02:30

02:30

Sheet Metal Fabrication: Manufacture the products based on design & concept by processes as cutting, bending, forming, welding that made from steel, stainless steel, aluminum at 0.5-20mm thick (gauge). Our sheet metal workshop is equipped with 2 laser cutting machines, 2 CNC punches, 10 CNC bending machines, and 15 welding machines as well as tools for other general fabrications as taping, drilling, nut inserting etc. Cutting: A way of removing material from sheet, mostly by • Laser Cutting • CNC Punch • Plasma Cutting • Waterjet Cutting • Shear Bending & Forming: A way of changing the sheet to reach the desired shape, mostly by • CNC Bending • Rolling Welding: A way of jointing 2 or more parts including • Tig Welding • Mig Welding • Spot Welding Extra Functional or Visual Furnish: • Taping: Drill threads on the material • Nut Insertion: Press or fit PEM nuts on the material. • Powder coating, zinc plating, hot dipped galvanization, painting etc.

Starway Engineering & Manufacturing Co., LTD, founded in 2010 and located in west Shanghai, is focusing on providing one-stop solution for metal parts & products. We are committed to help clients realize the concepts and designs with support of our engineering and manufacturing advantages that includes projects made of processes as: Sheet metal fabrication CNC machinning Stamping & forming Aluminum extrusion Casting Assembly

Contact Supplier 01:31

01:31

CNC Machining: It is mainly used for small or medium-size lot order production that requires fine surface, precise tolerance. Metal materials like steel, stainless steel or aluminum are suitable for this process. Starway is able to provide CNC machining services based on customers’ drawings or designs. CNC Machining Center: We have the CNC machining centers that are able to realize different manufacturing processes at high quality, precise tolerance. CNC Turning Machine: CNC lathe with universal tools to reach different features. CNC Milling Machine: Our milling machine work table is 1500*400mm max. Drilling Machine: We are able to provide drill Countersunk holes, Metric or imperial size threads. CNC Grinding Machine: It is used to manufacture products at high quality surface. EDM Wire Cutting Machine: It is used to cut thick plate with high quality cutting edge.

Starway Engineering & Manufacturing Co., LTD, founded in 2010 and located in west Shanghai, is focusing on providing one-stop solution for metal parts & products. We are committed to help clients realize the concepts and designs with support of our engineering and manufacturing advantages that includes projects made of processes as: Sheet metal fabrication CNC machinning Stamping & forming Aluminum extrusion Casting Assembly

Contact Supplier 01:43

01:43

Stamping and forming is the manufacturing process with toolings for large quantity, how cost, high efficiency, consistant quality production that includes manufacturing proceses as Punching, Trimming, Forming, Extruding, Deep drawing ect. Starway is able to provide manufacturing services such as Tooling design, Tooling fabrication, Stamping fabrication. Stamping fabrication with Stage die or Progressive die is available. Our stamping machines ranges from 25 tons to 350 tons which is suitable for thick material stamping. Tooling Shop Stamping shop

Starway Engineering & Manufacturing Co., LTD, founded in 2010 and located in west Shanghai, is focusing on providing one-stop solution for metal parts & products. We are committed to help clients realize the concepts and designs with support of our engineering and manufacturing advantages that includes projects made of processes as: Sheet metal fabrication CNC machinning Stamping & forming Aluminum extrusion Casting Assembly

Contact Supplier 01:13

01:13

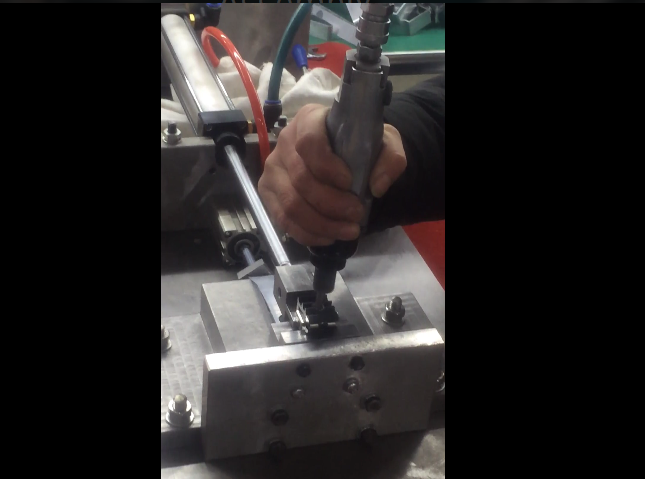

Starway provides Final assembly services with the components manufacture or outsourced by Starway. With the assembly services, we not only helps clients to save labor cost, shipping cost, but also and more important, it the assembly work verifies all the components manufacture or outsourced are correct. Starway takes charge of designing the assembly fixture, defining the assembly flow and quality control plan.

Starway Engineering & Manufacturing Co., LTD, founded in 2010 and located in west Shanghai, is focusing on providing one-stop solution for metal parts & products. We are committed to help clients realize the concepts and designs with support of our engineering and manufacturing advantages that includes projects made of processes as: Sheet metal fabrication CNC machinning Stamping & forming Aluminum extrusion Casting Assembly

Contact Supplier 01:00

01:00

Main Structure Features The compacting press is a mechanical crank connecting rod type of hydraulic pressure assisted powder forming machine; It is a high strength steel plate welding structure with stable mechanical structure toughness, good rigidity and high precision as well as stable production quality; The compacting press has the ability of mold and mandrel step forming; Using the touch screen control, improving the operation. With a various fault description and easy trouble shooting, the compacting is easy to maintain; It has the modular floating frame, which can be disassembled independently; Combined pneumatic clutch and brake make the compacting power press machine has fast response speed with high safety.

Founded in 1958 and located in Yangzhou City of Jiangsu province, our company is a professional manufacturer in making mechanical machines as well as a national&hi-tech enterprise, one of the leading enterprises in China NC sheet metal processing equipment production base.

Contact Supplier 01:58

01:58

Advantages: Low maintenance cost Easy operation(One person can operate two equipment) Extremely high yield (improved by 60% to 150%) Low break-down rate (servo structure) Product with high precision Characteristics : 1)The high-speed equipment of type 1 uses a multi-shaft balance structure, and therefore the number of rolling is improved by 40% -50% by comparing with that of middle speed. Due to the increase of the continuous feeding and rolling device, the yield is totally increased by at least 60% by comparing with that of the middle-speed shutdown servo equipment. 2)The high-speed equipment of type 2 uses a ‘galaxy’ balance structure, by which the rack can be driven without the connection rod, the inertia force generated in the rolling process can be neutralized further, and the number of rolling and yield can be improved significantly. By taking the type 2 equipment with the high speed of 15 for example, the speed, compared with that of the middle-speed shutdown servo equipment, is improved by 128%, and the yield is totally increased by 148% due to the configuration of the continuous feeding and rolling device. 3)The equipment of type 2 uses the feeding mode of single screw rod, so as to reduce the torque required in the work of the servo motor, and improve the response speed of the carriage. 4)All the high-speed and continuous feeding cold pilgering mills controlled by using 6-7 units of servo motor, and therefore the work of each moving part is more flexible. 5)The equipment is provided with a sliding cover, by which the roller can be replaced quickly, the time consumption is reduced, and the yield is improved. 6)The stroke of the saddles is increased, the long-journey rolling is carried out by annular ring type roller, the rotation angle of the roller is changeable, the groove working section is lengthened, the length of deformation zone is increased, and therefore the uniformity of metal deformation in the rolling process is increased, the feed amount can be increased, and the quality of the finished pipe can be improved. 7)The rotary feed system is controlled with German Rexroth AC servo, wherein the feed amount is accurate, reliable and stepless adjustable, the deviation of feed amount is not more than 2%, the size of the rotation angle can be adjusted, the billet will be rotated and fed for two times in the same rolling process, and therefore the distribution of rolling force is even, the axial force is reduced significantly, the high-precision pipe with small deviation of the outer diameter and wall thickness can be obtained, and the yield is high. 8)Compared with side feeding, the rolling mill, which uses end feeding mode, reduces mandrel-removing device; moreover, the position of the mandrel in the deformation zone is accurate, length of mill is shortened, the mode is suitable for the rolling of long billet, and the working efficiency of the rolling mill is improved. 9)Function of loading, unloading, feeding and other procedures are controlled with PLC program,, and therefore the degree of automation is high. 10)The rolling pressure of machine is reduced by using a curve type core bar, and therefore the deformation of the billet metal is even and reasonable. 11)The main gears are provided with hardened tooth grinding process, by which the transmission is smooth, and the noise is low. 12)The main shaft and important gear are made of high-strength alloy steel. 13)The inner surface of the billet used is lubricated to improve the inner surface quality of the pipe, while prolonging the service life of the core bar. 14)The rolling machine uses annular ring type roller, curve type mandrel, as well as the rolling mode of dual rotation and dual feed, and therefore the correction ability to the billet of which the wall thickness is uneven is relatively strong. 15)The equipment has a mandrel fracture detection device, by which the equipment will be automatically stopped in case of the fracture of mandrel, and therefore the equipment can be protected well. 16)A number of patented technologies are applied to the equipment, such as floating type brake, and hydraulic locking nut of the rack. (The feed of the before dead center shall be determined according to the specific rolling condition)

Shanghai Pan Zhihua Machinery Manufacturing Co.,LTD is located on the third largest island of China municipal industrial park----No.898,San Sha Hong Road. Among the company’s 160 staffs them,25 people have high-level technical title.The total area of the factory is 38000 square meters,with standard workshop 19800 square meters.

Contact Supplier 01:58

01:58

Advantages: Low maintenance cost Easy operation(One person can operate two devices) improved yield (improved by 20% to 30%) Low breakdown rate (servo structure) Product with high precision Characteristics : 1)The continuous feeding and rolling device is increased, and therefore the yield is increased by 20% at least. 2)The transmission of the main transmission system is carried out by either mean:1) Using a high-strength nylon-based flat transmission belt, in which the stress is even. 2) Main motor directly connects to driving shaft. The operation is reliable and smooth, and the rolling mill system has the function of overload protection. 3)The stroke of the saddles is increased, the long-journey rolling is carried out by annular ring type roller, the rotation angle of the roller is changeable, the groove working section is lengthened, the length of deformation zone is increased, and therefore the uniformity of metal deformation in the rolling process is increased, the feed amount can be increased, and the quality of the finished pipe can be improved. 4)The rotary feed system is controlled with German Rexroth AC servo, wherein the feed amount is accurate, reliable and stepless adjustable, the deviation of feed amount is not more than 2%, the size of the rotation angle can be adjusted, the billet will be rotated and fed for two times in the same rolling process, and therefore the distribution of rolling force is even, the axial force is reduced significantly, the high-precision pipe with small deviation of the outer diameter and wall thickness can be obtained, and the yield is high. 5)Compared with side feeding, the rolling mill, which uses end feeding mode, reduces mandrel-removing device; moreover, the position of the mandrel in the deformation zone is accurate, length of mill is shortened, the mode is suitable for the rolling of long billet, and the working efficiency of the rolling mill is improved. 6)Function of loading, unloading, feeding and other procedures are controlled with PLC program,, and therefore the degree of automation is high. 7)The rolling pressure of machine is reduced by using a curve type core bar, and therefore the deformation of the billet metal is even and reasonable. 8)The main gears are provided with hardened tooth grinding process, by which the transmission is smooth, and the noise is low. 9)The main shaft and important gear are made of high-strength alloy steel. 10)The inner surface of the billet used is lubricated to improve the inner surface quality of the pipe, while prolonging the service life of the core bar. 11)The rolling machine uses annular ring type roller, curve type mandrel, as well as the rolling mode of dual rotation and dual feed, and therefore the correction ability to the billet of which the wall thickness is uneven is relatively strong. 12)The equipment has a mandrel fracture detection device, by which the equipment will be automatically stopped in case of the fracture of mandrel, and therefore the equipment can be protected well. 13)A number of patented technologies are applied to the equipment, such as floating type brake, and hydraulic locking nut of the rack. (The feed of the before dead center shall be determined according to the specific rolling condition)

Shanghai Pan Zhihua Machinery Manufacturing Co.,LTD is located on the third largest island of China municipal industrial park----No.898,San Sha Hong Road. Among the company’s 160 staffs them,25 people have high-level technical title.The total area of the factory is 38000 square meters,with standard workshop 19800 square meters.

Contact Supplier 01:58

01:58

Advantages: Low maintenance cost Easy operation Low break-down rate (servo structure) Product with high precision Characteristics: 1)The transmission of the main transmission system is carried out by either mean:1) Using a high-strength nylon-based flat transmission belt, in which the stress is even.2) Main motor directly connects to driving shaft. The operation is reliable and smooth, and the rolling mill system has the function of overload protection. 2)The stroke of the saddles is increased, the long-journey rolling is carried out by annular ring type roller, the rotation angle of the roller is changeable, the groove working section is lengthened, the length of deformation zone is increased, and therefore the uniformity of metal deformation in the rolling process is increased, the feed amount can be increased, and the quality of the finished pipe can be improved. 3)The rotary feed system is controlled with German Rexroth AC servo, wherein the feed amount is accurate, reliable and stepless adjustable, the deviation of feed amount is not more than 2%, the size of the rotation angle can be adjusted, the billet will be rotated and fed for two times in the same rolling process, and therefore the distribution of rolling force is even, the axial force is reduced significantly, the high-precision pipe with small deviation of the outer diameter and wall thickness can be obtained, and the yield is high. 4)Compared with side feeding, the rolling mill, which uses end feeding mode, reduces mandrel-removing device; moreover, the position of the mandrel in the deformation zone is accurate, length of mill is shortened, the mode is suitable for the rolling of long billet, and the working efficiency of the rolling mill is improved. 5)Function of loading, unloading, feeding and other procedures are controlled with PLC program,, and therefore the degree of automation is high. 6)The rolling pressure of machine is reduced by using a curve type core bar, and therefore the deformation of the billet metal is even and reasonable. 7)The main gears are provided with hardened tooth grinding process, by which the transmission is smooth, and the noise is low. 8)The main shaft and important gear are made of high-strength alloy steel. 9)The inner surface of the billet used is lubricated to improve the inner surface quality of the pipe, while prolonging the service life of the core bar. 10)The rolling machine uses annular ring type roller, curve type mandrel, as well as the rolling mode of dual rotation and dual feed, and therefore the correction ability to the billet of which the wall thickness is uneven is relatively strong. 11)The equipment has a mandrel fracture detection device, by which the equipment will be automatically stopped in case of the fracture of mandrel, and therefore the equipment can be protected well. 12)A number of patented technologies are applied to the equipment, such as floating type brake, and hydraulic locking nut of the rack. (The feed of the before dead center shall be determined according to the specific rolling condition)

Shanghai Pan Zhihua Machinery Manufacturing Co.,LTD is located on the third largest island of China municipal industrial park----No.898,San Sha Hong Road. Among the company’s 160 staffs them,25 people have high-level technical title.The total area of the factory is 38000 square meters,with standard workshop 19800 square meters.

Contact Supplier 02:10

02:10

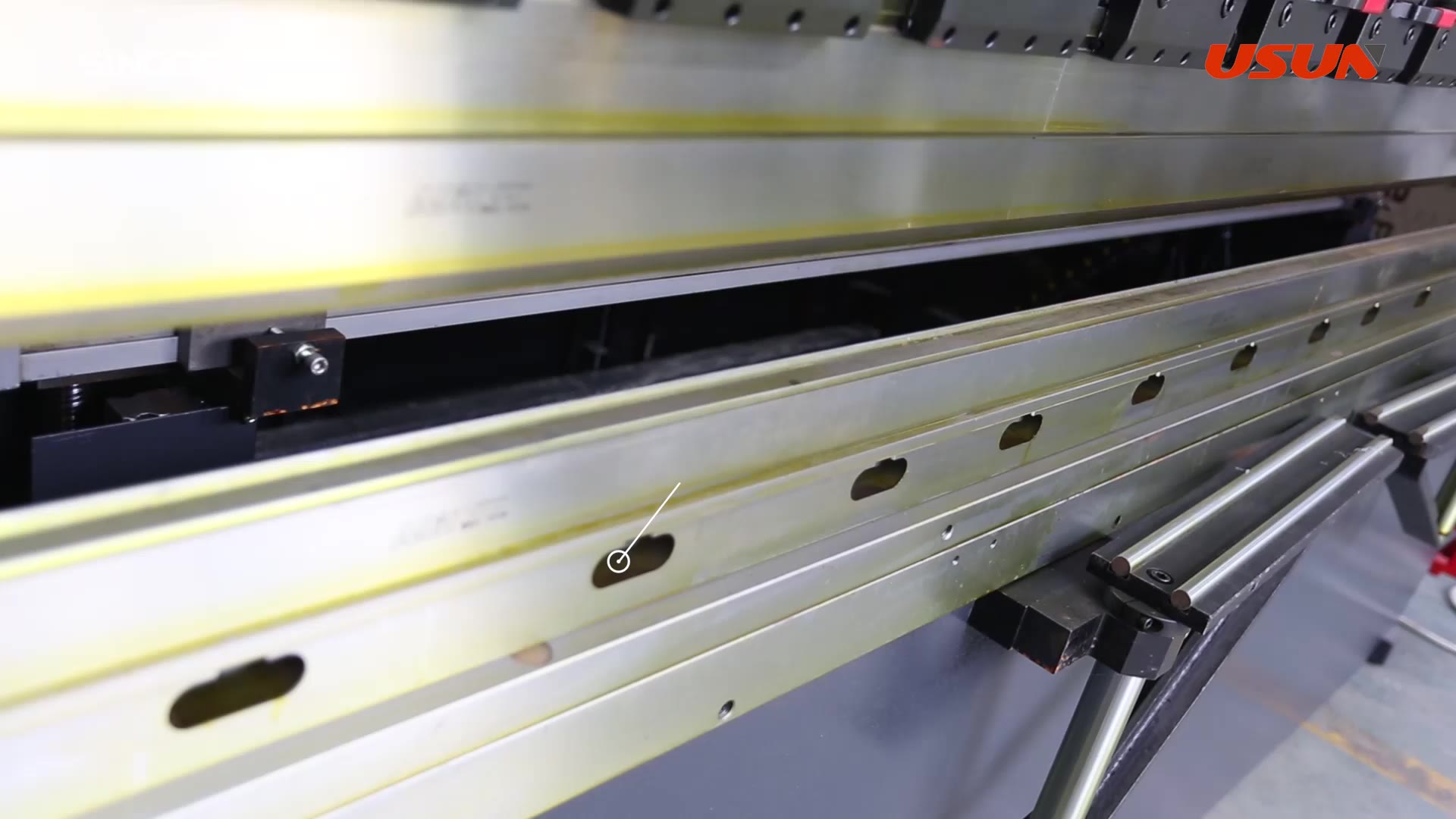

Standard Configuration : CNC sheetmetal pressbrake with streamlined desigh,hight speed ,hight precision,hight rigidity. Electro hydraulic servo system,full loop comtrolling the synchronizatio of the upperbeam. Equip with hydraulic crowning compensation on worktable and deformation compensation device on throat to make sure bending depth and precision. Backgauge is driven bu digital servo motor,moved by ball screw guided by linear guide. What should we know for choosing a press brake ? What’s your material of sheet ? What’s the minimum and maximum thickness of your sheet ? What’s the minimum and maximum width of your sheet ? What kind of product you make ? What’s the precision do you require for making products ? Machine Details: V-axis Table Compensation : V-axis is the CNC axis to control the adding convex amount of workbench, it can obtain accurate deflection compensation from the workbench. The adding convex workbench is made up of a group of beveled convex wedge, each wedge slope is designed by the deflection curve of finite element analysis of the slider and workbench vertical plate. CNC controller will calculate the required deflection amount according to the load when the work piece is working (The load will lead to the deflection and deformation), automatically control the relative motion of the convex wedge, and finally get an ideal work piece.

ADH Machine Tool is a professional manufacturer of bending machine, shearing machine, Our company is in the production of large bending machine, shearing machine ranked in the top five companies in the Domestic.the factory located in China. The registered capital is 33.8 million yuan. Annual production capacity of equipment is more than 5000 sets, assets more than 300 million. Our company is in strict accordance with the ISO9001:2008 international quality system to manage.product passed CE certification,Germany TUV certification and CQC China quality certification. We have 3 independent invention patents, 28 new patents. Donghai Machine Tool Co.,Ltd not only can meet special requirement of our customer, but also make personalized sheet metal processing equipment. So far,our products has sold to Europe (Russia,Poland, Germany,Ukraine) South America(Colombia, Argentina, Chile, Brazil, Peru)Middle East and Southeast Asia(India, Saudi Arabia, Egypt, Iran, Israel, Malaysia and Vietnam and so on).

Contact Supplier 00:14

00:14

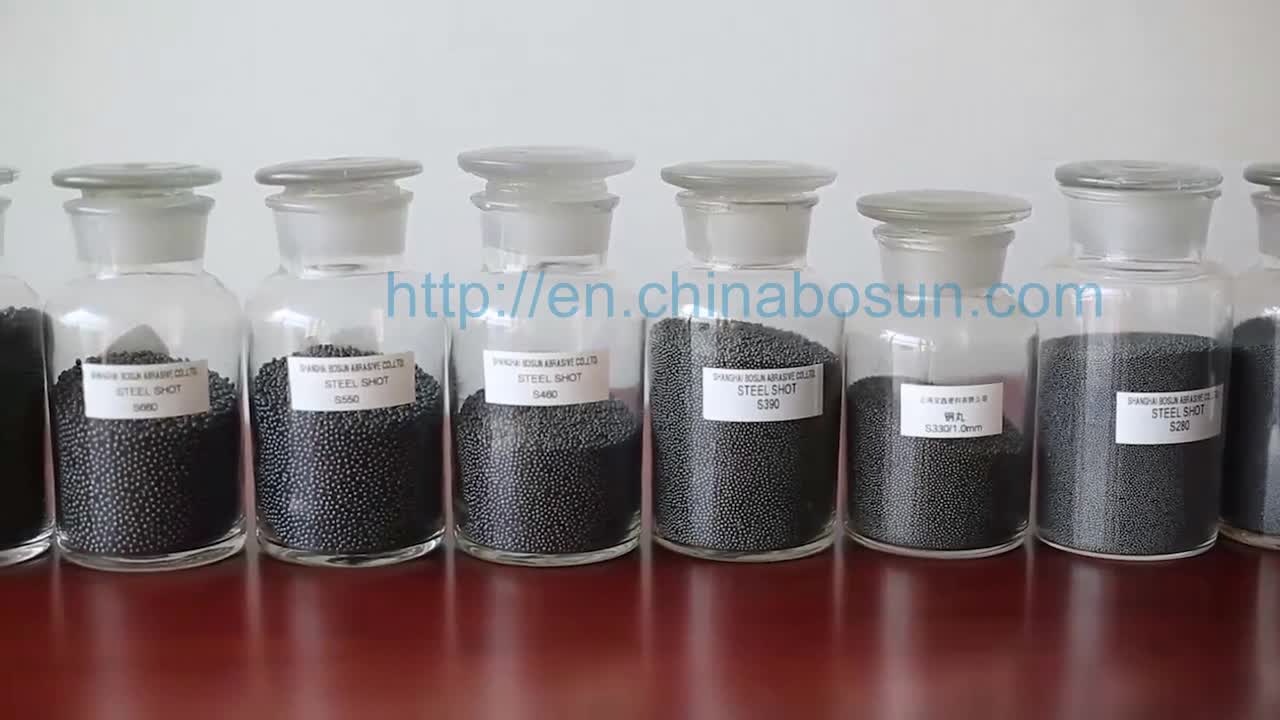

Grain Distribution of Steel Shot Packaging & Delivery Packaging Details: 25kg /bag 40 bags/ Big Ton bag 18-23 metric tons/ container Delivery Detail: 7 days after receive the deposite

Shanghai Bosun Abrasive Co., Ltd. is a professional abrasive company, which can research, produce and sell all kinds of abrasive. The main products include all kinds of steel shot, steel grit, steel cut wire shot, stainless steel balls, aluminum balls, zinc balls, copper balls as well as the copper sand, brown corundum, black corundum and so on. The company has advanced equipment and technology, strong technology strength and perfect quality inspection methods. The products are strictly produced and tested according to relative standard, so it is trusted by our customers and be chosen as designated product by many companies which producing sand-blast equipment.

Contact Supplier 00:09

00:09

Size: S70 Diameter: 0.2mm Hardness: 40-50HRC(377-509HV) Density: 7.2g/cm3 Grain Distribution of Steel Shot S70

Shanghai Bosun Abrasive Co., Ltd. is a professional abrasive company, which can research, produce and sell all kinds of abrasive. The main products include all kinds of steel shot, steel grit, steel cut wire shot, stainless steel balls, aluminum balls, zinc balls, copper balls as well as the copper sand, brown corundum, black corundum and so on. The company has advanced equipment and technology, strong technology strength and perfect quality inspection methods. The products are strictly produced and tested according to relative standard, so it is trusted by our customers and be chosen as designated product by many companies which producing sand-blast equipment.

Contact Supplier 00:14

00:14

Size: S110 Diameter: 0.3mm Hardness: 40-50HRC(377-509HV) Density: 7.2g/cm3 Grain Distribution of Steel Shot S110

Shanghai Bosun Abrasive Co., Ltd. is a professional abrasive company, which can research, produce and sell all kinds of abrasive. The main products include all kinds of steel shot, steel grit, steel cut wire shot, stainless steel balls, aluminum balls, zinc balls, copper balls as well as the copper sand, brown corundum, black corundum and so on. The company has advanced equipment and technology, strong technology strength and perfect quality inspection methods. The products are strictly produced and tested according to relative standard, so it is trusted by our customers and be chosen as designated product by many companies which producing sand-blast equipment.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery