00:40

00:40

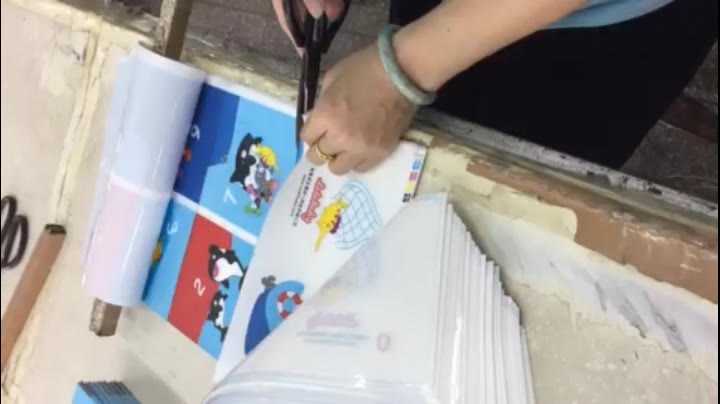

The rubber duck floating book is made of by the PEVA materials, inside by the sponge. The printing by the full color processes. And close by the button. The rubber duck floating book is good for the children and baby. The rubber duck floating book bring many fun for the baby who play with them, and good in their learning. The rubber duck floating book have the safety testing report. The rubber duck floating book each year have 10 millions sales in the market. Welcome your custom inquiry, pls email to caroline@childbookprinting.com. The cyc children's book also have the baby book, the cloth book, the bath book, the water playing book, the floating book, the eva foam book, etc. Q: What’s the special Children's Book Printing and Binding Floating Duck? A: Oh, my dear friend. Do you find the style the Children's Book Printing and Binding Floating Duck is very different from the market book? It is rubber duck design, each pages tell one action of the animal. It is perfect ideal. We admire the illustrator’s ideal of Children's Book Printing and Binding Floating Duck! Size 14 x 17.5cm Page 8 pages Materials 100% recycle EVA + Sponge Package each put into polybag with header card MOQ 3000 copies / title Approx Unit Price $0.6~1.10 Sample Cost $125 ~ $250 Sample Lead Time 15 days Mass Production Lead Time 30~45 days Shipping Term FOB Shanghai, China / CIF destination Port Payment Term T/T, T/T+L/C

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:40

00:40

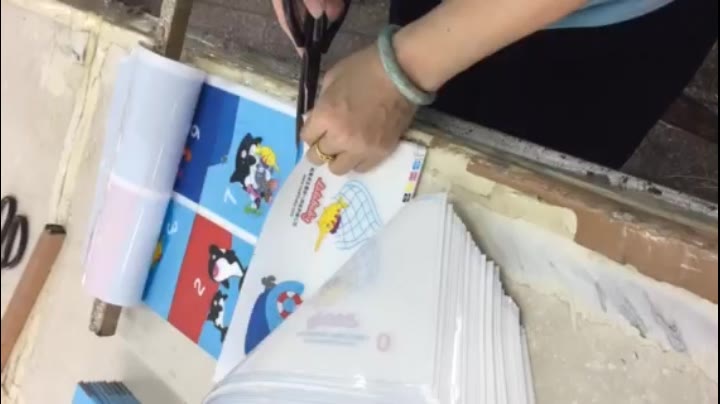

The cyc children's book printing special focus on the baby book printing for toddlers. In the past year 2017 produce around 200 titles baby book printing for toddlers for the worldwide publishers. Other products are bath book, waterproof baby book, the baby book printing for infants, the baby book, the playing baby book, activity baby book, etc. The baby book printing for toddlers size is 150mmx 150mm, cover and 3 spread, total 8 pages, printing by the standard baby book printing for toddlers techniques. We honest you can find the book you need, if you really could get what's you need, pls contact our production manager Caroline@childbookprinting.com. Q: What’s the special of Baby Book Printing in China for Toddlers? A: special in 3 parts, the materials is transparent, the hole on each pages, the ring of the book. Especially the content of the Baby Book Printing in China for Toddlers, very attractive. Q: How many the MOQ of the Baby Book Printing in China for Toddlers? A: usually 3000 piece Baby Book Printing in China for Toddlers. We find the publishing house usually develop 4 titles of the Baby Book Printing in China for Toddlers, and printing them one time. Size 15 x 15 cm Page 8 pages Materials 100% recycle EVA + Sponge Package each put into polybag with header card MOQ 3000 copies / title Approx Unit Price $0.6~1.10 Sample Cost $125 ~ $250 Sample Lead Time 15 days Mass Production Lead Time 30~45 days Shipping Term FOB Shanghai, China / CIF destination Port Payment Term T/T, T/T+L/C

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:40

00:40

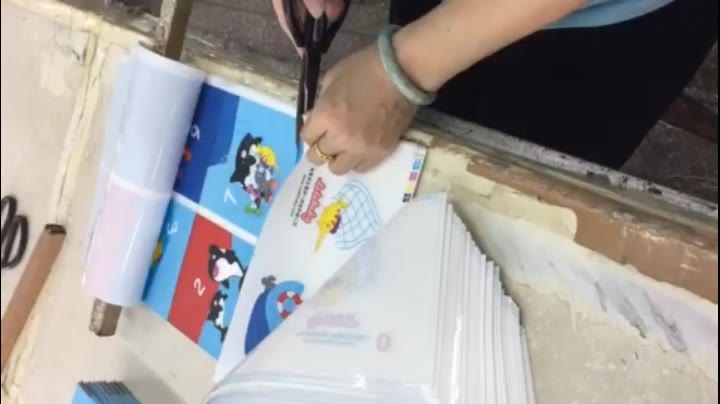

The Portuguese Bath Book packing most by the convenient way with the polybag and the header card. The materials is peva, also call peva bath book. The Portuguese Bath Book is warm welcome in the North America, due to the weather is very hot, so the children and parents are very love the portuguese bath book. The cyc company also produce the children's book, the water playing bath book, the bath time book, the waterproof book,the boat floating book, the peva bath book, the pvc bath book, the magic book, the water sensitive bath book, and the baby book, the fabric book, the cloth book, the soft cloth book, etc. Welcome your custom inquiry. Q: Is mostly packing header card and poly bag for such Libro de Bano a Bathing Book Printing, right? A: Right. Almost 70% Libro de Bano a Bathing Book Printing packing by this way. Because good in show and could hang on the market European supermarket hook. Size 15 x 15 cm Page 8 pages Materials 100% recycle EVA + Sponge Package each put into polybag with header card MOQ 3000 copies / title Approx Unit Price $0.6~1.10 Sample Cost $125 ~ $250 Sample Lead Time 15 days Mass Production Lead Time 30~45 days Shipping Term FOB Shanghai, China / CIF destination Port Payment Term T/T, T/T+L/C

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 02:11

02:11

Products Features Capacity: 12~35kw. Efficiency: 2.7~3.3 cop. Warranty: Compressor- 3 years limited. other parts-1 year limited. Structure Panels and frame are made from galvanized steel protected with polyester powder painting to ensure total resistance toatmospheric agents. Direct expansion coils with condensate drain tray. Hermetic compressor High efficiency scroll compressor for the whole range, with built-in thermal overload cut-out and crankcase heater,mounted on rubber vibration dampers Ripple type acoustic insulation for compressor section, and thermal insulation for coil and fan section, low noise Centrifugal fan Forward curve centrifugal fans for air treatment section and axial fans for condensation section. Front, side and underside air discharge of the treatment unit. High external pressure, long air supply distance Electric panel Electric panel consists of breakers and contactors for compressors and fan motors, phase sequence relay and other necessary protection devices for the main components. Easy operation line controller Cooling/Heating/Auto. Error indication. Timing on/off. Product options Economizer with fresh, return air dampers and fresh air hood. Free cooling function for low ambient temperature. Low ambient control device for operation of outdoor units at ambient temperatures from less than 20°C down to -10°C BMS devices. T3 (Tropical climate). Condenser coil guard. Roof curb. Metal / aluminum filter. Air pressure switch for indoor fan. High static condenser fan option with sealed + drain.condensing section. Optional water heating coil. Metal or plastic mesh on condenser coil. Optional supply / return air configurations. Upgraded evaporator fan motor drives. G4 filter, plate and bag filter.

Venttech is a company engaged in refrigeration equipment development, design, production, sales and installation of high-tech enterprises. In the early 21st century, Venttech set up factory in Shanghai and adopt foreign advanced technology. Venttech has more than 15 years experience in developing refrigeration equipment such as water chillers, cooling towers and dry coolers. Till now, our refrigeration equipments have exported to more than 30 countries.

Contact Supplier 00:00

00:00

water three-in-one washing, filling and sealing machine Application washing filling and capping three in one filling equipment is one high precision and speed liquid filling machine, product design adopts bottle-neck block technology, not only avoid bottle-neck second pollution, but also can produce different bottle shape filling in one machine. Greatly improve the equipment usage scope. Production capacity from 3000bottles per hour to 3600bottles per hour can be choose by customer. Main-frame machine adopts frequency conversion timing motor, convenience adjustment speed within throughput. Technical parameters Model Capacity 330ml 500ml 1000ml 1500ml 2000ml SD-XGF-12-12-4 4000 3000 2500 2000 1500 SD-XGF-18-18-6 8000 6000 5500 5000 4500 SD-XGF-24-24-8 10000 8000 6500 5500 5000 SD-XGF-32-32-8 14000 12000 10000 8000 6000 SD-XGF-40-40-12 18000 16000 12000 9000 7000

Shanghai Shouda Packaging Machinery & Material Co., Ltd. is a professional manufacturer of automatic packaging machineries & automatic filling and packing production line for liquid, gel, aerosol

Contact Supplier 00:37

00:37

Capacity: 120~300kw. Efficiency: 2.7~3.3 cop. Warranty: Compressor- 3 years limited. other parts-1 year limited. Structure Panels and frame are made from galvanized steel protected with polyester powder painting to ensure total resistance toatmospheric agents. Direct expansion coils with condensate drain tray. Hermetic compressor High efficiency scroll compressor for the whole range, with built-in thermal overload cut-out and crankcase heater,mounted on rubber vibration dampers Ripple type acoustic insulation for compressor section, and thermal insulation for coil and fan section, low noise Centrifugal fan Forward curve centrifugal fans for air treatment section and axial fans for condensation section. Front, side and underside air discharge of the treatment unit. High external pressure, long air supply distance Electric panel Electric panel consists of breakers and contactors for compressors and fan motors, phase sequence relay and other necessary protection devices for the main components. Easy operation line controller Cooling/Heating/Auto. Error indication. Timing on/off. Optional Economizer with fresh, return air dampers and fresh air hood. Free cooling function for low ambient temperature. Low ambient control device for operation of outdoor units at ambient temperatures from less than 20°C down to -10°C BMS devices. T3 (Tropical climate). Condenser coil guard. Roof curb. Metal / aluminum filter. Air pressure switch for indoor fan. High static condenser fan option with sealed + drain.condensing section. Optional water heating coil. Metal or plastic mesh on condenser coil. Optional supply / return air configurations. Upgraded evaporator fan motor drives. G4 filter, plate and bag filter.

Venttech is a company engaged in refrigeration equipment development, design, production, sales and installation of high-tech enterprises. In the early 21st century, Venttech set up factory in Shanghai and adopt foreign advanced technology. Venttech has more than 15 years experience in developing refrigeration equipment such as water chillers, cooling towers and dry coolers. Till now, our refrigeration equipments have exported to more than 30 countries.

Contact Supplier 00:00

00:00

Brief Introduction BXAZ ampoule cleaning, drying, filling and sealing compact production line is a new type of ampoule production line which adopted the advanced international technology, combined several FE Pharmatech’s patents and according to the domestic ampoule production situation. This line is composed by CLQ vertical ultrasonic cleaning machine, RSM sterilizing drying machine and AGF filling and sealing machine. It is divided into cleaning zone, sterilizing zone, filling and sealing zone. This compact line can work together as well as independently. Main Features 1The compact line realizes single linkage, continuous operation from washing, sterilizing,filling and sealing. The whole production process realizes cleaning operation; protects products from contamination, meets the GMP production standard. 2 This line adopts water and compressed air cross pressure jet wash and ultrasonic wash at inverted state. The cleaning effect is very good. 3 The ultra filtration technology is applied at the washing machine’s filter. The clean and sterile washing water and compressed air is obtained through terminal filter, which can improve the clarity of the washed bottle. 4 Bottle infeed auger and star wheel meet, the auger space is small. Ampoules can walk straight. Ampoules can transfer more stable and can hardly broken. 5 Double tank and double circulation. The circulation water tank and rough wash water tank are totally separate. The cleaning water is used step by step. The cleaning effect is much better. 6 The stainless manipulators are one side fix. The location is more accuracy. The manipulators are wearproof. When changing of pitch the manipulators no need stretch out and turn. The turning bearing wont contaminating the cleaning water. 7 The ampoules are sterilized by the hot air laminar flow sterilization principle. The heat distribution is more even. The ampoules are under the HDC high temperature sterilization condition, which meets the standard of GMP. 8 This equipment adopts negative pressure sealing principle to seal the high efficiency filter which are used for purify the tunnel. The filter is easy to install which can ensure the one hundred purification condition. 9 The equipment adopts hinge type seat heat and horizontal hot air fan structure. The maintenance of the equipment is more convenient and laborsaving. 10 This equipment adopts chain conveying belt with flank. The conveying belt won’t be off track, anticreeper, no bottle falling. 11 The equipment adopts advance technology such as multi-needle filling, front and rear nitrogen charging and wire drawing sealing, which can meet the standard of different type of products. 12 The fill-seal machine adopts balcony structure. The starwheel infeed and convey bottles continuously, the running of the equipment is stable and less bottle breakage. 13 This equipment is universal. It can’t be used to 1-20ml ampoules. Changing parts are convenient. In the meantime, the equipment can be used as vial washing, filling and capping compact line by changing some mould and outfeed wheel.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:00

00:00

Brief introduction & Advantage The whole production line is connected by several individual but attachable function modular. Improving traditional process and realizing humanized design of online gel adding . Each modular is controlled by its own PLC, only 3 skilled workers are needed for the whole line to reach 12000-15000pcs/h capacity. No human operation online, decreasing error caused by human difference between batches, which improves production efficiency and products quality. Production Procedures Schematic Diagram Tube Loading Station: Automatic loading through 2 molds base simultaneously. 20 tubes are loaded for one time. With the function of multi-aspect detection including stuck tube, missing tube, and reversed tube. Dosing Station: Adopting FMI metering pump, precision ceramic injection pump with highly atomized nozzle achieves accurate dosing and high stability by easy operation. Dosing value could be set on the touchscreen (FMI for metering) Drying Station: 4 sets of drying system adopting PTC heating method bring no pollution to the inside of tubes and achieve high efficiency of drying and production. There has correct positioning device inside of hot rod and tubes to prevent damage of tubes from hot rod. The system can be selectively opened according to production requirement. Capping Station: Increase the buffer zone of cap, and with unique device of cap fetching and distance adjusting, it rises the success rate and stability of capping. Vacuuming Station: With high precision digital-beginning detection for detecting, Panasonic controlling device, unique tamponade device and adopting high efficiency vacuum pump for vacuuming nterlaced Tray Loading: Newest technical device with the function of interlaced loading and distance adjusting. Simply adjust the distance and load. No need another changing step. Positioning rod for cap loading to prevent tray being injured caused by tube tilted. Applied to both type of the rectangular and interlaced.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact SupplierShanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:41

00:41

Purification systems engineering to meet assembly such as integrated circuit, optical system to the requirement of clean room and related controlled environment, mainly to control dust particles, according to the need to choose different clean level.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:00

00:00

Brief introduction & Advantage Tail-labeling machine connected online, non-label tube to be auto detected by world leading image technology after stoppering & capping and vacuuming (including rift of stopper or cap or glass tube, foreign matter inside tube, no additive, less additive and etc.). Conform tube move to labeling machine, non-conform tube to be rejected. Manual inspection-free technology is world leading. 1. Save labor cost: Other company’s production line need large manual inspection for each tube, include label, dosing, foreign matters inside tube and etc. Our line using world leading image technology to reject non-conform tube (include rift of stopper or cap or glass tube, foreign matter inside tube, no additive, less additive and etc.), reach 100% accuracy rate. 2. Reduce secondary pollution. Decrease tube multiple exposure, better guarantee tube aseptic. Glass tube after high temp sterilizing. (PET tube produced in Class 100,000 clean room workshop), worker only contact tube one time when loading tubes into auto loading machine, ensure tube cleanness during production in Class 10,000 clean room workshop. 3. Testing qualified products for automatic labeling, ensure packaging sequence according to Barcode Numbers. Packaging sequence according to Barcode Numbers can be up to export standard and usage requirements of large hospitals. 4. Auto inspection device rejects labeled tube if no label. Slanting label, poor adhesive label and etc., ensure labeled tube and finished tube with pass rate 100%. 5. Labeling speed matches the auto assembly line speed well to ensure whole line production capacity get 18000~24000pcs/h 6. The whole line only needs 3 skilled workers. Only manual tube loading at the very beginning, online image and labeling inspection rejects non-conform tubes automatically to ensure 100% pass rate. Save at least 15 workers to get production capacity of 18000~24000pcs/h. Production Procedures Schematic Diagram Aseptic Environment: equipped with clean laminar flow hood and adopt with high-powered fan and HEPA, it can be operated in long term under high static pressure and keep low noise. The space cleanness can up to class 10,000 (can be optional), which is the exclusive technology in China. Tube loading: adopting with automatic tube loading technology, loading the tube into clamps automatically with detector for no tube or inverse direction tube. The machine apply for any kind of label tubes and solve the defect of the avo label broken of traditional tube loading machine from other manufacturers. Atomization Dosing: The machine adopts with a set of 5 FMI precision ceramic metering pump and 1 set of five conjoined of micro - ceramic injection pump that can dose separately for biochemical tube and anticoagulant tube (EDTA salts, heparin salt); Another set of metering pump is dosing for sodium citrate tubes. Dosing volume controlled by PLC touch screen(see parameter), the error rate is ≦ 5%, and detect for no dosing tubes during the dosing process. Compared with other companies’ machine rely on stable air supply for dosing, our technology of dosing volume will not be influenced by any factors. 3 sets of dosing system meet all kinds of blood collection tubes production, that is the exclusive and advanced technology in China. Drying: Adopting with six sets of dust-free PTC heating dryer to make the inner of products with zero pollution so as to improve the drying effect and production efficiency. Compared with traditional heating method, our machine solves the problem of temperature instability and pollution. Online Stoppering & Capping: finish the combination of stopper & cap online quickly and efficiently (apply for both type: upward and downward), and avoid the nonuniform vacuum degree when dose the tubes after the combination of stopper and cap and it may cause the stopper not seal well against tube. Detect for cap and rubber stopper and avoid the possibility of no stopper or no cap.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 00:00

00:00

Machine Introduce: This machine can get perfect cut for licorice root. cutting size is adjustable from 1-20mm Specification: Model QYJ-200 QYJ-300 Capacity: (kg/h) 100-200 150-300 Power 2.2 KW , 3 Phase 4 KW , 3 Phase Cut range 1-20 mm adjustable Cut speed Fix adjustable Dimension:(L*W*H) 1900*840*1000mm 2060*1020*1020mm Weight: (Kg) 500 650

-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery