00:00

00:00

Squared performance description: 1.The tank cover spreading device: when the body enters, only the corresponding rationing tank cover, no tanks, no cover; 2. PLC operation panel design is reasonable and simple, convenient adjustment and maintenance; 3.High production capacity, high degree of automation, suitable for sealing cans production line equipment; 4. 304 stainless steel appearance, sealing roller is made by chrome steel, high hardness, good wear resistance, no rust, excellent sealing performance. Squared characteristics description: 1.Unmanned operation, automatic under cover and seal, in accordance with the artificial prices rising trend, the equipment will become the mainstream models; 2.Tanks not rotating sealing process design, to better products and body protection, machining accuracy is high, the sealing quality is better than the domestic similar products. 3.The production efficiency of the machine is semi-automatic sealing machine 2 ~ 3 times, and because of using automatic under cover and sealing device, save manpower cost at the same time, improve the production efficiency; 4.Suitable for all kinds of tinplate cans, aluminum cans, paper cans, etc all kinds of round specifications sealing cans, simple to operate, is the ideal equipment of food, beverage, pharmaceutical and other industries.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

This linear type pop can filling sealing machine is suitable for equal pressure filler and capper of drinks and oil, honey, butter, sauce and lots of products in beverage drink and food industry. It is in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit. It is suitable for plastic can and tin can. The machine adopts PLC, frequency converter, human machine interface controlling system, having the advanced controlling technologies, such as frequency control; no can no filling and so on. The accurate production rate and quantity will be displayed on touchscreen via the kinds of sensors on the machine. Moreover, the production rate can be set on the touch screen. The main motor and other electrical equipments are all in protection state. Meanwhile all of the malfunctions can be found out easily, because they will be displayed on the touch screen. The main electric and pneumatic components of the machine are famous imported brands, and it also can be disposed according to client’s requirements. Features High production capacity and high automatic grade. Dropping caps and sealing automatically without human. Sealing without twist off which can protect the damage to cans No bottle no filling. Unique drip proof device in production process, ensure no irrigation constant filling function. PLC and touch screen, east and fast to operate. The automatic machine will alarm or stop working automatically if unconventional problems happen(such as counting mistake, miss bottles)

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

Overview: This machine is a kind of controlled by microcomputer programmable, photoelectric sensor, pneumatic operation in the integration of new and high technology, filling equipment. This machine is widely used in fluid materials, such as tomato sauce meat sauce sea food oil honey and so on . Filling dose accurately, no drop leak, can be applied to 50-600 ml, all kinds of bottle filling, switch in a few minutes filling specifications, filling in the same period is short, high production capacity, intuitive picture, the operation is simple, convenient, canned each set separately, grade of 0.01 seconds, greatly ensure the filling precision. After-sales service, 1-2 years free maintenance, life-long maintenance, the company has a professional after-sales service team, for the customer service 24 hours a day. Feature: (1) man-machine interface, directly set filling volume, filling volume and filling speed adjustment is simple, the touch screen operation and display, beautiful appearance; (2) PLC program control, frequency converter speed control linear filling After sale service: (1)Long life service (2)One year warranty (3)Offering free parts for one year (4)Engnieers available to service machinery overseas

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:30

00:30

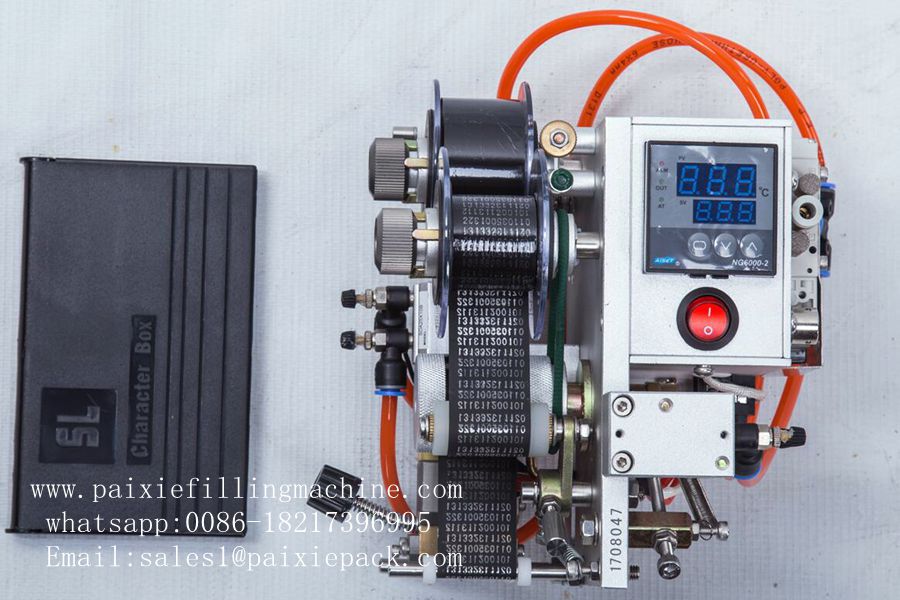

Overview: Hot code printer adopts thermal printing ribbon to avoid oil contamination, which can keep the surrounding clean. It can be used to print notes like production date on the plastic and paper bags in food and pharmaceutical industries. The words printed is clear and endurable against wear. Features: Hot color ribbon code printing machine. The machine is available for both automatic continuously printing code and control by pedal manual. The machine adopt color ribbon printing, has the features of clear printing, easy drying, non sticky, not easy to wipe off. It's able to print code on thin paperboard, paper sheet, leather, plastic film, aluminum foil, especially fit for coding on paper box of shoes and cloting. Adopt constant temperature control and the temperature is adjustable, suitabel for different material of color ribbon.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 01:03

01:03

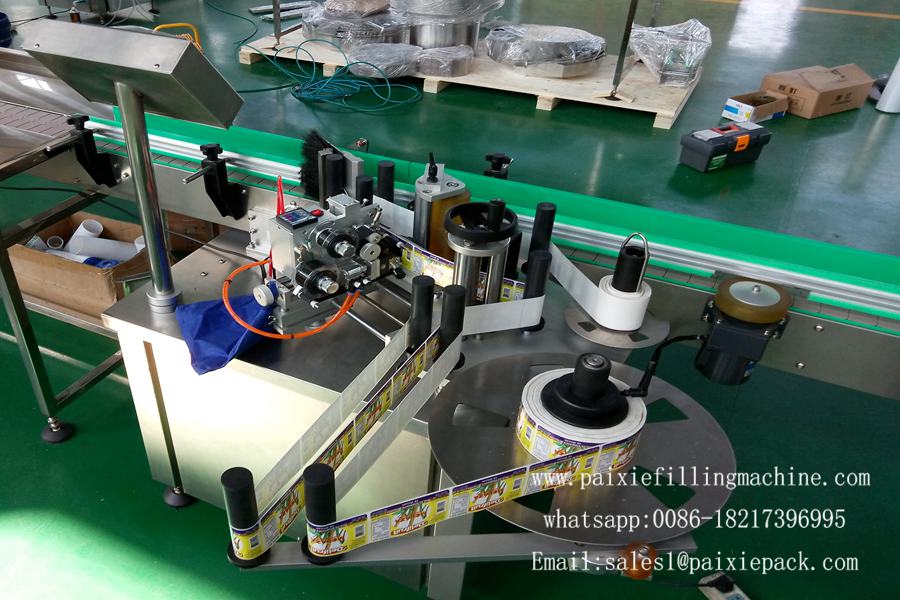

Overview : The Paixie Pack labeling machine have different types full automatic labeling machine suitable for round /flat /square/ irregular shape bottles . We have three types of the labeling machine adhesive labeling machine, glue wet labeling machine ,sleeve shrink labeling machine . Our Labeling machine is also suitable for all kinds of one side two sides neck labeling and so on. 1.Configuration oftaliban type coping mechanism, to ensure product delivery smoothly, and effectively eliminate bottle of high error in itself; 2.Configure automatic bottle body, guide the bottle before automatically separate spacing, ensure follow-up guide bottle, conveying and stick mark stability; 3.Mixer equipment mainly senior materials using 304 stainless steel and aluminum alloy, in line with the GMP standard production, overall structure and firm, the beauty is generous. 4.In pieces the electrical equipment USES is Panasonic servo motor, Mitsubishi electric eye, ensure the accuracy and speed stick mark requirements. After sale service : (1) Long life service (2) One year warranty (3) Offering free parts for one year (4) Engnieers available to service machinery overseas

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 02:18

02:18

Overview: This spouted pouch filling machineis specially applied to fill all kinds of liquid, such as fruit juice, milk, detergent, beverage, etc. customized according to real samples. Working process including pouches feeding, positioned filling, cleaning the nozzles, caps screwing, end-products discharging as well as liquid level controlling for ensuring exact filling volume. Dust-proof cover to ensure hygiene and good appearance. Easy operation and adjustment.With reasonable design, advanced functions, which is turned into the ideal packing machine for standing pouches.high efficiency. Quick Details Type: Filling Machine Condition: New Application: Food, Commodity, Medical, Chemical, Textiles Packaging Type: bags,stand-up pouch,spouted pouch Packaging Material: Plastic Automatic Grade: Automatic Driven Type: Pneumatic Voltage: 220v/380v/440v Power: 1.1KW Place of Origin: Shanghai, China (Mainland) Brand Name:spouted pouch filling machine Model Number: spouted pouch filling machine Dimension(L*W*H): 1800×1150×1950mm Certification: CE After-sales Service Provided: Engineers available to service machinery overseas material: ss304/ss316 control: PLC control ,touch screen type: liquid filling machine Description: working flows: Machine working full automatically Pouch feeding---pouch hanging---photoelectric detection---filling---spout head cleaning---cap putting---cap screwing---pouch discharging Machine Features: This automatic spout pouch filling and capping machine is suitable for liquid or semi-liquid,such as packing jelly, soy milk, yoghourt, mineral water, juice, ice cream, edible oil, seasoning, scour, laundry detergent etc; This Spouted Pouch Filling Systems provide solutions for filling and sealing pre-made pouches with spouts, caps and other fitments. rotary and inline pouch systems offer solutions for low output pouch filling and high productivity, high-volume pouch filling applications. Seal the spout in the pouch, fill through the spout, and then apply the cap closure Fill through pouch center spout and apply cap closure Corner spouted pouch: fill through top opening of pouch and seal General Information Place of Origin:shanghai Brand Name:PAIXIE Model Number:PX-2600 Certification:CE Business Terms Minimum Order Quantity:1 set Price:12000-25000 Packaging Details:strong wooden seaworthy cases Delivery Time:30 days after receiving 30% payment Payment Terms:30% advance payment,70% by T.T Supply Ability:20 sets per month

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:33

00:33

Overview: This bag packing machine using Japan PLC programmer and display screen, which is easy to predominate running state, trouble state, operation order, and production state. Using AC Alternating Current servo motor to control film pulling. In the cause of film pulling it is stable, and with high accuracy orientation. Lubricating is not needed it is possible to revise parameter and adjust position without stopping the machine. Using temperature controller to keep temperature of hot seal unaltered to use dent form sealer to seal film highly series is equipped with automatic trouble alert to find product to be cut by knife, door not to be closed, film wrapping not to run exactly and film to be used up ect. Main Technical Specifications: PXP-280 Sealing mode 3 sides seal/4 sides seal/centre sealing Packing speed 25-60bags/min Bag size L:100-1000mm W:120-500mm Filling quantity 100-5000g Power 220v 50Hz 1.5kw Machine weight 350kg Dimension 600*790*1800mm Function and Characteristics: 1. Safety device: Machine stop at abnormal air pressure, heater disconnection alarm。 2. It matchs with the glass safety door. The machine will stop working when you open the door. So that it could protect the safety of operators. At the same time, it could prevent dust. 3. Use the plastic bearing, don’t need put on oil, less pollution. 4. The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification 5. Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food 6. The part where touch to the material is made of stainless steel is accord with the request of GMP. 7. The canning mete and career can be accommodated, it is accurate. 8. The canning cobbra of the machine use the setting of defending leak and drawbench. Option: Gas flushing (Air or Nitrogen gas)、Tear notch 、Gusseted device、Air expeller、Hole punch device 、Polyethylene sealing system Multifunction weigher machine: Applications: It is suitable to use in the quantitative packing granular materials, such as washing powder, monosodium glutamate, chicken essence, salt, rice, seed. or a little bigger granules like pills, tablets, capsules, candies, nuts, peanuts, agricultural products, dry fruits, beef jerky, etc; or some sliced, blocked and puffed foods like potato slices, potato chips, rice crust, etc. Characteristic: Vibration feed Scale measurement, bagging Artificially-- Packaging specifications filling range, two scales in turn Cutting; Packaging specifications>filling range, two scales cutting together, the filling accuracy is no relationship with the proportion of the material--Packaging specifications is Adjustable Movable mask, event-type scale fighting, the card-fit-type splice mouth RS485 Computer networking, serial interface Dust-type splice mouth, mixing motor

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 01:22

01:22

Mixing tank The Tanks is widely used for the mixing, disposing and storing of all kinds of materials .it adopts all-closed construction and is made of high-quality stainless steel. it is equipped with fully auto-cleaning device auto-controlled device. it is the ideal equipment for storing juice, pure water and other liquid. It is made of stainless steel 316 completely, meeting the requirement of GMP. structure and function: Structure: by the bladder, jacket, insulation layer outer wrapping reducer impeller thermometer etc. The tank: adopt stainless steel plate 304 materials, surface polishing. Install: Adjust the equipment supporting feet to horizontal and vertical gear reducer, to install the pipeline, at work, must pay attention to the impeller to rotate clockwise, shall not be reversed. Characters: The body of this series of stainless steel storage tanks formed by cylindrical stainless steel, and equipped with sanitary manhole, cleaning ball, liquid level gauge. 1. The equipment is single layer structure. 2. The material is stainless steel SS304 .

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 02:29

02:29

Overview The 5 gallon bottle washing machine features advanced technology, newly design, reliable performance, easy operation, scientific process and good sanitary conditions. The complete production line combines empty bottles conveying, internal bottle pre-washing, automatic de-capper, external bottle washing, bottle feeding, bottle discharging, internal and external bottle washing, cap pressing. The fully automatic intelligent production and strict control for the whole production process can ensure that it meets state hygiene standards and regulations during the complete washing . Besides, strictly controlling for secondary contamination during filling to achieve aseptic production makes it the ideal, recognized and reliable automatic bottle production line.This 5 gallon bottle washing machine is made by SUS304, the length can design according to the buyer's workshop. It is very convenient to change sizes of bottles by means of advanced bottleneck clamping & bottle suspending technology and advanced programmable PLC is equipped to control the main machine. Characteristics 1. Model QGF series Barreled filling machine is combined with washer, filler and sealer machine on one unit, controlled by PLC 2. It is an ideal equipment to produce mineral water, distilled water, pure water production. The completed machine is full automatic, made of 304S.S. or 316 3. You can match with de-capper, leakgae inspection, cap loading and barrel loading device, shrinking film machine, coding system to be a complete full-automatic water barrel filling production line. 4. All the components are from international famous brands like Mitsubishi, Airtac. etc. 5. Capacity range: 100bph , 300bph, 450bph, 600bph, 900bph, 1500bph

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

According to the customer requirements and the source water quality, we adopt different equipment to produce pure water, mineral water,etc. The main equipments are silica sand filter, active carbon filter, sodium ion exchanger, hollow fiber, RO( reverse osmosis), UV sterilizer, precision filter, ozone generator,water tank,etc. The treatment capacity is 0.5-50 ton/hour. It can effectively get rid of muddy organic matter, iron, manganese and oxide, filter suspended substance, colloid, remained oxygen of microorganism and some of heavy metal ion in the water, reduce the hardness of the water to make all specifications of the water quality fully meet the state fresh water standard of fresh drink water.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

This metering pump filling machine is specially made for all viscous materials, such as honey, oil, jam, tomato paste, motor oil, lubricant oil etc. The machine adopts piston pump for filling. all machines can be customized according your samples and your requirement. This hot equipment adopts bottle neck holding transmission technology to realize fully automatic rinsing,filling and capping. It is equipped with perfect temperature control system, reverse-flow system, automatic cleaning system and control program. Each machine element that contacts with the liquid is made of high quality stainless steel and food-grade rubber. 1. All components are famous brands, no bottle, no filling; no bottle, no capping; no drop, bubble or spill. 2. Good stainless steel material, according with GMP requirement. 3. PLC control, stepless transducer control. 4. Human-machine interface touch screen with easy operation. 5. Accurate filling, no drop, bubble or spill.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier 00:00

00:00

1. The filling pump is peristaltic pump, the filling precision of this pump is high. 2. The mechanical hands of the machine absorb the stopper and cover with vacuum by rotation of the cam. The mechanical cam control the lift, so the stoppering and cover’s precision is high. The parts of plugging cover has capping motor which can control and complete a corrective and probably capping, in order to increase the qualified rate. 3. Capping parts use the transverse torque and automatic slipping unit. So it does not hurt the cover. 4. The bottles don’t follow with the capping head, the turntable does not hurt the bottle, so the design protects the beautiful of the packaging material. 5. The machine is controlled by touch screen and made with alarm.

Shanghai Paixie Packing Machinery CO.,LTD is located in Pujiang Town, Minhang area, Shanghai City in China, which is close to Pudong International Airport and Hongqiao Airport only need to take about 30-45 minutes, the transportation is very convenient either by car or railway. It covers a large area with beautiful scenery.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery