200 mm Rectangular 60 x 80 –100 x 140 mm 60 x 80 –100 x 200 mm 80 x 100 –150 x 200 mm - Wall thickness 1.5 mm – 5.0 mm 2.0 mm – 6.0 mm 2.0 mm – 8.0 mm - Tube length 6.0 m - 12.0 m 6.0 m - 12.0 m 6.0 m - 12.0 m - Line Speed Max. 45m/min Max. 40 m/min Max. 40 m/min - Welding Method Solid State High Frequency Welding Solid State High Frequency Welding Solid State High Frequency Welding - Forming Method Directly Forming to Square and Rectangular tube Directly Forming to Square and Rectangular tube Directly Forming to Square and Rectangular tube Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 04:46

04:46

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” TDG Series Directly Forming to Square and Rectangular Tube Mill Only one set of rollers can be continuously produced within a certain range of rectangular steel pipe, using the international advanced multi-radius combination molding process and high-frequency welding, forming by multi-channel symmetrical bending. It can be divided into small side bending, boardside bending, free bending at closed side, high frequency welding, precision straightening, produce the exact size and good quality pipe after cut off. Characteristic: One set mold roller can produces a range of rectangular tubes. This machine has characteristics such as no replace spindle, no remove roller stand and quick change rollers. Save mold, save time. Four square corner deformation part which can save extra deformation process then save energy consumption and equipment load. Specification of Directly Forming to Square and Rectangular Tube Mill SPEC TDG600X600 TDG500X500 TDG400X400 - Material to be processed Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon - Type Square & Rectangular tube Square & Rectangular tube Square & Rectangular tube Square 300 x 300 – 600 x 600 mm 250 x 250 – 500 x 500 mm 180 x 180 – 400 x 400 mm Rectangular 300 x400 – 500 x 600 mm 250 x350 – 300 x 500 mm 180 x200 – 300 x 400 mm - Wall thickness 6.0 mm – 22.0 mm 5.0 mm – 18.0 mm 5.0 mm – 14.0 mm - Tube length 6.0 m - 24.0 m 6.0 m - 18.0 m 6.0 m - 12.0 m - Line Speed Max. 20m/min Min.12m/min Max. 24 m/min Max. 30 m/min - Welding Method Solid State High Frequency Welding Solid State High Frequency Welding Solid State High Frequency Welding - Forming Method Directly Forming to Square and Rectangular tube Directly Forming to Square and Rectangular Directly Forming to Square and Rectangular Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 06:23

06:23

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” This HR Cut to Length Line series is applicable to coils of various specifications. It is used for the producing flattened plate through the procedure of uncoiling, flattening and cutting to required width and length. This line consists of loading cut, single pivot uncoiler, pre-leveler, hydraulic loop bridge, deviation corrector, fine leveler, servo length gauge, shear, belt conveyor, reversal discharger, stacker, discharging cart, servo transmission system, hydraulic system, etc. The machine performance has reached the international standard. This cut to length line series coil thickness range can be from 4.0mm to 25.0mm and coil width can be from 900mm to 2500mm,all these size steel coils are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of Cut To Length Line Model TLL16X2200 TLL20X2200 TLL25X2500 Material Type HR HR HR Coil Thickness(mm) 4.0-16.0 6.0-20.0 8.0-25.0 Plate Width(mm) 900-2200 900-2200 900-2500 Cutting precision(mm) ±1.0 ±1.0 ±1.0 Line Speed(m/min) 0-25 0-18 0-18 Coil Weight(T) 35 35 35 Finish Plate Length(mm) 2000-12000 2000-12000 2000-12000 Occupied Area(m) 38X10 42X11 45X11.5 Power(kw) 280 420 480

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 05:07

05:07

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” This HR Cut to Length Line series is applicable to coils of various specifications. It is used for the producing flattened plate through the procedure of uncoiling, flattening and cutting to required width and length. This line consists of loading cut, single pivot uncoiler, pre-leveler, hydraulic loop bridge, deviation corrector, fine leveler, servo length gauge, shear, belt conveyor, reversal discharger, stacker, discharging cart, servo transmission system, hydraulic system, etc. The machine performance has reached the international standard. This cut to length line series coil thickness range can be from 1.0mm to 12.0mm and coil width can be from 900mm to 2200mm,all these size steel coils are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of Cut To Length Line Model TML6X2000 TML8X2000 TML12X2200 Material Type HR HR HR Coil Thickness(mm) 1.0-6.0 2.0-8.0 3.0-12.0 Plate Width(mm) 900-2000 900-2200 900-2200 Cutting precision(mm) ±1.0 ±1.0 ±1.0 Line Speed(m/min) 0-28 0-28 0-25 Coil Weight(T) 30 30 35 Finish Plate Length(mm) 1000-6000 1000-8000 2000-12000 Occupied Area(m) 26X9 28X9 35X10 Power(kw) 110 140 220

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 06:03

06:03

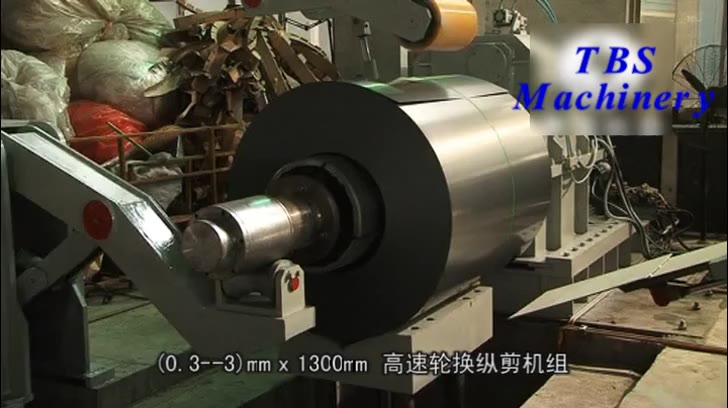

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” This line is used for coil with different specifications, through uncoiling-slitting-recoiling to needed width coil for the application of all kinds of stamping line. This line is reasonable in layout, easy operation, high level of automation, high productivity which could processing all kinds of CR and HR coil, silicon coil, stainless steel coil, colored coil, aluminum coil, galvanize coil or painted coil. This line is broadly applying in metal plate processing industry, like car, container, household appliance, packing, construction material, etc. This line is composed of coil car, uncoiler, slitter, scrap winder, shearer cutting coil head or tail, tension pad and recoiler, etc. as well as pendulum middle bridge, pinch device, steering device. This line is an auto coil processing equipment which integrate mechanical, electrical, hydraulic, pneumatic all together. The machine performance has reached the international standard. This slitting line series coil thickness range can be from 0.3mm to 3.0mm and coil width can be from 600mm to 1600mm,all these size steel coils are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of Steel Slitting Line Model THS2X1300 THS2X1600 THS3X1300 THS3X1600 Coil Thickness(mm) 0.3-2.0 0.3-2.0 0.5-3.0 0.5-3.0 Coil Width(mm) 600-1300 600-1600 600-1300 600-1600 No. of Strips 2-20 2-20 2-15 2-15 Strip Width precision(mm) ±0.1 ±0.1 ±0.15 ±0.15 Line Speed(m/min) 10-120 10-120 10-120 10-120 Coil Weight(T) 10 15 20 30 Coil I.D(mm) φ508 φ508 φ508,φ610 φ508,φ610 Recoiling I.D(mm) φ508 φ508 φ508 φ610 Main Shaft Dia(mm) φ220 φ240 φ240 φ240

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 03:25

03:25

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” HR coil slitting line is used for coil with different specifications, through uncoiling-slitting-recoiling to needed width coil for the application of all kinds field.It is consists of uncoiler, feeder, pinch, pre-leveler, cropping shear, slitter, scrap winder and recoiler, etc. It is used for slitting the wide raw coil into narrow strips in order to prepare material for subsequent processes as milling, pipe welding, cold forming, punch forming, etc. Moreover, this line can also slit various non ferrous metal coils by changing slitting tools of different materials. This line is reasonable in layout, easy operation, high level of automation, high productivity . The machine performance has reached the international standard. This slitting line series coil thickness range can be from 3.0mm to 20.0mm and coil width can be from 900mm to 2200mm,all these size steel coils are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of Coil Slitting Line Model TLS12X2200 TLS16X2200 TLS20X2200 Coil Thickness(mm) 3.0-12.0 4.0-16.0 5.0-20.0 Coil Width(mm) 900-2200 900-2200 900-2200 No. of Strips 2-7 2-5 2-3 Line Speed(m/min) 0-30 0-25 0-20 Coil Weight(T) 35 35 35 Finish Strip Width(mm) ≥80 ≥100 ≥150 Occupied Area(m) 35X11 38X11 56X11 Power(kw) 480 650 900

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 06:10

06:10

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” HR/pickling coil slitting line is used for coil with different specifications, through uncoiling-slitting-recoiling to needed width coil for the application of all kinds field.It is consists of uncoiler, feeder, pinch, pre-leveler, cropping shear, slitter, scrap winder and recoiler, etc. It is used for slitting the wide raw coil into narrow strips in order to prepare material for subsequent processes as milling, pipe welding, cold forming, punch forming, etc. Moreover, this line can also slit various non ferrous metal coils by changing slitting tools of different materials. This line is reasonable in layout, easy operation, high level of automation, high productivity . The machine performance has reached the international standard. This slitting line series coil thickness range can be from 1.0mm to 8.0mm and coil width can be from 900mm to 2000mm,all these size steel coils are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of Coil Slitting Line Model TMS6X2000 TMS8X2000 Coil Thickness(mm) 1.0-6.0 2.0-8.0 Coil Width(mm) 900-2000 900-2000 No. of Strips 2-10 2-8 Line Speed(m/min) 0-50 0-40 Coil Weight(T) 30 30 Finish Strip Width(mm) ≥50 ≥70 Occupied Area(m) 28X11 30X11 Power(kw) 320 340 Main Shaft Dia(mm) φ260 φ300

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 00:00

00:00

Product Name Copper or Alunminum Conductor Plastic Insulated Power Cable for Rated Voltage up to and Including 0.6/1KV Standard The product is manufactured according to the standards of IEC 60502 and GB/T 12706-2008 or IEC, BS, DIN, and ICEA up on repuest. Applications The product is suitable for using in power distribution networks or fixed installations for industrial equipments with rated voltage up to and including 0.6/1KV. Operating Characteristics 1. XLPE Insulated Electrical Cable for rated power frequency voltage Uo/U: 0.6/1kV. Max. Permissible continuous operating temperature of conductor: 90℃.). Max. Short-circuit temperature shall not exceed 250℃ ( 5s Max. Duration ). The ambient temperature under installation shall not below 0℃. The bending radius of a cable shall not less than 15 times of the cable diameter. 2. PVC Insulated Electrical Cable for rated power frequency voltage Uo/U: 0.6/1kV. Max. Permissible continuous operating temperature of conductor: 70℃. Max. Short-circuit temperature shall not exceed 160℃ ( 5s Max. Duration ). The ambient temperature under installation shall not below 0℃. The bending radius of a cable shall not less than 15 times of the cable diameter.

Wuxi Jiangnan Cable Co., Ltd., founded in 1985, is a National Key Hi-Tech. Enterprise, mainly manufacturing integrates wires and cables. By the end of 2015, With a floor space of more than 500,000 square meters, total built-up area of 350,000 square meters, and total assets worth above RMB 7 billion, the Company now has an employee size of 3,000-odd persons, of which, middle and high-level technical and managerial personnel with diploma of junior college or above make up more than 30 per cent of the Company’s total employees. In addition to boasting more than 1,400 sets (units) of China and the world first-class production and testing devices, the Company takes the lead in realizing whole-process dynamic monitoring and management over its logistics, capital flow, and human resources by virtue of its ERP network information management system, HER H.R. management system, and OA system, thus IT-based management in the Company comes true.

Contact Supplier 00:00

00:00

Product Name 66-500KV XLPE Power Cable Construction Standard IEC 60840 rated voltage 30KV(Um=36KV)and above to 150KV(Um=170KV)extruding insulation power cable and accessories-test meathod and requirement IEC 62067 rated voltage 150KV(Um=170KV)and above to 500KV(Um=550KV)extruded insulation power cable and accessories-test meathod and requirement Operating Environment Max admissible temperature for conductor: 90℃ under normal running condition; 250℃ under short circuit ( max. duration is 5s ) Min bending radius is recommended to be 20 times of cable overall diameter. PVC sheathed cables shall not be installed in the environment temperature is below 0 ℃, and if it is below 0℃, the cable should be heated before installation Metal sheath Cable with corrugated aluminum sheath: places where there is not much corrosion but much requirement for mechanical strength ( e.g. direct connection to transformers, laying on bridges and in certical shafts ) Plastic Outer Sheath Cable with PVC outer sheath (type02) are suitable for the high voltage cable transmission line with general fireproof requirement and somewhat insulation requirement on the outer sheath. Cables with PE outer sheath (Type03) are suitable for high voltage transmission line directly buried underground with higher insulation requirement on the outer sheath; and if they are laid in tunnels or vertical shafts, anti-fire and flame-retardant measures must be taken.

Wuxi Jiangnan Cable Co., Ltd., founded in 1985, is a National Key Hi-Tech. Enterprise, mainly manufacturing integrates wires and cables. By the end of 2015, With a floor space of more than 500,000 square meters, total built-up area of 350,000 square meters, and total assets worth above RMB 7 billion, the Company now has an employee size of 3,000-odd persons, of which, middle and high-level technical and managerial personnel with diploma of junior college or above make up more than 30 per cent of the Company’s total employees. In addition to boasting more than 1,400 sets (units) of China and the world first-class production and testing devices, the Company takes the lead in realizing whole-process dynamic monitoring and management over its logistics, capital flow, and human resources by virtue of its ERP network information management system, HER H.R. management system, and OA system, thus IT-based management in the Company comes true.

Contact Supplier 00:00

00:00

Product Name Aerial Insulated Cable for rated voltage 1kv, 10kv, 20kv, and 35kv Reference Standard The product shall comply with the standards of ASTMB231 and GB 14049-2008 and ASTMB398. Applications The product fit for transmitting line and distributing line of rated voltage 1kv, 10kv 20kv and 25kv in tall buildings ,traveling development area and wooded tract. Operating Characteristics 1. The rated voltage of cables has four classes: 1kv, 10kv, 20kv, 35kv 2. Continuous permissible operating temperature: PVC insulation: 70℃ PE insulation: 70℃ HEPE insulation: 75℃ XLPE insulation: 90℃ 3. Max. Temperature of cable under short-circuit ( 5 sec. Max. Duration ) PVC Insulation: 160℃ PE Insulation: 130℃ HDPE Insulation: 150℃ XLPE Insulation: 250℃ 4. Laying temperature of cable not less than -20℃ 5. Operating ambient temperature of cables: -40℃~+40℃ 6. Permissible bending radius of cable: Cable for rated voltage up and including 0.6/1kv Bending radius not less than 4D for cable diameter < 25mm Bending radius not less than 6D for cxable diameter ≥ 25mm Cable for rated voltage 10kv、20kv and 35kv Single-core cable bending radius not less than 20(D+d) Multi-core cable bending radius not less than 15(D+d) Note: D-over: all Diameter of cable; d-over: all Diameter of conductor.

Wuxi Jiangnan Cable Co., Ltd., founded in 1985, is a National Key Hi-Tech. Enterprise, mainly manufacturing integrates wires and cables. By the end of 2015, With a floor space of more than 500,000 square meters, total built-up area of 350,000 square meters, and total assets worth above RMB 7 billion, the Company now has an employee size of 3,000-odd persons, of which, middle and high-level technical and managerial personnel with diploma of junior college or above make up more than 30 per cent of the Company’s total employees. In addition to boasting more than 1,400 sets (units) of China and the world first-class production and testing devices, the Company takes the lead in realizing whole-process dynamic monitoring and management over its logistics, capital flow, and human resources by virtue of its ERP network information management system, HER H.R. management system, and OA system, thus IT-based management in the Company comes true.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery