More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc.

Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer.

We always keep strong faith in “Thinking for what customer think”.

Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales”

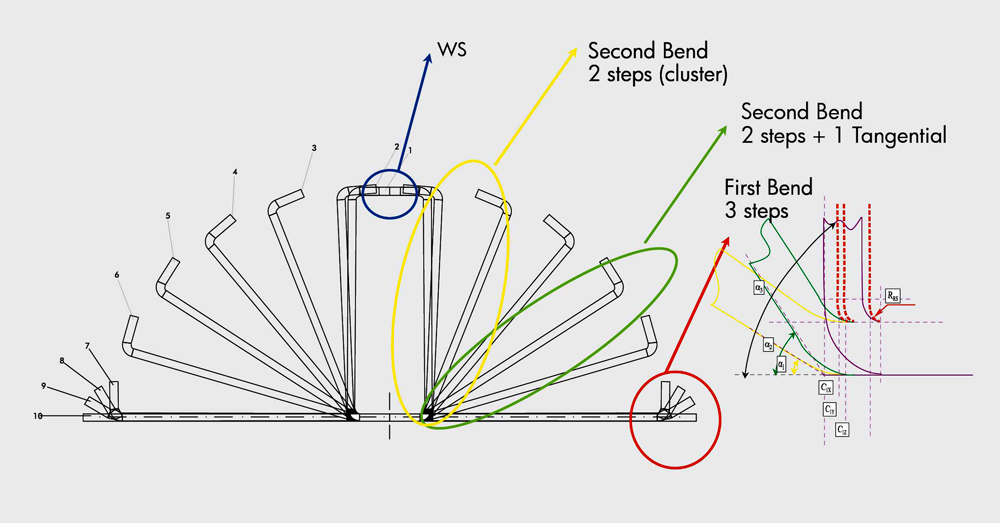

TDG Series Directly Forming to Square and Rectangular Tube Mill Only one set of rollers can be continuously produced within a certain range of rectangular steel pipe, using the international advanced multi-radius combination molding process and high-frequency welding, forming by multi-channel symmetrical bending. It can be divided into small side bending, boardside bending, free bending at closed side, high frequency welding, precision straightening, produce the exact size and good quality pipe after cut off.

Characteristic:

One set mold roller can produces a range of rectangular tubes.

This machine has characteristics such as no replace spindle, no remove roller stand and quick change rollers.

Save mold, save time.

Four square corner deformation part which can save extra deformation process then save energy consumption and equipment load.

Specification of Directly Forming to Square and Rectangular Tube Mill

|

SPEC |

TDG600X600 |

TDG500X500 |

TDG400X400 |

|

- Material to be processed |

Carbon Steel, strip coils of weld able grade with max. 0.2% carbon |

Carbon Steel, strip coils of weld able grade with max. 0.2% carbon |

Carbon Steel, strip coils of weld able grade with max. 0.2% carbon |

|

- Type |

Square & Rectangular tube |

Square & Rectangular tube |

Square & Rectangular tube |

|

Square |

300 x 300 – 600 x 600 mm |

250 x 250 – 500 x 500 mm |

180 x 180 – 400 x 400 mm |

|

Rectangular |

300 x400 – 500 x 600 mm |

250 x350 – 300 x 500 mm |

180 x200 – 300 x 400 mm |

|

- Wall thickness |

6.0 mm – 22.0 mm |

5.0 mm – 18.0 mm |

5.0 mm – 14.0 mm |

|

- Tube length |

6.0 m - 24.0 m |

6.0 m - 18.0 m |

6.0 m - 12.0 m |

|

- Line Speed |

Max. 20m/min |

Min.12m/min Max. 24 m/min |

Max. 30 m/min |

|

- Welding Method |

Solid State High Frequency Welding |

Solid State High Frequency Welding |

Solid State High Frequency Welding |

|

- Forming Method |

Directly Forming to Square and Rectangular tube |

Directly Forming to Square and Rectangular |

Directly Forming to Square and Rectangular |

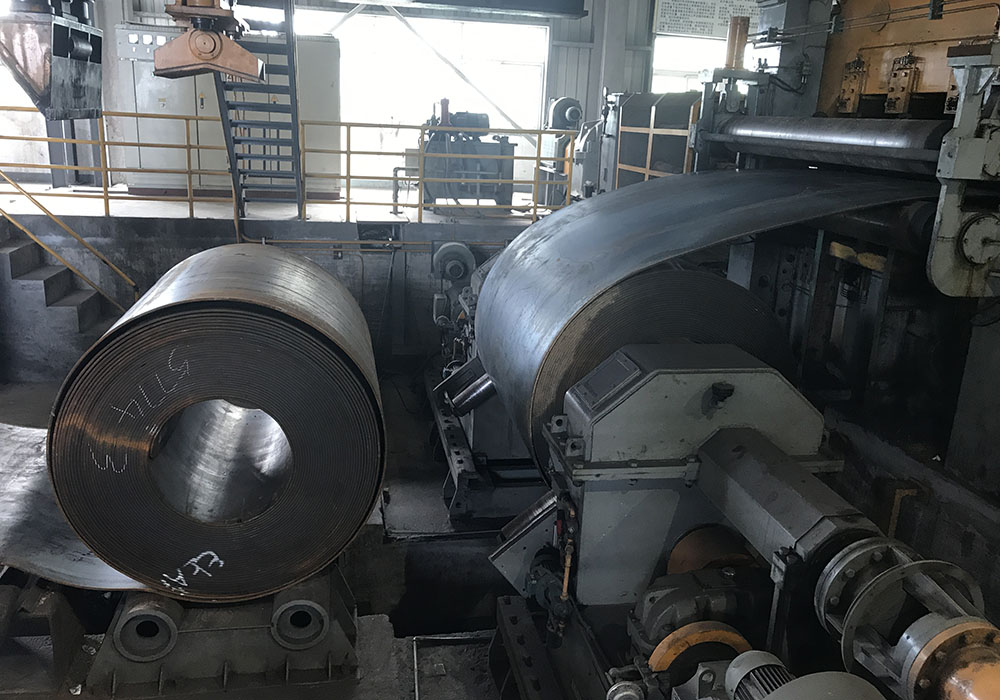

Finished Products

|

Product (steel tube) Process Flow: |

|

Raw material (steel coil) → uncoiling → shearing and end welding → material accumulating → non-power leveling → mill-forming → high-frequency welding → removing burrs outside of weld seam → cooling → sizing → roughly straightening → fixed length cutting → finishing tube |

Milling Type Flying Saw Introduction

The milling type flying saw is used on the welded pipe tube mill line for continuously cutting big-size round pipes square and rectangular pipes into specific length when the production line running.

The pipe is length cut by 4/2 milling disk cutting head.We use 4/2 milling heads to finish cutting along with outer contour line.We adopt two blades for cutting 219 pipe(The diameter of round pipe,the diagonal of square and rectangular pipes).

The numerical control system calculates trolley’s start-up point,acceleration curves,deceleration curve,maximum return speed and also displays the running curves of the trolley to ensure the system running at a good state.The position and speed of the trolley are measured by a incremental encoder which is installed on the trolley’s drive motor.Along with the rotation of drive motor,the measuring value is sent to numerical control system to precisely control the cutting position from drive to pipe.During the cutting process,the velocity fluctuation of pipe has no effect to the control precision.The copying cuting contour line can be set up on touch screen which has round,square and rectangle three interface figure.The intuitionist and easy operation make the complicated cutting curve be set up by simply figure parameters.

1.Uncoiler

1.Uncoiler 2.Shear and butt weld

2.Shear and butt weld 3.Horziontal accumlator

3.Horziontal accumlator 4.Forming

4.Forming 5.HF welding

5.HF welding 6.Turkey straightener head

6.Turkey straightener head 7.Cut off saw

7.Cut off saw  8.Run out table

8.Run out table 9.Press roller

9.Press roller