02:35

02:35

Product Name: 8"Back Support(With Stays) Ingredients: Nylon/Polyester/Cotton/Rubber/PP Package: PE bags in bulk for Stabilizer Compression Support Sleeve Package QTY: 1pc Product Features: Functional back support, the eight elastic support of the central waist can strengthen the back support, provide dynamic protection for the movement of the trunk in the process of movement Design Features: 9" width back,The elastic support of the waist and the side of the abdomen, the full strengthening of the waist support,provide dynamic protection for the movement of the trunk in the process of movement.Double band to strong pressure to maintain proper abdominal vertebra good posture,relieve fatigue caused by frequent movement or long term fixation. Materials: Breathable medical ungird, eight supporting bars, and can be used for other accessories such as collocation. Users: Low back pain, back muscle contusion, lumbar disc herniation, vertebral displacement, nerve root sex, bone disease, osteoporosis Size: S:58.4-71.1; M:71.1-83.8; L:83.8-96.5; XL:96.5-109

Shanghai Guardian Industrial Co.,Ltd Located in Suzhou Industrial Park Suzhou,Medsport Products Co., Ltd. (formername: Shanghai Guardian Medical Instrument Co.,Ltd.) is a high-tech joint venture which specializes in producing wound dressing and it'smainly engaged in technology research and development of bioengineering and innovation and production of health-care device.

Contact Supplier 02:05

02:05

Imitation marble decorative sheet extrusion line adopts a special curing technology, to provide a mirror effect on the product surface, with a strong artistic appeal, can create a magical change, bright colors, the magnificent visual effects. Product saturation film surface, similar to ceramic stone transparent glass layer, it can achieve such as stone-like three-dimensional affect, with high hardness, impact resistance, acid-resistance, weathering-resistance, low coefficient of expansion, non-absorbent, good flatness and other advantages, and the exclusion of natural stone harmful substances and radiation elements, is an ideal new generation of green building materials. Specification: Extruder type 1220*2440MM Product thickness 1-4.5MM Max. extrusion capacity 350-450kg/h Main motor power 55KW

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 02:10

02:10

PVC faux marble strip are widely used in the walls of the waist, door line, foot line, such as TV backdrop income sideline, hotels, commercial buildings, villas, public places, ideal family home decoration materials. Features: 1. Environmental-friendly, beautiful use. 2. Recycled materials can be used, low price. 3. Like a real marble, no radioactive element. 4. Wear resistance, scratch resistance. 5. Shiny appearance, anti-skidding, water-proof, fire-proof, etc. Extruder type 240/400 Max. extrusion capacity 150-250kg/h Main motor power 37/5.5KW

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 00:00

00:00

This profile production line is according to different profile section and mould to choose different conical or parallel twin-screw extruder and provide relative vacccum sizing tank, haul-off, cutter, stacker and auxiliary equipment. Capacity of main frame can be optionally chosen from 60-700 kgs/hour. The haul-off unit has applied unique lift technique of our co. Its work is stable, its reliability is good, its pulling force is large. Vacuum setting has applied special enlarged vortex cooling system which is good for cooling and calibrating so as to meet demand of high speed extruding. Movement speed and drawing speed of cutting machine keep synchronous. All movements are controlled by imported PLC, the design is reasonable, the operation is stable, it can conduct automatic cutting with fixed length. Powder & dust suction device can be provided. With different molds, the tilter platform can choose such specifications as 4-meter, 6-meter, 8-meter, 11-meter, etc. With twin parallel screws extruder, it is particularly suitable for high speed extruding of profiled material. Model SJZ45/90 SJZ50/105 SJZ55/110 SJZ65/132 SJZ80/156 Motor power 15 18.5 22 30-37 55 Screw diameter 45/90 50/105 55/110 65/132 80/156 Screw rotation speed 34.7 34.7 34.7 34.7 34.7 Output capacity(PVC) 60-80 80-100 120 150-250 250-400 Model YF108 YF180 YF240 YF300 YF400 Max. profile width 108 180 240 300 400 Haul off width 100 100 150 150 150 Haul off force 2 2 2 2 3 Haul off speed 0-6 0-5 0-5 0-5 0-5 Total power (without extruder) 9.9 18.7 27.5 31 35

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 00:00

00:00

This extrusion line consists of conical twin screw extruder, vacuum calibrator table, haul off, cutter and stacker. Model YF108 YF180 YF240 YF300 YF400 Max. profile width 108 180 240 300 400 Haul off width 100 100 150 150 150 Haul off force 2 2 2 2 3 Haul off speed 0-6 0-5 0-5 0-5 0-5 Total power (without extruder) 9.9 18.7 27.5 31 35

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 00:00

00:00

As a new material to replace wood, Wood Plastic Composite is widely used in fields of building decoration and outdoor building materials, such as edge and corner lines, fence of flowers nursery, skirting board, ceiling line, blind window, stair railing, decorative wall board, outdoor pavilion and so on. WPC Profile Extrusion Line can produce all kinds of profile, for example, window, door and door frame, pallet, cladding of outdoor wall, faciliry of ourside park, floor etc. This extrusion line consists of conical twin screw extruder, vacuum calibrator table, cutter and stacker. Main Features 1. Low power consumption. 2. Low trouble as advanced design. 3. Low maintenance cost. Model YF108 YF180 YF240 YF300 YF400 Max. profile width 108 180 240 300 400 Haul off width 150 150 150 150 150 Haul off force 2 2 2 2 3 Haul off speed 6 5 5 5 5 Total power(without extruder) 10 19 28 31 35

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 00:00

00:00

Structure of the WPC foamed board extrusion line: Outer surface layer is rigid PVC and inner layer foamed PVC, it feature in low machine and formula cost compared with PVC skinned foamed plate, meanwhile, the product and parameters( 1.22m width with 5-20mm thickness product dimension, ~0.5g/cm3 density, 50-75 Rockwell hardness) are all equal or better. Also, the surface of the product can be printed or laminated to get different patterns. The machine consists main extruder & co-extruder, distributor, calibrator moulding block, cooling rack, haul off, cutter & stacker. Type ZJFB-1220 Product width 1220mm Product thickness 5-25mm Capacity 200-500kg/h Extruder type SJZ80/156&SJZ65/132 Mould spec. 1400mm Total power ~220kw

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 01:04

01:04

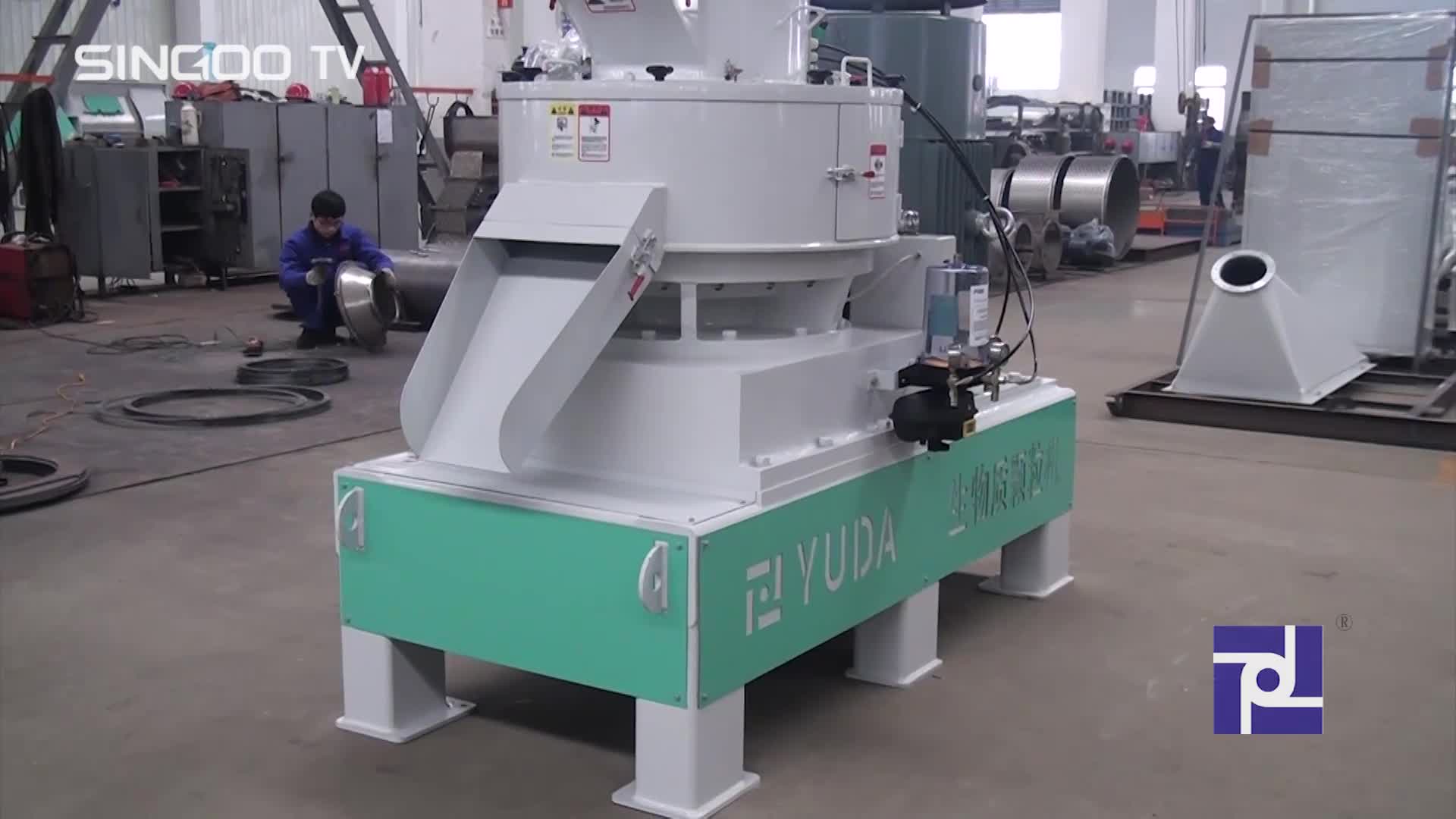

Quick details: After-sale service provided: engineers available to service machinery overseas. Min. order quantity: 1 piece Port : Shanghai port, China Payment terms:L/C, D/A, D/P, T/T and so on. Condition: new Place of origin: Jiangsu, China(Mainland) Certification: CE, SGS, ISO9001 Packaging details: steel rack, or iron pallet, also can be customized Delivery details: 30-60 days after getting the deposit What is biomass pellet mill? Biomass pellets fuel is a new environmentally friendly renewable resource.Biomass pellet mill, also called biomass granulator, is a kind of pellet mill producing biomass pellets. Biomass pellets making machine is a high efficient machine to make waste materials into solid fuel. YUDA Machinery is specialized in manufacturing series biomass machinery, biomass pellet machine, biomass ring die pellet mill, biomass pellet granulator, biomass fuels pellet machine, wood pellet mill, etc. Description of biomass pellet mill: 1. Big gear, gear shaft with high precision gear grinding machine, run more smoothly; 2. All bearings in the box body are SKF bearing; 3. Pellet mill base is made of 12mm steel plate welding production slots; 4. With outside circulation cooling oil lubricating system, integrating cooling, filtering, alarm; 5. With overload protection device, easy to overload protection host equipment main parts; 6. Equipped with movable high precision pneumatic pumps; 7. With ring mould lifting device, convenient user disassembling ring die and the roller. 8. Compact structure, good appearance, high output, less power consumption, convenient use, low maintenance cost, reliable operation,etc. Details of three roller biomass pellet mill: Three rollers Doulbe layers ring die, make pellets more effectively. Finished pellets:

YuDa Machinery CO., LTD is located in the beautiful national AAAA level tourist area—Tianmu Lake along zhongguancun science and technology industrial park, Jiangsu. She is a professional high—tech enterprise engaged in grain and oil machinery, forage, fertilizer and feed machinery manufacturing. The company covers 34500 square meters, construction area of 27895 square meters, she gathers industry technical elite from Nanjing agricultural university, Jiangsu university and other scientific research institutions for technical cooperation. The company has passed national ISO9001: 2008 quality management system certification, European CE certification and SGS certification.

Contact Supplier 01:08

01:08

Quick details: After-sale service provided: engineers available to service machinery overseas. Min. order quantity: 1 piece Port : Shanghai port, China Payment terms:L/C, D/A, D/P, T/T and so on. Condition: new Place of origin: Jiangsu, China(Mainland) Certification: CE, SGS, ISO9001 Packaging details: steel rack, or iron pallet, also can be customized Delivery details: 30-60 days after getting the deposit Model Power Ring die Produce Capacity Forming rate [dB(A)]Noise MZLH(W)420 75-90kw Φ8-10mm(1:5.0-6.0) Biomass pellet 0.8-1.2 t/h ≥96% ≤80 MZLH(W)508 110-160kw Φ8-10mm(1:5.0-6.0) Biomass pellet 1.5-2.5 t/h ≥96% ≤80 MZLH(W)678 180-220kw Φ8-10mm(1:5.0-6.0) Biomass pellet 2-3.5 t/h ≥96% ≤80 Characters of biomass pellet mill: Application: biomass pellet mill Type: double conditioners ring die pellet mill Pellet forming rate: ≥96% Material: stainless steel Structure:equipped with ring die and at least one conditioner Description of biomass pellet mill: 1. The box body of our biomass pellet mill adopted the HT250 materials for molding casting. 2. Big gear wheel, gear shaft all processed by high-precision gear grinding machine, ensures the more stability of operation. 3. All adopting the SKF series bearing. 4. The pedestal of biomass pellet mill is made of 12mm steel plate slot by welding. 5. With the outside loop of cooling and oil lubricating system, combining the cooling, filtering and alarming. 6. With the overload protection device, convenient for protecting the main spare parts of main engine while overloading. 7. Equipped with portable and high-precision pneumatic gasoline pump. 8. Equipped with ring die lifting device, easy to disassemble the ring die and roller. Details of biomass machinery Finished biomass pellets Packing Certifications Shipping

YuDa Machinery CO., LTD is located in the beautiful national AAAA level tourist area—Tianmu Lake along zhongguancun science and technology industrial park, Jiangsu. She is a professional high—tech enterprise engaged in grain and oil machinery, forage, fertilizer and feed machinery manufacturing. The company covers 34500 square meters, construction area of 27895 square meters, she gathers industry technical elite from Nanjing agricultural university, Jiangsu university and other scientific research institutions for technical cooperation. The company has passed national ISO9001: 2008 quality management system certification, European CE certification and SGS certification.

Contact Supplier 01:43

01:43

The extrusion line can produce pressure water pipes ,drainage pipes ,industrial pipes and cables threading pipe. The screw structure for the corresponding designed to meet the processing of high filling material(Caco3) pipe requirements,according to the use of pipe,change molds and the corresponding auxiliary equipment,can be processed produce UPVC pipe ,C-PVC pipe ,foam core layer pipe,foam inside the Spiral hollow wall spiral pipe. Extruder SJZ-51/105 SJZ-55/110 SJZ-65/132 SJZ-80/156 SJZ-92/188 Pipe diameter GF-63 16-63 16-63 50-160 50-250 110-250 200-400 200-400 315-630 500-800 Mould(pipe/s) single double double single single single single single single single Downstream equipment GF-63 GF-63*2 GF-63*2 GF-160 GF-250 GF-250 GF-400 GF-400 GF-630 GF-800 Total power 60 70 91 85 86.5 114 131 212 220 240

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier 01:53

01:53

What is pellet mill? Pellet mill , also called granulator, is a kind of feed processing equipment, it is the key part of feed processing machine during pelletizing process, suppression is mainly used for grain feed processing. Pellet mill machine pelletizing fast and has good effect. Feed pellet machine designed special hole of screener and it can screen carefully. This pellet mill equipment is widely adopted in medicine, chemical, food and feed industries etc. PRODUCTS MODEL POWER CAPACITY REMARK SZLH508 PELLET MILL SZLH508 110KW 6-15T/H With CPM3020 models SZLH508 132KW 6-17T/H With CPM3020 models SZLH508 160KW 6-20T/H With CPM3020 models SZLH508B1 110KW 6-11T/H With CPM3020 models SZLH508B2 110KW 6-11T/H With CPM3020 models SZLH508B3 110KW 6-11T/H With CPM3020 models SZLH508B1 132KW 6-17T/H With CPM3020 models SZLH508B2 132KW 6-17T/H With CPM3020 models SZLH508B3 132KW 6-17T/H With CPM3020 models SZLH508B1 160KW 6-20T/H With CPM3020 models SZLH508B2 160KW 6-20T/H With CPM3020 models SZLH508B3 160KW 6-20T/H With CPM3020 models SZLH558 132KW 6-18T/H With CPM3022 models SZLH558 160KW 8-20T/H With CPM3022 models SZLH558 185KW 8-22T/H With CPM3022 models SZLH630 185KW 10-25T/H With CPM3025 models SZLH630 200KW 10-28T/H With CPM3025 models SZLH630 220KW 10-32T/H With CPM3025models SZLH678 220KW 11-32T/H With CPM7726 models SZLH678 250KW 11-36T/H With CPM7726 models SZLH678 280KW 11-40T/H With CPM7726 models SZLH768 250KW 12-38T/H With CPM7730 models SZLH768 280KW 12-42T/H With CPM7730 models SZLH768 315KW 12-46T/H With CPM7730 models How pellet mill works? Main structures of ring die pellet mill: Animal feed pellet mill machine consists of feeder, conditioner, pelletizer, transmission and lubrication system etc. During pellet mill process, moisture of compound material is not more than 15%. Finally through the chute to iron removing device which removes the impurities in the powder material, then into the press pelletizing chamber to make pellet. Characters of pellet mill: Application: animal feed pellet mill Type: ring die pellet mill Pellet forming rate: ≥95% Material: stainless steel pellet machine Structure: equipped with ring die and at least one conditioner Description of pellet mill: 1、YUDA pellet mill has the latest technology adopted to product many kinds of feed. 2、The bearings, oil seal, O-Rings of the drive part of the pellet machine are all import. 3、The design, quality and façade of the feed pellet mill is in the international advanced level. 4、The main drive part of the feed granulator uses high-precision gear revolve, with this the production improved 15-20%. 5、The gear revolve of the feed pellet machine uses high-precision gear grinding, reduced the vibration and noise. 6、The outside painting of pellet mill equipment is sprayed, light and fastness. 7、The pellet mill improves the efficiency and reduces the labor intensity. 8、The material of conditioning system is stainless steel,sanitary, the service time of it extend. 9、There are several air inlets to add steam, it made the material heated enough, the effect of it is better. 10、The engine oil circulating cooling lubrication system improves the cooling and lubrication effect of the key bearings. Details of SZLH pellet mill: Packing Shipping Certifications

YuDa Machinery CO., LTD is located in the beautiful national AAAA level tourist area—Tianmu Lake along zhongguancun science and technology industrial park, Jiangsu. She is a professional high—tech enterprise engaged in grain and oil machinery, forage, fertilizer and feed machinery manufacturing. The company covers 34500 square meters, construction area of 27895 square meters, she gathers industry technical elite from Nanjing agricultural university, Jiangsu university and other scientific research institutions for technical cooperation. The company has passed national ISO9001: 2008 quality management system certification, European CE certification and SGS certification.

Contact Supplier 00:00

00:00

YF series PVC profile production line is mainly for producing PVC window profile, according to different profile section and mould to choose different conical or parallel twin-screw extruder and provide relative vacccum sizing tank, haul-off, cutter, stacker and auxiliary equipment. Model SJZ45/90 SJZ50/105 SJZ55/110 SJZ65/132 SJZ80/156 Motor power 15 18.5 22 30-37 55 Screw diameter 45/90 50/105 55/110 65/132 80/156 Screw rotation speed 34.7 34.7 34.7 34.7 34.7 Output capacity(PVC) 60-80 80-100 120 150-250 250-400 YF108 YF180 YF240 YF300 YF400 Max. profile width 108 180 240 300 400 Haul off width 100 100 150 150 150 Haul off force 2 2 2 2 3 Haul off speed 0-6 0-5 0-5 0-5 0-5 Total power (without extruder) 9.9 18.7 27.5 31 35

Neotek manufactures variety of equipment for plastic industry ranging from raw materials handling, extrusion, to waste material recycling and pelletizing. Neotek’s extrusion equipment has been exported to Asia, Africa, South America, Europe and many other parts of the world.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery