01:51

01:51

Introduction H1’s color is transparent and moist with a hint of green in milky white. Buildings of screen are full of archaic rhyme. Simple, quiet clean and elegant, expensive optima pastoral and not arrogant. Features 1.Green, environmental protection, safety and no radiation The making of Queen Longjade has artificial removal of radioactive elements. It is the modern and safe new-type and green environmental material not like the natural stone with harms to human body. 2.Moist and delicate, like natural jade Queen Longjade is special micro crystal structure, which may produce even and harmonious diffuse reflection effect, and form natural soft texture if emitting from any angles. 3.Hard and wear-resistant, high strength, good toughness Compared with natural stone, Queen Longjade is characterized by even stone texture, high density, high hardness, anti-bending, anti-impact, not easy to damage. 4.Dense texture, antifreeze, nonabsorbent, easy to clean Queen Longjade has low water absorption rate and is not easy to be polluted. We may not worry about freezing damage and rust, concrete mud, gray infiltration of pollutants harm. In addition to stone whiskering, the pollutants attached on the surface area easy to be cleaned. 5.Strong weather resistance, acid and alkali corrosion, never fade, resistant to weathering Queen Longjade is Inorganic non-metallic material. The special nano crystal structure determines its resistance to acid and alkali, and its corrosion resistance is higher than that of granite and marble. It has prominent weather-resistant property especially, even though it is exposed in wind, rain and polluted air, it will not produce dDeterioration and fading, strength reduction. 6.Plasticity which other stones cannot compare Queen Longjade has larger application space with its excellent physical properties. In addition to the decoration building materials, it may build the varying arts of work or accessories and play the scientific and technical effect which may be compared with natural jade. It has Good performance in aerospace, industry, and other areas of life. 7.Excellent transparency The permanent performance of Queen Longjade may play the perfect effect under the sunshine conditions. The color is even and clear, the light effect is soft and elegant, showing a great sense of vision.

Shanghai Golden Swallow & Cedar International Trading Co., Ltd (hereinafter referred to as GSC) was established in 2013 in China (Shanghai) Free Trade Zone. Product display experience Museum was set up in the busy road of Pudong New Area. With “Queen Longjade” as a leading brand, it is a private enterprise integrating the production, sales and brand operation of Multi functional green environmental protection nano microcrystalline jade products. The factory is located in Jianping County Industrial Park, Chaoyang City, Liaoning City - the birthplace of Chinese Hongshan culture.

Contact Supplier 01:51

01:51

Introduction It is white as Suet white jade with degree of relaxation, inclusive of excellence. It is pure as white snow, fine as bitty cream. It improves the openness of decoration space and makes the mind away from the noisy and annoying. Features 1.Green, environmental protection, safety and no radiation The making of Queen Longjade has artificial removal of radioactive elements. It is the modern and safe new-type and green environmental material not like the natural stone with harms to human body. 2.Moist and delicate, like natural jade Queen Longjade is special micro crystal structure, which may produce even and harmonious diffuse reflection effect, and form natural soft texture if emitting from any angles. 3.Hard and wear-resistant, high strength, good toughness Compared with natural stone, Queen Longjade is characterized by even stone texture, high density, high hardness, anti-bending, anti-impact, not easy to damage. 4.Dense texture, antifreeze, nonabsorbent, easy to clean Queen Longjade has low water absorption rate and is not easy to be polluted. We may not worry about freezing damage and rust, concrete mud, gray infiltration of pollutants harm. In addition to stone whiskering, the pollutants attached on the surface area easy to be cleaned. 5.Strong weather resistance, acid and alkali corrosion, never fade, resistant to weathering Queen Longjade is Inorganic non-metallic material. The special nano crystal structure determines its resistance to acid and alkali, and its corrosion resistance is higher than that of granite and marble. It has prominent weather-resistant property especially, even though it is exposed in wind, rain and polluted air, it will not produce dDeterioration and fading, strength reduction. 6.Plasticity which other stones cannot compare Queen Longjade has larger application space with its excellent physical properties. In addition to the decoration building materials, it may build the varying arts of work or accessories and play the scientific and technical effect which may be compared with natural jade. It has Good performance in aerospace, industry, and other areas of life. 7.Excellent transparency The permanent performance of Queen Longjade may play the perfect effect under the sunshine conditions. The color is even and clear, the light effect is soft and elegant, showing a great sense of vision.

Shanghai Golden Swallow & Cedar International Trading Co., Ltd (hereinafter referred to as GSC) was established in 2013 in China (Shanghai) Free Trade Zone. Product display experience Museum was set up in the busy road of Pudong New Area. With “Queen Longjade” as a leading brand, it is a private enterprise integrating the production, sales and brand operation of Multi functional green environmental protection nano microcrystalline jade products. The factory is located in Jianping County Industrial Park, Chaoyang City, Liaoning City - the birthplace of Chinese Hongshan culture.

Contact Supplier 00:35

00:35

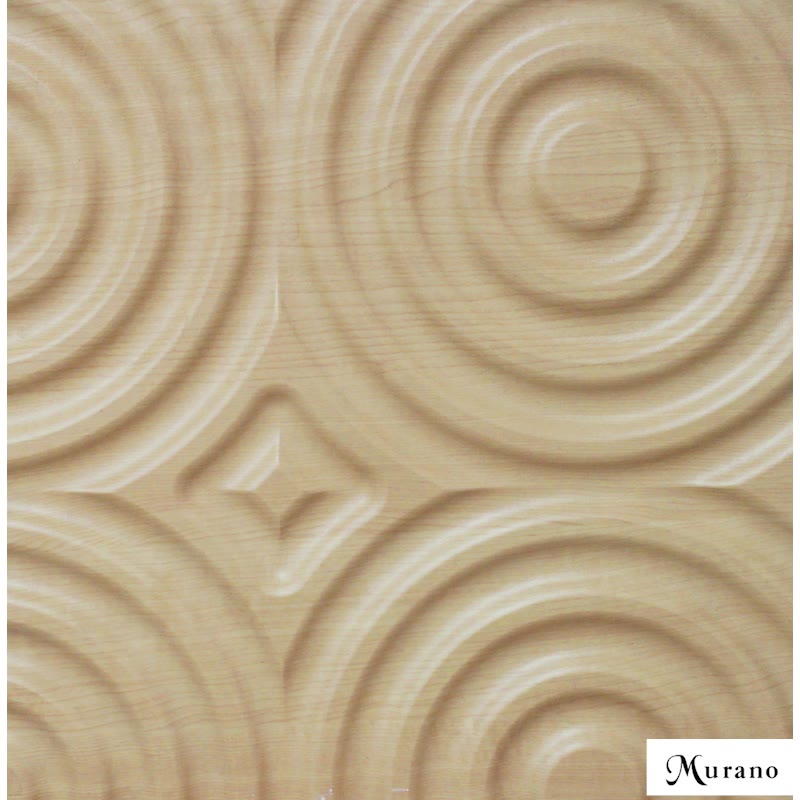

Introduction: 3D Wave panels are made to the highest standards from high quality MDF with damp proof melamine backing to prevent warping once installed. The 3D carving is carried out on high tech computerized CNC router beds so that every panel matches perfectly when installed. All MDF panels come in primed and sanded smooth finish, making easy work to paint in your choice of color and paint finish. Specification: Material: MDF Dimension: 1220 x 2440mm Thickness: 12mm Finish: Painting/PVC Backing: Melamine Film Density:760kg/m³

Thanks to the application of advanced technology and acoustic theory, the Murano diversity of acoustic panels and decorative panels have been developed.

Contact Supplier 01:28

01:28

Catalogue Download Feature • Hexagon crimping type • Ergonomically designed handles and Ratchet control • Different handle color for your choice: one is single color, another is double color • Reduce 50% energy when crimping. • Precise crimping die sets and integral lock with self-releasing machanism ensure high-quality crimping effect after crimping repeatedly. • Light and compact structure keep crimping effect. Parameters Model LXC8 6-6/6-6R Terminal Type Cord End Sleeve and Wire Ferrules Crimping Capacity 0.25-6 mm² / 24-10AWG Length 175mm Weight 0.38kg Application Our cable crimper mainly used for electrical working, State Grid construction, underground cable construction, Building construction etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 00:16

00:16

Products Features 1. Scroll hermetic compressor: international brand with free maintenance. 2.Electrical elements and refrigeration components are used from world-renowned brand. 3.Industrial and durable design, with stainless stell water tank and high-lift pumps. 4.Perfect breakdown protection: high and low pressure protection, air discharge protection, oil level protection, water flow protection, reverse and lack phase protection, chilled water anti-freezing protection, cooling water overheat protection. Friendly choose to use environmentally R407C, R134A or R404A refrigerant ect.

