02:53

02:53

This type of panel is the 1990s world most prevailing roofing panel,selflock fasteners with buckle and edgefixed are all hidden.There is no screw outside of the roofing.Installing swift and convenient,having good section characteristic,its life is raised by more than 2 times than ordinary.There is no seepage definitely,suitable for all roofing,stock the over the past several years main regeneration product.Cooperated with roll forming machine of curve,it can produce roofing system with skeleton. 1.Manual decoiler: manual decoil, passitive expansion 2.Inner diameter of decoiler: 508mm, 610mm 3.Decoiler capacity: 5T 4.Machine stand: welded by steel structure, shot blast after welding, get rid of inside stress 5.Motor power of forming machine:7.5KW 6.Motor power of hydraulic station:3KW 7.Roll stand:24 stations 8.Forming speed:12m/min 9.Material of roller:high-grade 40Cr alloy steel 10.The surface of roller coating chrome:single surface 0.05mm 11.Type of forming machine: wallboard type chain transmission 12.Bearing guard: ¢50 13.Diameter of shaft: ¢75mm 14.Chain: 16A 15.type of cutting:hydraulic cutting 16.Material of cutting blade: Cr12, Quenching hardness HRC58°-62° 17.Thickness of steel coil: 0.4-0.8mm 18.Panel width of feeding: 1000mm 19.Tolerance of length:10m±2mm 20.Specific size of profile: conform to roll forming panel GB/T12755-2008 standard used for china construction 21.Form of guiding with feeding station:side trolley type 22.Transducer: Holip (Danfoss) 23.Computer adopts PLC,OMRON Series 24.Hydraulic systemic working pressure: 12Mpa 25.Computer control system: whole machine adopts industrial computer PLC control, operating board adopts Xinjie OP320A 26.Output table: roller type

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:09

00:09

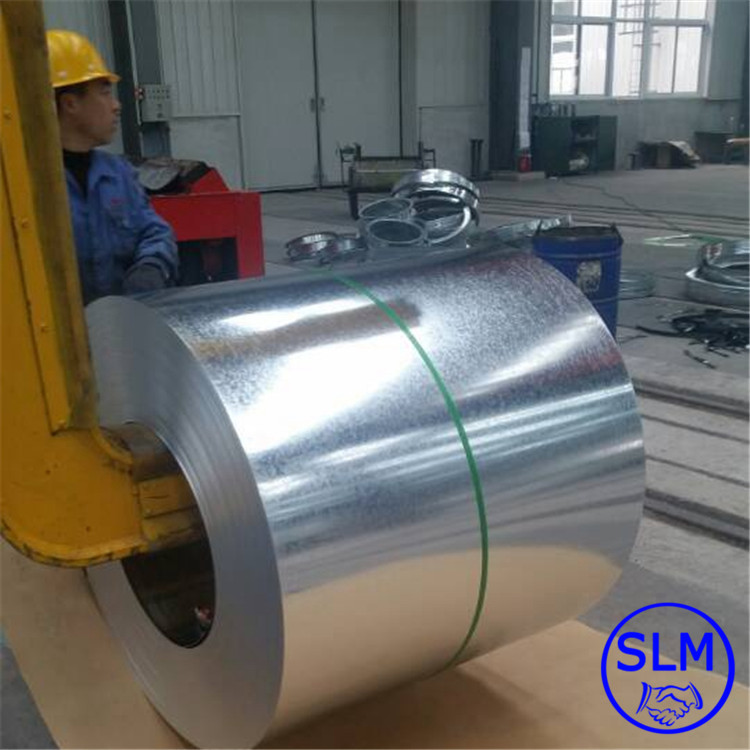

Thickness 0.14mm-3.0mm Width Prime.coil:1000mm,1219mm and 1250mm Slitting width: Minimum Width 4mm,7mm etc as your requirements. Length Cutting as your requirements,Minimum:200 mm length. Zinc Coating China Standard:30-600 G/cm 2 ASTM Standard:A40,A60,G60,G90,G1,G14,G16,G18,G21 JIS Standard: Z12,Z18,Z22,Z25,Z27,Z35,Z43,Z50,Z60 Spangle Small, regular or zero spangle Standard ASTM, AISI,JIS,DIN, GB etc. Material (most common) DX51D+Z,DX52D+Z,DX53D+Z,DX54D+Z,DX56D+Z DC51D+Z,DC51D+ZF,DC53D+Z,DC53D+Z,DC53D+ZF SGCC,JAC270D,MJAC270D Processing Pickling, cold rolling, annealing, degreasing, leveling, shear (transverse, longitudinal), Application Household Electric Appliances,Auto parts,Container plate etc. Coil Weight 3-8 tons normally Coil ID 508/610 mm Packing Simple package: Oil paper. Good package: Wooden box or steel box Payment T/T or L/C at sight Min order 1 ton

Shanghai Leading Metal Co., Ltd is Shanghai-based steel provider which has been focusing on the steel service for more than ten years. Our main business is construction-based steel commodities including coil, plate etc. We are especially experienced in Copper Steel ,Aluminum Steel and Steel Roofing Sheet . And our un-allocated inventory is 30,000 tons. There are 11 staff in the sales office, 67 workers in the warehouse, we are still developing and welcome more advice from you. A team (5 person with more average more than 5-year experienced) service for you.Save total cost is our advantage.

Contact Supplier 01:09

01:09

1.Manual decoiler: manual decoil, passitive expansion 2.Inner diameter of decoiler: 508mm, 610mm 3.Decoiler capacity: 5T 4.Machine stand: welded by steel structure, shot blast after welding, get rid of inside stress 5.Motor power of forming machine:7.5KW 6.Motor power of hydraulic station:3KW 7.Hydraulic oil pump:gear pump CB-E314 8.Roll stand:30 stations 9.Forming speed:10m/min 10.Material of roller:No. 45 forging steel 11.The surface of roller coating chrome:single surface 0.05mm 12.Type of forming machine: wallboard type chain transmission 13.Diameter of shaft: ¢75mm 14.Height of center: 130mm 15.Chain: 16A 16.Cutting ways: hydraulic forming cutting 17.Material of cutting blade: Cr12, Quenching hardness HRC60°-62° 18.Thickness of steel coil: 0.3-0.6mm 19.Panel width of feeding: 1220mm 20.Tolerance of length:10m±2mm 21.Specific size of profile: conform to roll forming panel GB/T12755-2008 standard used for china construction 22.Form of guiding with feeding station:side trolley type 23.Transducer: Hongquan (Taiwan Brand) 24.Computer adopts PLC,Mitsutishi FX-IS Series 25.Hydraulic systemic working pressure: 12Mpa 26.Computer control system: whole machine adopts industrial computer PLC control, operating board adopts Xinjie OP320A 27.Output table: roller type 28.Voltage: 380V50HZ3PH

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 01:21

01:21

a. Parameter of machine part: 1) Type:WHZW6000 2) Working length:6000mm 3) Press head:6 4) Weight:4800kg 5) Pressing power:130kn 6) Bending range:0-1250 7) Depth of throat:800mm(Max. working width of material in clamp) 8) Folder low worktable:back and forth 27mm, with quad of 12.7mm can be knock down 9) Width of up and low worktable:28mm 10) Hinge:parallel four connected pole 11) Act component of worktable:hydraulic double oil cylinder 12) Circle time:Max. bending limit take about 12 seconds 13) Motor power of hydraulic station:11kw 14) Total power:11.5kw 15) Outline dimension(length×width×height):7395×1842×1375mm b. Parameter of slitting system: 1) Type:rotary blade 2) Diameter:Ø100mm 3) Material:W18Cr4V 4) Drive system:hydraulic motor and chain for transmission 5) Guiding device:fix linear rolling rail on low worktable of folder 6) Slitting speed:about 0.8m/second 7) Slitting distance: about 50mm of upper blade stand c. Parameter of folding and slitting capability: 1) Max. bending thickness 1.2mm steel panel(yield intensity≤250Mpa) 2.0mm soft aluminum panel 0.8mm stainless steel 2) Max. bending length 6000mm 3) Max. slit thickness 1.2mm steel panel(yield intensity≤250Mpa) 2.0mm soft aluminum panel 0.8mm stainless steel 4) Min. folding dimension 10mm(panel thickness<1.2mm) 20mm(panel thickness≥1.2mm) d. Parameter of hydraulic power system: 1)Type:pressure compensate and load pressure induce system 2)Capability:11kw、150bar、40L/min 3)Capacity of oil tank:180L e. Parameter of computer controlling system 1) System:industry PC and rotary encoder for controlling bending angle 2) Numerical control locating system:servo system to control bending length automatically 3) Operating table:operating display fixed on the swing arm, which has automatic and manual function 4) Angle programme:0-1250 with 10 as accuracy,input on the screen 5) Control of upper worktable:inching control by handspike and pedal on the controlling box 6) Control of low worktable:use operating pole when manual control, use button when automatic control 7) Slitting control:button for controlling ahead,stop and back 8) Emergency stop:long pedal for control

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 00:40

00:40

Offset press Offset printing is a widely used Print Book technique. Offset Print Book is where the inked image is transferred (or "offset") from a plate to a rubber blanket. An offset transfer moves the image to the Print Book surface. When used in combination with the lithographic process, a process based on the repulsion of oil and water; the offset technique employs a flat (planographic) image carrier. So, the Print Book to be printed obtains ink from ink rollers, while the non-printing area attracts a film of water, keeping the non-printing areas ink-free. Currently, most Print Book and newspapers are printed using the technique of offset lithography. Here is the specification about the print book, Size 125 x 135mm Pages 8 pages Materials PEVA outside, inside foam Packing pp polybag with header card Price USD 0.6~0.9 per copies basing on the print book quantity

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:40

00:40

On Demand Printing for Baby (POD) is a printing technology and business process in which book copies (or other documents) do not print until the company receives an order, allowing prints of singular or small quantities. While other industries established the build to order business model, "On Demand Printing for Baby" could only develop after the beginning of digital printing, because On Demand Printing for Baby was not economical to print single copies using traditional printing technology such as letterpress and offset printing. Many traditional small presses have replaced their traditional printing equipment with On Demand Printing for Baby equipment or contract their printing to POD service providers. Many academic On Demand Printing for Baby publishers, including university presses, use POD services to maintain large backlists (lists of older publications); some use POD for all of their publications. Larger publishers may use On Demand Printing for Baby in special circumstances, such as reprinting older, out of print titles or for test marketing. Following is the specification about the On Demand Printing for Baby, Size 125 width x H 140mm pages 8 pages Materials PEVA outside, inside is foam Packing PP polybag with header card MOQ 3,000 copies per title

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:40

00:40

Canada Dora Coloring Book Printing or colour printing is the reproduction of an image or text in color (as opposed to simpler black and white or monochrome printing). Any natural scene or color photograph can be optically and physiologically dissected into three primary colors, red, green and blue, roughly equal amounts of which give rise to the perception of white, and different proportions of which give rise to the visual sensations of all other colors. The additive combination of any two primary colors in roughly equal proportion gives rise to the perception of a secondary color. For example, red and green yields yellow, red and blue yields magenta (a purple hue), and green and blue yield cyan (a turquoise hue). Only yellow is counter-intuitive. Yellow, cyan and magenta are merely the "basic" secondary colors: unequal mixtures of the primaries give rise to perception of many other colors all of which may be considered "tertiary." Following is the specification of the Canada Dora Coloring Book Printing, Size 140 x 140mm Materials PEVA outside, inside is foam Pages 8 pages Packing polybag with header card MOQ 3,000 copies Canada Dora Coloring Book Printing per title

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:40

00:40

A Print on Demand Picture Books combines visual and verbal narratives in a book format, most often aimed at young children. The images in Print on Demand Picture Books s use a range of media such as oil paints, acrylics, watercolor, and pencil, among others. Two of the earliest books with something like the format Print on Demand Picture Books s still retain now were Heinrich Hoffmann's Struwwelpeter from 1845 and Beatrix Potter's The Tale of Peter Rabbit from 1902. Some of the best-known Print on Demand Picture Books s are Robert McCloskey's Make Way for Ducklings, Dr. Seuss' The Cat In The Hat, and Maurice Sendak's Where the Wild Things Are. The Caldecott Medal (established 1938) and Kate Greenaway Medal (established 1955) are awarded annually for illustrations in children's literature. From the mid-1960s several children's literature awards include a category for Print on Demand Picture Books s. Here is the specification of the Print on Demand Picture Books, Size 140 x 140mm Pages 8 pages Materials PEVA outside, inside is foam Packing polybag with header card MOQ 3,000 copies Print on Demand Picture Books

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 00:40

00:40

Book Baby Print can be used to track a child's development or mark developmental milestones. Many have ledgers that can track disease and immunizations. Some books are pre-fabricated with fill-in-the blank areas and places to put special mementos, such as a lock of hair from the baby's first haircut, a hospital bracelet, birth announcements, or cards from the baby shower. Parents may include ultrasound pictures, pictures of the baby at birth, and pictures as the child grows up.Parents can look at Book Baby Print for memories. Book Baby Print have also been used for research. UCLA has a collection of Book Baby Print dating back to 1882 used for the study of the history of childhood, family, art, medicine, architecture, and other disciplines. Here is the specification of the Book Baby Print, Size 125 x 140mm Pages 8 pages Materials PEVA outside, inside is foam Packing polybag with header card Price USD 0.6~0.9 basing on Book Baby Print quantity

CYC children's book printing company focus on the bath book producing & baby fabric book producing. Up to now already 12 years. Present the whole products involve in baby book, cloth book, fabric book, soft fabric panel, bath book, waterproof book, peva book, pvc bath book, etc. Bearing the belief of " “Honesty, Quality, Professional, Express delivery”, we promise to offer you better quality products with better prices.

Contact Supplier 02:50

02:50

a. Material:δb≤380Mpa galvanized steel sheet and painted steel sheet b. Thickness of material:δ=0.5-3.0mm c. Width of material: 1500mm d. Slitting accuracy:width tolerance ± 0.15mm e. Width of side scrap: 3-15mm f. Quantity of side scrap: 2 strips g. Slitting burr: ≤0.05 thickness δ h. Weight of side scrap: ≤ 100kg / per coil i. Slitting speed with two shifts:δ≤0.5-1.5㎜ 120m/min δ≤3㎜ 70m/min j. Min. slitting width:≥50mm k. Slitting strips:δ 0.5-1.5㎜ 13 strips; δ 3㎜ 7 strips l. Weight capacity of decoiler:15T m. Inner diameter of steel coil: Φ508mm, Φ610mm, Φ762mm n. Outer diameter of steel coil:≤Φ1600mm o. Diameter of slitting blade shaft:Φ225mm, material is 42CrMo p. Size of slitting blade:Φ225×Φ350×20mm q. Material of slitting blade:Cr12MoV r. Hardness of slitting blade:HRC580-HRC600 s. Inner diameter of recoiler:Φ508 mm t. Floor area: 25m×8m

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 01:03

01:03

a. Thickness of material:0.5mm-3.0mm b. Width of material:1500mm c. Material for processing:cold rolled coil, hot rolled coil, painted coils, galvanized coils d. Outer diameter of steel coil:≤Ø1800mm e. Inner diameter of steel coil:Ø508mm, Ø610mm, Ø762mm f. Weight of steel coil:≤15T g. Tolerance of cutting length:±0.5mm (take panel of 1.5mm thickness and 2000mm length for measurement) h. Tolerance of diagonal:±1.0mm (take panel of 2m length for measurement) i. Cutting speed:21 pcs / min(take panel of 2m length for measurement) j. Leveling speed:0- 60m/min k. Quantity of working roller:19 rollers l. Diameter of working roller:¢60mm m. Material of working roller:90Cr2MoV n. Hardness of working roller:HRC58°-60° o. Quantity of middle roller:21 rollers p. Material of middle roller: 9CrSi q. Hardness of middle roller:HRC50°- 52° r. Quantity of supporting roller:138 rollers (6 rows) s. Weight capacity of stacking lifting table:5000kg t. Stacking length range:500-4000mm(side discharge) u. Max. stacking height:400mm v. Floor area:about 24000 × 7000mm (L × W)

Wuxi Weihua Machinery Co., Ltd. is a professional manufacturer which is engaged in researching and developing, manufacturing and providing service for energy saving enclosure equipment for construction. Established in 1990s, Weihua has more than 20 years’ history of development. Company covers an area of 38 thousand square meters, the construction area of workshop and office area is 28 thousand square meters. Our products cover three areas: cold forming sectional steel equipment such as color steel purlin deck floor in the construction system; sandwich panel production line; coil slitting machine, leveling machine and cut to length machine. Among them, the whole sandwich panel production line technology and pentane foaming technology have been taking the leading position in the industry. It is also the only one manufacturer which has the whole technology of sandwich panel production line. The company is committed to developing, researching and innovating new products. And its scientific and technological content and technical level have been in the leading position in the industry. Among these years, it has provided equipment for several famous projects in the world, such as the United Nations protecting atmospheric ozone layer and eliminating HCFC project, Moscow International Airport, Guangzhou Baiyun Airport, Shanghai Pudong Hongqiao Airport, Beijing Olympic Games, Shanghai World Expo and so on. Our company has passed ISO international quality management system certification and CE certification, and now we have obtained dozens of patents. It has been classified as Wuxi municipal science and technology research and development unit. All products are exported all over the world.The enterprise tenet of Weihua is to make a positive contribution to the construction of energy-saving projects continuously .

Contact Supplier 02:19

02:19

Filling head 8 heads Filling volume range 50ml -1L(

Changzhou Mic Machinery Co., LTD., founded in 1999, is located Changzhou Jintan area for chemical and agrochemical etc production packaging machines. 2013 year, it started to invest in cosmetics and pharmaceutical machines in Changzhou Wujin area which is junction of Wuxi and Changzhou city. It covers an area of more than 3000 square meters, with 20 technicians. Professional research and development in the manufacturing of intelligent filling machine, capping machine, labeling machine and pretreatment equipment for cosmetics such as vacuum emulsifier mixer, etc. The Company cites foreign mechanical transmission technology and the secondary development of filling technology research and development team, and always adheres to technological innovation. It has a group of independent intellectual property rights on products and technologies applied in various industries of filling and packaging production line. The Company takes "the customer's requirement is our standard" as its main goal, with 15 years of experience in professional design and excellent design team, providing customers with unique professional solutions such as filling and packaging production. At the same time, the company introduces the foreign advanced technology and constant innovation successfully for the chemical, pharmaceutical, cosmetic, and chemical industry. We equip first-class brand products on electrical configuration to ensure stability and durability, and we are very careful on material selection for mechanical parts and processing to ensure customer satisfaction. The Company has import and export rights, and products are exported to Europe, America, the Middle East, Southeast Asia, South America, and more than 50 countries, thus we have a very deep understanding of quality system, such as the European CE certification system and ISO 9001 certification system, etc. The Company has tens of millions of annual sales, and, at the same time, maintains a long-term and stable cooperation relationship with local dealers. Practice makes professional machine, In Food, cosmetic, pharmaceutical, chemical, and agriculture business, Our two workshop will be able to full fill your requirements. We hope Mic Machinery will become your most trusted partner!

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery