10L Tested kettle---42m3large-scale reaction kettle

2.Specification of Raw Material and Utilities :

| Material / Utility | Value | Unit |

|---|---|---|

| Formalin | 37-52 | % |

| Urea | 46.5 | % |

| Melamine | 99.8 | % |

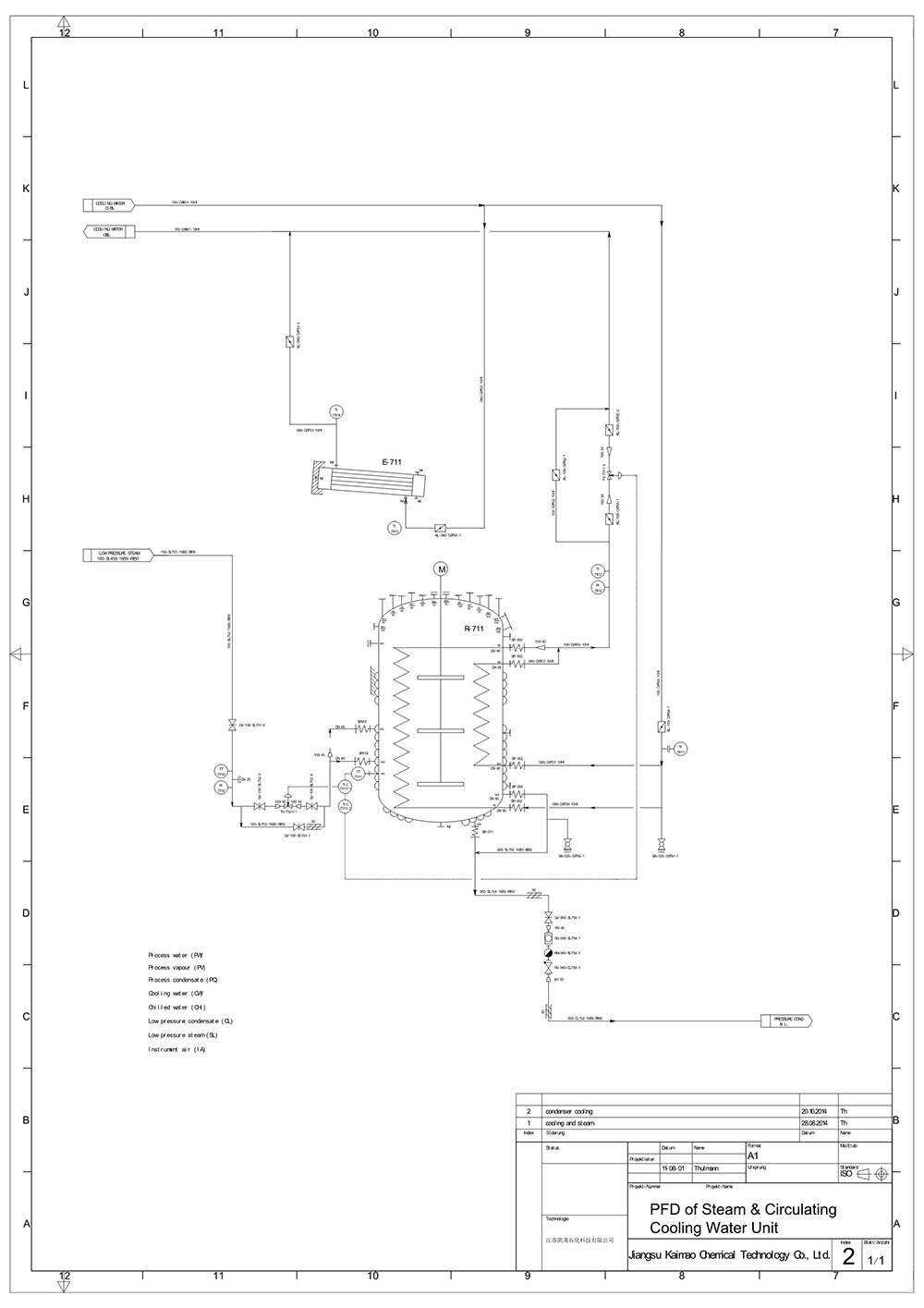

| Process water | 500 | kg/h |

| 0.3 | Mpa | |

| Cooling water | 250 | m3/h |

| 31 | °C | |

| 0.3 | Mpa | |

| Low pressure steam | 2500 | kg/h |

| 0.6 | Mpa | |

| Instrument air | 28 | Nm3/h |

| 0.4 | Mpa | |

| Electrical power | install219 | kW |

| employ170 | kW |

3.Product Quality:

| S/N | Item | Index | |||

| UF RESIN E2 | MUF RESIN E2 | UF RESIN E1 | UF RESIN E0 | ||

| 1 | Appearance | Semi opaque viscous liquid | |||

| 2 | Viscosity at 30 ° C | 200-250 cps | 200 cps | 50-200 | 180 cps |

| 3 | Solids Content at 2hr/120oC | 49-51% | 56% | 50-54% | 54% |

| 4 | Specific Gravity at 30oC | 1.180-1.200 | 1.21 | 1.18-1.20 | 1.205 |

| 5 | pH at 30oC | 8.0-9.0 | 8.75 | 7.0-8.0 | 9.00 |

| 6 | Gel time | 30-40 sec | 50 sec | 50-90 sec | 200 sec |

4. Consumption Index:

Taking example of UF glue with E0 level:

Formaldehyde------37% formaldehyde ~468.5 kg/t

Urea—— ~346.7 kg/t

Electricity —— workshop electricity quantity ~8.4 kWh/t ( not including the utilities)

Steam--- It is about half an hour for the reaction starting steam and about 1.2 hours for the dewatering starting steam. The DN80 pipe is estimated with the total steam consumption of 4.352t(0.6Mpa). The steam consumption per ton is ~0.22 t/t(0.6Mpa), interrupted to supply.

The circulation cooling water--- The materials in the glue making tank need cooling after reaction, and the estimated time is 1.5h. The materials in the glue making tank need cooling after dewatering, and the estimated time is 0.8 hour, and the total period is 2.3hours.

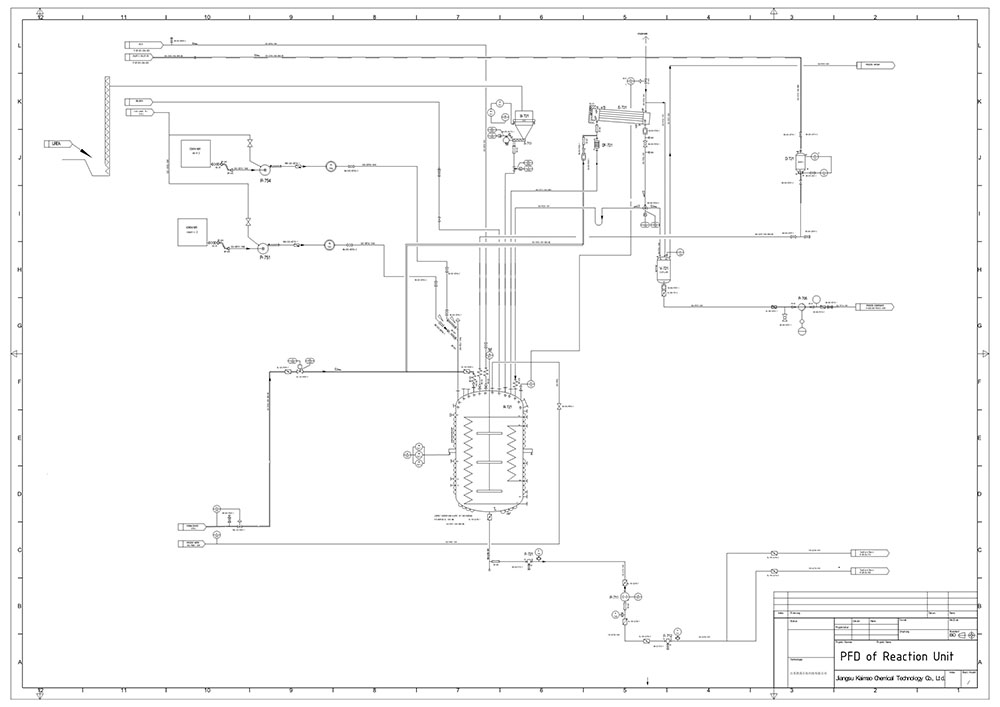

• The brief introduction of process:

1.Addition phase: adding formaldehyde and U1, adjusting the PH value to 7.5~8.0,increasing the temperature to 85-90℃,having insulation for 30 minutes, adjusting the PH value to be acidic condition and waiting for the natural reaction, forming glue. Having test on the viscosity and adding alkali to stop the reaction.

2 First polycondensation: adding U2, with reaction time of 20-30 minutes.Testing the viscosity degree and adding alkali to stop the reaction.

3 Second polycondensation: adding U3, with insulation of 20-30 minutes ,temperature is decreased to be below 75℃. Adding U4 and adjusting the PH value to be 7.0-7.2, and decreasing the temperature to be below 50 degree, having glue.

Instruction: It is decided by the needed glue environmental protection level and the the matched wood material to add Poly (vinyl alcohol), melamine, additives and ammonia, with PH vale, temperature,reaction period per phase and insulation period being different, which is flexible to grasp.

•Plant and the technology features:

1.The heat exchanging technology with same band and turbulence stirring technology are adopted by the resin stirring kettle, with bigger heat exchanging area, fasted heat exchanging rate, to better the heat exchanging, to increase and decrease the temperature faster and to keep temperature at all points more consistent. The stirring in the kettle will be more even and the glue residue will be less. The glue quality will be somehow improved, with the production quantity of glue improved to be more than 5%.

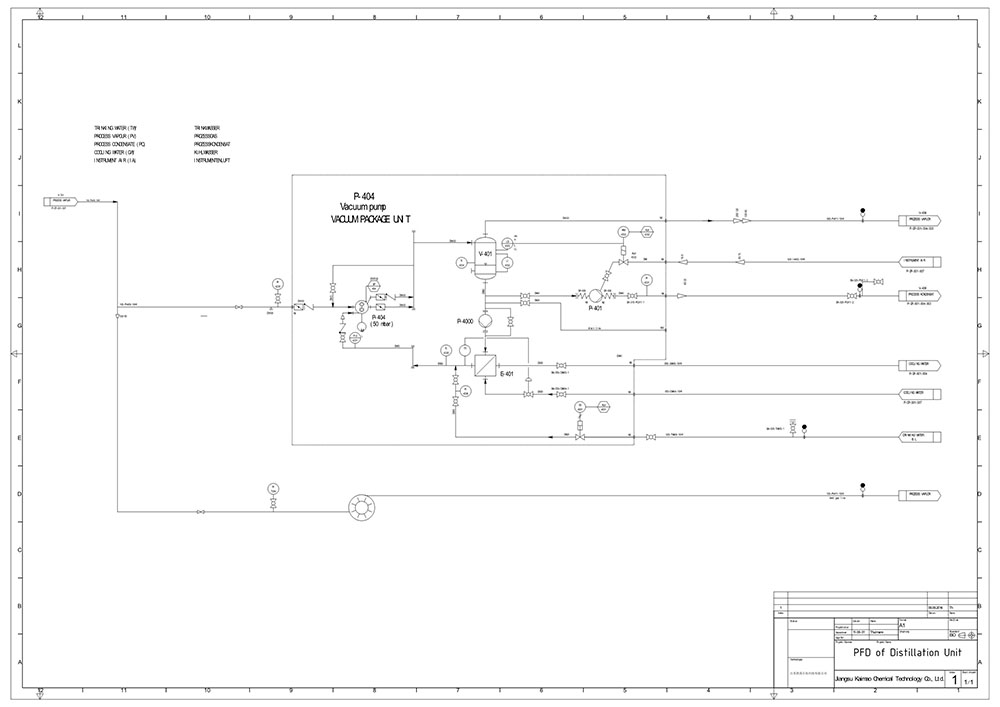

2.The high efficiency cooler adopts the high efficient heat exchanging structure, with faster heat exchanging rate, better heat exchanging effects, and more saved space.

3.The PLG controlling technology is adopted in the electric controlling system, with all the adding materials, temperature controlling points controlled by the computers, reducing the operation mistakes caused by artificial reasons , and also offering curve records of temperature and weight, and ensuring the safety production and high quantified glue.