00:12

00:12

Key Features > 1/2" 8MP Low illumination Progressive CMOS Sensor > H.265&H.264 dual-stream encoding > 4K 3840×2160@15fps, 5MP 2592*1944@30fps > 3.6mm/2.8mm 4K fixed lens(Optional 3.6-10mm manual varifocal lens) > 18pcs SMD IR LEDs, up to 30m IR distance > 1/1 audio in/out > DWDR, Day/Night(ICR), 3DNR, AWB, AGC, BLC > Optional interfaces:1/1*Alarm I/O, 1*Reset, 1*RS485, 1*CVBS output > Intelligence analysis: Alarm line,alarm region,goods stranded,video block,fuzzy detection,scene change > Metal, Vandalproof

Shenzhen PolyCam Technology Co., Limited, was founded in June 2015 in order to exporting security video camera and surveillance products to worldwide with brand PLSECU. Shenzhen PolyCam has comprehensive IP surveillance product lines that encompass its broad range of Smart Network Camera, NVR XVR, 4in1 HD Cameras, Video Management Software, covering a diverse vertical markets including retail, building, industry, education, commercial, city surveillance etc.

Contact Supplier 00:13

00:13

Multiple Effect Evaporator (MEE) Multi-effect evaporation concentration system Application Range Solutions for concentrating material with non-fouling performance, easy evaporation, thermal sensitive features. System components Evaporator, separator, condenser, vacuum and discharging system, delivery pump, PLC, electrical appliance and instruments, valves, pipelines etc. Multi-effect evaporation concentration equipment The Live steam as the thermal energy for heating the first effect evaporator then generates secondary vapor which drawn into the second effect evaporator and so on. The multiple evaporators attached to form the whole multiple effect evaporation system. The latent heat will be recycled and reused, thus reducing the energy consumption and enhance thermal efficiency. Diagram Features The classic popular evaporation and concentration equipment. As the effects increased, the more vapor energy shall be saved. Lower up-front investment, but a large amount of vapor energy consumption bring about a strong energy consumption intensity. It's suitable to use in low-cost vapor energy field. Friendly to the concentration of thermally sensitive material. Evaporator Energy consumption Evaporator Parameter Installed projects

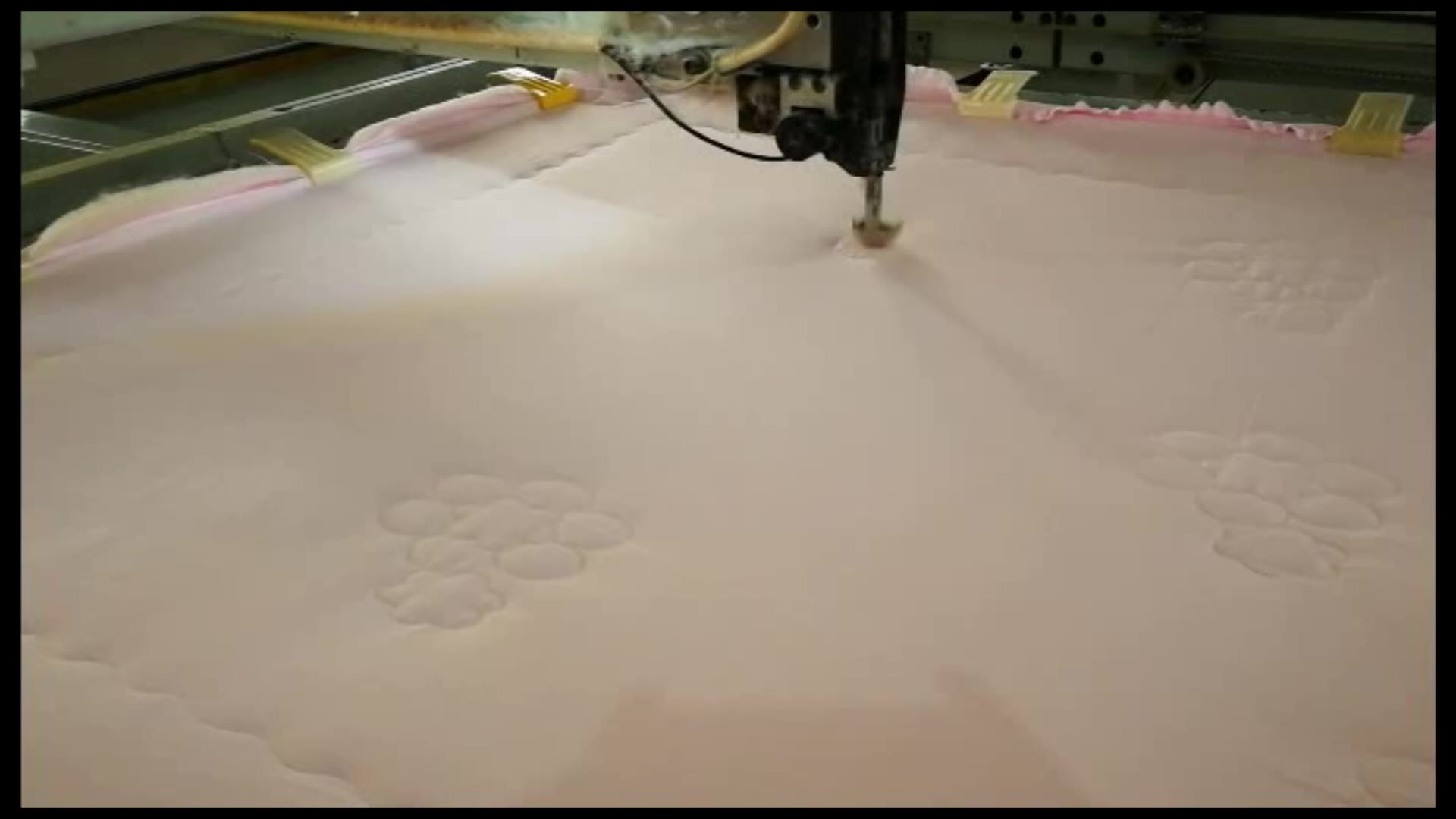

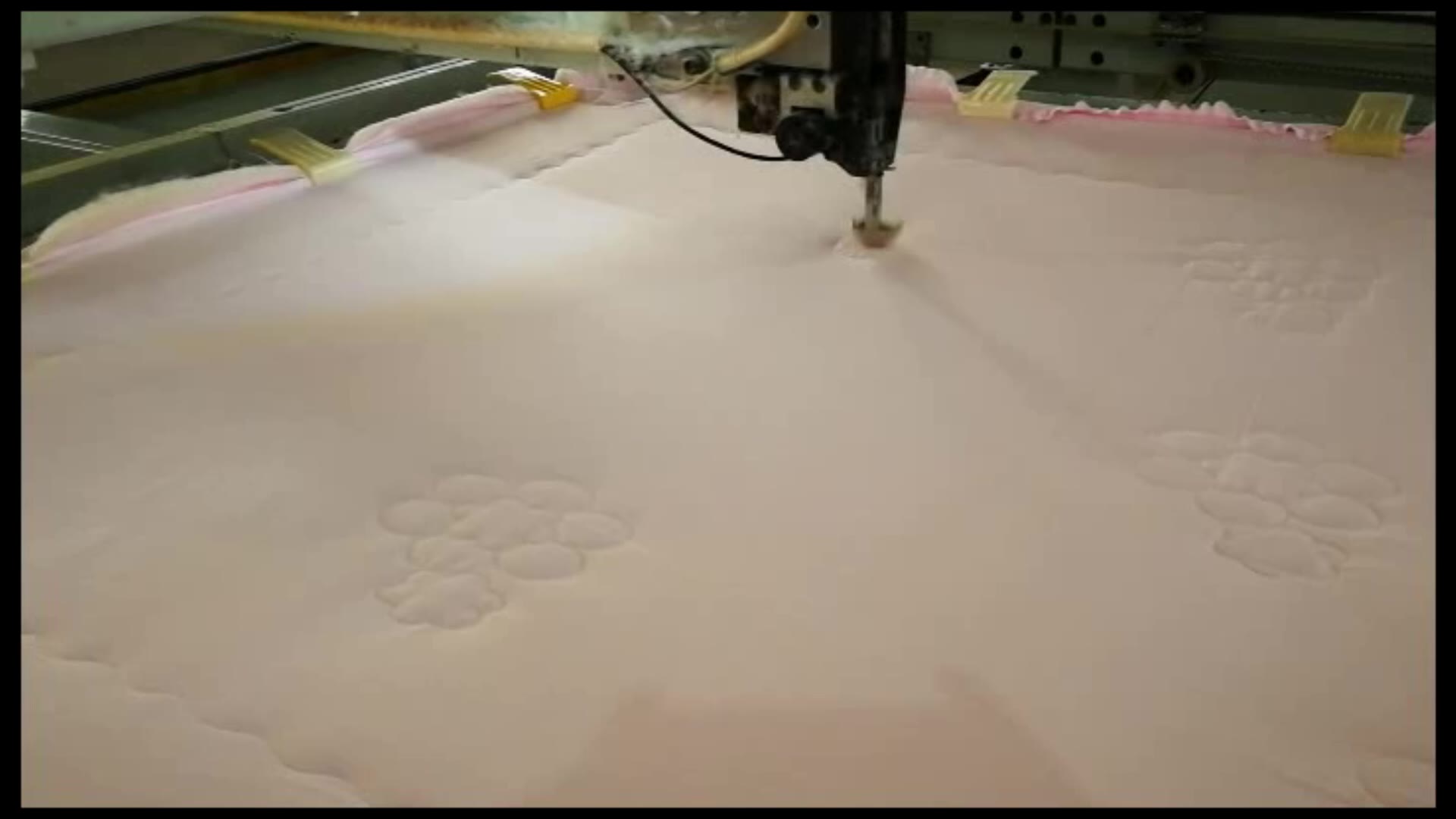

Nomia Machinery Co.,Ltd is professional in manufacturing MVR evaporator, multiple effect evaporator, falling/rising film evaporator, forced-circulation evaporator which are highly specialized of engineering services process design, manufacturing, installation and commissioning. Nomia go through the national high-tech enterprise certification, with the qualification for pressure vessel manufacturing, won ISO9001 quality management system and CE certification for Europe. Nomia machinery owns the first-class highly professional team, technical team, technically advanced manufacturing facilities and a meticulous quality control system, committed to be the respected leading enterprise in evaporation & concentration, continuous evaporation & crystallization, zero liquid discharge of industrial effluents etc. Most important of all, we focus on high efficiency and energy saving.

Contact Supplier 00:00

00:00

This machine is mainly used for plastic tube filling and sealing. It has been widely used in the fields of pharmacy, cosmetic, food and chemical etc. This machine function is : 1. Manual loading tube 2. Automatic benchmarking 3. Aumatic filling and no tube no filling and could be bottom filling system according to customer materail viscosity 4. Automatic heating (inner heating and outer heating) 5. Automatic sealing and printing the date code 6. Automatic cut the over part after sealing then output finish product This machine body made by stainless steel, and the working process is controlled by buttons, and the filling speed is adjustable. This machine is suitable for filling, sealing, printing and cutting of plastic tubes of various specifications. The shape of the sealing tail is beautiful and neat, the sealing is firm, the measuring accuracy is high, and the stability is good.According to customer materail viscosity could be heating and stiring hopper and bottom filling system. According to customer’s requirement, we will offer our technician for oversea to install and adjust machine , We provide the full-lifetime warranty consult with one year free accessories, even two years. If you need, we also can arrange the engineer to your factory do field installation guidance. we will take video for: 2. how to operate the machine 4. how to adjust machine to different bottle or material. you can also check for: → Our machine lately export news ←

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:10

00:10

Mechanical Vapor Recompression Evaporator ( MVR Evaporation system) MVR Working principles MVR applied mechanical vapor recompression unit for compressing the secondary vapor so that recycle the secondary vapor completely in a closed-loop circulation system. As a result of the vapor compressor, temperature and pressure of the secondary vapor raised, the heat efficiency boosted. The effectiveness of live steam is equal to 30 effects of multiple effect evaporator. Thus reducing the demand for external live vapor and cooling resources, energy conservation and less pollution attained. Application Range Evaporator, separator, condenser, vacuum and discharging system, delivery pump, groundwork, PLC, electrical appliance and instruments, valves, pipelines etc. Features MVR energy conserving evaporator is the advanced evaporation technology in nowadays. It only consumes a few vapors in the first two hours of the evaporator operation, almost no vapor consumption after then. As a compressor provided with thermal energy, compared with the traditional evaporator, MVR evaporator got a low temperature-trip, which is good for feeding material quality and avoiding scale forming. Not required a condenser or required a very small condenser CIP cleaning system Evaporation temperature: 50-100 C, less effect on feeding material nature Energy consumption: Evaporating 1-ton water shall consume 15-27 degree power, while the material with low boiling point, the consumption shall be below 20 degrees. About the energy consumption depends on local vapor and power cost. We suppose the vapor supply cost 180 RMB/T, electricity supply cost 0.7 RMB per degree. Evaporating one-ton water will conserve 0.23*180-20*0.7=27.4 RMB. If you evaporating 100Tons, the evaporator is supposed to run 330 days every year, 24hours per day, MVR will save 27.4*100*24*330=21700800 RMB. The energy conservation efficiency is 60% more than five-effect evaporator. Evaporator selection notice compared with electricity and vapor supply cost ahead of time. MVR invest more than multi-effect evaporator at the early stage, but the cost shall be covered after 300days service.

Nomia Machinery Co.,Ltd is professional in manufacturing MVR evaporator, multiple effect evaporator, falling/rising film evaporator, forced-circulation evaporator which are highly specialized of engineering services process design, manufacturing, installation and commissioning. Nomia go through the national high-tech enterprise certification, with the qualification for pressure vessel manufacturing, won ISO9001 quality management system and CE certification for Europe. Nomia machinery owns the first-class highly professional team, technical team, technically advanced manufacturing facilities and a meticulous quality control system, committed to be the respected leading enterprise in evaporation & concentration, continuous evaporation & crystallization, zero liquid discharge of industrial effluents etc. Most important of all, we focus on high efficiency and energy saving.

Contact Supplier 00:09

00:09

Solution for concentrating material with non-fouling performance, easy evaporation, thermal sensitive features. System components The Live steam as the thermal energy for heating the first effect evaporator then generates secondary vapor which drawn into the second effect evaporator and so on. The multiple evaporators attached to form the whole multiple effect evaporation system. The latent heat will be recycled and reused, thus reducing the energy consumption and enhance thermal efficiency. Features

Nomia Machinery Co.,Ltd is professional in manufacturing MVR evaporator, multiple effect evaporator, falling/rising film evaporator, forced-circulation evaporator which are highly specialized of engineering services process design, manufacturing, installation and commissioning. Nomia go through the national high-tech enterprise certification, with the qualification for pressure vessel manufacturing, won ISO9001 quality management system and CE certification for Europe. Nomia machinery owns the first-class highly professional team, technical team, technically advanced manufacturing facilities and a meticulous quality control system, committed to be the respected leading enterprise in evaporation & concentration, continuous evaporation & crystallization, zero liquid discharge of industrial effluents etc. Most important of all, we focus on high efficiency and energy saving.

Contact Supplier 00:00

00:00

cosmetic, pharmacy, foodstuff, bond industries and other similar products. The machine main function is : 2. Automatic filling material , filling system can customize according to different material 4. High efficient and high precise 6. Stainless steel machine body , next and beautiful Its working principle is: The tubes in tube chamber vertically enter into the first-station tube holder one by one, and transferred together with the rotating turn plate to the second-station for I. Marking detection. The third station is for tube locating and reversal inspection (nitrogen jet tubes cleaning is optional). The material filling is in the fourth station and then come to the sealing(and tail bending) station for heating (PE tube) folding (metal tube), tail sealing (PE), clamping (metal), batch number printing, cooling, cutting and at last finished products discharging. Every tube should go through the whole procedure and then finished after filling and sealing. The main structure of the machine is consisted of main transmission, feeding, rotation, tail sealing, filling and electricity control system. This machine is a 1 filling head filling machine with a heating gun. It has total 12 positions for filling and sealing. And materials such as paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste etc., are all applicable. About the machine use problem, after the sales, 1. how to connect the power 3. how to maintain the machine and how often to do it you can also check for: → Our machine lately export news ←

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier 00:34

00:34

is_customized: Yes Fabric Density: 200 * 200 Color Fastness (Grade): 3-4 Grade: Grade A Type: Comforter Sets Age Group: All ages Filling: Cotton Style: Jacquard Size: Full Feature: Nondisposable Brand Name: ICOSYHOME Product Name: 100% pima cotton bedding set pima cotton bed Fabric: 100% cotton Logo: Accept Customized Logo Detailed: 1 Cover 1flat Sheet 2 pillowcase Packing: PVC Bag + Insert Card + Cardboard

Shanghai Civo International Trade Company,is committed to developing、manufacturing and exporting home textiles of high quality. Our main products are latex products and bedding sets etc. After many years of world famous brand OEM experience,we build our own brand of ICOSYHOME in 2018.The strategic ideology of “To be professionally, to lead with comfort.” make Civo one of the most competitive enterprises in home textile industry.

Contact Supplier 00:34

00:34

Product Type Pure Cotton Bedding set Brand ICOSYHOME Model CB0232 Material Pure Cotton Technics Active Dye Print,Embroidery Parts Sewn-in Lable, Tag Feature Anti-Pilling ,Anti-Static Executive standards GB/T22844-2009 SGS Stand Size 250*250 230*250mm or customized

Shanghai Civo International Trade Company,is committed to developing、manufacturing and exporting home textiles of high quality. Our main products are latex products and bedding sets etc. After many years of world famous brand OEM experience,we build our own brand of ICOSYHOME in 2018.The strategic ideology of “To be professionally, to lead with comfort.” make Civo one of the most competitive enterprises in home textile industry.

Contact Supplier 00:35

00:35

Product Type 100% Cotton Bedding set Brand ICOSYHOME Model CB-0026 Material 100% Cotton Technics Active Dye Print Quantity Four Pcs Parts Sewn-in Lable, Tag Feature Anti-Pilling ,Anti-Static Executive standards GB/T22844-2209 SGS Stand Size 250*250 230*250mm or customized

Shanghai Civo International Trade Company,is committed to developing、manufacturing and exporting home textiles of high quality. Our main products are latex products and bedding sets etc. After many years of world famous brand OEM experience,we build our own brand of ICOSYHOME in 2018.The strategic ideology of “To be professionally, to lead with comfort.” make Civo one of the most competitive enterprises in home textile industry.

Contact Supplier 00:43

00:43

The rotary type magnetic separator is composed of a ring-shaped magnetic grid, a stainless steel case and a geared motor. The rotary type magnetic separator drives the ring-shaped magnetic grid to rotate by the gear motor, thereby effectively preventing the material from bridging when flowing through the rotatory magnetic separator. Blockage and the like occur to efficiently remove iron impurities in the loose agglomerated material. Rotary type magnetic separator is mainly used for sorting fine iron impurities in powder materials with relatively poor fluidity and easy to accumulate. These materials are more likely to be blocked or piled up by using traditional magnetic grid or drawer type magnetic separator. Widely used in food, food additives, pharmaceuticals, fine chemicals, lithium battery positive and negative materials, pigments, carbon black, flame retardants and other industrial production lines.

TaiXiong Magnet is a professional magnet and magnetic separator manufacturer. We have three factories in China, we have been magnet manufacture over than 15 years. Our Major product is Rare earth magnet, Rubber magnet and Magnetic separator.

Contact Supplier 00:35

00:35

Product Type 3D Bedding Set Brand ICOSYHOME Model 3D0003 Material 100% Polyester Size Standard size or customized Technics Active Dye Print Parts Sewn-in Lable, Tag Feature Innate softness Executive standards GB/T22844-2009 SGS

Shanghai Civo International Trade Company,is committed to developing、manufacturing and exporting home textiles of high quality. Our main products are latex products and bedding sets etc. After many years of world famous brand OEM experience,we build our own brand of ICOSYHOME in 2018.The strategic ideology of “To be professionally, to lead with comfort.” make Civo one of the most competitive enterprises in home textile industry.

Contact Supplier 00:05

00:05

Industrial Falling Film Evaporator Projects information: Brine treatment, RO waste, ZLD system, fish meal production, chemicals crystallization, milk/stick water/ tomato paste/mango juice/orange juice/ Garlic water concentration etc. Processing capacity: 50kg/hr, 100kg/hr, 300kg/hr, 500kg/hr, 1t/hr, 3 T / hr , 5T / hr , 10 T / hr ,15 T / hr , 20 T/hr, 25T/hr Installed Projects: Vietnam / China / the Philippines /Indonesia / America/ Hungary ect. Introduction for the machine The combination of tube type, plate type and tube plate can be used. MVR mechanical compression and TVR steam compression technology can be added. Scope of application Falling film type single, double, triple, fourth, fifth, Sixth, seventh, eighth efficiency, effect evaporator, suitable for evaporation and concentration in milk, starch, glucose, xylose, pharmaceutical, chemical, biological engineering, environmental engineering, waste recycling and other industries, especially suitable for easy scaling easy evaporation strong or heat sensitive materials, including plate, pipe, tube plate combination, can join the MVR, the energy-saving technology of TVR device. Evaporator, separator, condenser, vacuum and discharging system, delivery pump, PLC, electrical appliance and instruments, valves, pipelines etc. Multi-effect evaporation concentration technology Evaporator selection notice 1. compared with electricity and vapor supply cost ahead of time. 2. MVR invest more than multi-effect evaporator at the early stage, but the cost shall be covered after 300days service. 3. The evaporators are custom-built according to feeding liquid and real situation, Please contact us to consult about the design, manufacture, installation, commissioning etc.

Nomia Machinery Co.,Ltd is professional in manufacturing MVR evaporator, multiple effect evaporator, falling/rising film evaporator, forced-circulation evaporator which are highly specialized of engineering services process design, manufacturing, installation and commissioning. Nomia go through the national high-tech enterprise certification, with the qualification for pressure vessel manufacturing, won ISO9001 quality management system and CE certification for Europe. Nomia machinery owns the first-class highly professional team, technical team, technically advanced manufacturing facilities and a meticulous quality control system, committed to be the respected leading enterprise in evaporation & concentration, continuous evaporation & crystallization, zero liquid discharge of industrial effluents etc. Most important of all, we focus on high efficiency and energy saving.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery