06:23

06:23

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” This HR Cut to Length Line series is applicable to coils of various specifications. It is used for the producing flattened plate through the procedure of uncoiling, flattening and cutting to required width and length. This line consists of loading cut, single pivot uncoiler, pre-leveler, hydraulic loop bridge, deviation corrector, fine leveler, servo length gauge, shear, belt conveyor, reversal discharger, stacker, discharging cart, servo transmission system, hydraulic system, etc. The machine performance has reached the international standard. This cut to length line series coil thickness range can be from 4.0mm to 25.0mm and coil width can be from 900mm to 2500mm,all these size steel coils are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of Cut To Length Line Model TLL16X2200 TLL20X2200 TLL25X2500 Material Type HR HR HR Coil Thickness(mm) 4.0-16.0 6.0-20.0 8.0-25.0 Plate Width(mm) 900-2200 900-2200 900-2500 Cutting precision(mm) ±1.0 ±1.0 ±1.0 Line Speed(m/min) 0-25 0-18 0-18 Coil Weight(T) 35 35 35 Finish Plate Length(mm) 2000-12000 2000-12000 2000-12000 Occupied Area(m) 38X10 42X11 45X11.5 Power(kw) 280 420 480

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 04:46

04:46

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” TDG Series Directly Forming to Square and Rectangular Tube Mill Only one set of rollers can be continuously produced within a certain range of rectangular steel pipe, using the international advanced multi-radius combination molding process and high-frequency welding, forming by multi-channel symmetrical bending. It can be divided into small side bending, boardside bending, free bending at closed side, high frequency welding, precision straightening, produce the exact size and good quality pipe after cut off. Characteristic: One set mold roller can produces a range of rectangular tubes. This machine has characteristics such as no replace spindle, no remove roller stand and quick change rollers. Save mold, save time. Four square corner deformation part which can save extra deformation process then save energy consumption and equipment load. Specification of Directly Forming to Square and Rectangular Tube Mill SPEC TDG600X600 TDG500X500 TDG400X400 - Material to be processed Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon - Type Square & Rectangular tube Square & Rectangular tube Square & Rectangular tube Square 300 x 300 – 600 x 600 mm 250 x 250 – 500 x 500 mm 180 x 180 – 400 x 400 mm Rectangular 300 x400 – 500 x 600 mm 250 x350 – 300 x 500 mm 180 x200 – 300 x 400 mm - Wall thickness 6.0 mm – 22.0 mm 5.0 mm – 18.0 mm 5.0 mm – 14.0 mm - Tube length 6.0 m - 24.0 m 6.0 m - 18.0 m 6.0 m - 12.0 m - Line Speed Max. 20m/min Min.12m/min Max. 24 m/min Max. 30 m/min - Welding Method Solid State High Frequency Welding Solid State High Frequency Welding Solid State High Frequency Welding - Forming Method Directly Forming to Square and Rectangular tube Directly Forming to Square and Rectangular Directly Forming to Square and Rectangular Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 05:49

05:49

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” TDG Series Directly Forming to Square and Rectangular Tube Mill Only one set of rollers can be continuously produced within a certain range of rectangular steel pipe, using the international advanced multi-radius combination molding process and high-frequency welding, forming by multi-channel symmetrical bending. It can be divided into small side bending, boardside bending, free bending at closed side, high frequency welding, precision straightening, produce the exact size and good quality pipe after cut off. Characteristic: ·One set mold roller can produces a range of rectangular tubes. ·This machine has characteristics such as no replace spindle, no remove roller stand and quick change rollers. ·Save mold, save time. ·Four square corner deformation part which can save extra deformation process then save energy consumption and equipment load. Specification of Directly Forming to Square and Rectangular Tube Mill SPEC TDG120X120 TDG150X150 TDG200X200 - Material to be processed Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon Carbon Steel, strip coils of weld able grade with max. 0.2% carbon - Type Square & Rectangular tube Square & Rectangular tube Square & Rectangular tube Square 60 x 60 – 120 x 120 mm 70 x 70 – 150 x 150 mm 80 x 80 – 200 x 200 mm Rectangular 60 x 80 –100 x 140 mm 60 x 80 –100 x 200 mm 80 x 100 –150 x 200 mm - Wall thickness 1.5 mm – 5.0 mm 2.0 mm – 6.0 mm 2.0 mm – 8.0 mm - Tube length 6.0 m - 12.0 m 6.0 m - 12.0 m 6.0 m - 12.0 m - Line Speed Max. 45m/min Max. 40 m/min Max. 40 m/min - Welding Method Solid State High Frequency Welding Solid State High Frequency Welding Solid State High Frequency Welding - Forming Method Directly Forming to Square and Rectangular tube Directly Forming to Square and Rectangular tube Directly Forming to Square and Rectangular tube Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 04:17

04:17

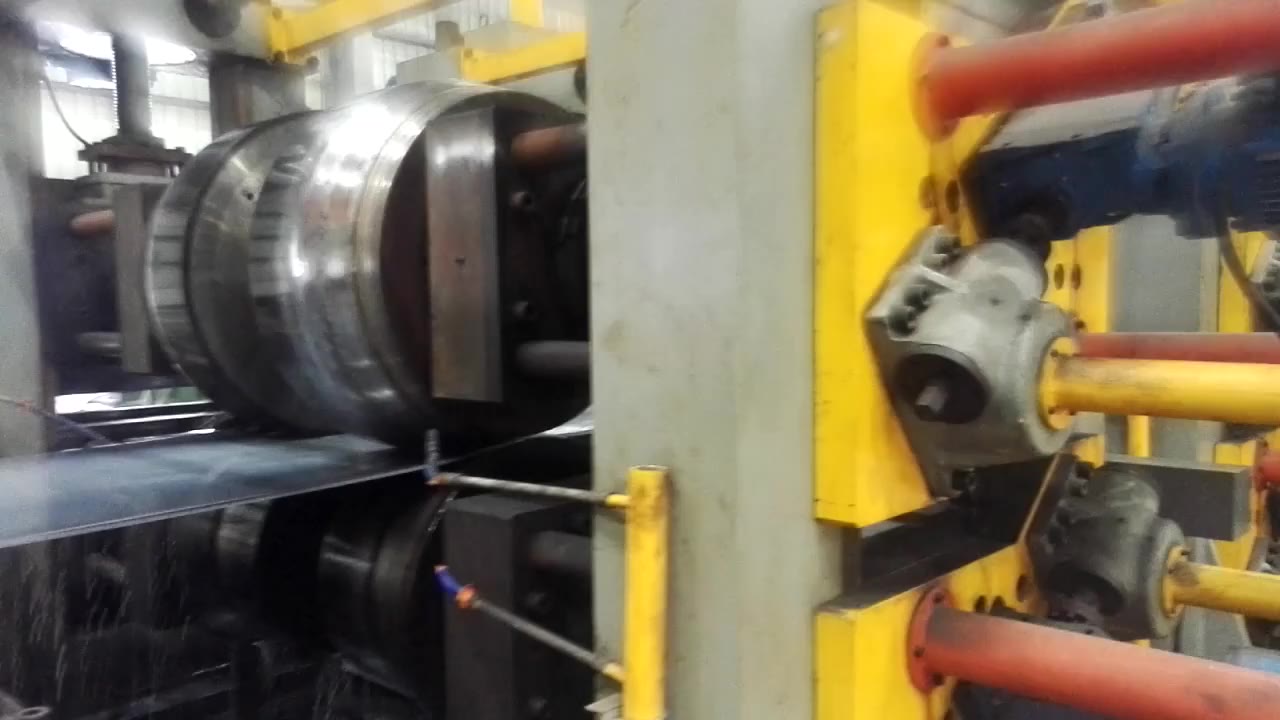

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut to length line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” Our TZG series ERW/API Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation. This ERW/API tube mill series with excellent design, selected high precision durable roller under strictly quenching , high performance cutting saw, complete machine body with heat treatment, accurate fabrication, precise assembly. The machine performance has reached the international ERW welded tube standard. This tube mill series outer diameter range can be from Φ140mm to Φ 630mm and wall thickness of 4.0~22.0mm,all these size tubes are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of ERW/API Welded tube mill line Model Tube O.D.(mm) Wall Thickness(mm) Speed(m/min) H.F. power(Kw) TZG-325 φ140-325 4.0-12.7 12-35 800 TZG-508 φ165-508 6.0-20.0 10-30 1000 TZG-630 φ273-630 6.0-22.0 6-20 1200 Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 02:11

02:11

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut to length line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” Our TZG series High Precision Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation. This high precision tube mill series with excellent design, selected high precision durable roller under strictly quenching , high performance cutting saw, complete machine body with heat treatment, accurate fabrication, precise assembly. The machine performance has reached the international ERW welded tube standard. This tube mill series outer diameter range can be from Φ7mm to Φ 50.8mm and wall thickness of 0.2~2.0mm,all these size tubes are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of High precision series tube mill line Model Tube O.D.(mm) Wall Thickness(mm) Speed(m/min) H.F. power(Kw) Main motor(Kw) TZG-12 φ7-16 0.2-0.5 30-100 60 15 TZG-16 φ8-25 0.3-1.0 30-90 60 22 TZG-25 φ8-30 0.4-1.3 30-90 100 37 TZG-28 φ10-38 0.5-1.5 30-80 100 45 TZG-32 φ13-50.8 0.6-2.0 20-90 100 75 Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 02:41

02:41

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut to length line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” Our TZG series High Precision Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation. This high precision tube mill series with excellent design, selected high precision durable roller under strictly quenching , high performance cutting saw, complete machine body with heat treatment, accurate fabrication, precise assembly. The machine performance has reached the international ERW welded tube standard. This tube mill series outer diameter range can be from Φ13mm to Φ 100mm and wall thickness of 0.8~4.5mm,all these size tubes are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of High precision series tube mill line Model Tube O.D.(mm) Wall Thickness(mm) Speed(m/min) H.F. power(Kw) Main motor(Kw) TZG-45 φ13-50.8 0.8-2.0 20-70 100 75 TZG-50 φ15-63.5 0.8-2.5 20-70 150 90 TZG-60 φ16-63 1.0-3.0 20-60 200 132 TZG-76 φ25-80 1.2-4.0 15-60 300 160 TZG-90 φ32-100 1.5-4.5 15-50 350 180 Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 03:21

03:21

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” Our TZG series High Precision Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation. This high precision tube mill series with excellent design, selected high precision durable roller under strictly quenching , high performance cutting saw, complete machine body with heat treatment, accurate fabrication, precise assembly. The machine performance has reached the international ERW welded tube standard. This tube mill series outer diameter range can be from Φ40mm to Φ 219mm and wall thickness of 1.5~8.0mm,all these size tubes are produced with large output, best quality and high precision.Our customized machines are also can be used for different processed material and meet nearly all applications. Specification of High precision series tube mill line Model Tube O.D.(mm) Wall Thickness(mm) Speed(m/min) H.F. power(Kw) Main motor(Kw) TZG-115 φ40-115 1.5-5.0 15-50 400 264 TZG-165 φ76-165 2.0-6.0 15-50 600 320 TZG-219 φ114-219 3.0-8.0 15-40 800 600 Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 00:31

00:31

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut to length line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” Our TAG series Alumnium High Precision Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation. Featured ERW Welded line for Aluminium Spacer Bar To meet the demand of aluminum spacer bar market,we also design High Frequency Welded line of Aluminium Spacer Bar for hollow glass that is based on 3003 aluminium the material .Adopt the technology roller forming and high frequency welding that does not destroy the molecular structure of raw material ,to ensure the molecular sieve activity,bending and filling without splitting. Our High frequency welding aluminum spacer bar production line has reached international standard .The finished alumium spacer bar have bright ,smooth surface with perfect single side and double line hole to ensure activity of desiccant.Strictly control of raw material procument and production of in order to guarantee to make sure the finished products no errors,no deformation and keep size precise. High Frequency welding for aluminium adopt one right angle connection technology to produce hollow glass without any joint parts,sealing effect is perfect that can avoid no leakage,Prolong the hollow galss working life. Advantage of ERW Welded line for Aluminium Spacer Bar Compare with ordinary aluminium bar,the high frequency welding have following advantage 1. Anti-rust,anti-corrosion, brighter surface. 2. The surface hole of aluminium bar is in unformity,,no deformation, good straighteness 3. High strength ,good toughness,the material can be bent continuously into aluminium frame in any angle by bending machine 4. Ensure the activity of molecular sieve and excellent adhension with all kinds of rubber. Aluminum Spacer Bar Products Spectification 1:1 Section Model Section Width(mm) Section Height(mm) Thickness (mm) Length(m/root) 6A 5.5 6.5 0.2-0.35 If more than 4m,we can sizing 8A 7.5 6.5 0.2-0.35 9A 8.5 6.5 0.23-0.35 10A 11.5 6.5 0.25-0.35 12A 11.5 6.5 0.25-0.35 15A 14.5 6.5 0.27-0.35 6.0 6.0 6.5 0.2-0.35 8.0 8.0 6.5 0.2-0.35 10.0 10.0 6.5 0.23-0.35 11.0 11.0 6.5 0.25-0.35 Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 02:03

02:03

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “think for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” Our TBG series stainless steel Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation. This stainless steel tube mill series with excellent design, selected high precision durable roller under strictly quenching , high performance cutting saw, complete machine body with heat treatment, accurate fabrication, precise assembly. The machine performance has reached the international welded tube standard. This tube mill series outer diameter range can be from Φ12.7mm to Φ 325mm and wall thickness of 1.0~10.0mm,all these size tubes are produced with large output, best quality and high precision.Our customized machines are also can be used for stainless material and meet nearly all applications. Specification of TBG Stainless Steel Welded Tube Mill Model Min O.D.(mm) Max O.D.(mm) Min Thickness(mm) Max Thickness(mm) Speed(m/min) TBG-32 12.7 33.4 1.0 3.0 TBG-50 22 60.3 1.0 3.5 TBG-76 25.4 89 0.8 4.0 0.5-6 TBG-102 76 168 1.5 6.0 0.5-3 TBG-219 89 219 2.0 8.0 0.5-2 TBG-325 114 325 2.5 10.0 0.5-1.8 Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 01:04

01:04

More than 45 years of professional manufacturing experience, WUXI TBS SCIENCE AND TECHNOLOGY CO., LTD have been one of the leading manufacturer in China,mainly specialize in ERW Tube&Pipe Mill Line, Slitting Line, Cut To Length Line, etc. Throughout many decades team efforts for improvement of superior product quality and pursuit of advanced technology, we have widely won high praise from domestic and overseas customer. We always keep strong faith in “Thinking for what customer think”. Our mission: “Customized Technical Support,Most Cost-Effective Commerical Solution,High Performace Machine Supply,Reliable Service After-Sales” Our TCG series Copper ERW Welded Pipe&Tube Line with the latest technology,meet high efficiency output ,easily operated and stable running performance,also the complete tube mill line meet a high level automation. This Copper ERW tube mill series with excellent design, selected high precision durable roller under strictly quenching , high performance cutting saw, complete machine body with heat treatment, accurate fabrication, precise assembly. The machine performance has reached the international ERW welded tube standard. All these size tubes are produced with large output, best quality and high precision.Our customized machines are also can be used for copper material and meet nearly all applications. Finished Products

Wuxi TBS Science&Technology Co.,Ltd was established in 1971. TBS Company is located in Jiangsu province, China.Now we have two manufacturing plants: one in Yangzhou, which specializes in tube mill line,this plant covering area of 86700 sq.m,another one in Wuxi,which focus on cut to leng and slitting line. Thoughout 40 years continuous team efforts the total fixed asserts of TBS reach 30Million USD and registrated capital is 5 Million USD with annual sales of 40 Million USD. TBS company own 250 sets of fabricating machinery used in our workshop for ensuring running precision and stabiltiy of our own equipment.Our products have passed ISO90001:2015 Quality managing-system cerfification and CE security system authentication. In the earlier of 20 years we focus on the designing and manufacturing of roller mould tooling, electrical auto control mainly contribute to some national contruction project. Since 1990 we started to produce small duty ERW High Precision Tube Mill based on China domestic market demands. In 2012 our company established R&D Center for Jiangsu precision CNC roller mould forming mechnical Engineering.Considering demands from tube and pipe making producer,we builded another plant in wuxi since the year of 2000 that mainly produce cut to length and slitting line so as to offer complete turnkey solution from customized steel coil process to customer final products. Thanks to the recent 20 years rapid growth of China Industry and civil Infrastucture TBS company have been one of leading manufacturer mainly specilized in ERW Tube and Pipe Mill line ,steel coil slitting line,cut to length line that used for fabricating from steel coil processed to finished tube and required size of steel products.

Contact Supplier 01:16

01:16

Catalogue Download Feature • Stainless steel material. • Results in a super-neat and super-strong swage. • Precise crimping die sets and integral lock with self-releasing mechanism ensure high-quality crimping effect after crimping repeatedly. • Accurate adjustment before ex works delivery. • Light and compact structure keep crimping effect. Parameters < Model HL-800D Crimping range Wire ropeΦ1.5- 5mm 1/16”-3/16” Cutting range Wire rope Φ5mm Length 540mm Weight 6 kg Application Our cable crimper mainly used for electrical working, State Grid construction, underground cable construction, Building construction etc.

Haicable is specialized in manufacturing quality tools for power industry and supplying full solution around Cable and Wire. We own various styles of Crimping Tools, Cutting Tools, Stripping Tools, Hydraulic Tools, Battery powered tools, Bus bar Tools, etc. We provide our clients with comprehensive ODM / OEM services, rich experience in exporting to EU, America, Australia, Middle East and Southeast Asia with diversified customized products.

Contact Supplier 00:05

00:05

Titanium M VR Evaporator Application Range Evaporator, separator (crystallizer), condenser, vacuum and discharging system, delivery pump, PLC, electrical appliance and instruments, valves, pipelines etc. MVR evaporator technology MVR applied mechanical vapor recompression unit for compressing the secondary vapor so that recycle the secondary vapor completely in a closed-loop circulation system. As a result of the vapor compressor, temperature and pressure of the secondary vapor raised, the heat efficiency boosted. The effectiveness of live steam is equal to 30 effects of multiple effect evaporator. Thus reducing the demand for external live vapor and cooling resources, energy conservation and less pollution attained. Evaporator performance

Nomia Machinery Co.,Ltd is professional in manufacturing MVR evaporator, multiple effect evaporator, falling/rising film evaporator, forced-circulation evaporator which are highly specialized of engineering services process design, manufacturing, installation and commissioning. Nomia go through the national high-tech enterprise certification, with the qualification for pressure vessel manufacturing, won ISO9001 quality management system and CE certification for Europe. Nomia machinery owns the first-class highly professional team, technical team, technically advanced manufacturing facilities and a meticulous quality control system, committed to be the respected leading enterprise in evaporation & concentration, continuous evaporation & crystallization, zero liquid discharge of industrial effluents etc. Most important of all, we focus on high efficiency and energy saving.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery