00:14

00:14

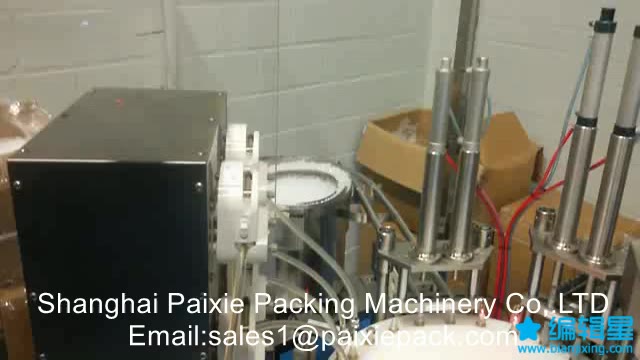

The rinser filler capper 3 in 1 machine is for fill light liquid. It can carry washing filling capping in one machine. It can be used alone or connected with other machines. It can connect with bottle unscrambler, or air conveyor, cap elevator ,labeling machine and so on. The rinsing, filling and capping process will be carried out using a continuous system in a fully enclosed safety interlocked chamber using our years of experience and the latest technology. Features (1)The all machine applies bottle handling technical and the filling valves go up-down when filling, which make sure the bottle filling goes stable, reliable during high speed. The bottle handling technical also make the different bottle changing easily without changing too many accessories. (2) This machine uses new generation stainless steel spring washing clips and the clips do not contact the upside of bottle screw avoiding the second pollution. It can both clear the inside and the outside of the bottle. (3) The advanced normal pressure filling principle was applied. Filling is quick, and stable. Not contacting with the liquid avoids second pollution and oxidation. (4) Magnetic torque is used for screw capping, and the power of screw capping can be adjusted steplessly. Capping is reliable and do no harm to the caps. (5) Advanced technologies, such as human-machine interface touch-screen and PLC program control are adopted in this machine. (6) All parts that have direct contact with the water are made of high quality stainless steel. The critical electrical components are from famous international companies, such as Mitsubishi, Omron to name a few.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Overview This Machine adopt auger to measure and fill powder and granular, with high filling speed and filling accuracy. The auger is driven by servo motor. It fits more to the fluidic or low-fluidity materials, like coffee powder, albumen powder, pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide, granular additive, and so on. The automatic small powder filling sealing machine ’s spiral driven by servo motor drive which is not easy to wear, it can fix position precisely, set the speed and work stably. It can add dust collect device in the outlet of material for filling without dust of the automatic small powder filling sealing machine An optional diving nozzle mechanism plunges the filling nozzles into the container for increased production speeds without splashing, and we can produce the different filing nozzles for your different speed requirement. Filling volumes are programmable and can be adjusted from the touch screen. Features It is applicable to different-shaped bottles and plastic bottles: plastic,glass bottle and mould bottle.The bottle-in and bottle-out has specialized structure .It doesn't drop bottles or nip bottles The surface of whole machine is made by stainless steel 304. Knockdown transparent hopper is easy cleaned. The hopper is specially made with a cover and a mix in it to prevent dust and make the powder even. The metering system is adjustable auger, which is driven by servo motor, with quick speed and high filling accuracy. PLC+ Human-computer touch screen control system: easy adjustment and easy operation. It also can save the parameters for later use. Online electronic scale can weight the powder gram automatically, ensure the filling accuracy. Bottle position correct device.To ensure the bottles and filling nozzles are in the correct position, we add a special bottles position device to make the whole filling process smooth and stable. No bottle no filling. Functions A high yield of cap-fastening Turntable fastness, replace simply and convenient. Come in and out bottle is easy, frequency conversion adjusting speed. Operate easily. It is easy maintenance. Concatenation work, automatism production, Saving time, improve efficiency. The whole machine is designed to meet GMP standard. Our advantages We provide our customers with all components for free within 1 year. We offer long life maintenance, technical support is available. We offer videos of installation and debugging. Our machine is easy for installation. We will take pictures of the disconnect parts of machines, you can install the machines according to pictures. We attach marks on the machines that need to connect, you can install the machines by yourselves. It is cost saving for you. The spare parts are optional according to customers needs. The handle of the machine can be freely and conveniently turned to adjust so that various types of bottles can be used.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Overview This metering pump filling machine is specially made for all viscous materials, such as water, gel, shampoo, oil etc. The machine adopts piston pump and for filling. By adjusting the position pump, it can fill all of the bottles in one filling machine, with quick speed and high precision. Feature 1. Adopts piston pump to fill, suitable for all kinds of liquid, high precision; The structure of pump adopts shortcut dismantling organ, convenient to wash, sterilize. 2. The piston ring of volumetric injection pump use different material of silicone, polyclonal or other kinds according to liquid characteristic, use ceramic pump in special industry. 3. PLC control system, frequency conversion adjusting speed, high degree automation. 4. No bottle, no filling, auto count the quantity. And have the anti-drop device. 5. Filling quantity of all pumps is adjusted in a lump, minim adjustable for each pump. Easy and quick operate. 6. Filling head is equipped with anti-dropping equipment, diving to the bottom to fill, rise slowly, to avoid bubble. 7. The whole honey bottle filling machine is suitable bottles in different size, easy adjusting, and can be finished in short time. 8. The whole machine meets GMP requirement. After sale service (1) Long life service (2) One year warranty (3) Offering free parts for one year . (4) Engnieers available to service machinery overseas

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Overview (1) the machine use the special filling valve, high vacuum pump, with low vacuum filling principle, bottle filling, don't choke wine, no foam, ensure consistent after filling the liquid surface. (2) filling the sealed bottle, liquid along the bottle wall downstream, the bottle has a broken bottle automatic irrigation, effectively control the filling of liquid shock bubbles, prevent the spill, do not spill liquid, not broken bottles, bottle automatically adapt to the high error. (3) the machine frequency control of motor speed, filling speed, the overload protection device, card bottle of downtime, boot soft start, elastic device, is used to reduce the breakage of the bottle. (4) with reference to foreign most advanced filling, sealing products and pour sauce) design and manufacturing of the seal, no body contact pneumatic tank under automatic control, production capacity for the touch screen control, is the domestic tomato sauce, honey or beverage product and cannery ideal equipment Feature (1) This filling machine’s tank is a double tank, which can be heated to keep the honey filling temperature & also with a mixer to make the tomato paste even. (2) The machine adopts full-auto PLC and human-computer touch screen control system, there are 8 languages for different persons. After sale service (1) Long life service (2) One year warranty (3) Offering free parts for one year . (4) Engnieers available to service machinery overseas

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact SupplierSpeedtek is specialized in production of home electronic and furniture lighting more than 15 years . With the relocation to Dongguan, our goal was to strengthen our product development. So far we have launched new products such as USB operated vests and shoe dryers, USB chargers, bluetooth headphones beanies, in-car DAB devices, DAB earmuffs, sport camera beanies and bluetooth work lamps. All of them received very good market response because of their high level of innovation and design. Our focus market includes European, American and Oceanian countries, with most OEM and ODM clients from the a.m. markets. We proudly announce our own brand new production plant with modern testing facilities, well-equipped production lines, skilled workers and an experienced R&D team. All of our products retain the latest internationally recognized certificates incl. GS, CE, S, BS, UL, CETL, SAA etc. We apply the newest technology and offer you professional products, which possess characteristics like smart controls, energy-saving solutions, modern lifestyle designs, convenient innovations, and much more. If you are interested in any of our products or have any inquiries, please do not hesitate to contact us. You are sincerely welcome to visit our factory or meet us at various trade fairs.

Contact SupplierShanghai New Terminal Industrial Co., Ltd. was founded in 1999 and is a professional home electronic products exporter and furniture lighting manufacturer located in Shanghai, which is the economical centre of China. With our own production in Shanghai , two purchasing offices in Dongguan and Ningbo, we can offer a wide range of electronic products, specializing in the following product groups: lighting, heating , household electronic devices and appliance , home security , hardware etc.. Our main market is West Europe , especially in Germany, UK, Scandinavian countries. We offer one-stop service wich is maximized in quality. We are also able to meet customer's specific needs. Our service covers the entire purchase chain, from product sourcing, development/ management, packing designing, to in-house testing, inspection, logistics and other important functions. We work with high passion and team spirit. We endeavor ourselves on the marketing of enviroment-frindly products. We do believe that our products will bring safety, energy-saving, comfort and convinience to you.

Contact SupplierShanghai New Terminal Industrial Co., Ltd. was founded in 1999 and is a professional home electronic products exporter and furniture lighting manufacturer located in Shanghai, which is the economical centre of China. With our own production in Shanghai , two purchasing offices in Dongguan and Ningbo, we can offer a wide range of electronic products, specializing in the following product groups: lighting, heating , household electronic devices and appliance , home security , hardware etc.. Our main market is West Europe , especially in Germany, UK, Scandinavian countries. We offer one-stop service wich is maximized in quality. We are also able to meet customer's specific needs. Our service covers the entire purchase chain, from product sourcing, development/ management, packing designing, to in-house testing, inspection, logistics and other important functions. We work with high passion and team spirit. We endeavor ourselves on the marketing of enviroment-frindly products. We do believe that our products will bring safety, energy-saving, comfort and convinience to you.

Contact Supplier 00:24

00:24

Key Feature > 5MP 1/2.8" SONY IMX335 illumination Progressive Scan CMOS > H.265+, H.265, H.264 dual-stream video compression > Up to 5Mp 2592*1944@15fps resolution; > 2.8-12mm Manual Vari-Focal Lens > 24pcs SMD IR LED, up to 30m IR distance > DWDR, True Day/Night(ICR), 3DNR, AWB, AGC, BLC > Optional 1ch audio input, 1ch audio output; > Intelligent analysis: Motion Detection, Brightness Detection, Virtual Cordon, Area Intrusion, Color Detection, Sound Detection, Residue Detection > Cloud Server, P2P, Mobile remote monitoring, CMS; > Support ONVIF, Compatible with other party CMS and platforms of Hikvision, Dahua, XM, Videopark, AEVision, Milestone etc. > Power supply DC12V, PoE

Shenzhen PolyCam Technology Co., Limited, was founded in June 2015 in order to exporting security video camera and surveillance products to worldwide with brand PLSECU. Shenzhen PolyCam has comprehensive IP surveillance product lines that encompass its broad range of Smart Network Camera, NVR XVR, 4in1 HD Cameras, Video Management Software, covering a diverse vertical markets including retail, building, industry, education, commercial, city surveillance etc.

Contact Supplier 00:13

00:13

Overview Automate bottle filling capping for small bottles , it is a high performance compact piston pump liquid filling machine and can be customized. We also can equip the peristaltic pump for filling. The system aseptically and precisely fills liquid to small bottles. An optional diving nozzle mechanism plunges the filling nozzles into the container for increased production speeds without splashing, and we can produce the different filing nozzles for your different speed requirement. Filling volumes are programmable and can be adjusted from the touch screen. Descriptions This machine is the matching product for various kinds of bottle packaging equipment and can automatically delivery the bottles into the conveying belt of the equipment, thus assuring the normal work of the bottle packaging equipments. The machine is applicable for small mass production. To the mass production, please select Automatic Bottle Distributing Machine. The machine completely meets the GMP standard.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:15

00:15

Overview Automate bottle filling capping for small bottles , it is a high performance compact piston pump liquid filling machine and can be customized. We also can equip the peristaltic pump for filling. The system aseptically and precisely fills liquid to small bottles. An optional diving nozzle mechanism plunges the filling nozzles into the container for increased production speeds without splashing, and we can produce the different filing nozzles for your different speed requirement. Filling volumes are programmable and can be adjusted from the touch screen. Characteristics ● It is applicable to different-shaped bottles and plastic bottles: PP , PE , PVC ,glass bottle and mould bottle. ● The bottle-in and bottle-out has specialized structure .It doesn't drop bottles or nip bottles ● The part which touches the liquid medicine is made of SS304 stainless material completely, meeting the requirement of CE GMP. ● It can be connected with the bottle-washing machine and the label-attaching machine to form a complete set of produce line. After sale service (1) Long life service (2) One year warranty (3) Offering free parts for one year . (4) Engnieers available to service machinery overseas

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 02:22

02:22

1.CNC bending machine with streamlined design,high speed,high precision,high rigidity. 2.Electro hydraulic servo system,full loop controlling the synchronization of the upper slider. 3.Mechanical compensation on the crowning of worktable and deformation compensation on throat,ensuring good bending strength and precision 4.Backgauge is driven by digital AC servo motor,moeved with ball screw,guided by linear guide 5.Muti-axis can be optional (3+1、4+1、6+1、8+1) 6.ManyCNC control system can be choose

Maanshan YuXiang Intelligent Equipment Technology Co.LtdLtd Was established in July 2015. It is a wholly-owned subsidiary of Anhui Donghai Machine Tool Co.,Ltd.It is a high-tech enterprise specializing in the production of optical fiber laser cutting machine, CNC bending machine, CNC shearing machine, CNC turret punching machine, CNC planer and other sheet metal intelligent equipment. Yuxiang is a comprehensive enterprise which with automatic control system design, new product development and research, equipment manufacturing industry innovation platform. It is located in Bowang Industrial zone,Maanshan City,Anhui Province,An hour in the Yangtze river delta economic circle and nanjing metropolitan circle, with ning an inter-city railway, high speed, hangzhou expressway, shanghai-nanjing expressway along the river and the Yangtze river golden waterway, 30 kilometers to Nanjing lukou international airport, the geographical location is superior with beautiful environment and convenient transportation.

Contact Supplier 02:52

02:52

1.CNCbending machine with streamlined design,high speed,high precision,high rigidity. 2.Electro hydraulic servo system,full loop controlling the synchronization of the upper slider. 3.Mechanical compensation on the crowning of worktable and deformation compensation on throat,ensuring good bending strength and precision 4.Backgauge is driven by digital AC servo motor,moved with ball screw,guided by linear guide 5.Muti-axis can be optional (3+1、4+1、6+1、8+1) 6.Many CNC control system can be choose V-Axis Table Compensation: V-axis is the CNC axis to control the adding convex amount of workbench, it can obtain accurate deflection compensation from the workbench. The adding convex workbench is made up of a group of beveled convex wedge, each wedge slope is designed by the deflection curve of finite element analysis of the slider and workbench vertical plate. CNC controller will calculate the required deflection amount according to the load when the work piece is working (The load will lead to the deflection and deformation), automatically control the relative motion of the convex wedge, and finally get an ideal work piece.

Maanshan YuXiang Intelligent Equipment Technology Co.LtdLtd Was established in July 2015. It is a wholly-owned subsidiary of Anhui Donghai Machine Tool Co.,Ltd.It is a high-tech enterprise specializing in the production of optical fiber laser cutting machine, CNC bending machine, CNC shearing machine, CNC turret punching machine, CNC planer and other sheet metal intelligent equipment. Yuxiang is a comprehensive enterprise which with automatic control system design, new product development and research, equipment manufacturing industry innovation platform. It is located in Bowang Industrial zone,Maanshan City,Anhui Province,An hour in the Yangtze river delta economic circle and nanjing metropolitan circle, with ning an inter-city railway, high speed, hangzhou expressway, shanghai-nanjing expressway along the river and the Yangtze river golden waterway, 30 kilometers to Nanjing lukou international airport, the geographical location is superior with beautiful environment and convenient transportation.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery

00:00

00:00