00:00

00:00

This machine is mainly used for aluminum tube filling and sealing. It has been widely used in the fields of Pharmacy, cosmetic, food and chemical etc. This machine function is: 1. Manual tube loading 2. Cam cylinder system-Diving filling with tube base up (Fully filling from tube bottom to head) 3. Air-blow cutting after each filling (Design for high viscosity material like paint, silicone etc.) 4. Nitrogen dosing filling device (Insulate material from air) 5. Automatic benchmarking (Cursor positioning) 6 Automatic tube filling sealing & No tube no filling 7. Automatic tube folding sealing 8. Material hopper can heating and stirring 9. Automatic printing the batch dates code 10. Can update with European accessories like Siemens, Omron and Schneider etc. -Machine design using your actual sample tubes and material, we support tube testing before payment -The machine has CE certification, comply with GMP hygiene standard. -We provide full-lifetime warranty with one year free accessories we will take video for: 1. how to connect the power 2. how to operate the machine 3. how to maintain the machine and how often to do it 4. how to adjust machine to different bottle or material. you can also check for: → Our machine lately export news ←

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:00

00:00

1. Consists of tube feeding system, orientation system, filling system, internal-heating system, outside heating system, Sealing and batching system, end cutting system, ejection system. 3. Adopts slot wheel dividing system to drive the turntable to do intermittent movement 5. This machine has stable performance and work without any noise and pollution. * Adopts turn valves, speed at 30-35 piece per min. * Hydraulic pressure machine is dispersing machine equipment for high viscosity products, its role is to be produced by the mixer high viscosity glue dispensing or discharge. The equipment consists of a hydraulic system, rack, lifting bracket and control box and other components. Its characteristics are: hydraulic cylinder can be adjusted within the range of pressure levels 0-20Mpa,Piston rod can stay in any position, And can work continuously under pressure maintaining and Regulators work, Aprons platen in contact with the tank wall within the container (which can carry the vacuum degassing apparatus, the material inside the container can be drained without stagnation. Is supported by a hydraulic crane lifted to the top position, easy to operate as sub-working staff, it has a simple structure, convenient operation. we will take video for: 2. 3. 4. how to adjust machine to different bottle or material. you can also check for:

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:00

00:00

Syrup, oral liquid, E-liquid, Eye-drops and Ear-drops into various round and flat Glass bottles with the range from 10-50ml. 1. Automatic conveyor belt running 3. 4. Automatic aluminum Caps capping 6. 7. No bottles no capping Can be customized according to different bottles shape and size And the filling valve is easy to open. It is convenient to wash and clean. About the machine use problem, after the sales, 1. how to connect the power how to operate the machine how to maintain the machine and how often to do it Thank you for the reading this article, → Our machine lately export news ←

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:00

00:00

This filling machine is suitable for: Daily chemistry, cosmetics. Smallglass bottles and plastic bottles such as electronic liquids, essential oils, syrups, etc. This machine function is: 1. Man-machine dialogue system setting,visual convenient operation ,accurate filling level 2. The mainframe running speed is step frequency conversion. 3. The product quantity can be controlled. 4. Multi-failure prompt function (such as depression, no filling and no inserting plug etc). 5. Automatic stop function, if there is no filling, no inner plug in any rail, it may stop automatically. This machine body made by stainless steel, and the working process is controlled by touch screen, and the filling volume is adjustable. This machine is suitable for filling capping e-liquid bottle of various specifications. According to customer filling material viscosity to choose piston filling system or peristaltic pump filling system. According to customer’s requirement, we will offer our technician for oversea to install and adjust machine , We provide the full-lifetime warranty consult with one year free accessories, even two years. If you need, we also can arrange the engineer to your factory do field installation guidance. About the machine use problem, after the sales, Thank you for the reading this article, → Our machine application ← → Our machine lately export news ←

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 01:35

01:35

Brief introduction This product belongs to our company's innovative design of drug ,cream,food packaging machinery, It’s applicable to plastic, paper, aluminum and aluminum composite sealed packaging for capsules, tablets, big honeyed pills, candy, liquids, pastes, disposable syringes and special objects in pharmaceuticals, health products, foods, cosmetics, medical equipment and other industries. The machine adopts microcomputer programming control, frequency control and touch panel operation, with high degree of automation. It is an ideal blister packaging equipment. Samples

Shanghai Grepack Packing Machinery Co.,ltd founded in 2002, is a professional manufacturer of packaging machinery. with hard work, We export machines to more than 70 countries and help thousands of customers to find suitable packing solutions to improve production efficiency. Our main products are the bottle filling machine line (include bottle turning table, filling machine, labeling machine, capping machine, sealing machine, cartoning system, robot palletizer) and Pouch packing line (including Stand up Pouch with spout/zipper, premade pouch, sachet & stick ), Providing client a perfect packaging solution for a different product in terms of powder, liquid, and granule, etc from filling, weight checking, metal detecting, cartoning & robot palletizing. with the idea of “ we always think more for you” as a core service value, We gained a good reputation from our customers around the world. our factory located workshop over 8000 ㎡, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solution!

Contact Supplier 00:00

00:00

1. Automatic conveyor belt running 3. Automatic four filling heads and filling 5.

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:09

00:09

1.The counterflow cooling tower adopts the bottle type design with the smallest windward load, easy assembly, and sturdy and durable. Each component is produced strictly according to ISO9001 standard, and has the highest test efficiency and can operate with ultra-low noise. The shell is made of RP (glass fiber reinforced plastic), which has good water resistance and high strength. The surface can be mirrored with silver gray to prevent UV rays from aging. High-performance automatic rotating water-spraying head, using advanced reinforced plastic or aluminum alloy casting, low pressure and uniform water, uniform heat exchange rate, economical and practical, ideal for small and medium air conditioning. 2.It adopts the motor for totally enclosed cooling tower, which is suitable for long-term continuous work under high temperature and high humidity environment. It has the characteristics of high efficiency, low noise, safety and reliability, and can also be equipped with the specified brand motor and corresponding inverter according to user requirements. 3.With the imported V-belt, the outer casing is completely enclosed, the operation is stable, the noise is low, and the transmission efficiency is high. 4.Made of high-quality aluminum alloy, linear, high air volume, high efficiency, low noise and corrosion resistance. 5.Automatic rotary sprinkler, can evenly distribute water to every corner of the packing, long life, corrosion resistance, high blocking efficiency, energy saving 6.High quality high grade PVC inclined ladder with corrugated winding. The surface has good hydrophilicity, large surface area growth rate, small wind resistance, is not easy to block, and has high cooling efficiency.

Venttech is a company engaged in refrigeration equipment development, design, production, sales and installation of high-tech enterprises. In the early 21st century, Venttech set up factory in Shanghai and adopt foreign advanced technology. Venttech has more than 15 years experience in developing refrigeration equipment such as water chillers, cooling towers and dry coolers. Till now, our refrigeration equipments have exported to more than 30 countries.

Contact Supplier 00:00

00:00

This filling capping machine is suitable for: Cosmetics, light industry (daily chemical industry), pharmaceutical, food and other industries, for enterprise products selected plastic bottles, glass bottles for packaging containers, the device can cream, ointment, cream, gel or viscous fluid. The equipment is divided into a turntable into the bottle, automatic lift filling, automatic pre-spin cover, servo capping, a few bottles, such as the operation of the bottle into the bottle, filling the bottle, filling the bottle, and then the bottle capping operation. 1. Bottle inlet: by the artificial bottle to be filled into the hopper hopper, with the operation of the equipment in order to enhance the bottle. 2. Bottle detection: the photoelectric sensor detects whether there is an empty bottle on the main turntable, and sends the detection signal into the control computer to control the filling of the bottle, without bottle filling. 3. Filling function: If the front has detected a bottle, no bottle is not filling, PLC control filling mouth into the bottle for filling. 4. Load cover device: automatic load cover, high efficiency and more stable. 5. Capping: detection of a cover, this capping head will dive down and fix the bottle position to cap, very stable and with low noise. 6. Bottle outlet: at the last, capped bottles come out at the conveyor belt, and how to connect the power 2. how to maintain the machine and how often to do it 4. how to adjust machine to different bottle or material. Thank you for the reading this article, you can also check video for: → Our machine lately export news ←

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:09

00:09

Design and structure features: With cross-flow cooling, the drift rate is extremely low. The interior space is large and the maintenance is very convenient. Fully enclosed circulation to prevent blockage caused by debris The heat exchanger adopts a modular stacking method, which can be installed and disassembled layer by layer. No need for a pool, small footprint, easy to access. Automatic digital display temperature control, energy saving and environmental protection The operation is simple and the maintenance cost is low. Product Performance: Using the combination of feng shui and mixed flow two times heat exchange coil and PVC packing technology, to achieve efficient heat exchange. As the air and spray water flow through the coil, the sprinkler to the maximum extent possible to cover the surface of the coil to ensure that the surface of the coil is completely moist. Compared with the reverse structure of feng shui, it greatly reduces the formation of dry point and scale of the coil wall.

Venttech is a company engaged in refrigeration equipment development, design, production, sales and installation of high-tech enterprises. In the early 21st century, Venttech set up factory in Shanghai and adopt foreign advanced technology. Venttech has more than 15 years experience in developing refrigeration equipment such as water chillers, cooling towers and dry coolers. Till now, our refrigeration equipments have exported to more than 30 countries.

Contact Supplier 00:36

00:36

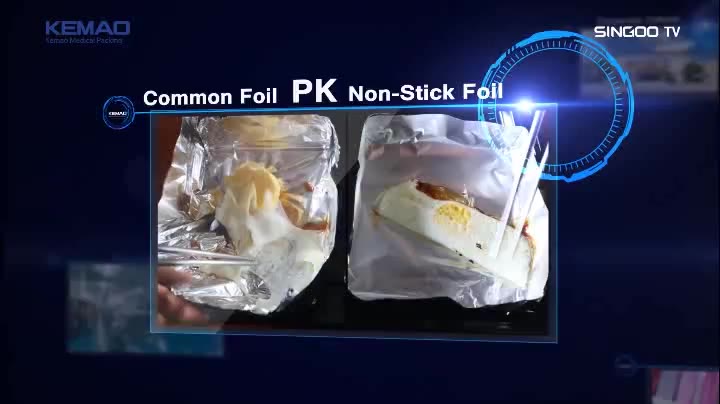

Outstanding Non-stick qualities, which is perfect for all sticky food situations. It’s safe at any temperature ranging from -40° F to 650° F Application: Suitable for the oven, grill and freezer use, Cook- Line pans, foods slide off. No need to grease or spray pans, clean up easily. Cover/Wrap - Cheese, Poultry Skin and Sauces stay on food and won’t stick to cover. Freeze - It provides great protection against Freezer burn, there’s no sticking or prying frozen foods apart. (*) Thickness, size of the foil can be adjusted to meet customer’s requirements.

Shanghai Kemao Medical Packing Co. Ltd is one of the Chinese leading manufacturers of Pharmaceutical Blister Aluminum foil and Food Packaging Aluminum Foil. Estimated in 2005 with registered staff about 100 people. Factory located in Baoshan district of Shanghai City.

Contact Supplier 02:29

02:29

1) Outline size of machine(L×W): 12000X800 2) Line Speed:12m/min 3) Load Capacity of Decoiler:5T 4) Roller station: 28 stations 5) Diameter of roller shaft: ¢60㎜ 6) Material of roller adopts high-quality alloyed 45# steel 7) Supplier of Roller Material:Shanghai Steel Factory 8) Quenching Type of Roller:quenching in salt bath furnace 9) Main Shaft of Roller:high grade 40Cr 10) Material of Roller shaft: 40Cr(thermal refining) 11) Quenching Type of Roller Shaft:quenching in salt bath furnace 12) Thickness of Steel Coil:0.4mm-0.8mm 13) Motor Power:7.5kw 14) Oil Pump Model:radial piston oil pump 63SCY14-1B 15) Computer System: adopts PLC,Model: OMRON 16) Computer Operating Board: adopts Xinjie OP320A

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 01:07

01:07

Model DPM-C Driving Mode Servo motor Yield(pcs/min) 10-80 (depends on box and label size) Operating direction Left or Right Conveyor Speed(m/min) ≤40 Labeling Accuracy ±1.0 mm Inner diameter of label roll 76 mm Outer diameter of label roll 350 mm(max) Suitable label size Width 10-150 mm length 10-260 mm Suitable labeling products size Can customized depends on client product Printer use air 5kg/cm ² Voltage (can customized) 110V/220V/380V Power(w) 650W Weight(kg) 260 Machine size 1800(L) 800 (W) 1300 (H) mm

Shanghai SKILT Machinery Equipment Co.Ltd was founded in 1998. We focus on research and manufacture intelligent automatic labeling code equipment, with a full range labeling equipment, including Online printing Labeling for Logistics Monitoring System; Round&square&flat bottle labeling machine; Carton corner labeling machine; Double Sides labeling machine for different kinds products and so on. All the machines have passed ISO9001 and CE certificate. “Professional·create value” is our motto. With 15 years experience in professional and excellent design team, We provide unique identifier assigned code and labeling solutions depending on client’s different kinds of requirements. Our company have import and export right authorized by China government. And our customers are all over the world, like Europe, US, Middle East, Southeast Asia and South American. Meanwhile, our annual revenue goes nearly RMB10 million. We are familiar with international standards, such as CE and UL certifications, haveing stable long-term relationship with local dealer/agents. Teaching technology as our forerunner and quality as our survival, we introduce the advanced technology from Foreign countries, researched and developing high quality product line. Hope SKILT can be your most trusted partner!

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery