Established in 1996,Shanghai Changlong Industrial Equipment Co.,Ltd. is an enterprise specialized in sterilizer equipment, including designing and researching various series of plate type(tubular) heat exchangers,plate type (tubular) whole set sterilizer units, ice cream whole set equipment, concentrators,degassing units,tanks and vessels etc,.providing a chain of services including design,manufacturing,installation,commissioning and training etc.for the equipment and projects.

-

Flash Evaporating Unit

Product introduction: The flash evaporating equipment is applicable to food, fruit juice, dairy and vegetable juice etc. industries. By using the vaporization principle under te vacuum status, with high evaporation efficiency, it will realize the purpose of enhancing the dry materials of liquids(the

6 -

Milk Sterilizer

Company Info Established in 1996, Shanghai Changlong Industrial Equipment Co., Ltd. is an enterprise specialized in designing and researching various series of plate type(tubular) heat exchangers, plate type(tubular) whole set sterilizer units, ice cream whole set equipment, conc

45

- Contacter: Mr he

- Tel: +86-21-33658300

- Fax: +86-21-33658306

- Email: yenan0607@chang-long.net

-

Company Address:

No.1555 Xiaonan Rd, Jianghai Economic Zone, Fengpu, Shanghai

Flash Evaporating Unit

Product introduction: The flash evaporating equipment is applicable to food, fruit juice, dairy and vegetable juice etc. industries. By using the vaporization principle under te vacuum status, with high evaporation efficiency, it will realize the purpose of enhancing the dry materials of liquids(the dry material of fresh milk can be increased above 0.8%).

The equipment has such features as simple operation and convenient maintenance.

It is mainly composed of flash evaporating tank, double-seal material pump, condenser, condensed water pump, water ring type vacuum pump and electric control etc.

Structural form: integral unit form, form fit fot the sterilizer.

Technical Parameter

Model

TQ-2-3-A

TQ-4-6-A

Capacity

4~5t/h

8~10t/h

Evaporation

250~320kg/h

510~650kg/h

Working pressure

-0.0070~-0.090Mpa

-0.0070~-0.090Mpa

Energy consumption

12kw

14kw

Outline dimensions

2100*1200*320

2700*1250*3500

Flash Evaporating Unit

Product introduction: The flash evaporating equipment is applicable to food, fruit juice, dairy and vegetable juice etc. industries. By using the vaporization principle under te vacuum status, with high evaporation efficiency, it will realize the purpose of enhancing the dry materials of liquids(the dry material of fresh milk can be increased above 0.8%).

The equipment has such features as simple operation and convenient maintenance.

It is mainly composed of flash evaporating tank, double-seal material pump, condenser, condensed water pump, water ring type vacuum pump and electric control etc.

Structural form: integral unit form, form fit fot the sterilizer.

Technical Parameter

Model

TQ-2-3-A

TQ-4-6-A

Capacity

4~5t/h

8~10t/h

Evaporation

250~320kg/h

510~650kg/h

Working pressure

-0.0070~-0.090Mpa

-0.0070~-0.090Mpa

Energy consumption

12kw

14kw

Outline dimensions

2100*1200*320

2700*1250*3500

Milk Sterilizer

Company Info

Established in 1996, Shanghai Changlong Industrial Equipment Co., Ltd. is an enterprise specialized in designing and researching various series of plate type(tubular) heat exchangers, plate type(tubular) whole set sterilizer units, ice cream whole set equipment, concentrators, degassing units, tanks and vessels etc., providing a chain of services including design, manufacturing, installation, commissioning and training etc.

Our products not only enjoy high reputation in the country, but also have been exported to Germany, Japan, Australia, Russia, Southeast Aisa and Mid East., etc. Changlong is certified to ISO9001:2000 Quality System.

Changlong have been working on several specific prodcuts which makes us an expert. Our product are wildly applied in milk, cream, yoghurt, beer, chilli sauce, ketchup, tamato sauce, juice and beverage.

Honey

Ketchup

Tomato Sauce

Chilli Sauce

Jam

Cream

Yoghurt

Fruit

Fruit Juice

Tea Beverage

Soy Sauce

Veniger

We have the confidence to provide you the products and service you need.

Technology introduction

Technology: 5℃→65℃Homogenization→95℃30S→140℃4S→25℃

Ice water 1:1(≤2℃spare) Cooling water 1:1(30℃spare)

Techinical Parameter

model and specification

capacity

steam consumption

steam pressure

power

outline dimensions of integral type

outline dimensions of split type

weight

pipe diameter

t/h

kg/h

bar

kw

l*w*h

l*w*h

kg

material

steam

medium

TG-UHT-1MQJ

1

40

6.0

4.0

3.3*1.6*1.8

1960

25

DN25

25

TG-UHT-1.5MQJ

1.5

60

6.0

4.0

3.3*1.6*1.8

1960

25

DN25

25

TG-UHT-2MQJ

2

80

6.0

6.0

3.5*1.8*2.0

2160

38

DN25

38

TG-UHT-3MQJ

3

120

6.0

6.0

3.5*1.8*2.0

2420

38

DN32

38

TG-UHT-4MQJ

4

160

6.0

7.0

4.5*2.0*2.0

6.5*0.9*1.4

2570

38

DN32

38

TG-UHT-5MQJ

5

200

6.0

7.0

4.5*1.8*2.0

6.5*0.9*1.4

2940

51

DN40

51

TG-UHT-6MQJ

6

240

6.0

7.0

4.5*2.0*2.2

6.5*0.9*1.4

3300

51

DN40

51

TG-UHT-8MQJ

8

320

6.0

11.0

4.5*2.0*2.2

6.5*0.9*1.4

3700

51

DN50

51

TG-UHT-10MQJ

10

400

6.0

11.0

4.5*2.0*2.2

6.5*0.9*1.4

4200

51

DN50

51

Milk Sterilizer

Company Info

Established in 1996, Shanghai Changlong Industrial Equipment Co., Ltd. is an enterprise specialized in designing and researching various series of plate type(tubular) heat exchangers, plate type(tubular) whole set sterilizer units, ice cream whole set equipment, concentrators, degassing units, tanks and vessels etc., providing a chain of services including design, manufacturing, installation, commissioning and training etc.

Our products not only enjoy high reputation in the country, but also have been exported to Germany, Japan, Australia, Russia, Southeast Aisa and Mid East., etc. Changlong is certified to ISO9001:2000 Quality System.

Changlong have been working on several specific prodcuts which makes us an expert. Our product are wildly applied in milk, cream, yoghurt, beer, chilli sauce, ketchup, tamato sauce, juice and beverage.

Honey

Ketchup

Tomato Sauce

Chilli Sauce

Jam

Cream

Yoghurt

Fruit

Fruit Juice

Tea Beverage

Soy Sauce

Veniger

We have the confidence to provide you the products and service you need.

Technology introduction

Technology: 5℃→65℃Homogenization→95℃30S→140℃4S→25℃

Ice water 1:1(≤2℃spare) Cooling water 1:1(30℃spare)

Techinical Parameter

model and specification

capacity

steam consumption

steam pressure

power

outline dimensions of integral type

outline dimensions of split type

weight

pipe diameter

t/h

kg/h

bar

kw

l*w*h

l*w*h

kg

material

steam

medium

TG-UHT-1MQJ

1

40

6.0

4.0

3.3*1.6*1.8

1960

25

DN25

25

TG-UHT-1.5MQJ

1.5

60

6.0

4.0

3.3*1.6*1.8

1960

25

DN25

25

TG-UHT-2MQJ

2

80

6.0

6.0

3.5*1.8*2.0

2160

38

DN25

38

TG-UHT-3MQJ

3

120

6.0

6.0

3.5*1.8*2.0

2420

38

DN32

38

TG-UHT-4MQJ

4

160

6.0

7.0

4.5*2.0*2.0

6.5*0.9*1.4

2570

38

DN32

38

TG-UHT-5MQJ

5

200

6.0

7.0

4.5*1.8*2.0

6.5*0.9*1.4

2940

51

DN40

51

TG-UHT-6MQJ

6

240

6.0

7.0

4.5*2.0*2.2

6.5*0.9*1.4

3300

51

DN40

51

TG-UHT-8MQJ

8

320

6.0

11.0

4.5*2.0*2.2

6.5*0.9*1.4

3700

51

DN50

51

TG-UHT-10MQJ

10

400

6.0

11.0

4.5*2.0*2.2

6.5*0.9*1.4

4200

51

DN50

51

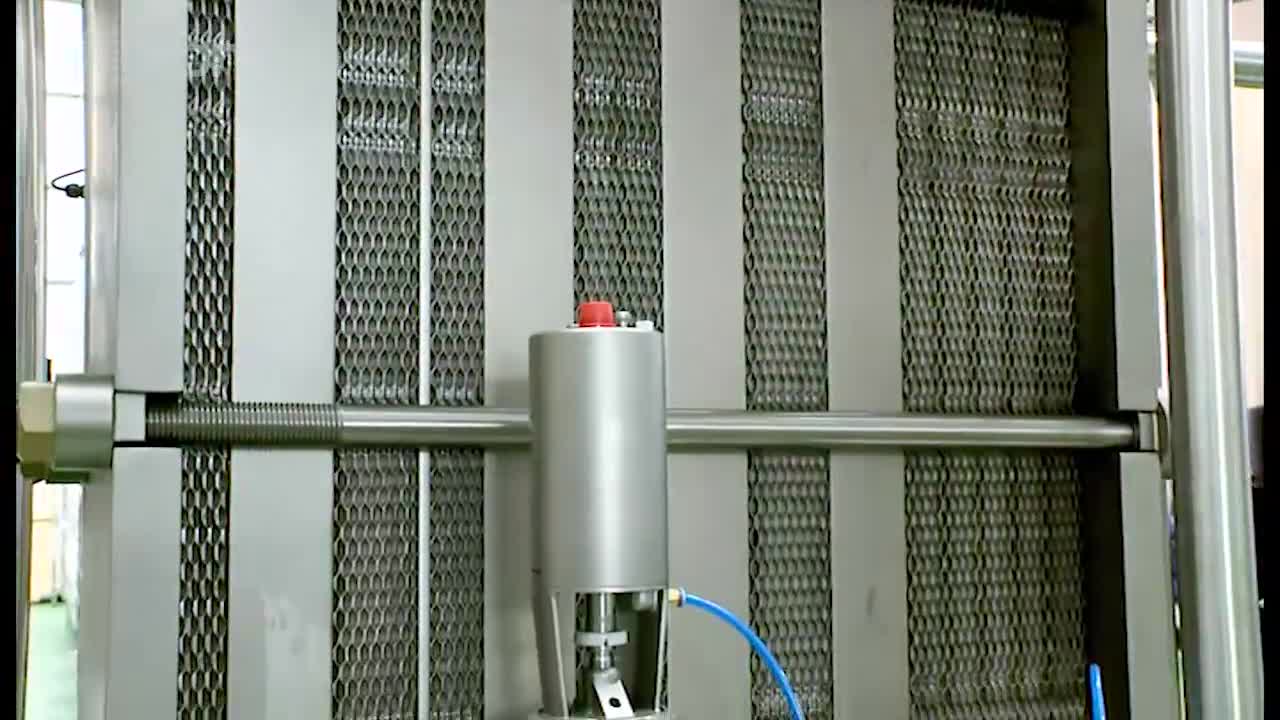

Tubular UHT Sterilizer

Company Info

Established in 1996, Shanghai Changlong Industrial Equipment Co., Ltd. is an enterprise specialized in designing and researching various series of plate type(tubular) heat exchangers, plate type(tubular) whole set sterilizer units, ice cream whole set equipment, concentrators, degassing units, tanks and vessels etc., providing a chain of services including design, manufacturing, installation, commissioning and training etc.

Our products not only enjoy high reputation in the country, but also have been exported to Germany, Japan, Australia, Russia, Southeast Aisa and Mid East., etc. Changlong is certified to ISO9001:2000 Quality System.

Changlong have been working on several specific prodcuts which makes us an expert. Our product are wildly applied in milk, cream, yoghurt, beer, chilli sauce, ketchup, tamato sauce, juice and beverage.

Honey

Ketchup

Tomato Sauce

Chilli Sauce

Jam

Cream

Yoghurt

Fruit

Fruit Juice

Tea Beverage

Soy Sauce

Veniger

We have the confidence to provide you the products and service you need.

Product introduction

The sterilization process of tubular ultra-high temperature sterilizer not only can be suitable for common products, but also can satisfy special requirements of customers,for example:long term production of products with granules or medium and high viscosity. Such an cream,pure milk etc.products(milk, fruit juice and cream )of high viscosity:products containing fiber and larger pulp granules, products of high acidity and products corrosive to the dead angle. The products can be sterilized at high temperature and ultra-high temperature of 120~140℃.

Main features:Hard to agglomerate,long working time;PLC control with simple and correct operation;touch screen display, which is direct and full; self-provided CIPcleaning system,easy cleaning;reliable materials with high pressure withstanding capacity;low maintenance cost. It can be customized to satisfy infividualized requirements of different customers.

Techinical Parameter

Name

TG-7-1.6-35

TG-7-1.6-45

TG-7-1.6-58

TG-7-1.6-72

Production capacity

t/h

2

3

4

5

Heat exchanging area

m2

35

45

58

72

Temperature of material inlet

℃

5

5

5

5

Temperature of material outlet

℃

25

25

25

25

Sterilizing temperature

℃

95-137

95-137

95-137

95-137

Heat preservation period

S

15-4

15-4

15-4

15-4

Ice water consumption

multiple

3

3

3

3

Cooling water consumption

multiple

2

2

2

2

Energy consumption

kw

10

10

12

14

Outline dimensions

mm

4500*1900*1880

4500*1900*1880

4500*1900*1880

6500*2000*1880

Tubular UHT Sterilizer

Company Info

Established in 1996, Shanghai Changlong Industrial Equipment Co., Ltd. is an enterprise specialized in designing and researching various series of plate type(tubular) heat exchangers, plate type(tubular) whole set sterilizer units, ice cream whole set equipment, concentrators, degassing units, tanks and vessels etc., providing a chain of services including design, manufacturing, installation, commissioning and training etc.

Our products not only enjoy high reputation in the country, but also have been exported to Germany, Japan, Australia, Russia, Southeast Aisa and Mid East., etc. Changlong is certified to ISO9001:2000 Quality System.

Changlong have been working on several specific prodcuts which makes us an expert. Our product are wildly applied in milk, cream, yoghurt, beer, chilli sauce, ketchup, tamato sauce, juice and beverage.

Honey

Ketchup

Tomato Sauce

Chilli Sauce

Jam

Cream

Yoghurt

Fruit

Fruit Juice

Tea Beverage

Soy Sauce

Veniger

We have the confidence to provide you the products and service you need.

Product introduction

The sterilization process of tubular ultra-high temperature sterilizer not only can be suitable for common products, but also can satisfy special requirements of customers,for example:long term production of products with granules or medium and high viscosity. Such an cream,pure milk etc.products(milk, fruit juice and cream )of high viscosity:products containing fiber and larger pulp granules, products of high acidity and products corrosive to the dead angle. The products can be sterilized at high temperature and ultra-high temperature of 120~140℃.

Main features:Hard to agglomerate,long working time;PLC control with simple and correct operation;touch screen display, which is direct and full; self-provided CIPcleaning system,easy cleaning;reliable materials with high pressure withstanding capacity;low maintenance cost. It can be customized to satisfy infividualized requirements of different customers.

Techinical Parameter

Name

TG-7-1.6-35

TG-7-1.6-45

TG-7-1.6-58

TG-7-1.6-72

Production capacity

t/h

2

3

4

5

Heat exchanging area

m2

35

45

58

72

Temperature of material inlet

℃

5

5

5

5

Temperature of material outlet

℃

25

25

25

25

Sterilizing temperature

℃

95-137

95-137

95-137

95-137

Heat preservation period

S

15-4

15-4

15-4

15-4

Ice water consumption

multiple

3

3

3

3

Cooling water consumption

multiple

2

2

2

2

Energy consumption

kw

10

10

12

14

Outline dimensions

mm

4500*1900*1880

4500*1900*1880

4500*1900*1880

6500*2000*1880

Plate Pasteurizer

Company Info

Established in 1996, Shanghai Changlong Industrial Equipment Co., Ltd. is an enterprise specialized in designing and researching various series of plate type(tubular) heat exchangers, plate type(tubular) whole set sterilizer units, ice cream whole set equipment, concentrators, degassing units, tanks and vessels etc., providing a chain of services including design, manufacturing, installation, commissioning and training etc.

Our products not only enjoy high reputation in the country, but also have been exported to Germany, Japan, Australia, Russia, Southeast Aisa and Mid East., etc. Changlong is certified to ISO9001:2000 Quality System.

Changlong have been working on several specific prodcuts which makes us an expert. Our product are wildly applied in milk, cream, yoghurt, beer, chilli sauce, ketchup, tamato sauce, juice and beverage.

Coconut milk

Coconut Water

Juice

Milk

Fresh Milk

Soymilk

Yoghurt

Beer

Beverage

We have the confidence to provide you the products and service you need.

Product description

It is applicable to heating, sterilization, heat-preservation and cooling etc. technology requirements of fresh milk, fruit beverage and alcohol etc. heat sensitive liquids. The equipment has such features an high heat recovery, energy saving and low consumption, compact structure, simple operation and convenient maintenance etc.

Control methods--semi-automatic control, full-automatic control(PLC control, touch screen display)

Main accessories--material pump, balancing tank, hot water system, temperature controller and recorder, electric control sysem etc.

Production capacity--0.5--50t/h

Sterilizing temperature--85-95 degree

Heat preservation period--15--30s

Techinical Parameter

Name

BR1-PUT-8B

BR16-PUT-13B

BR26-PUT-28B

BR26-PUT-52B

Production capacity

t/h

1

2

5

10

Heat exchanging area

m2

8

13

28

52

Temperature of material inlet

℃

5

5

5

5

Temperature of material outlet

℃

5

5

5

5

Sterilizing temperature

℃

85-95

85-95

85-95

85-95

Heat preservation period

s

25

25

25

25

Ice water temperature

℃

1

1

1

1

Ice water consumption

multiple

3

3

3

3

Cooling water consumption

multiple

2

2

2

2

Connector size

mm

32

38

51

51

Energy consumption

kw

3

3

6

10

Outline dimensions

mm

1500*1500*1800

1800*2000*1800

2200*2000*2000

2600*2000*2200

Plate Pasteurizer

Company Info

Established in 1996, Shanghai Changlong Industrial Equipment Co., Ltd. is an enterprise specialized in designing and researching various series of plate type(tubular) heat exchangers, plate type(tubular) whole set sterilizer units, ice cream whole set equipment, concentrators, degassing units, tanks and vessels etc., providing a chain of services including design, manufacturing, installation, commissioning and training etc.

Our products not only enjoy high reputation in the country, but also have been exported to Germany, Japan, Australia, Russia, Southeast Aisa and Mid East., etc. Changlong is certified to ISO9001:2000 Quality System.

Changlong have been working on several specific prodcuts which makes us an expert. Our product are wildly applied in milk, cream, yoghurt, beer, chilli sauce, ketchup, tamato sauce, juice and beverage.

Coconut milk

Coconut Water

Juice

Milk

Fresh Milk

Soymilk

Yoghurt

Beer

Beverage

We have the confidence to provide you the products and service you need.

Product description

It is applicable to heating, sterilization, heat-preservation and cooling etc. technology requirements of fresh milk, fruit beverage and alcohol etc. heat sensitive liquids. The equipment has such features an high heat recovery, energy saving and low consumption, compact structure, simple operation and convenient maintenance etc.

Control methods--semi-automatic control, full-automatic control(PLC control, touch screen display)

Main accessories--material pump, balancing tank, hot water system, temperature controller and recorder, electric control sysem etc.

Production capacity--0.5--50t/h

Sterilizing temperature--85-95 degree

Heat preservation period--15--30s

Techinical Parameter

Name

BR1-PUT-8B

BR16-PUT-13B

BR26-PUT-28B

BR26-PUT-52B

Production capacity

t/h

1

2

5

10

Heat exchanging area

m2

8

13

28

52

Temperature of material inlet

℃

5

5

5

5

Temperature of material outlet

℃

5

5

5

5

Sterilizing temperature

℃

85-95

85-95

85-95

85-95

Heat preservation period

s

25

25

25

25

Ice water temperature

℃

1

1

1

1

Ice water consumption

multiple

3

3

3

3

Cooling water consumption

multiple

2

2

2

2

Connector size

mm

32

38

51

51

Energy consumption

kw

3

3

6

10

Outline dimensions

mm

1500*1500*1800

1800*2000*1800

2200*2000*2000

2600*2000*2200

Plate Heat Exchanger

Company Info

Established in 1996, Shanghai Changlong Industrial Equipment Co., Ltd. is an enterprise specialized in designing and researching various series of plate type(tubular) heat exchangers, plate type(tubular) whole set sterilizer units, ice cream whole set equipment, concentrators, degassing units, tanks and vessels etc., providing a chain of services including design, manufacturing, installation, commissioning and training etc.

Our products not only enjoy high reputation in the country, but also have been exported to Germany, Japan, Australia, Russia, Southeast Aisa and Mid East., etc. Changlong is certified to ISO9001:2000 Quality System.

Changlong have been working on several specific prodcuts which makes us an expert. Our product are wildly applied in milk, cream, yoghurt, beer, chilli sauce, ketchup, tamato sauce, juice and beverage.

Coconut milk

Coconut Water

Juice

Milk

Fresh Milk

Soymilk

Yoghurt

Beer

Beverage

We have the confidence to provide you the products and service you need.

Two-section ice cream cooling(cooling and heat recovery of dispensing water)

Material: 85℃→35℃→5℃

Recovery of dispensing water:

Ice water: (4:1)2℃→12℃

Two-section ice cream cooling

Material: 85℃→40℃→5℃

Recovery of dispensing water: (3:1)30℃→42℃

Ice water: (4:1)2℃→12℃

Technical Parameter

Model

Flow rate

Material diameter

Medium diameter

Outline dimensions

Weight

(l/h)

(mm)

(mm)

(mm)

(kg)

BR16-JZH-8B

1000

Φ25

Φ38

600*310*1320

750

BR16-JZH-10B

2000

Φ38

Φ38

800*310*1320

850

BR26-JZH-16B

3000

Φ51

Φ38/51

1000*460*1520

950

BR26-JZH-20B

4000

Φ51

Φ38/51

1100*460*1520

1050

BR26-JZH-24B

5000

Φ51

Φ38/51

1200*460*1520

1150

BR4-JZH-30B

6000

Φ63

Φ51/63

1200*700*1550

1180

BR4-JZH-36B

8000

Φ63

Φ51/63

1300*700*1550

1280

BR56-JZH-42B

10000

Φ76

Φ51/76

1500*810*1600

1450

Material cooling(two-sectioncooling)

Material: 65℃→35℃→5℃

Cooling water: (tower water 2.5:1)30℃→42℃

Ice water: (3:1)2℃→12℃

Technical Parameter

Model

Flow rate

Material diameter

Medium diameter

Outline dimensions

Weight

(l/h)

(mm)

(mm)

(mm)

(kg)

BR1-JZH-2.5B

1000

Φ25

Φ25

550*285*810

150

BR1-JZH-5B

2000

Φ25/38

Φ38

600*285*810

220

BR16-JZH-10B

3000

Φ38

Φ38

800*350*1320

750

BR26-JZH-15B

6000

Φ51

Φ51

1000*460*1520

950

BR26-JZH-25B

10000

Φ51

Φ63

1200*460*1520

1050

BR26-JZH-35B

15000

Φ63

Φ63

1400*460*1520

1150

BR4-JZH-45B

20000

Φ76

Φ76

1500*700*4550

1250

BR56-JZH-65B

30000

Φ76

Φ101

1700*810*1600

1350

Plate Heat Exchanger

Company Info

Established in 1996, Shanghai Changlong Industrial Equipment Co., Ltd. is an enterprise specialized in designing and researching various series of plate type(tubular) heat exchangers, plate type(tubular) whole set sterilizer units, ice cream whole set equipment, concentrators, degassing units, tanks and vessels etc., providing a chain of services including design, manufacturing, installation, commissioning and training etc.

Our products not only enjoy high reputation in the country, but also have been exported to Germany, Japan, Australia, Russia, Southeast Aisa and Mid East., etc. Changlong is certified to ISO9001:2000 Quality System.

Changlong have been working on several specific prodcuts which makes us an expert. Our product are wildly applied in milk, cream, yoghurt, beer, chilli sauce, ketchup, tamato sauce, juice and beverage.

Coconut milk

Coconut Water

Juice

Milk

Fresh Milk

Soymilk

Yoghurt

Beer

Beverage

We have the confidence to provide you the products and service you need.

Two-section ice cream cooling(cooling and heat recovery of dispensing water)

Material: 85℃→35℃→5℃

Recovery of dispensing water:

Ice water: (4:1)2℃→12℃

Two-section ice cream cooling

Material: 85℃→40℃→5℃

Recovery of dispensing water: (3:1)30℃→42℃

Ice water: (4:1)2℃→12℃

Technical Parameter

Model

Flow rate

Material diameter

Medium diameter

Outline dimensions

Weight

(l/h)

(mm)

(mm)

(mm)

(kg)

BR16-JZH-8B

1000

Φ25

Φ38

600*310*1320

750

BR16-JZH-10B

2000

Φ38

Φ38

800*310*1320

850

BR26-JZH-16B

3000

Φ51

Φ38/51

1000*460*1520

950

BR26-JZH-20B

4000

Φ51

Φ38/51

1100*460*1520

1050

BR26-JZH-24B

5000

Φ51

Φ38/51

1200*460*1520

1150

BR4-JZH-30B

6000

Φ63

Φ51/63

1200*700*1550

1180

BR4-JZH-36B

8000

Φ63

Φ51/63

1300*700*1550

1280

BR56-JZH-42B

10000

Φ76

Φ51/76

1500*810*1600

1450

Material cooling(two-sectioncooling)

Material: 65℃→35℃→5℃

Cooling water: (tower water 2.5:1)30℃→42℃

Ice water: (3:1)2℃→12℃

Technical Parameter

Model

Flow rate

Material diameter

Medium diameter

Outline dimensions

Weight

(l/h)

(mm)

(mm)

(mm)

(kg)

BR1-JZH-2.5B

1000

Φ25

Φ25

550*285*810

150

BR1-JZH-5B

2000

Φ25/38

Φ38

600*285*810

220

BR16-JZH-10B

3000

Φ38

Φ38

800*350*1320

750

BR26-JZH-15B

6000

Φ51

Φ51

1000*460*1520

950

BR26-JZH-25B

10000

Φ51

Φ63

1200*460*1520

1050

BR26-JZH-35B

15000

Φ63

Φ63

1400*460*1520

1150

BR4-JZH-45B

20000

Φ76

Φ76

1500*700*4550

1250

BR56-JZH-65B

30000

Φ76

Φ101

1700*810*1600

1350