00:00

00:00

Brief introduction & Advantage Tail-labeling machine connected online, non-label tube to be auto detected by world leading image technology after stoppering & capping and vacuuming (including rift of stopper or cap or glass tube, foreign matter inside tube, no additive, less additive and etc.). Conform tube move to labeling machine, non-conform tube to be rejected. Manual inspection-free technology is world leading. 1. Save labor cost: Other company’s production line need large manual inspection for each tube, include label, dosing, foreign matters inside tube and etc. Our line using world leading image technology to reject non-conform tube (include rift of stopper or cap or glass tube, foreign matter inside tube, no additive, less additive and etc.), reach 100% accuracy rate. 2. Reduce secondary pollution. Decrease tube multiple exposure, better guarantee tube aseptic. Glass tube after high temp sterilizing. (PET tube produced in Class 100,000 clean room workshop), worker only contact tube one time when loading tubes into auto loading machine, ensure tube cleanness during production in Class 10,000 clean room workshop. 3. Testing qualified products for automatic labeling, ensure packaging sequence according to Barcode Numbers. Packaging sequence according to Barcode Numbers can be up to export standard and usage requirements of large hospitals. 4. Auto inspection device rejects labeled tube if no label. Slanting label, poor adhesive label and etc., ensure labeled tube and finished tube with pass rate 100%. 5. Labeling speed matches the auto assembly line speed well to ensure whole line production capacity get 18000~24000pcs/h 6. The whole line only needs 3 skilled workers. Only manual tube loading at the very beginning, online image and labeling inspection rejects non-conform tubes automatically to ensure 100% pass rate. Save at least 15 workers to get production capacity of 18000~24000pcs/h. Production Procedures Schematic Diagram Aseptic Environment: equipped with clean laminar flow hood and adopt with high-powered fan and HEPA, it can be operated in long term under high static pressure and keep low noise. The space cleanness can up to class 10,000 (can be optional), which is the exclusive technology in China. Tube loading: adopting with automatic tube loading technology, loading the tube into clamps automatically with detector for no tube or inverse direction tube. The machine apply for any kind of label tubes and solve the defect of the avo label broken of traditional tube loading machine from other manufacturers. Atomization Dosing: The machine adopts with a set of 5 FMI precision ceramic metering pump and 1 set of five conjoined of micro - ceramic injection pump that can dose separately for biochemical tube and anticoagulant tube (EDTA salts, heparin salt); Another set of metering pump is dosing for sodium citrate tubes. Dosing volume controlled by PLC touch screen(see parameter), the error rate is ≦ 5%, and detect for no dosing tubes during the dosing process. Compared with other companies’ machine rely on stable air supply for dosing, our technology of dosing volume will not be influenced by any factors. 3 sets of dosing system meet all kinds of blood collection tubes production, that is the exclusive and advanced technology in China. Drying: Adopting with six sets of dust-free PTC heating dryer to make the inner of products with zero pollution so as to improve the drying effect and production efficiency. Compared with traditional heating method, our machine solves the problem of temperature instability and pollution. Online Stoppering & Capping: finish the combination of stopper & cap online quickly and efficiently (apply for both type: upward and downward), and avoid the nonuniform vacuum degree when dose the tubes after the combination of stopper and cap and it may cause the stopper not seal well against tube. Detect for cap and rubber stopper and avoid the possibility of no stopper or no cap.

Shanghai IVEN Pharmatech Engineering Co., Ltd was established in 2005, with great efforts we developed four excellent plants for pharmaceutical machinery, blood collection tube machinery, water treatment equipment and clean room facilities. We’re the pioneer supplier in China to provide integrated engineering solution for worldwide pharmaceutical factory and medical factory in compliance with EU GMP / US FDA standard and WHO principle. Our company cooperates closely with well-known scientific research institutions and pharmaceuticals industry designing institutes to provide the most reasonable project design, the best quality equipment and the customized service to different pharmaceutical / medical factories from different markets. IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on: *Pre-engineering consulting service *Production process selection *Equipment model selection and customization *Installation and commissioning *Validation of the equipment and process *Production technology transferring *Hard and soft documentation *Training for skilled workers and so on. Based on the needs of users from worldwide, IVEN continuously doing a lot of deep research and study on the development of pharmaceutical and medical industry, pursue the endless improvement of our machinery and project quality. We will sincerely cooperate with pharmaceutical and medical enterprises from worldwide and make unremitting efforts for human health.99999

Contact Supplier 01:08

01:08

SGD150/300/450/600 Automatic Hard Candy Depositing Machine SGD150/300/450/600 servo driven PLC controlled automatic hard candy depositing machine is the most advanced production line for deposited hard candy and lollipop manufacturing. This line mainly consists of auto weighing and mixing system (optional), pressure dissolving system, micro-film cooker, depositor and cooling tunnel and adopt the advanced servo system to control the processing. Besides, this line also has following characteristics: 1.Sugar and all other materials are automatic weighed, transferred and mixed through adjust touch screen. Various kinds of recipes can be programmed in the PLC and applied easily and freely when required. 2.PLC, touch screen and servo driven system are imported brand, more reliable and stable performance and durable use-life. 3.Depositing volume (candy weight) can be changed easily through setting data on touch screen. More accurate depositing and continuous production makes minimal product wastage. 4.Simple and compact machine structure, menu style operation interface, convenient operation and maintenance, high efficiency, low-noise, stable performance and long life. 5.Ball and flat lollipop stick-insert machine for producing lollipop in the same line is optional. Products sample produced by this machine:

Shanghai Candy Machine Co., Ltd offer the worldwide food manufacturers with professional processing equipment for confectionery, chocolate and cereal bar products rely on experience and technology of past decades. The factory was founded in year 2002, located in the South of Shanghai City, China. Modern workshop and office building cover an area of total 6000 square meters. CANDY’S main products include confectionery cooking equipment, deposited and die formed type candy machine, lollipop machine, deposited jelly candy machine, deposited toffee candy machine, advanced chocolate moulding machine, candy bar production line etc. In recently years, CANDY developed peanuts nougat machine, chocolate injection machine etc. CANDYs Manufactured machines have been exported to many countries and regions, including America, South America, Southeast Asia, Middle East, South Africa etc. Relay on high quality, sufficient technology and experience, reasonable price and excellent service, CANDY obtain long term trust and support from the clients in past years. Warmly welcome worldwide customers to visit Shanghai CANDY machine Co., Ltd., your advisable choice for candy machines.

Contact Supplier 01:19

01:19

SGDQ150/300/450/600 Jelly Gummy Candy Depositing Machine Jelly gummy candy depositing line is an advanced and continuous plant which is independent researched by our company for making high quality jelly candies by replacing moulds and filling plates. The whole line consists of jacketed dissolving tank, jelly mass mixing and storage system, depositing machine, cooling tunnel, conveyor, sugar coating machine (optional). It is applicable for all kinds of jelly-based material, such as gelatin, pectin, carrageenan, acacia gum etc. Automated production not only save time, labor and space, but also reduce the production cost. Electrical heating system is optional. Deposited jelly candy processing flowchart: Gelatin melting→Sugar & glucose boiling→Add melt gelatin to the syrup mass →Storage→Add flavor, color and citric acid→Depositing→Cooling→Demoulding→Conveying→drying→packing→Final product. Products sample produced by this machine:

Shanghai Candy Machine Co., Ltd offer the worldwide food manufacturers with professional processing equipment for confectionery, chocolate and cereal bar products rely on experience and technology of past decades. The factory was founded in year 2002, located in the South of Shanghai City, China. Modern workshop and office building cover an area of total 6000 square meters. CANDY’S main products include confectionery cooking equipment, deposited and die formed type candy machine, lollipop machine, deposited jelly candy machine, deposited toffee candy machine, advanced chocolate moulding machine, candy bar production line etc. In recently years, CANDY developed peanuts nougat machine, chocolate injection machine etc. CANDYs Manufactured machines have been exported to many countries and regions, including America, South America, Southeast Asia, Middle East, South Africa etc. Relay on high quality, sufficient technology and experience, reasonable price and excellent service, CANDY obtain long term trust and support from the clients in past years. Warmly welcome worldwide customers to visit Shanghai CANDY machine Co., Ltd., your advisable choice for candy machines.

Contact Supplier 02:08

02:08

Description Unit VMCL850 Travel X travel mm 850 Y travel mm 500 Z travel mm 510 Distance between spindle nose and worktable surface mm 150-660 Distance from table center to stand column surface mm 287-787 Worktable Table area mm 430*950 Max. loads kg 630 T-slot width mm 3×18H8X125 Spindle Max. spindle speed rpm 8000 Angle of spindle taper - BT-40 Feed rate X/Y/Z rapid speed m/min 32/32/32 Max. cutting feedrate m/min 10 Automatic Tool Changing System Mechanic hand tool magazine Qty. Of tools pcs 24 Tool changing time sec 1.55 Max. tool length mm 300 Max. tool diameter/adjacent without tool mm 80/150 Max. tool weight kg 8 Motor Spindle motor kw 7.5/11 X/Y/Z axis motor kw 1.8/1.8/3 Cooling pump motor w 0.37+0.55 Precision(SN precision according to standard GB/T18400.4-2010) Positioning accuracy mm 0.01 Repetitive positioning accuracy mm 0.005 Machine Dimension Overall height of machine mm 2570 Floor area(L×W) mm 2800×2660 Weight kg 6000 Power supply kw 22

COMPANY PROFILE Nantong Hangzhi Equipment Technology Co., Ltd. is a wholly owned subsidiary of AVIC Aviation High-technology Group Co., Ltd. In March 16, 2016, the company completed the renamed registration. Total assets of the company are RMB 330 million. Nantong Hangzhi Equipment Technology Co., Ltd was founded in 1956, Former Nantong Machine TOOL Works, Trademark include: “NANTONG”、“TONMAC”、“TONTEC”,It is one of six listed companies in Chinese machine tool industry. The company undertakes the aircraft in the original Department of AVIC HT’s machine tool business and AVIC Beijing Aeronautical manufacturing technology research Institute of high-end intelligent equipment and aviation equipment business. The main products are CNC milling machines, CNC lathes, Vertical machining center, Horizontal machining center, Gantry type vertical machining center and Aviation equipment, etc. The company employs more than 500 people, including nearly 150 professional, technical and engineering management staff. The company has domestic first-class production and processing equipment, which imports more than 130 sets of thin equipment, including Japan SNK five face machining center, Germany”s WARLDRICH precision guideway grinder, the United States CICINNATIE machining center, Switzerland DIXI coordinate boring machine, Zeiss coordinate measuring instrument and other world famous brand processing and testing equipment. The company independently developed machine tool products by a number of patents, which in the validity period of the invention patent 14, utility model patents 18. A number of key technologies like MCH63 precision horizontal machining center fill the gaps, accessing to the 2007 machine tool industry ten new product title, China Machinery Industry Science and Technology Progress Award. VMCL1100 vertical machining center series won the second prize of scientific and technological progress in Nantong City, Jiangsu Province, third prize of scientific and technological progress. Products are widely used in mold manufacturing, auto parts, wind energy nuclear power, marine ships, military aerospace, teaching and other fields. The company's sales network is throughout the South China, Zhejiang, Jiangsu, China and the West, North China, northeast and other regions, with a professional sales and after-sales team.

Contact Supplier 02:08

02:08

Description Unit VMCL1100 Travel X travel mm 1100 Y travel mm 560 Z travel mm 575 Distance between spindle nose and worktable surface mm 200-775 Distance from table center to stand column surface mm 337-887 Worktable Table area mm 550×1200 Max. loads kg 800 T-slot width mm 4×18H8 Spindle Max. spindle speed rpm 8000 Angle of spindle taper - BT-40 Feed rate X/Y/Z rapid speed m/min 32/32/32 Max. cutting feedrate m/min 15 Automatic Tool Changing System Manipulator Qty. Of tools pcs 24 Tool changing time sec 1.55 Max. tool length mm 300 Max. tool diameter/adjacent without tool mm φ100/φ180 Max. tool weight kg 8 Motor Spindle motor kw 7.5/11 X/Y/Z axis motor kw 3/3/4 Cooling pump motor w 0.37+0.55 Precision(SN precision according to standard JB/T8772.4-1998) Positioning accuracy mm 0.012/0.01 Repetitive positioning accuracy mm 0.008/0.006 Machine Dimension Overall height of machine mm 3160 Floor area(L×W) mm 3340×3065 Net Weight kg 6800 Power supply kw 30

COMPANY PROFILE Nantong Hangzhi Equipment Technology Co., Ltd. is a wholly owned subsidiary of AVIC Aviation High-technology Group Co., Ltd. In March 16, 2016, the company completed the renamed registration. Total assets of the company are RMB 330 million. Nantong Hangzhi Equipment Technology Co., Ltd was founded in 1956, Former Nantong Machine TOOL Works, Trademark include: “NANTONG”、“TONMAC”、“TONTEC”,It is one of six listed companies in Chinese machine tool industry. The company undertakes the aircraft in the original Department of AVIC HT’s machine tool business and AVIC Beijing Aeronautical manufacturing technology research Institute of high-end intelligent equipment and aviation equipment business. The main products are CNC milling machines, CNC lathes, Vertical machining center, Horizontal machining center, Gantry type vertical machining center and Aviation equipment, etc. The company employs more than 500 people, including nearly 150 professional, technical and engineering management staff. The company has domestic first-class production and processing equipment, which imports more than 130 sets of thin equipment, including Japan SNK five face machining center, Germany”s WARLDRICH precision guideway grinder, the United States CICINNATIE machining center, Switzerland DIXI coordinate boring machine, Zeiss coordinate measuring instrument and other world famous brand processing and testing equipment. The company independently developed machine tool products by a number of patents, which in the validity period of the invention patent 14, utility model patents 18. A number of key technologies like MCH63 precision horizontal machining center fill the gaps, accessing to the 2007 machine tool industry ten new product title, China Machinery Industry Science and Technology Progress Award. VMCL1100 vertical machining center series won the second prize of scientific and technological progress in Nantong City, Jiangsu Province, third prize of scientific and technological progress. Products are widely used in mold manufacturing, auto parts, wind energy nuclear power, marine ships, military aerospace, teaching and other fields. The company's sales network is throughout the South China, Zhejiang, Jiangsu, China and the West, North China, northeast and other regions, with a professional sales and after-sales team.

Contact Supplier 03:20

03:20

Parameters Unit GMC2560 Table size 2500*6000 Table load kg/m2 2000 T-slot size(width x nos.) mm 28*13 X travel mm 6500 Y travel mm 3300 Z travel mm 1000(1250 optional) Width passed the gantry mm 3100 Distance from spindle nose to table surface mm 200-1200(200-1450 optional) Spindle nose — ISO №50 Main motor power(cont/30min.) kW SIEMENS:30/41(optional 37/51) FANUC:30/37(optional 37/45) Max. Speed of spindle rpm 2000(3000、6000 optional) Cutting feed speed mm/min 1—5000 Rapid speed m/min 10 Type of tool magazine Mechanical arm Type of tool handle BT-50、JT-50 Magazine capability Mechanical arm 32(40、60 optional) Chain type - Max. Tool diameter mm φ125(adjacent:φ200) Max. Tool length mm 400 Max. Tool weight kg 20 Positioning accuracy mm Repetitive positioning accuracy mm Dimension mm 15300*6700*7020 Machine weight T 110 Attachment milling head Right angle milling head, universal milling head, extended milling head and special milling head. Optional parts Attachment milling head and integrity protective shield

COMPANY PROFILE Nantong Hangzhi Equipment Technology Co., Ltd. is a wholly owned subsidiary of AVIC Aviation High-technology Group Co., Ltd. In March 16, 2016, the company completed the renamed registration. Total assets of the company are RMB 330 million. Nantong Hangzhi Equipment Technology Co., Ltd was founded in 1956, Former Nantong Machine TOOL Works, Trademark include: “NANTONG”、“TONMAC”、“TONTEC”,It is one of six listed companies in Chinese machine tool industry. The company undertakes the aircraft in the original Department of AVIC HT’s machine tool business and AVIC Beijing Aeronautical manufacturing technology research Institute of high-end intelligent equipment and aviation equipment business. The main products are CNC milling machines, CNC lathes, Vertical machining center, Horizontal machining center, Gantry type vertical machining center and Aviation equipment, etc. The company employs more than 500 people, including nearly 150 professional, technical and engineering management staff. The company has domestic first-class production and processing equipment, which imports more than 130 sets of thin equipment, including Japan SNK five face machining center, Germany”s WARLDRICH precision guideway grinder, the United States CICINNATIE machining center, Switzerland DIXI coordinate boring machine, Zeiss coordinate measuring instrument and other world famous brand processing and testing equipment. The company independently developed machine tool products by a number of patents, which in the validity period of the invention patent 14, utility model patents 18. A number of key technologies like MCH63 precision horizontal machining center fill the gaps, accessing to the 2007 machine tool industry ten new product title, China Machinery Industry Science and Technology Progress Award. VMCL1100 vertical machining center series won the second prize of scientific and technological progress in Nantong City, Jiangsu Province, third prize of scientific and technological progress. Products are widely used in mold manufacturing, auto parts, wind energy nuclear power, marine ships, military aerospace, teaching and other fields. The company's sales network is throughout the South China, Zhejiang, Jiangsu, China and the West, North China, northeast and other regions, with a professional sales and after-sales team.

Contact Supplier 03:20

03:20

Description Unit VGC2000 X travel mm 2000 Y travel mm 1400 Z travel mm 900 Distance between spindle nose and worktable surface mm 200-1100 Distance from spindle center to Z axis guide surface mm 155 Table area mm 2000×1200 Max. loads kg 4000 T-slot width mm 7×22H8×160 Max. spindle speed rpm 6000 Angle of spindle taper - BT50 X/Y/Z rapid speed m/min 10/15/15 Max. cutting feedrate m/min 5 Qty. Of tools pcs 32 Max diameter of tool φ125/φ250 Max Length of tool 400 Tool changing time sec 3.2 Spindle motor kw 15/18.5 X/Y/Z axis motor kw 7 Positioning accuracy mm X:0.18 Y/Z:0.01 Repetitive positioning accuracy mm 0.008 Overall size mm 6180×3870×4645 Weight kg 25000

COMPANY PROFILE Nantong Hangzhi Equipment Technology Co., Ltd. is a wholly owned subsidiary of AVIC Aviation High-technology Group Co., Ltd. In March 16, 2016, the company completed the renamed registration. Total assets of the company are RMB 330 million. Nantong Hangzhi Equipment Technology Co., Ltd was founded in 1956, Former Nantong Machine TOOL Works, Trademark include: “NANTONG”、“TONMAC”、“TONTEC”,It is one of six listed companies in Chinese machine tool industry. The company undertakes the aircraft in the original Department of AVIC HT’s machine tool business and AVIC Beijing Aeronautical manufacturing technology research Institute of high-end intelligent equipment and aviation equipment business. The main products are CNC milling machines, CNC lathes, Vertical machining center, Horizontal machining center, Gantry type vertical machining center and Aviation equipment, etc. The company employs more than 500 people, including nearly 150 professional, technical and engineering management staff. The company has domestic first-class production and processing equipment, which imports more than 130 sets of thin equipment, including Japan SNK five face machining center, Germany”s WARLDRICH precision guideway grinder, the United States CICINNATIE machining center, Switzerland DIXI coordinate boring machine, Zeiss coordinate measuring instrument and other world famous brand processing and testing equipment. The company independently developed machine tool products by a number of patents, which in the validity period of the invention patent 14, utility model patents 18. A number of key technologies like MCH63 precision horizontal machining center fill the gaps, accessing to the 2007 machine tool industry ten new product title, China Machinery Industry Science and Technology Progress Award. VMCL1100 vertical machining center series won the second prize of scientific and technological progress in Nantong City, Jiangsu Province, third prize of scientific and technological progress. Products are widely used in mold manufacturing, auto parts, wind energy nuclear power, marine ships, military aerospace, teaching and other fields. The company's sales network is throughout the South China, Zhejiang, Jiangsu, China and the West, North China, northeast and other regions, with a professional sales and after-sales team.

Contact Supplier 04:13

04:13

Description Unit MCH50 Capacity X travel mm 700 Y travel mm 580 Z travel mm 580 Distance between spindle nose and worktable surface mm 110-690 Distance from table center to spindle end face mm 120-700 Table Table Size mm 500×500 Max. Table load kg 500 Spindle Max. spindle speed r/min 60-6000 Angle of spindle taper - BT50 Rotary worktable Rotate speed r/min 5 Turntable(B axis)indexing 1° Feed rate X/Y/Z rapid speed m/min 24 Cutting feedrate mm/min 1-10000 Automatic Tool Changing System Tool stations pcs 24 Tool changing time sec 3.27 Max. tool length mm 350 Max. tool diameter mm 120(full tool) 200(adjacent air tool) 230(adjacent without tool) Max. tool weight kg 18 Motor Spindle motor kw 11/15 X/Y/Z axis motor Nm 22/30/22 Turntable motor Nm 8 Hydraulic station motor power kw 4 Cooling pump motor kw 0.4 Precision(SN precision according to standard JB/T8771.4-1998) Positioning accuracy mm 0.01 Repetitive positioning accuracy mm 0.006 Turntable positioning accuracy 12” Turntable Repetitive positioning accuracy 6” Machine Dimension Overall height mm 2810 Floor area (L*W) mm 4000×2600 Weight kg 12000 Power supply kw 40 Work Environment Environmental temperature ℃ -5-45 Relative humidity 0-90% Air pressure Mpa 0.6 Hydraulic system working pressure Mpa 5.3 Power 50Hz 380V±10% Note: if the SINUMERIK 802D CNC system is selected, main motor power and servo motor torque will be changed with it.

COMPANY PROFILE Nantong Hangzhi Equipment Technology Co., Ltd. is a wholly owned subsidiary of AVIC Aviation High-technology Group Co., Ltd. In March 16, 2016, the company completed the renamed registration. Total assets of the company are RMB 330 million. Nantong Hangzhi Equipment Technology Co., Ltd was founded in 1956, Former Nantong Machine TOOL Works, Trademark include: “NANTONG”、“TONMAC”、“TONTEC”,It is one of six listed companies in Chinese machine tool industry. The company undertakes the aircraft in the original Department of AVIC HT’s machine tool business and AVIC Beijing Aeronautical manufacturing technology research Institute of high-end intelligent equipment and aviation equipment business. The main products are CNC milling machines, CNC lathes, Vertical machining center, Horizontal machining center, Gantry type vertical machining center and Aviation equipment, etc. The company employs more than 500 people, including nearly 150 professional, technical and engineering management staff. The company has domestic first-class production and processing equipment, which imports more than 130 sets of thin equipment, including Japan SNK five face machining center, Germany”s WARLDRICH precision guideway grinder, the United States CICINNATIE machining center, Switzerland DIXI coordinate boring machine, Zeiss coordinate measuring instrument and other world famous brand processing and testing equipment. The company independently developed machine tool products by a number of patents, which in the validity period of the invention patent 14, utility model patents 18. A number of key technologies like MCH63 precision horizontal machining center fill the gaps, accessing to the 2007 machine tool industry ten new product title, China Machinery Industry Science and Technology Progress Award. VMCL1100 vertical machining center series won the second prize of scientific and technological progress in Nantong City, Jiangsu Province, third prize of scientific and technological progress. Products are widely used in mold manufacturing, auto parts, wind energy nuclear power, marine ships, military aerospace, teaching and other fields. The company's sales network is throughout the South China, Zhejiang, Jiangsu, China and the West, North China, northeast and other regions, with a professional sales and after-sales team.

Contact Supplier 03:25

03:25

Item Description Unit SL50 Process Range Max. swivel diameter of spindle over bed mm 500 Max. swivel diameter of spindle over saddle mm 280 Max.machining diameter mm 450 Max. machining length mm 650 Spindle Chuck diameter mm 254 Spindle nose model - A2-8 Taper of spindle bore - 1:20 Max. speed rpm 3000 Motor power Kw 11/15 Travel X axis travel mm 265 Z axis travel mm 680 Feed rate X/Z axis rapid shift m/min 12/16 Max. Cutting feed rate m/min 10 Tool turret Qty. Of tools pcs 8 OD tool size mm 25*25 Boring tool handle diameter mm φ32 Tool changing time (adjacent/far) sec 0.68/1.5 Tailstock Shaft diameter of tailstock mm 95 Center taper - MT5 Center travel mm 120 Tailstock travel mm 500 Motor X/Z motors kw 2.5 Cooling pump motor kw 0.4 Precision Positioning precision mm X/Z:0.016/0.025 Repetitive positioning precision mm X/Z:0.007/0.01 Reverse difference mm X/Z:0.006/0.012

COMPANY PROFILE Nantong Hangzhi Equipment Technology Co., Ltd. is a wholly owned subsidiary of AVIC Aviation High-technology Group Co., Ltd. In March 16, 2016, the company completed the renamed registration. Total assets of the company are RMB 330 million. Nantong Hangzhi Equipment Technology Co., Ltd was founded in 1956, Former Nantong Machine TOOL Works, Trademark include: “NANTONG”、“TONMAC”、“TONTEC”,It is one of six listed companies in Chinese machine tool industry. The company undertakes the aircraft in the original Department of AVIC HT’s machine tool business and AVIC Beijing Aeronautical manufacturing technology research Institute of high-end intelligent equipment and aviation equipment business. The main products are CNC milling machines, CNC lathes, Vertical machining center, Horizontal machining center, Gantry type vertical machining center and Aviation equipment, etc. The company employs more than 500 people, including nearly 150 professional, technical and engineering management staff. The company has domestic first-class production and processing equipment, which imports more than 130 sets of thin equipment, including Japan SNK five face machining center, Germany”s WARLDRICH precision guideway grinder, the United States CICINNATIE machining center, Switzerland DIXI coordinate boring machine, Zeiss coordinate measuring instrument and other world famous brand processing and testing equipment. The company independently developed machine tool products by a number of patents, which in the validity period of the invention patent 14, utility model patents 18. A number of key technologies like MCH63 precision horizontal machining center fill the gaps, accessing to the 2007 machine tool industry ten new product title, China Machinery Industry Science and Technology Progress Award. VMCL1100 vertical machining center series won the second prize of scientific and technological progress in Nantong City, Jiangsu Province, third prize of scientific and technological progress. Products are widely used in mold manufacturing, auto parts, wind energy nuclear power, marine ships, military aerospace, teaching and other fields. The company's sales network is throughout the South China, Zhejiang, Jiangsu, China and the West, North China, northeast and other regions, with a professional sales and after-sales team.

Contact Supplier 03:25

03:25

Item Description Unit SLL50 Process Range Max. swivel diameter of spindle over bed mm 560 Max. swivel diameter of spindle over saddle mm 280 Max.machining diameter mm 480 Max. machining length mm 290 Spindle Chuck diameter mm φ254 Spindle nose model - A2-8 Taper of spindle bore - 1:20 Max. speed rpm 3000 Motor power Kw 15/18.5 Travel X axis travel mm 260 Z axis travel mm 700 Feed rate X/Z axis rapid shift m/min 18/24 Max. Cutting feed rate m/min 10 Tool turret Qty. Of tools pcs 8(12 optional) OD tool size mm 25*25 Boring tool handle diameter mm φ32 Tool changing time (adjacent/far) sec 0.68/1.5 Tailstock Shaft diameter of tailstock mm 95 Center taper - MT5 Center travel mm 120 Tailstock travel mm 650 Motor X/Y/Z motors Kw 3 Cooling pump motor Kw 0.4 Precision Positioning precision mm X/Z:0.01/0.12 Repetitive positioning precision mm X/Z:0.005/0.006 Reverse difference mm X/Z:0.006/0.012

COMPANY PROFILE Nantong Hangzhi Equipment Technology Co., Ltd. is a wholly owned subsidiary of AVIC Aviation High-technology Group Co., Ltd. In March 16, 2016, the company completed the renamed registration. Total assets of the company are RMB 330 million. Nantong Hangzhi Equipment Technology Co., Ltd was founded in 1956, Former Nantong Machine TOOL Works, Trademark include: “NANTONG”、“TONMAC”、“TONTEC”,It is one of six listed companies in Chinese machine tool industry. The company undertakes the aircraft in the original Department of AVIC HT’s machine tool business and AVIC Beijing Aeronautical manufacturing technology research Institute of high-end intelligent equipment and aviation equipment business. The main products are CNC milling machines, CNC lathes, Vertical machining center, Horizontal machining center, Gantry type vertical machining center and Aviation equipment, etc. The company employs more than 500 people, including nearly 150 professional, technical and engineering management staff. The company has domestic first-class production and processing equipment, which imports more than 130 sets of thin equipment, including Japan SNK five face machining center, Germany”s WARLDRICH precision guideway grinder, the United States CICINNATIE machining center, Switzerland DIXI coordinate boring machine, Zeiss coordinate measuring instrument and other world famous brand processing and testing equipment. The company independently developed machine tool products by a number of patents, which in the validity period of the invention patent 14, utility model patents 18. A number of key technologies like MCH63 precision horizontal machining center fill the gaps, accessing to the 2007 machine tool industry ten new product title, China Machinery Industry Science and Technology Progress Award. VMCL1100 vertical machining center series won the second prize of scientific and technological progress in Nantong City, Jiangsu Province, third prize of scientific and technological progress. Products are widely used in mold manufacturing, auto parts, wind energy nuclear power, marine ships, military aerospace, teaching and other fields. The company's sales network is throughout the South China, Zhejiang, Jiangsu, China and the West, North China, northeast and other regions, with a professional sales and after-sales team.

Contact Supplier 02:37

02:37

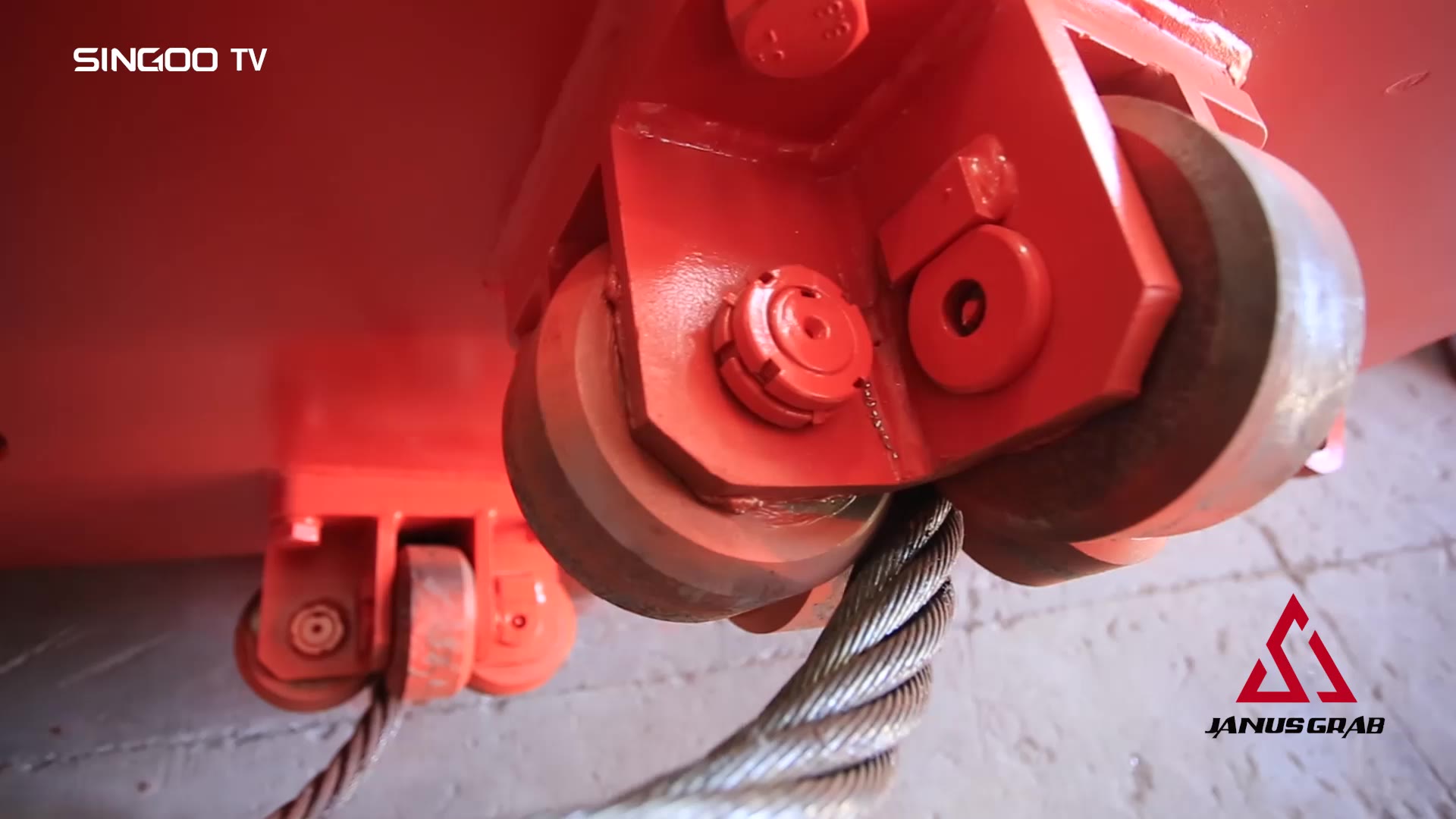

Remote Control grab is an efficient tool for loading and unloading bulk cargo. The grab can close by lifting up hook of crane and open by remote control in the air without any additional power. The hydraulic and electric parts use the plug-in modular design, easily maintain and repair, suitable for ship ocean voyages. The Electric system and hydraulic system is water proof design, which can prevent washing of the wave and rain. Each bulk grab is test strictly by immersed under the water 24hours. Multistep buffering opens type, which reduce the impact to the grab from the crane and ensure to unload quickly. The grab can work continuous for 24 hours with low trouble rate. Grab uses less energy, a full battery can keep the use of more than 180 hours. Easy operation, the crane does not need any other auxiliary equipment. The grab can service after being put on the hook. Now the grabs are widely used in bulk vessels, ports, and are exported in batches. It can be used to bulk a lot of kind material which the piled density is 0.9-2.5t/m3 Type Volume(m3) Crane Capacity (t) Dead Weight (t) Dimensions (mm) Sheave Dia. (mm) Steel Rope Dia. (mm) A B C D E YK10[3-6]4.5 3-6 10 4.5 2600 3338 3756 4071 2700 Ø445 Ø24 YK14[4-7]6 4-7 14 6 2780 3398 4092 4448 2800 Ø520 Ø28 YK16[4-8]7 4-8 16 7 2780 3398 4092 4448 3000 Ø520 Ø28 YK20[5-10]8 5-10 20 8 2810 3591 4192 4513 3560 Ø560 Ø32 YK25[6-12]9.5 6-12 25 9.5 3000 3837 4487 4850 4100 Ø650 Ø36 YK28[8-16]10 8-16 28 10 3060 3887 4559 4881 4320 Ø650 Ø36 YK32[10-20]13.5 10-20 35 14 3270 4109 5008 5391 4600 Ø720 Ø40 YK40[12-24]17 12-24 40 17 3520 4374 5136 5495 4700 Ø800 Ø45 YK50[15-30]21 15-30 50 21 4000 4873 5850 6072 4900 Ø880 Ø52

Shanghai Janus Grab Co., Ltd is a global reputed grab specialist, with more than 30 years experience in grabs design, R&D, and manufacturing. Highly educated professionals in steel structure, hydraulic and electric system make Janus grabs competitive in world-wide markets.

Contact Supplier 00:44

00:44

Principle The milling basket, containing thegrinding bead is lowered into the millbase, the fast circulation of the millbase within the milling basket is generated by the dissolver disc and integrated pump wheel, a very narrow particle size distribution can be achieved very quickly. Characteristics: ● Suita for producing small batch product and middle test. Dispersing and grinding are finished in one machine and one container, no need extra pumps, piping, valves etc . ● Easy cleaning, no residues, convenient product replacement. ● Little grinding media required.Excellent grinding efficience and effect. ● Double-walled container for cooling and heating. ● Modular design of parts make it much more convenient to disassemble, maintain and overhaul, almost no need of professional maintainer. Materials Viscosity: ≤ 5000 cps Production Capacity: 50-3000L Application Industry: Suitable for dispersing, grinding materials in industries such as biology.pharmacy, cosmetic, food, paint, ink, color paste, dyestuff, fertilizer etc. Applicable Materials: Materials shall be with viscosity less than 5000cps, with comparatively high requirements of final grinding result or with many varieties such as emulsion paint, industrial paint, color paste, water-borne ink, fertilizer suspension, etc Product Advantages ● High grinding efficiency and excellent grinding result Driven by the strong kinetic energy, the zirconium pins drive the grinding medium inside the basket to carry out irregular movement. The mediums crush, friction with each other to grind the powder into smaller particle size within a short period. For general materials, it can be down to approx. 5um, some even can be down to submicron or even nano level. ● Convenient and safe operation Adopt hydraulic tank as liting actuator. Control the hydraulic up, stop, down through the oil pump, easy operation and stable.With different clamping types to fix the tanks properly to prevent from accident due to the tank displacement during operation.Little temperature increase, stable finished product. The tank working with the machine is with cooling jacket. Excellent cooling result can be achieved by inputting cooling water into the jacket when the machine is running . Normally thetemperature increase will be less than 10. Basket part with jacket can be customized.Customized options ● The machine can be Exproof type. ● Grinding chamber can be made of Zirconium. ● The machine can be vacuum type. ● The materials for the machine can be SS316L Working Principle The rotating motor drives the pins and dispersing disc to rotate at high speed, which makes the upper part of dispersing disc and inner grinding chamber become vacuum. The slurry is inhaled into grinding chamber. The grinding medium driven by the driving pin inside the chamber produces force in all directions,which put materialsunder the action of constant collision and friction to smaller the particle size andnarrow the particle size range. The vortex flow generated by high speed rotation dispersing disc absorbs materials out from the basket (grinding chamber), and the milled materials are absorbed again, excellent dispersing and grind result will be achieved. Lift the hydraulic piston by running the hydraulic pump to have the driving mechanism and grinding chamber lift up and down.

Farfly Company was established in 2003 with 1000 million fund registered. The headquarters located at Hongqiao International square of the big Hongqiao’s business district. Two manufacturing base respectively located at Fenxian chemical industrial park of Shanghai and Gushan industrial park of wuxi city, Jiangsu province. China Farfly is a specialized manufacturer in Chemical machinery equipment with total area about 18,000 square meters.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery