00:54

00:54

High strength and firm structure The main body of the cone crusher a box shaped cast steel structure, whose high load areas are reinforced by hard steel. Finite element design WL series high efficiency cone crusher is designed with the help of modern CAD technology. All series models have gone through the FEM technology analysis, which ensures all stress levels inside within appropriate range and guarantees the high strength structure and stable performance of WL series high efficiency cone crusher. High reliability and practicability originates from excellent design High efficiency compound cone crusher adopts tapered roller bearing to replace the old style horizontal shaft copper sleeve at both ends of the horizontal drive shaft and thus largely improves its rotation speed. Dust proof ring is assembled between the mantle cone and the seat liner. The maze O-ring is full of lubrication oil. The dust proof ring is supported by the spring in the seat liner so as to prevent dust from entering. The machine adopts electric automatic lubrication system that connects the main motor. If the pressure is insufficient or the temperature is too high, the main motor stops immediately to prevent the main engine from damage. The machine is installed with hydraulic pressure adjustment device so as to quickly adjust the discharge mouth size and clear the crushing chamber and therefore reduce the time of machine hault. High capacity,low cost and easy Our machine's fine crushing chamber shape increases the effective crushing surface. The machine has the capacity to process larger feed size, increases 1/3 production capacity comparing with other cone crushers and can produce fine particles and cubic products. The mantle core and the crushing chambre are processed by digital control CNC machine, which makes the replacement of wearing plates quick and easy, eliminates the need to fill epoxide resin and improves the operational efficiency. Traditional cone crusher with the ancient crushing chamber structure, has limited crushing surfaces, low production and produces more elongated and flaky particles content. Epoxide resin needs to be filled between the mantle cone the crushing surface, which makes the replacement difficult, increases the failure rate and machine halt time and causes unstable performance of the machine. Less downtime Using the Hydraulic Pressure Chamber Clearing mean the WL Series cone crushers can pass tramp iron that would stall many competitors’ crushers. Using the Hydraulic Pressure Adjustment Device setting adjustment with the adjustment under load capability makes it easy to balance the crushing circuit and optimize crusher productivity. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. WHITE LAI cone crushers are widely used in mines and quarries around the world and have earned a reputation for being tough and reliable. Two main types of cone crushers are available: the Standard type for coarse crushing. the short head type for fine crushing. These two crusher types are designed for secondary or tertiary crushing of highly abrasive materials in ether fixed or mobile plants.

Shanghai WHITE LAI Road and Bridge Machinery Co., Ltd is a renowned crushing and screening machinery equipment provider in China. We provide our clients with a whole series of crushing and screening machinery equipment, including hydraulic cone crusher, jaw crusher, impact crusher, vertical shaft impact crusher, vibrating screening and all complete set of stone crushing and sand making production lines. Our products had passed the quality system certification of ISO9001:2008, and the European CE certificate.

Contact Supplier 00:44

00:44

Improved efficiency and throughput Cascading material combines with material from the rotor to form a denser particle population, which optimises reduction by increasing the chance of a good rock-on-rock collision. This most efficient use of the rock on-rock crushing action leads to improved crusher efficiency and increased throughput, giving the operator more value for money by providing more inter-particle action where it is needed most in the crushing chamber. The unmatched producer of superior concrete and asphalt aggregate Less cement can be used and stronger concrete created by using Barmac S-Series VSI product. The Barmac S-Series VSI combines high velocity impact crushing with high pressure attrition grinding to produce high volumes of cubically shaped product. Continuous control of the product shape and gradation provides a product which meets the size distribution required. A proven producer of quality manufactured sand Superior particle shape and consistent gradation are a direct result of the rock-on rock principle of the S-Series VSI crusher. Impact, grinding and abrading within the crusher simulates the action of nature, eroding the particles to a cubical shape. The only viable crusher for extremely abrasive fine material The rock-on-rock crushing principle of the Barmac S-Series VSI minimises metallic wear resulting in low maintenance and wear costs. The low wear of internal components ensures extremely low contamination of fi ne products by wearing metal parts. The User-Friendly VSI crusher The roof lifter has been developed to provide quick and easy access to the internal workings of the Barmac S-Series VSI. This allows for rapid rotor and wear part changes and minimises down time while maximising availability. The simple and reliable design of the roof lifter means only one person is required for operation and can eliminate the requirement for an external crane. The cascade feed system The Barmac S-Series VSI uses the cascade feed system to introduce a second stream of material, in a controlled quantity, into the crushing chamber turbulence. This causes a supercharging of the particle population within the chamber, thereby improving the energy transfer between the particles. The cascade feature enables the operator to make optimal use of the power available and to manipulate the product grading and shape to best suit their requirements. The cascade feed system provides: • Higher crusher throughputs for the same power consumption. • Maximum use of available power without fear of motor overload. • Gradation control to optimise product fractions. • ‘Free’ crushing at no extra expense to the operator. • Shape control. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. The S Series Vertical Shaft Impact(VSI) crusher was improved on basis of the technology of Barmac,it has had a huge impact on the global quarrying and minerals processing industries. The Barmac S-Series VSI is unique due to its crushing process. Whereas most other types of crusher use metallic parts to crush rock, the Barmac VSI uses the rock fed into the machine to crush itself. This autogenous crushing process produces the best-shaped aggregate on the market today. The high velocity impact crushing achieved in a Barmac S-Series VSI improves the soundness and shape of stone, reducing product moisture and easing the screening task while producing superior products at a minimum cost.

Shanghai WHITE LAI Road and Bridge Machinery Co., Ltd is a renowned crushing and screening machinery equipment provider in China. We provide our clients with a whole series of crushing and screening machinery equipment, including hydraulic cone crusher, jaw crusher, impact crusher, vertical shaft impact crusher, vibrating screening and all complete set of stone crushing and sand making production lines. Our products had passed the quality system certification of ISO9001:2008, and the European CE certificate.

Contact Supplier 01:00

01:00

Jaw Plates WHITE LAI replacement crusher jaws are engineered to last longer and crush more efficiently, while reducing wear and tear on the crusher. The crusher jaws produce better quality rock more consistently than standard original equipment jaws, while reducing the need for re-screening and re-crushing. WHITE LAI offers a full range of options for all popular jaw crushers, including various tooth designs, curves and alloys. WHITE LAI's crusher jaws give you: ● Machined surfaces for a consistent fit with less hassle and downtime ● Large selection of tooth and curve configurations for optimum performance in any application ● Unsurpassed alloys for extended wear life and lower cost per ton Mantles & Concaves WHITE LAI supplies replacement wear parts to fit all major cone crusher models, including the new high-horsepower crushers. WHITE LAI cone crusher wear parts are engineered to maximize production by retaining the feed opening throughout the part’s lifespan, and balancing the mantle and bowl liner wear. Cone parts can be custom fit to match any application. WHITE LAI’s cone crusher wear parts give you: ● Custom configuration ensures consistent production ● Long-lasting manganese steel and durable parts increase crusher uptime ● Precise fitting distributes stresses across the frame for less wear and tear on the equipment Gripper Slot Bowl Liner The WHITE LAI gripper slot bowl liner is specifically engineered to permit oversized rock to enter the chamber and keep the feed opening clear. The ribbed mantle helps begin the crushing process higher up in the chamber for cobblestone and river rock material that is typically difficult to grab. The result is more even wear and improved production. Main Frame Cone Crusher Liners WHITE LAI also fabricates Main Frame Liners and inserts that provide an economical alternative to OEM parts. Our selection of WHITE LAI plates and chromium carbide overlay plate offers a wider choice to address wear protection. Magotteaux Blow bar Xwin® Martensitic Steel is a standard MMC (Metal Matrix Composit) solution which was first developed to recycle building waste; it has now been used for many years and is hence renowned on the market. Combining the high wear resistance of the ceramic compound with a high chrome white iron increases the lifetime while keeping the physical parameters of the required matrix. Against white iron solutions, which are breakable, the use of Xwin® Martensitic solutions reduces the risk of breakage of the blow bars to its lowest level according to applications. Key Benefits: ● Increase the lifetime of blow bars(from 80 up to 120%) ● Reduced maintenance ● Maintained original wear profile ● Improved productivity VSI Wear Table WHITE LAI S series VSI crusher wear parts are cast from premium chrome white iron alloys 35S and 33F-MC for maximum abrasion resistance. Careful production control ensure that parts wear uniformly. In addition, weight is maintained to a very close tolerance to minimize vibration. WHITE LAI offers high quality throw shoes and anvils for S series VSI crushers,also offers such VSI accessories as rim liners, lid liners, table liners, feed tubes, feed discs and pedestal liners. Key product features include: ● Material: high manganese steel, high Chromium or 45 carbon steel; Depending on the specific conditions, all wear parts can be ordered as high manganese steel, high chrome cast iron or Cr-Mo alloy steel. ● Process: polished and rust-resistant as per your requests.

Shanghai WHITE LAI Road and Bridge Machinery Co., Ltd is a renowned crushing and screening machinery equipment provider in China. We provide our clients with a whole series of crushing and screening machinery equipment, including hydraulic cone crusher, jaw crusher, impact crusher, vertical shaft impact crusher, vibrating screening and all complete set of stone crushing and sand making production lines. Our products had passed the quality system certification of ISO9001:2008, and the European CE certificate.

Contact Supplier 01:23

01:23

Description Tetris Space building is made by a range of modules. Each module adopts either the shipping container or light gauge steel structural system with different types of renovative environmental materials, which is produced from the production line. This product can be stand-alone or combined verticallly and horizontally to create the modular complex buildings. According to the structural system, there are CONTAINER STRUCTURAL SYSTEM BUILDING and LGS STURCTURAL SYSTEM BUILDING two major series. The architectural, structural, electrical, drainage and decorative works of each module are premanufactured in the factory, and transported to the construction site as complete modules, then by using the crane to lift to exact position to finish the final assembling. This product is widely used in residential, industry, commercial and public service area as the hotels, apartments, offices, supermarkets, educational facilities, government settlement housing, tourist spots, military camp and etc. Advantages Highly prefabricated, short constructin period - Tetris Space is one of the most prefabricated products in the modular field. After fully documented and produced in the factory, transferred to construction site to be assembled mechanizedly. The production cycle is much less than the tranditional types of buildings, and every step is pre-scheduled and foreseeable. Line production, low cost - Each module comes from the production line, thus the quality is strickly controlled and the production efficiency is very high, so the manufacturing cost is reduced to minimum. Functional usage, suitable for all - Each module can be designed and made as office, accommodation, lounge, bathroom, kitchen, dining, gym, recreation, clinic, laundry, storage and other different spaces based on clients' inquiries. High stability, durable life time - The structural systems have been tested by many authorities to ensure the stability and safety of the buildings. They have long service life time and high seismic resistance, crushing resistance, sound insulation performance, thermal performance, fire resistance, water resistance and windproof performance. According to the different regulations and needs of different areas or inquiries, this product can be made as permanent or semi-permanent buildings. Various combinations, great livability - By using different ways of combining modules and materials to create different types of architectural space and facade appearance. The maximum sizes of single module our factory can produce is 16154mm long, 4600mm wide and 3300mm high, which has covered up most sizes of required demands in the world, and gives the designers more flexibility. Integral module, easy for transporting and assembling - Each module is an integrality, which is easy for transporting by road, railway or ship freights. Compare with other prefab buildings, it has less packaging cost and time.

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 01:15

01:15

Description • Limited budget • Tense construction time • Various floor layouts • High-standard aesthetic requirements The upgraded EASY HOUSE (Prefab house) series are designed, based on the traditional portable panel buildings by adopting the same structure and basic materials, to solve all the issues above. This product adopts the light gauge steel as the structure, the renovative wall panels as the enclosure components and the cladding and different types of paints as the finishing material while is using the standard modular system to arrange the layout. The main structure can be assembled by bolts to achieve the fast and easy erection. Different proposals of structural systems, material selections, exterior appearances, floor plans are provided according to the development levels, weather conditions, living habits and cultural background of different areas, to meet the requirements of different people. Advantages Attractive Appearance Variouslayouts are easily formed by using the standard modularity, and the appearances and colours of the facades and the locations of window and door are adjustable to satisfy particular requirements for people from different backgrounds. Affordable & Practical According to the different levels of economic development and the weather conditions, different options of budget and design are available. Great Durability Under normal circumstances, the EASY HOUSE (Prefab house) has long performance life for over 20 years. Easy Transporting Limited onsite work, averagely every four experienced workers can erect approximately 80m2 main structure of EASY HOUSE every day. Fast Assembling Limited onsite work, averagely every four experienced workers can erect approximately 80m2 main structure of EASY HOUSE every day. Environmental Friendly Each component is pre-manufactured in the factory so the onsite construction rubbish is reduced to the minimum, very economy and environmental friendly.

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 01:37

01:37

Description Flat-Pack is a type of modular products designed by using the steel frame and light-weight wall panels system. One Flat-Pack consists of top frame, bottom frame, 4 posts and 14 pieces exchangeable wall panels. It can be flattened for easy transporting. Advantages FLEXIBLE COMBINATION – stand alone,or combined horizontally to create big open space, or stacked vertically up to 3 storeys. FULL-RANGE FACILITIES – different types of roof, corridor, canopy and staircase are available; plus specialized bathroom and kitchen containers to choose; can be decorated both inside and outside. FAST ASSEMBLING - averagely 4 workers can erect 1 container within 3 hours. The container also can be assembled in factory and then transferred to the site. SAFE AND DURABLE – over 15-year lifetime,seismic resistance to 8 degree, wind resistance to 11 degree. Typical Layouts Flat-Pack(camp house) can be used as the office, accommodation, canteen, bathroom and other big open spaces, to meet the needs of construction site, fieldwork camp, social housing, disaster site and other commercial purposes. Flat-Pack is widely used in Europe, Japan, Middle East, Southeast Asia, Africa and other areas. Office Accommodaton Single Studio Shower Toilet

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 01:08

01:08

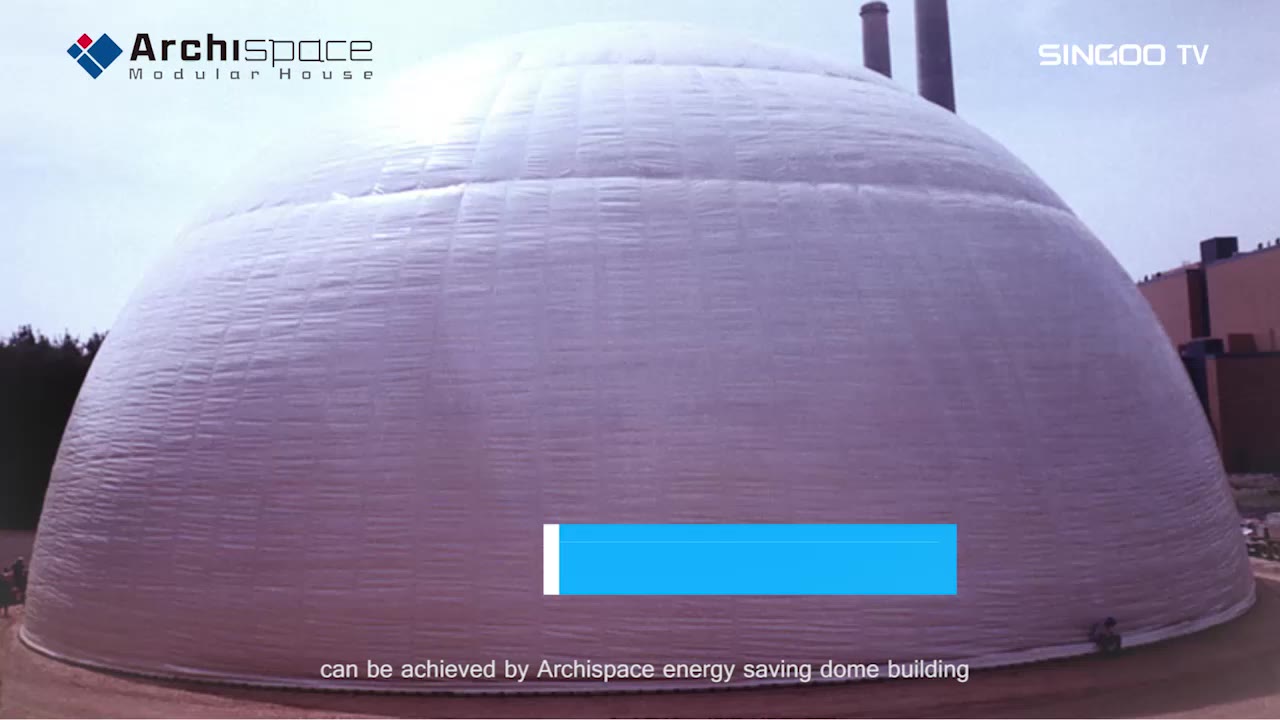

Characteristics 1、Pure-green construction without any beam and column 2、USA patent,warm in winter and cool in summer,power saving,no leaking and insect resistance 3、Short construction period,various model change 4、RC structures as permanent construction 5、Hurricane resistance and anti-seismic(mainly use in school and refugee shelter) 10 advantages 1. High tension intensity 2. High thermal-insulation efficiency 3. Good fire-proof performance 4. Good leaking proof performance 5. Good insect resistance 6. Good performance of hurricane resistance 7. Strong capability of anti-seismic 8. Lower construction cost 9. Lower operating cost 10. Lower maintenance cost Applications ●Hall & Theatre ●Disaster Relief ●Hotel & Apartment ●School ●Tourist ●Commercial Building ●Exhibition

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 00:53

00:53

Description K-House (prefabricated panel house) is a type of Yahgee’s renovative and eco-friendly products for temporary use. This product adopts light gauge steel as the structural frame, color-coated sandwich panes as the enclosure material, is designed with standard module to form the layouts and the primary components are connected by bolts. K-house can be assembled and disassembled quickly. The design concept of K-House (labor camp) is universal, standardized and modular, which is advantageous to achieve the development of line products, industrialized manufacture, supply of complete set, fast assembling or disassembling and repetitive use. It can be widely used for construction site, government settlement housing, disaster relief, public events and etc. Parameter K-House specification: mK x nK x uP m=3,4,5 6≤n≤32 u=3,6,9 1K=1820mm 1P=950mm Advantages Easy Transporting Up to 250~300m2 K-House can be stored into a standard 40' container; K-House can also be transported by different types of inland trucks. Fast Assembling Limited onsite work, averagely every 6 experienced workers can erect approximately 120m2 K-House every day. Various Layouts Various layouts are easily formed by using the standard modularity, and the locations of window and door are adjustable, all of these are to satisfy particular requirements for people from different backgrounds. Safe Stability K-House can resist up to magnitude-7 earthquake and magnitude-10 hurricane. Repeatable Use Under normal circumstances, the K-House has long performance life up to 8~10 years, also it can be disassembled and re-erected on another site. Environmental Friendly Each component is pre-manufactured in the factory so the onsite construction rubbish is reduced to the minimum, very economy and environmental friendly. Single-Storey K-House Double-Storey K-House Triple-Storey K-House

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 01:02

01:02

Description ISO Container is weatherproof, fully enclosed and is used for loading the right goods, except frozen cargo and animal/plant, with suitable size, weight and without attemperation requirements, such as articles of daily use, food, machinery, instrument, household appliances, medicine, valuables and etc. 10' Container 20' Container 20'HQ Container 40'ft Container 40'HQ Container 45'Ft Container 53'ft Container

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 00:53

00:53

Description T-House(Prefabricated panel house) is a type of temporary buildings using the steel structure as the fundamental system for the floor load bearing,and the self strength of sandwich panels as the load transferring factor, while connecting them by the efficient method. The design of T-House(labor camp) is modularized, which means the external and internal appearances are neater and more beautiful, the layouts are more flexible, the thermal and sound insulating performances are much better. This product can be widely used in the construction site, camp site, government settlement housing, public events, commercial events and etc. Parameter T-House specification: mT x nT x uH m=4,5,6 6≤n≤48 u=3,6 1T=1150mm 1H=1000mm Standard room 3T Advantages Attractive Appearance The spacing between columns is wider and columns are hidden inside of the building, thus the external appearance is much neater and more beautiful. High Performance By adopting the splicing of wall panels, the building has excellent thermal and sound insulating performance. Environmental Friendly Factory prefabricated, thus to minimize the onsite work and the construction waste, very environmental friendly. Easy Transporting Simple structure means limited components, which is good for store and transport. Up to 200~250m2 T-House can be stored into a standard 40' container. Single-Storey T-House with Pitched Roof Single-Storey T-House with Flat Roof Double-Storey T-House with Flat Roof

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 01:10

01:10

Description Basically, there are two types of construction methods of Yahgee Domus (Light Gauge Steel House). One is called LGS-style Yahgee Domus, which is using light gauge steel as the structural frame and adopting the glass wool or rock wool as the thermal material, the internal and external wall panels are installed on site; the other is using profiled steel as the structural frame, and finished by the factory prefab wall panels, which are transported and assembled as complete pieces on site; thus this type is called Panel-Style Yahgee Domus.. The most common wall panel materials for the second construction method are fiber cement board, OSB panel, plaster board, ALC panel, GRC panel and etc. There are many optional materials available for the internal walls, external walls and roof tiles of the Yahgee Domus, to satisfy different inquiries for different clients. The complexity designs of layout and facade to satisfy people from different background or with different artistic taste can be easily achieved according to the various options of construction methods of Yahgee Domus. This type of buildings has over 50-year service lifetime, because of the durably structural and decorative materials, which has been approved by the western countries. Luxury, elegance and aesthetics are the first expression of the Yahgee Domus to people. Comfort, durability and safety are the second expression of the Yahgee Domus to people. Advantages Some of the main properties of LGS are as follows: • Lightness in weight • High strength and stiffness • Ease of prefabrication and mass production • Fast and easy erection and installation • Substantial elimination of delays due to weather • More accurate detailing • Non shrinking and non creeping at ambient temperatures • Termite-proof and rot proof • Economy in transportation and handling • Non combustibility • Recyclable material Note: We have no inventory, no retail business, we we provide customized wholesale business.

Archispce dedicated to the development, design and manufacture of innovative building system under the most strict quality standards in international level to meet the needs of living condition adapted to different applications in works and events. Archispce affiliated with yahgee Yahgee Modular House (Group) Co., Ltd. was founded in 2001 and currently is the largest manufacturer of prefabricated houses and marine accommodation cabins in China with over 7000 employees operating in more than 200 large and medium-sized cities throughout China. In December 2009,YAHGEE was successfully listed at Shenzhen Stock Exchange (Stock Code:002314), becoming the first publicly listed company of prefabricated housing industry in China. YAHGEE now renews the company name with Nanshan Holding in Nov 4th, 2015, general assets RMB3.5 billion.

Contact Supplier 01:38

01:38

Product Name AAAC、AAC&ACSR Reference Standard This product is produced with the standard of IEC 61089-1991 Applications Aerial transmission and distribution line, State Grid Project Performance Featured with convenient erection & maintenance, low cost of line construction, high transmission capacity, facilitate laying in special geographical condition such as across rivers and valleys, good conductivity and enough mechanical strength & tensile strength, pole distance could be increased and so on.

Wuxi Jiangnan Cable Co., Ltd., founded in 1985, is a National Key Hi-Tech. Enterprise, mainly manufacturing integrates wires and cables. By the end of 2015, With a floor space of more than 500,000 square meters, total built-up area of 350,000 square meters, and total assets worth above RMB 7 billion, the Company now has an employee size of 3,000-odd persons, of which, middle and high-level technical and managerial personnel with diploma of junior college or above make up more than 30 per cent of the Company’s total employees. In addition to boasting more than 1,400 sets (units) of China and the world first-class production and testing devices, the Company takes the lead in realizing whole-process dynamic monitoring and management over its logistics, capital flow, and human resources by virtue of its ERP network information management system, HER H.R. management system, and OA system, thus IT-based management in the Company comes true.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery