01:42

01:42

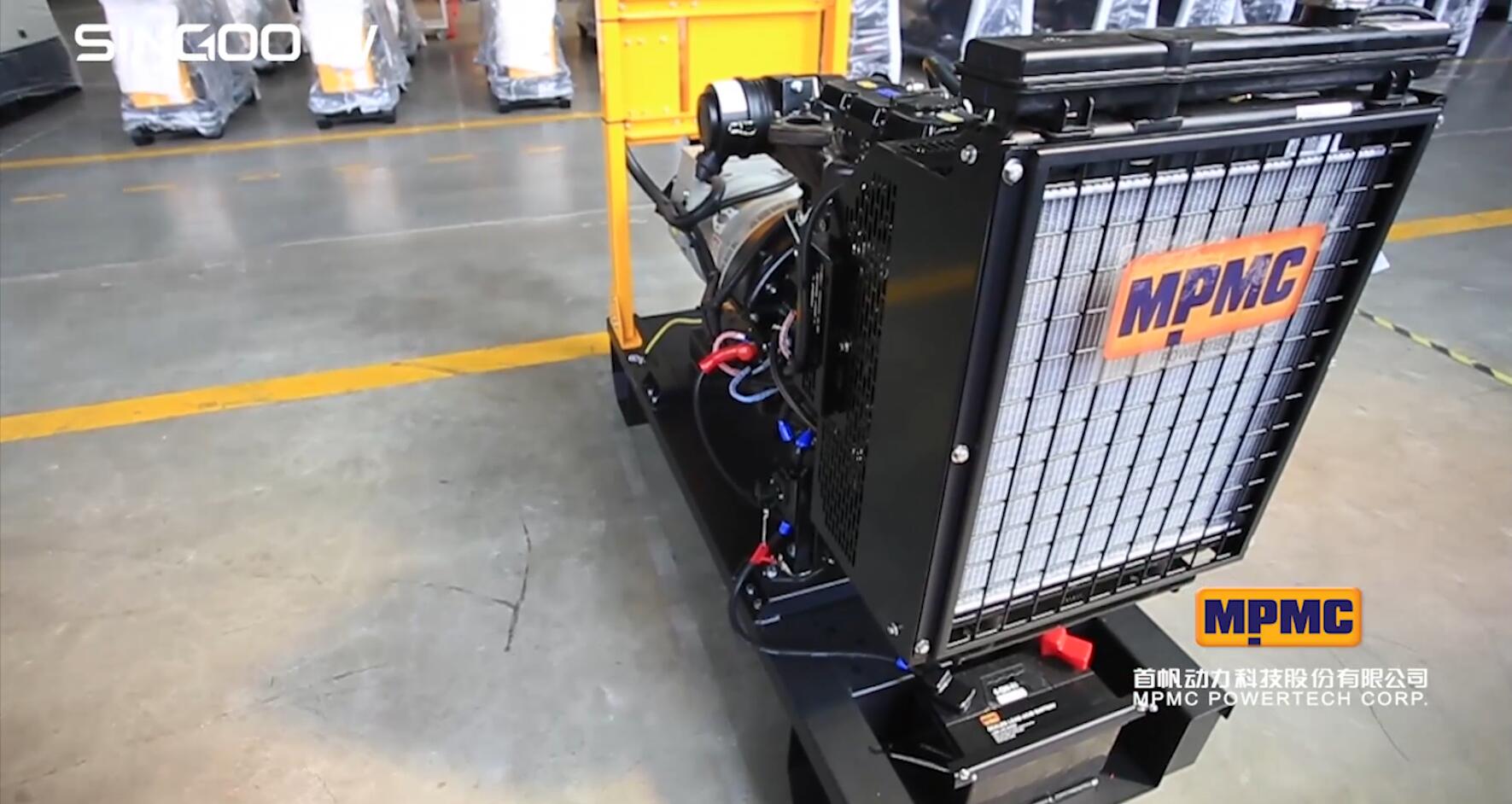

MPMC is an Original Equipment Manufacturer (OEM) of diesel generator sets powered by Perkins diesel engines. We choose Perkins(UK) engine, with quick and reliable cold start performance, applying advanced technologies, optimized combustion, making low fuel consumption and low noise, which is energy-saving and environment protective. We can provide a wide range of generators powered by Perkins engine. Introduction to Perkins: 1)Perkins is one of the world’s leading diesel engine manufacturers since 1932, produced nearly 400,000 units for one year and quickly occupied the world market for the full specification, good structure, reliable performance, easy maintenance, low exhaust and long period maintenance. In the auto car, construction, agricultural, industrial and marine markets, major original equipment manufacturers choose Perkins Engines for the reliable and durable use. 2) Perkins (Wuxi) Factory is the only production base of Perkins engine in China and it can manufacture 400 series, 1106 series of Perkins engine now. Features of Genset Powered by Perkins: 1. International Warranty Service 2. EU emission standard 3. With ISO9001& CE certification 4. Spare parts are easy to get from worldwide market with much cheaper price 5. Coupled with Stamford, Meccalte, Leroysomer alternator or China alternator 6. Perfect after-service network 7. Power range from 9kva to 2250kva 8. Rigorous test including 50% load, 75% load, 100% load and 110% load 9. Warranty: One year or 1500 Working Hours from the shipment date, whichever comes first. Standard Configuration of Perkins Open Type: 1. Perkins engine 2. Leroy Somer alternator (Stamford, Meccalte, MPMC brand for option) 3. Deepsea DSE3110 control panel as standard, AMF Control Panel Deepsea DSE7320& Smartgen HGM6120 for Option, ATS for Option 4) Chint breaker as standard, ABB, Schneider Breaker for Option 5) 8 Working Hours Base Fuel Tank (for the genset ≤ 650kVA prime, only Base Frame for other models) 6) Anti-Vibration Mounted System 7) Battery and battery switch 8) Industrial silencer and flexible exhaust hose For open type, the genset will be much easier to maintain and repair with more durable performance and longer service life, so the cost performance is higher.

Welcome to MPMC MPMC POWERTECH CORP. We're now providing comprehensive stable and timely solutions for Electricity Power Supplying Systems in all application fields ...

Contact Supplier 01:25

01:25

High rigidity separated structure casting frame, with guide pillar / sleeve unit. Suitable for Automatic high speed stamping of motor lamination. J76 series straight side high-speed Two-point Press line is Separated-structure and high-rigidity cast iron frame, base and crossbeam are tightened by four tensile screw rods, with high rigidity and less deformation; Automatic temperature control system and using the thermal compensation technology to control the position of bottom dead center in high precision; Four point crankshaft supporting structure, enhancing the strength of crankshafts, less deformation, high rigidity and strong load deviation resistant capability. Gas chamber balance device, to balance the slide and the weight of upper die, ensuring the balance of the press in running; Imported pneumatic combination friction clutch-brake, with low noise, long service life, large clutch torque and small braking angle, to ensure reliable safety and flexible action The machine has dynamic balancing system, reducing the noise from vibration, extending the service life of the dies and improving working environment; Suitable for Automatic high speed stamping of motor lamination. Main Structure Features Separated structure and high rigidity cast-iron frame High strength eccentric alloyed steel crankshaft Imported bearings and four-point crank supporting structure(80-300T) Slide is guided by liner clearance-free ball bearing plunger bushes Low vibration and low noise Big torque, low inertia, pneumatic clutch-brake unit Hydraulic locking device for adjustment rods , ensuring the precision of bottom dead center Forced lubrication system, automatic temperature control system and using the thermal compensation technology to control the position of bottom dead center in high precision Programmable cam controller Touch screen

Founded in 1958 and located in Yangzhou City of Jiangsu province, our company is a professional manufacturer in making mechanical machines as well as a national&hi-tech enterprise, one of the leading enterprises in China NC sheet metal processing equipment production base.

Contact Supplier 01:01

01:01

H-type whole steel-welded frame Suitable for single and multi-station stamping This frame presses spare has a steel welded body with the features of good rigidity, transmission gear gumming lubrication, low noise and stable transmission;The functions of Hydraulic overload protection device and automatic emergency stop guarante the safety of press machine and mould; The number of frame double crank presses is adjustable and applicable to different parts of the job requirements. Main Structure Features Alloyed steel double crank with reverse running, countersct the side force High off-set load capability in L-R direction High accuracy, reaches JIS-Grade1 Straight side structure and high rigidity, steel welded frame High precision, 8-side long guide rail Pneumatic clutch-brake unite Imported safety dual-solenoid valve for clutch High sensitive HOLP 500T (below 500) Automatic grease lubrication system, 500T (above) Automatic oil cycle lubrication system FDI (frequency drive inveter) PLC, encoder, cam controller Optional Components: Output shaft, air cushion, slide knockout device, automatic feeder, etc

Founded in 1958 and located in Yangzhou City of Jiangsu province, our company is a professional manufacturer in making mechanical machines as well as a national&hi-tech enterprise, one of the leading enterprises in China NC sheet metal processing equipment production base.

Contact Supplier 02:37

02:37

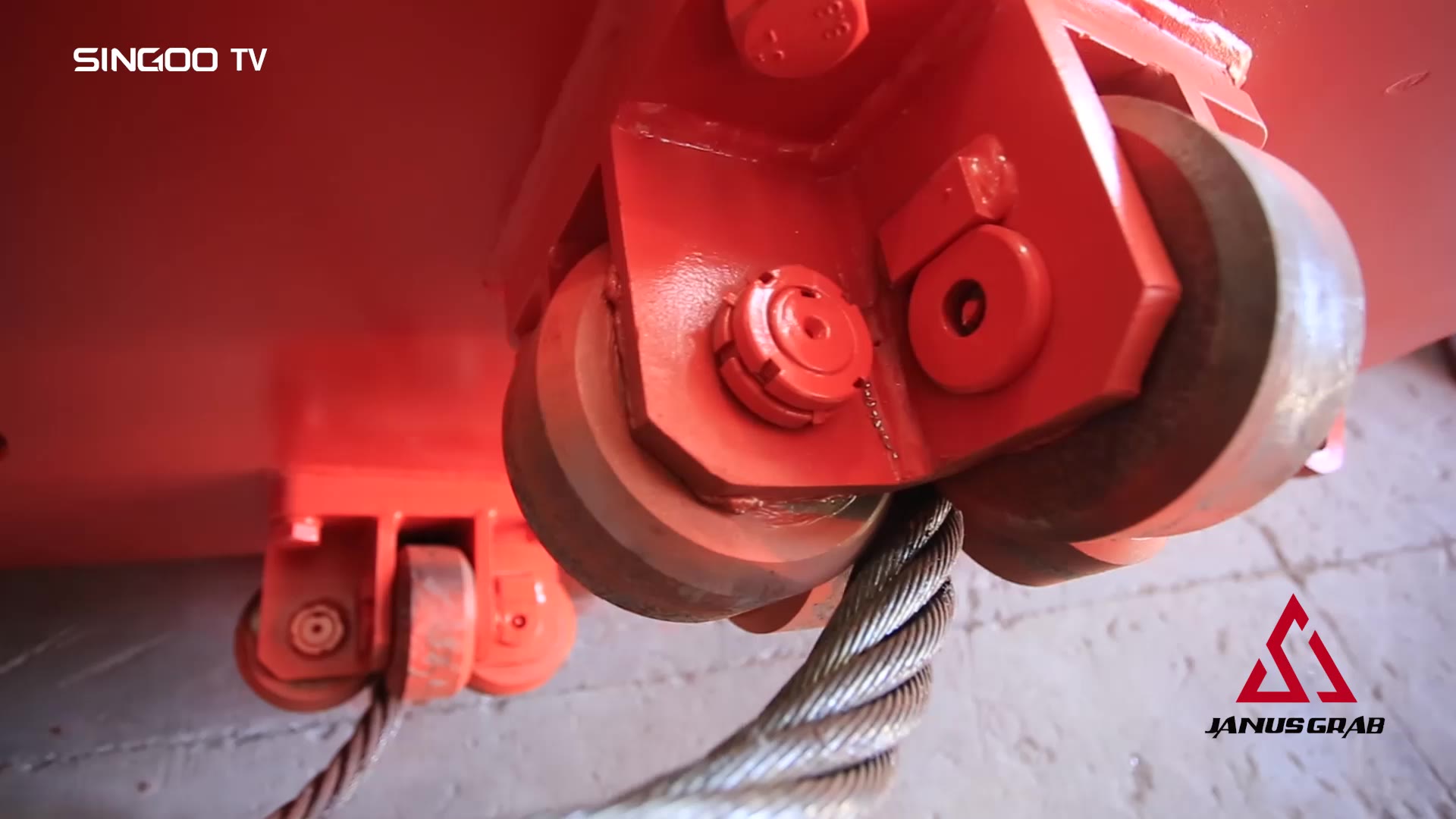

Remote Control grab is an efficient tool for loading and unloading bulk cargo. The grab can close by lifting up hook of crane and open by remote control in the air without any additional power. The hydraulic and electric parts use the plug-in modular design, easily maintain and repair, suitable for ship ocean voyages. The Electric system and hydraulic system is water proof design, which can prevent washing of the wave and rain. Each bulk grab is test strictly by immersed under the water 24hours. Multistep buffering opens type, which reduce the impact to the grab from the crane and ensure to unload quickly. The grab can work continuous for 24 hours with low trouble rate. Grab uses less energy, a full battery can keep the use of more than 180 hours. Easy operation, the crane does not need any other auxiliary equipment. The grab can service after being put on the hook. Now the grabs are widely used in bulk vessels, ports, and are exported in batches. It can be used to bulk a lot of kind material which the piled density is 0.9-2.5t/m3 Type Volume(m3) Crane Capacity (t) Dead Weight (t) Dimensions (mm) Sheave Dia. (mm) Steel Rope Dia. (mm) A B C D E YK10[3-6]4.5 3-6 10 4.5 2600 3338 3756 4071 2700 Ø445 Ø24 YK14[4-7]6 4-7 14 6 2780 3398 4092 4448 2800 Ø520 Ø28 YK16[4-8]7 4-8 16 7 2780 3398 4092 4448 3000 Ø520 Ø28 YK20[5-10]8 5-10 20 8 2810 3591 4192 4513 3560 Ø560 Ø32 YK25[6-12]9.5 6-12 25 9.5 3000 3837 4487 4850 4100 Ø650 Ø36 YK28[8-16]10 8-16 28 10 3060 3887 4559 4881 4320 Ø650 Ø36 YK32[10-20]13.5 10-20 35 14 3270 4109 5008 5391 4600 Ø720 Ø40 YK40[12-24]17 12-24 40 17 3520 4374 5136 5495 4700 Ø800 Ø45 YK50[15-30]21 15-30 50 21 4000 4873 5850 6072 4900 Ø880 Ø52

Shanghai Janus Grab Co., Ltd is a global reputed grab specialist, with more than 30 years experience in grabs design, R&D, and manufacturing. Highly educated professionals in steel structure, hydraulic and electric system make Janus grabs competitive in world-wide markets.

Contact Supplier 00:15

00:15

84V Lithium Brushless Blower Voltage: DC 84V Capacity:2.5Ah Cell: Samsung Max air volume: 500CFM Max air speed: 125mph Max working time: 90mins Speed setting: 4 levels Motor: Brushless

Shanghai Worth Garden Products Co., Ltd. was established in 2000 with Headquarters in Shanghai, China. The company owns three factories. Now we are proud to present the “Worth” brand, a first-class and affordable gardening products and accessories, aiming to help creating an enjoyable gardening lifestyle & to enhance a better living standard.

Contact Supplier 00:15

00:15

Pro 84V Cordless Hedge Trimmer Rating Voltage: DC 84V Cutting Capacity: 33mm Cutting length: 640mm Speed: 3200-3800spm Electric brake Anti-block Motor: brushless Working time: 8H

Shanghai Worth Garden Products Co., Ltd. was established in 2000 with Headquarters in Shanghai, China. The company owns three factories. Now we are proud to present the “Worth” brand, a first-class and affordable gardening products and accessories, aiming to help creating an enjoyable gardening lifestyle & to enhance a better living standard.

Contact Supplier 00:15

00:15

Pro 84V Cordless Brush Cutter Rating Voltage: DC 84V Cutting Capacity: 350mm Speed: 7000rpm Line release: bump-head Line length: 5m Motor: brushless Working time: 2H

Shanghai Worth Garden Products Co., Ltd. was established in 2000 with Headquarters in Shanghai, China. The company owns three factories. Now we are proud to present the “Worth” brand, a first-class and affordable gardening products and accessories, aiming to help creating an enjoyable gardening lifestyle & to enhance a better living standard.

Contact Supplier 00:44

00:44

Technique ∙The dissolver is a fast, high-capacity disperser with a wide range of speeds and high level of efficiency ∙Push-button speed control ∙Speed indicator and automatic speed reduction ∙The product is accelerated radially by the dispersion disk, deflected to the top and bottom at the tank wall and directed back to the dispersion disk through formation of a vortex ∙Shear forces around the circumference of the toothed disk result in highly efficient dispersion, good wetting and deagglomeration ∙For high-viscosity products, a tank wall scraping device can aid the mixing and dispersing process ∙Hydraulic lifting/lowering device ∙Push-button stroke adjustment ∙Adjustable tank clamping mechanism ∙Stainless steel shaft and dispersion disk; additional product-specific mixing tools available depending on the application ∙Manufactured in accordance with CE guidelines Options ∙Application-specific tank cover designs ∙Vacuum design ∙Scraping device for tank wall ∙Temperature sensor ∙Timer ∙Design for ceiling installation with hinged head ∙Various explosion protection ratings ∙Special tank clamping mechanisms ∙PLC-controlled units Advantage ∙ Easy handling which reduces costs and time ∙ Customized solutions on request ∙ A wide range of variously equipped versions available for highest process safety ∙ Various, easily exchangeable mixing tools to increase the efficiency ∙ Temperature measurement by wand or agitator shaft which increases the reliability of the production process ∙ Optimal positioning of the mixing tool via hydraulic lifting/lowering device ∙ Dissolver only starts When the vessel is correctly positioned ∙ At the lowest possible speed ∙ Two-handed operation for lifting/lowering of the tank cover (optional design) ∙ Automatic switch-off, if the toothed disks are lifted above the level of the tank ∙ Protection against accidental contact with the rotating shaft ∙ Bellows serving as dust protection for the shaft

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier 01:26

01:26

Diesel Forklifts Model designation FD20 FD25 FD30 FD35 FD40 Engine ISUZU ISUZU ISUZU ISUZU ISUZU Rated capacity kg 2000 2500 3000 3500 4000 Load center mm 500 500 500 500 500 Lift height mm 3000 3000 3000 3000 3000 Overhead guard(cabin) height mm 2150 2150 2160 2160 2230 Height, mast lowered mm 2060 2060 2060 2060 2190 Height, mast extended mm 4220 4220 4265 4265 4270 Fork size mm 1070x122x40 1070x122x40 1070x125x45 1070x125x50 1070x150x50 Turning radius mm 2220 2240 2400 2550 2800 Overall length mm 2510 2540 2700 2850 3035 Overall width mm 1160 1160 1226 1226 1400 Service weight kg 3530 3880 4350 4560 5300

SSE Machinery is a highly responsible company for global clients. We focus on material handling equipments, agricultural machineries and spare parts business. The factory is located in Suzhou city, China with 60 years history. The management team with over 30 years’ experience is regarded as our incredibly valuable assets. Based on the “Belt and Road Initiative” proposal from China government, SSE srtives to be one of the CAMELS to bring all the wealth and happiness to worldwide friends!

Contact Supplier 03:21

03:21

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” Our TZG series High Precision Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation. This high precision tube mill series with excellent design, selected high precision durable roller under strictly quenching , high performance cutting saw, complete machine body with heat treatment, accurate fabrication, precise assembly. The machine performance has reached the international ERW welded tube standard. This tube mill series outer diameter range can be from Φ40mm to Φ 219mm and wall thickness of 1.5~8.0mm,all these size tubes are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of High precision series tube mill line Model Tube O.D.(mm) Wall Thickness(mm) Speed(m/min) H.F. power(Kw) Main motor(Kw) TZG-115 φ40-115 1.5-5.0 15-50 400 264 TZG-165 φ76-165 2.0-6.0 15-50 600 320 TZG-219 φ114-219 3.0-8.0 15-40 800 600 Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 01:13

01:13

The most prominent advantage of GPU series is environmental, low noise and dust-free operation. The follow 2 pictures show the totally different working conditions under unloading with GPU series and traditional portal crane. Unloading grain with traditional portal crane Unloading grain with GPU series Besides this, we can get more details about GPU through below features: 3 types undercarriages Rail-type, fixed or steerable rubber tires can be selected based on your working condition. Wide range of application The GPU series can be widely used at different kind of vessels, from barges to panama or tankers. Applicable to various cargos Grain: wheat, rice, soybeans, corn and rapeseeds etc. Powder: cement, mineral powder, fly ash and pulverized lime etc. Special material: cement clinker, sulfur, aluminum, alumina, soda ash, salt, fertilizer, petrol coke and pulverized coal etc. Multi-stage turbo blower, save nearly 30% energy More than 30% energy can be saved, compare to the unloader with roots blower. Low noise and anti-fraying. Reliable operation with long life cycle. Environmental The noise is less than 80db within 10m. Dust-free through closed conveying, dedusting efficiency as high as 99.5% Obtain the environmental certification from Chinese government. Local service team, quick response For each project we will organize the service team of local people with expertise and rich experience. Local spare parts warehouse and quick response service team, no need to worry about the communication barriers and response speed.

GENMA, specialized in material handling solution providing, has nearly 20 years’ experience and deep know-how in cargo handling. Withhold the expert experience in container handling solution, GENMA is also expanding broadly in bulk handling business.

Contact Supplier 05:07

05:07

Model: GHC100TD Undercarriage: Tyre-type Client: Paradip Qty: 3 More details Model: GHC60 Undercarriage: Rail-type Client: Runhe port Qty: 2 More details Model: GHC100 Undercarriage: Tyre-type Client: MIP Qty: 2 More details Model: GHC200 Undercarriage: Rail-type Client: Ruitai Qty: 1 More details Model: GHC63 Undercarriage: Tyre-type Client: Jiangsu Wenqiang Ocean Engineering Co., Ltd Qty: 1 More details

GENMA, specialized in material handling solution providing, has nearly 20 years’ experience and deep know-how in cargo handling. Withhold the expert experience in container handling solution, GENMA is also expanding broadly in bulk handling business.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery