More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut to length line, etc.

Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer.

We always keep strong faith in “Thinking for what customer think”.

Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales”

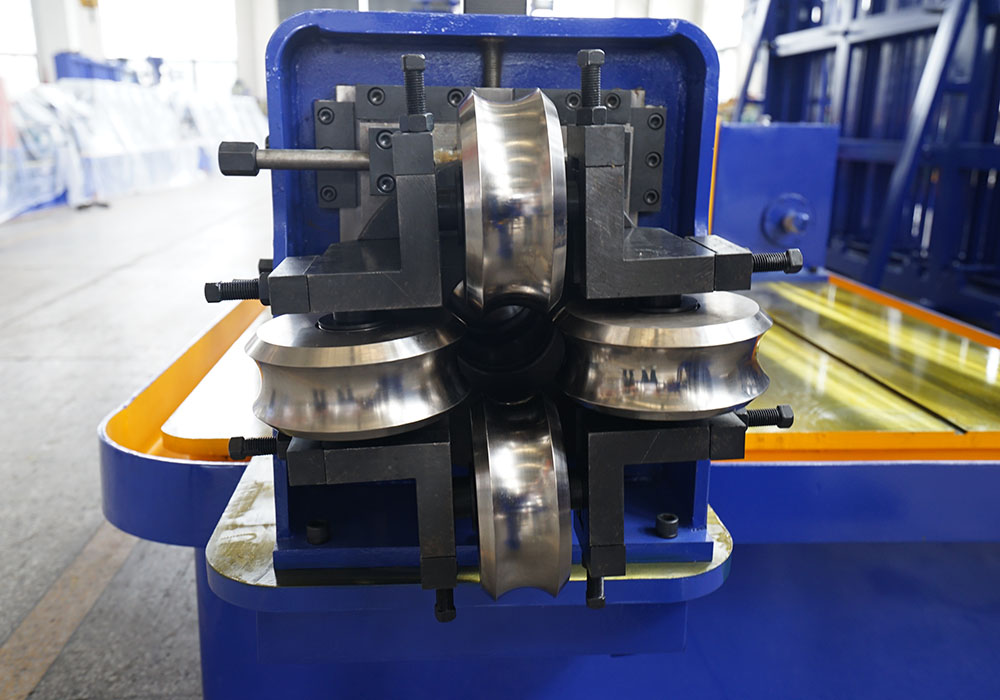

Our TZG series High Precision Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation.

This high precision tube mill series with excellent design, selected high precision durable roller under strictly quenching , high performance cutting saw, complete machine body with heat treatment, accurate fabrication, precise assembly.

The machine performance has reached the international ERW welded tube standard. This tube mill series outer diameter range can be from Φ7mm to Φ 50.8mm and wall thickness of 0.2~2.0mm,all these size tubes are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications.

Specification of High precision series tube mill line

|

Model |

Tube O.D.(mm) |

Wall Thickness(mm) |

Speed(m/min) |

H.F. power(Kw) |

Main motor(Kw) |

|

TZG-12 |

φ7-16 |

0.2-0.5 |

30-100 |

60 |

15 |

|

TZG-16 |

φ8-25 |

0.3-1.0 |

30-90 |

60 |

22 |

|

TZG-25 |

φ8-30 |

0.4-1.3 |

30-90 |

100 |

37 |

|

TZG-28 |

φ10-38 |

0.5-1.5 |

30-80 |

100 |

45 |

|

TZG-32 |

φ13-50.8 |

0.6-2.0 |

20-90 |

100 |

75 |

Finished Products

|

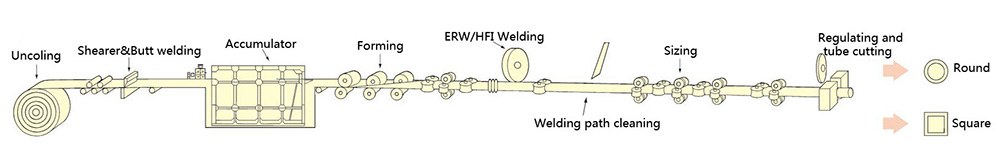

Product (steel tube) Process Flow: |

|

|

Raw material (steel coil) → uncoiling → shearing and end welding → material accumulating → non-power leveling → mill-forming → high-frequency welding → removing burrs outside of weld seam → cooling → sizing → roughly straightening → fixed length cutting → finishing tube |

|

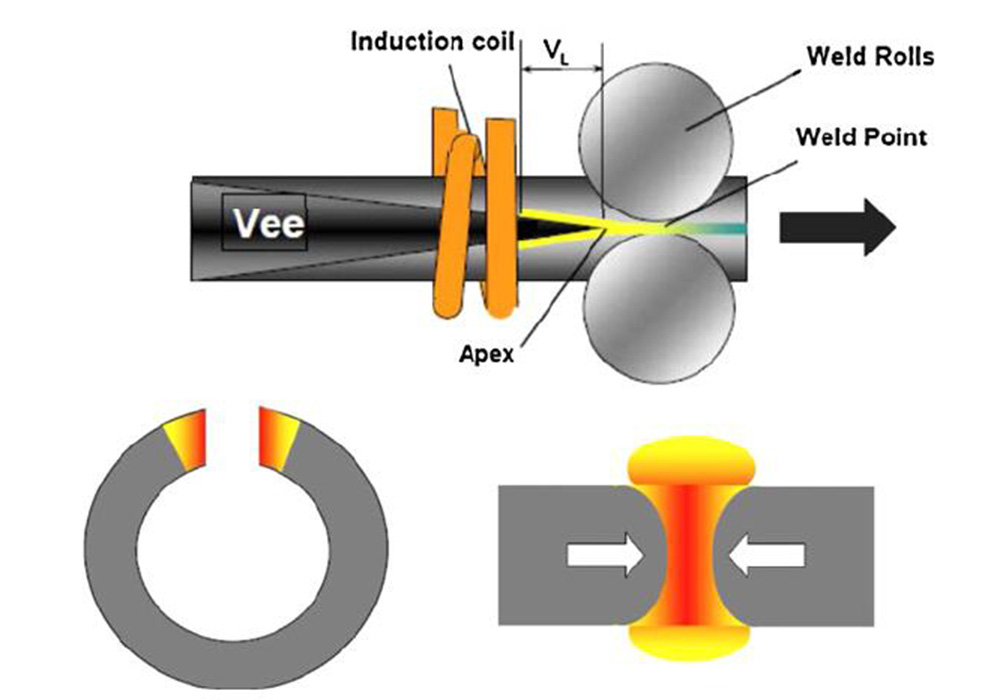

Working Principle of ERW Tube & Pipe Mill

TBS Equipment provides complete ERW welding solutions for tube and pipe manufacturer to ensure the final products in perfect quality.

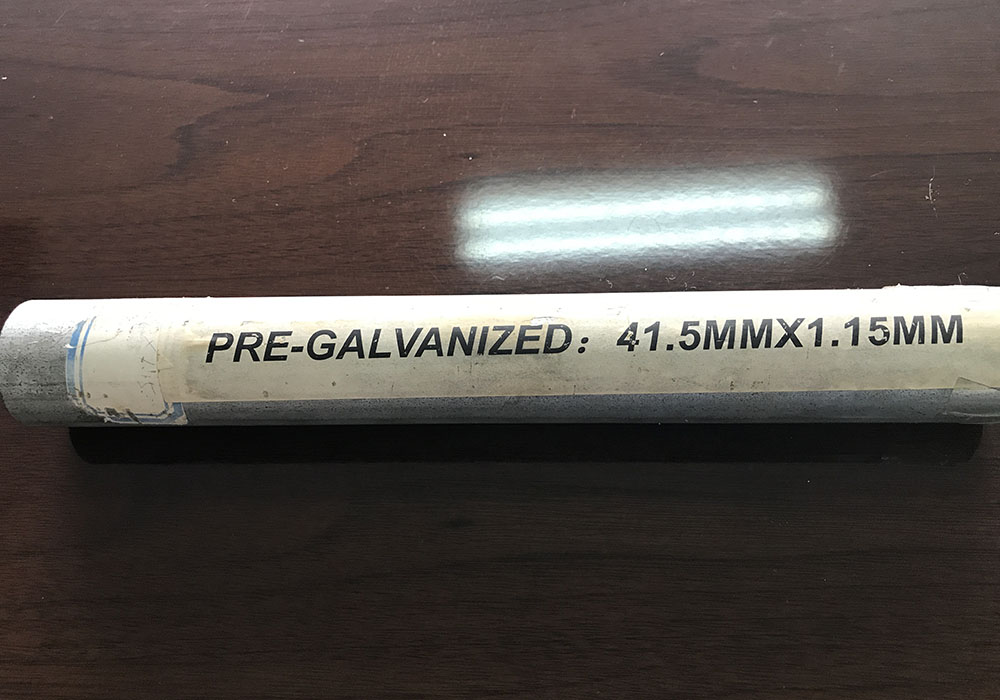

Product Materials

●HR/CR carbon steel or galvanized steel

●High-Strength Low -Alloy- Steel(HSLA)

●Advanced High-Strength Steels (AHSS)

●Stainless Steel

●Aluminum

●Copper

●Titanium

Applications Field:

●Standard Pipe

●Structural steel Pipes&Tube

●Pressure Tube

●Line Pipes

●Enegery API&OCTG Pipe

●Mechanical Tubing

●Automobile Tube

●Steel Conduit

The precise measured strips, precut from high quality HR or CR steel coil strips by slitting line then transfer into the forming section of tube mill, gradually formed into round profile by designed precise roller with open seam along its length in the forming mill.

A high-frequency induction welding technology is adopted to seam edge heat fusion and longitudinal seam welding joint by high frequency solid state welder in order to form strong continuous seam joint.

The strip is welded continuously in round shape. The welded pipe passes through welding seam cleaning and cooling, then sizing and forming into round or square or rectangular profile with specified tolerance.

Finally the welded pipe will be cut to desired and required lengths by cut-off section

Finished tubes will be round, square or rectangular shape and bundled.

1.Uncoiler

1.Uncoiler 2.Shear and butt weld

2.Shear and butt weld 3.Horziontal accumlator

3.Horziontal accumlator 4.Forming

4.Forming 5.HF welding

5.HF welding 6.Turkey straightener head

6.Turkey straightener head  7.Cut off saw

7.Cut off saw 8.Run out table

8.Run out table 9.Vertical accumlator

9.Vertical accumlator