Venttech is a company engaged in refrigeration equipment development, design, production, sales and installation of high-tech enterprises. In the early 21st century, Venttech set up factory in Shanghai and adopt foreign advanced technology. Venttech has more than 15 years experience in developing refrigeration equipment such as water chillers, cooling towers and dry coolers. Till now, our refrigeration equipments have exported to more than 30 countries.

Contact Supplier 00:44

00:44

Catalogue Download Feature • This portable rebar cutter can cut off construction rebar, deformed rebar, round rebar and rebar rod . widely used in construction engineering. • The rebar cutter is with stable performance, Tool is light and compact. • Regarding the operation of this machine, it is of easy and convenient. • When the steel bar (rebar) is cut off completely, release switch Piston retracts automatically. • The rebar machine self-contained electric/hydraulic unit will also cut other items such as chain, bolts and rod. • Cutting shear unlike saws with abrasive blades and cutting torches,because there are no sparks of flame when cutting all kinds of steel bar of rebar. Parameters Model RC-22 Cutting Capacity Φ4-22mm Cutting Speed 3.5-4.5 s Voltage 220V/110V Wattage 1000W/1350W Machine size 4420*120*230mm Weight 15kg Application Our tying machine mainly used for Building construction, steel plants, railroads, bridge construction, oil & gas etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 00:40

00:40

This is we produced small children's book, we also produce the bath book, pvc bath book, plastic book, waterproof book and baby books. Q: What's the special character of the Small Children's Books? Answer, the small children's books specialized in the waterproof character. Also the small children's book special for play with learning, and book have the light weight. The inside could insert in the rattle, BB whistle, and heat change colors, etc. Also the shape of the book impression the baby, attract his/her attention. Here is the detail specification about the Small Children's Books Fish Book Printing, Size 16 x 16 cm Page 8 pages Materials 100% EVA + Sponge Accessories: Fish cartoon characters Package polybag + headercard + master carton MOQ 3000 copies / title Approx Unit Price $0.9~1.40 Sample Cost $125 ~ $250 (this kind pattern have the mold charge) Sample Lead Time 15 days Mass Production Lead Time 30~45 days Shipping Term FOB Shanghai, China / CIF destination Port Payment Term T/T, T/T+L/C We accept the custom small children's books, if you could not find the children's book as your request, pls send email to us to caroline@childbookprinting.com, or contact wechat / whatsapp 86-13585530707. We will be very happy received your inquiry, all the inquiry will be reply within 12 hours.

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 02:08

02:08

Description Unit VMCL1100 Travel X travel mm 1100 Y travel mm 560 Z travel mm 575 Distance between spindle nose and worktable surface mm 200-775 Distance from table center to stand column surface mm 337-887 Worktable Table area mm 550×1200 Max. loads kg 800 T-slot width mm 4×18H8 Spindle Max. spindle speed rpm 8000 Angle of spindle taper - BT-40 Feed rate X/Y/Z rapid speed m/min 32/32/32 Max. cutting feedrate m/min 15 Automatic Tool Changing System Manipulator Qty. Of tools pcs 24 Tool changing time sec 1.55 Max. tool length mm 300 Max. tool diameter/adjacent without tool mm φ100/φ180 Max. tool weight kg 8 Motor Spindle motor kw 7.5/11 X/Y/Z axis motor kw 3/3/4 Cooling pump motor w 0.37+0.55 Precision(SN precision according to standard JB/T8772.4-1998) Positioning accuracy mm 0.012/0.01 Repetitive positioning accuracy mm 0.008/0.006 Machine Dimension Overall height of machine mm 3160 Floor area(L×W) mm 3340×3065 Net Weight kg 6800 Power supply kw 30

COMPANY PROFILE Nantong Hangzhi Equipment Technology Co., Ltd. is a wholly owned subsidiary of AVIC Aviation High-technology Group Co., Ltd. In March 16, 2016, the company completed the renamed registration. Total assets of the company are RMB 330 million. Nantong Hangzhi Equipment Technology Co., Ltd was founded in 1956, Former Nantong Machine TOOL Works, Trademark include: “NANTONG”、“TONMAC”、“TONTEC”,It is one of six listed companies in Chinese machine tool industry. The company undertakes the aircraft in the original Department of AVIC HT’s machine tool business and AVIC Beijing Aeronautical manufacturing technology research Institute of high-end intelligent equipment and aviation equipment business. The main products are CNC milling machines, CNC lathes, Vertical machining center, Horizontal machining center, Gantry type vertical machining center and Aviation equipment, etc. The company employs more than 500 people, including nearly 150 professional, technical and engineering management staff. The company has domestic first-class production and processing equipment, which imports more than 130 sets of thin equipment, including Japan SNK five face machining center, Germany”s WARLDRICH precision guideway grinder, the United States CICINNATIE machining center, Switzerland DIXI coordinate boring machine, Zeiss coordinate measuring instrument and other world famous brand processing and testing equipment. The company independently developed machine tool products by a number of patents, which in the validity period of the invention patent 14, utility model patents 18. A number of key technologies like MCH63 precision horizontal machining center fill the gaps, accessing to the 2007 machine tool industry ten new product title, China Machinery Industry Science and Technology Progress Award. VMCL1100 vertical machining center series won the second prize of scientific and technological progress in Nantong City, Jiangsu Province, third prize of scientific and technological progress. Products are widely used in mold manufacturing, auto parts, wind energy nuclear power, marine ships, military aerospace, teaching and other fields. The company's sales network is throughout the South China, Zhejiang, Jiangsu, China and the West, North China, northeast and other regions, with a professional sales and after-sales team.

Contact Supplier 00:00

00:00

soft tube filling and sealing machine is mainly used for plastic tube filling and sealing. It has been widely used in the fields of pharmacy, cosmetic, food and chemical etc. This MIC-R30 SEMI-auto perfume filling & capping machine is a simple operate sealing filling machine with inside heat and outside heat heads. It has total 8 positions for filling and sealing. And materials such as paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste etc., are all applicable.

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:00

00:00

Design Volume : 5000 L Work volume : 4500L Mixer motor power : 7.5KW Paddle type stirring speed is 0-200r/min (frequency conversion speed regulation) The cover contains a feed inlet and outlet, manhole, window mirror lamp etc. Material is 316 stainless steel, single layer 8mm thickness Leg type

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:39

00:39

Brushless Cordless Hammer Drill 26MM 18V 871004 Product Feature. 1 Brushless Cordless Hammer Drill 2.LED working light and power lamp 3.Very short design for perfect handling, even in the tightest spaces 4. Soft grip make handle comfortable 5. Forward / reverse operation 6. Electronic single cell protection Battery Voltage : 18 V Battery Capacity (Li-ion) 4.0Ah No-Load Speed: 0-1200 / min Impact Rate 0-5300 / min Max.Drill Diameter:: 26mm Accessories: 1* Slow charger Package: Color Box / BMC Sample Time: 3 days Delivery Time: Within 35 Days after Receiving the Deposit Payment Terms: T/T ,L/C

We (Landing tools). is one of the leading exporters of tools, hardware and householdware in China. we have built kinds of professional teams to support our operation. SALES TEAM, which has a exact grasp and understanding of clients' requirements. Make prompt, clear and complete replies according to different markets and quality requests of products. R&D TEAM has the full ability to organize and actualize preponderant production against the drawings and samples. PACKAGING & APPEARANCE DESIGN TEAM, in accordance with clients' requests, we supply the different appearances of products, color assortment, packaging design and making. SOURCING TEAM, which is familiar with the full range information in our field. We offer steady, highest cost-effective products. QC TEAM has established complete and comprehensive assessment system of suppliers Documentation team provide our clients with timely, secure and suitable mode of storage and transportation. Our goal is to supply Ideal Solutions for the full process. We will make our remaining efforts to meet and exceed the requirements of customers. We are ready to serve for every potential customers and sincerely looking forward to cooperate with you in the future.

Contact Supplier 00:20

00:20

Rock wool glue spray foaming machine: inject two kinds of PU glue into the spray-head by metering pump, mixed in static mixing head and spray evenly on the up and down steel plate through damping hole,and then the glue will reflect and retrogradation. Rock wool glue spray device is the core part of the whole production line. We adopt two- group glue system:1A, 2B, each group is controlled by measuring frequency converter, the system can change the out-put flow and mixture ratio. The working mode of the system is online mixture, the out-put A and B glue through the measurement unit, high-pressure atomize head, static state hybrid tube. The whole machine adopt HMI man-computer interface control, making the spray glue quantity in tandem with the main machine speed, animate the working process to ensure the constant of spray glue quantity.

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery