00:56

00:56

RFID Blocking Card is the size of a credit card that is designed to protect personal information stored on credit cards, debit cards, smart cards, RFID driver’s licenses and any other RFID Cards from e-pickpocket thieves using handheld RFID scanners. The Scanner Guard Card is half as thick as a standard credit card so it will not increase the size of your wallet. It is very flexible and durable.

When the Smart Card industry kicked off in mainland China 20 years ago, RFIDHY were at the forefront. In 1995, we began by producing plastic magnetic cards. We are the first supplier of magnetic cards as the ticket for AFC (Automatic Fare Collection) system for Shanghai Metro No1 line. Our products line covered Plastic card, Smart cards, Contactless cards, RFID inlay and RFID products tags with growing of technology and applications in this area. Our experience is not only in RFID products R & D, but also system and solution design, and system integration manufactures, but also development. Our success in oversea market was apparent – from the first client in Spain in Europe in 2005, and expanded to hundreds of clients covering up to 100 countries and regions in several years.

Contact Supplier 02:19

02:19

Single use fabric RFID wristbands for concert and event ticketing and cashless venues. Fabric RFID wristbands in both 125 KHz and 13.56 MHz for short to medium range reads of up to 60mmm depending on the reader. Fabric RFID wristband is customizable to include customer branding and the RFID tag face can be custom printed with a customer logo. Specification Dimension 265*26*19mm,350*26*16mm Antenna LF/HF:copper antenna,UHF AL etching antenna Material PVC tag and Fabric wristband Protection Waterproof Frequency 125KHz, 13.56 MHz, 860 MHz to 960 MHz Protocol ISO14443A, ISO15693, ISO18000-6C Read Distance ISO14443A: 2-5cm, ISO15693: 2-8cm, UHF 1-6m Operating Temperature -10°C to 60°C Storage Temperature -20°C to 85°C Humidity Package 40%-80% RH Package Carton Size: 490mm*380mm*350mm 265*26*19mm: 100 pcs per opp bag. 1000pcs per carton,12KG 350*26*16mm: 100 pcs per opp bag. 1000pcs per carton, 5.5KG Application Concert, Event Ticketing, Music Festival, Party, Theme, Water Parks, Resorts, Trade Shows, RFID Experimental Marketing Events, etc. Product Description Our fabric RFID wristbands are made of a cloth wristband with an RFID tag encapsulated in a housing that slides onto the band. Customer branding can be either woven or dye sub printed onto the band, customer logo can be printed on the tag face, serial numbers can be lasered onto band or tag to meet any requirement. Plastic clasp is used to secure the band so that it locks on and cannot be removed unless cloth wristband is cut to remove it from the wrist. RFID tag remains readable after the cloth wristband is cut. Optional re-usable clasp can make the band easy to put on and remove. Available chip technologies Chip Type Protocal Capacity Anti Collision Function Available 125KHz Chip TK4100 / 64bit No Read Only EM4200 / 128bit No Read Only T5577 / 330bit No Read/Write Hitag 1 ISO 11784/5 2kbit No Read/Write Hitag 2 ISO 11784/5 256bit No Read/Write Hitag S 2048 ISO 11784/5 2kbit No Read/Write Available 13.56MHz Chip F08 ISO14443A 1KB No Read/Write Ntag203/213/215/216 ISO14443A 168/180/540/924 byte No Read/Write MIFARE® S50 ISO14443A 1KB No Read/Write MIFARE® S70 ISO14443A 4KB No Read/Write MIFARE® Plus ISO14443A 2KB/4KB No Read/Write MIFARE® DESFire ISO14443A 2KB/4KB/8KB No Read/Write MIFARE® Ultralight EV1 ISO14443A 640bit No Read/Write MIFARE® Ultralight C ISO14443A 1184bit No Read/Write I CODE SLI ISO15693 128 byte Yes Read/Write Ti2048 ISO15693 2KB Yes Read/Write Available 860-960MHz Chip Alien H3 ISO18000-6C 512 bit Yes Read/Write Other ICs are available upon request.

When the Smart Card industry kicked off in mainland China 20 years ago, RFIDHY were at the forefront. In 1995, we began by producing plastic magnetic cards. We are the first supplier of magnetic cards as the ticket for AFC (Automatic Fare Collection) system for Shanghai Metro No1 line. Our products line covered Plastic card, Smart cards, Contactless cards, RFID inlay and RFID products tags with growing of technology and applications in this area. Our experience is not only in RFID products R & D, but also system and solution design, and system integration manufactures, but also development. Our success in oversea market was apparent – from the first client in Spain in Europe in 2005, and expanded to hundreds of clients covering up to 100 countries and regions in several years.

Contact Supplier 01:19

01:19

MIC 32-8 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Ink printer (LINX BRAND) 7> Can washing machine 8> CIP Clean system 9> CIP cleaning liquid recycle system Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. →We sold one to The Kingdom of Morocco on May 8,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:58

01:58

MIC 12-1 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> CIP cleaning system 7> CIP cleaning liquid recycle system 8> Ink date printer (LINX BRAND) Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. Recent export news: (click for check news) →We sold one to the United States of America on May 18,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:13

01:13

MIC 12-1 It is applicable for can filling seaming machine for juice tea and coffee drinks can package (Hot filling temperature at 85-90 degree) Adopt products: energy drinks , juice, sugar water, cider, vitamin water, health care drinks , tea, coffee etc liquid like juice. Machine working principle: 1. Gravity filling system, controled by gravity, accuracy is +/-1%,liquid level difference is not more than 2mm. easy adjustmeant on liquid level. 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About oxygen content, we have device nitrogen filling for replace air. 4. About gems sterilizing, we could use bottle invertor for the cap, and pasteurization for juice, hot filling for can. and sterilizing tunnel (with cooling spray) for second steilizing and cool off. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Nitrogen filling machine 7> Pasteurization, inventor and sterilizing tunnel. Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, energy drinks filling machine, fruit juice filling machine, vitamin drink filling machine, Vegetables drinks filling machine, healty care drinks filling machine.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 02:18

02:18

MIC 18-1 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. We sold one to The Republic Of Poland on April 27,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:40

01:40

MIC 24-6 It is applicable for can filling seaming machine for juice tea and coffee drinks can package (Hot filling temperature at 85-90 degree) Adopt products: energy drinks , juice, sugar water, cider, vitamin water, health care drinks , coffee etc liquid like juice. Machine working principle: 1. Gravity filling system, controled by gravity, accuracy is +/-1%,liquid level difference is not more than 2mm. easy adjustmeant on liquid level. 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About oxygen content, we have device nitrogen filling for replace air. 4. About gems sterilizing, we could use bottle invertor for the cap, and pasteurization for juice, hot filling for can. and sterilizing tunnel (with cooling spray) for second steilizing and cool off. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Nitrogen filling machine 7> Pasteurization, inventor and sterilizing tunnel. Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, energy drinks filling machine, fruit juice filling machine, vitamin drink filling machine, Vegetables drinks filling machine, healty care drinks filling machine. The machine is a device developed exclusively by MIC machinery on the basis of digesting and absorbing domestic and international (still) pop can filling and seaming machine (sealing machines). It adopts the normal pressure filling principle. Filling and sealing is the overall designed, power system by filling sealing system to ensure that both the absolute synchronization and coordination. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip long-distance control system according to the customers’ request. It is the preferred equipment for the medium beer and beverage plant

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:08

01:08

MIC 24-6 It is applicable for can filling seaming machine for energy drinks can package. Adopt products: energy drinks , juice, sugar water, cider, vitamin water, health care drinks etc liquid like juice. Machine working principle: 1. Gravity filling system, controled by gravity, accuracy is +/-1%,liquid level difference is not more than 2mm. easy adjustmeant on liquid level. 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About oxygen content, we have device nitrogen filling for replace air. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, energy drinks filling machine, fruit juice filling machine, vitamin drink filling machine, Vegetables drinks filling machine, healty care drinks filling machine. We sold one to The Federal Republic of Germany on May 2,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:13

01:13

MIC 18-6 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum can and metal can are ok problem working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler. Recent export news: (click for check news) We sold one to The Republic of Angola on April 25,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:02

01:02

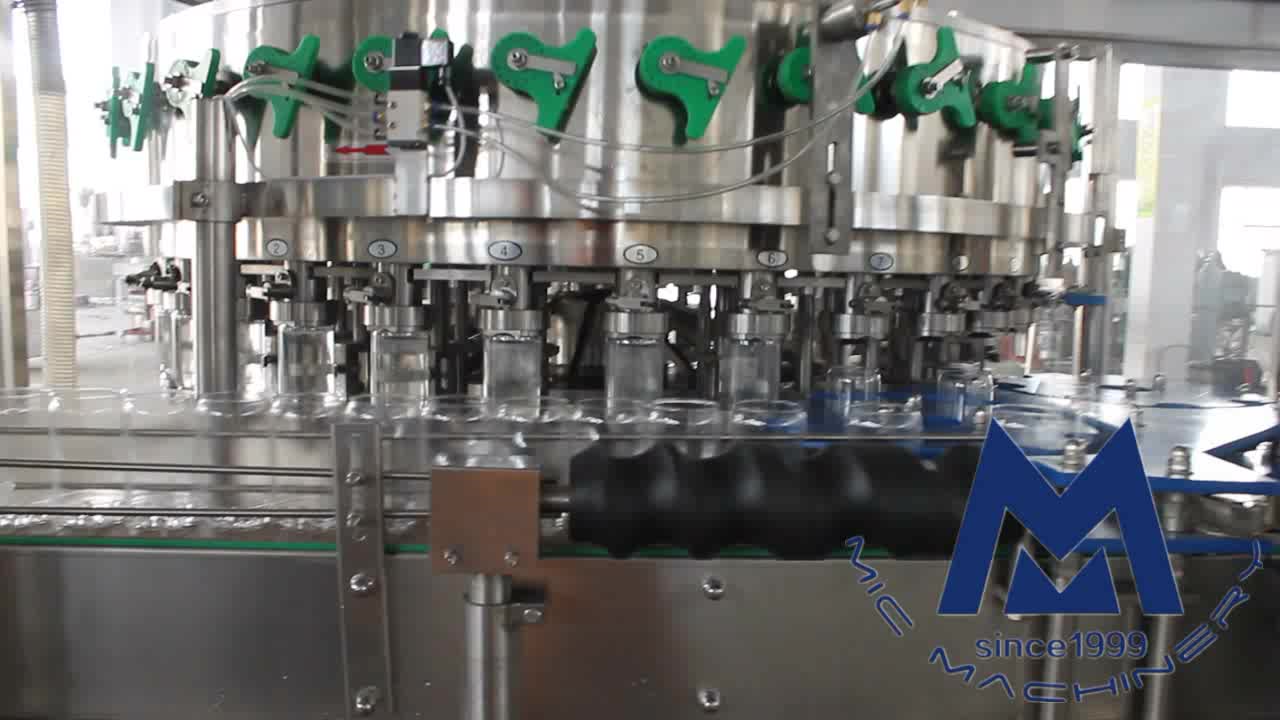

MIC-24-24-6 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry. Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks. Machine working principle: 1. Isobaric filling system, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degree). 2. Cap capping machine is qualified for Chinese seaming standard, and no air leakage at all. 3. About beer oxygen content, we have device for foaming after fill and remove oxygen of beer, and nitrogen filling for replace air too. 3. Aluminum cap and crown cap are ok problem working on our capping machine (different heads), We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> CIP cleaning system 7> CIP cleaning liquid recycle system 8> Ink date printer (LINX BRAND) 9> Wet glue labeling mahine Related machines are: bottle filling capping machine, glass bottle capping machine, rotated oil bottle filling machine, rotated oil filling machine, beer filling machine, beer capping machine, beer bottling machine and beer filler.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:30

01:30

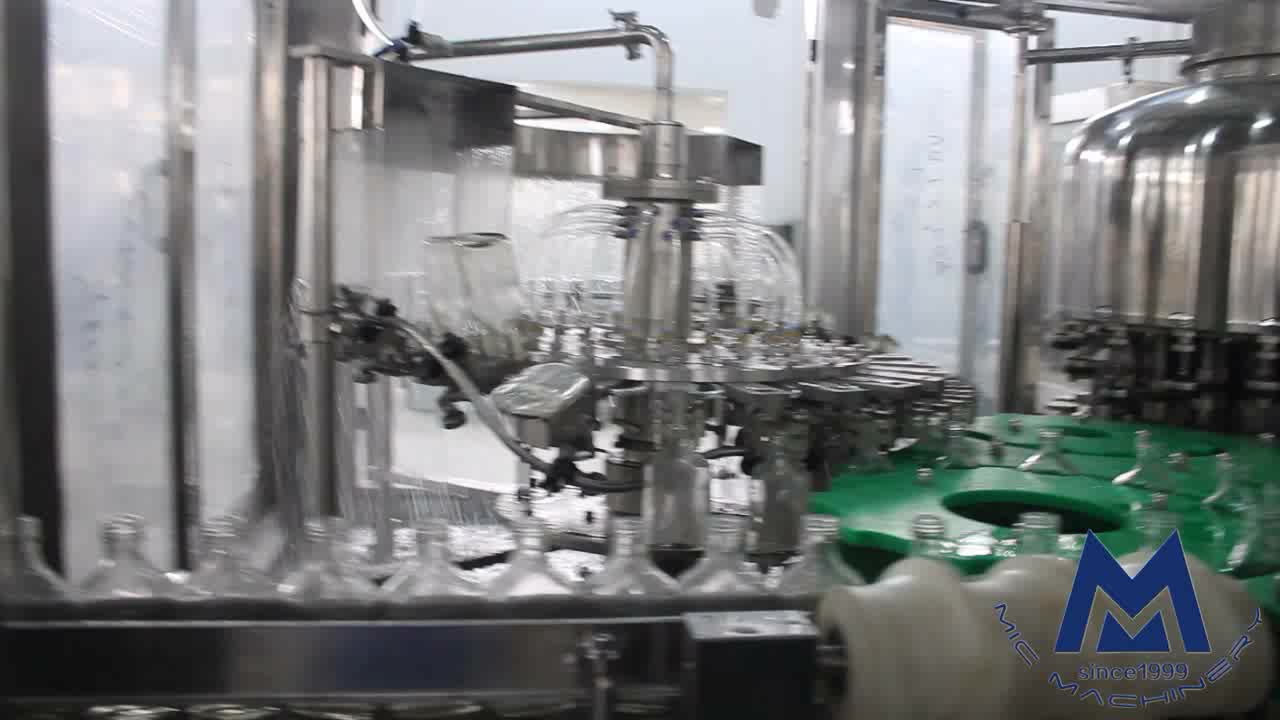

MIC 18-18-6 It is applicable for glass bottle filling capping machine for whisky, alcohol drinks and spirit. (if need hot filling temperature at 85-90 degree) Adopt products: whisky ,alcohol drinks, spirit, chivas, liquor, vodka, vinegar, soy sauce etc liquid products. Machine working principle: 1. Negative pressure filling(slightly), controled by pressure, accuracy is +/-1%,liquid level difference is not more than 4-5mm(cause bottle has difference when it produced). easy adjustmeant on liquid level. 2. Glass bottle capping machine is qualified for Chinese capping standard, and no air leakage at all, machine capping rate is 99.5%. 3. About oxygen content, we have device nitrogen filling for replace air. 4. About gems sterilizing, we could use bottle invertor for the cap, and pasteurization for juice, hot filling for can. and sterilizing tunnel (with cooling spray) for second steilizing and cool off. 3. Aluminum cap and crown cap are ok problem working on our capping machine(different capping head), We use our own technical drawing and own processing machine, to make sure our capping head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Nitrogen filling machine 7> CIP cleaning system 8> Pasteurization, inventor and sterilizing tunnel. 9> Glass bottle air washing machine Related machines are: Glass bottle filling machine, glass bottle capper, glass bottling companies, bottle filling machine, bottle equiment, bottle filling, bottle filling capping machine, bottle filler, bottle capper, bottle capping machine, crown bottle capper, bottle capping machine price, Whisky filling capping machine, vodka filling capping machine, liquor filling machine, spirit filling machine. Lately news for shipment: →We sold one to Belize on May 10,2017.

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier 01:12

01:12

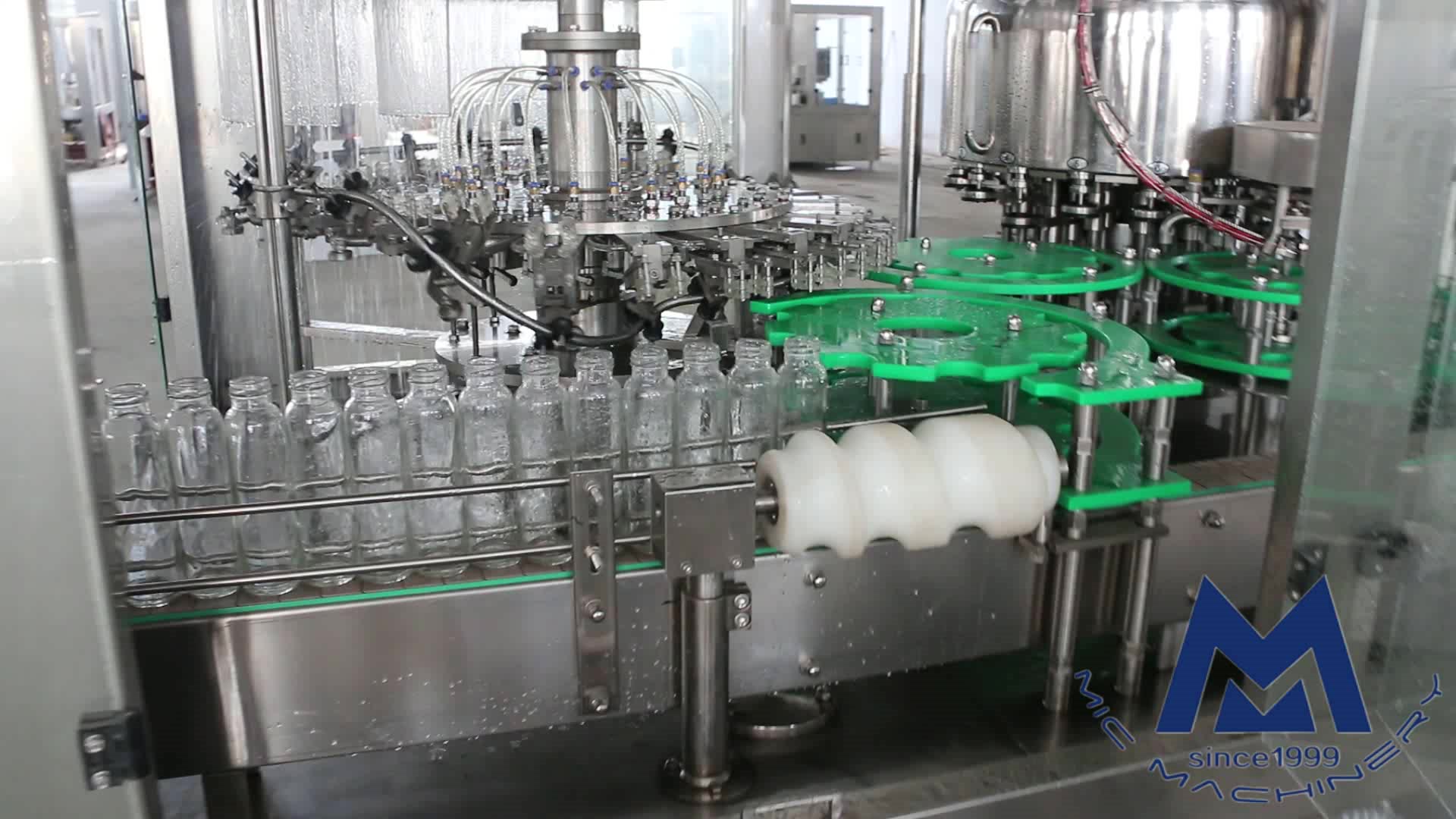

MIC 18-18-1 It is applicable for glass bottle filling capping machine for whisky, alcohol drinks and spirit. (if need hot filling temperature at 85-90 degree) Adopt products: whisky ,alcohol drinks, spirit, chivas, liquor, vodka, vinegar, soy sauce etc liquid products. Machine working principle: 1. Negative pressure filling(slightly), controled by pressure, accuracy is +/-1%,liquid level difference is not more than 4-5mm(cause bottle has difference when it produced). easy adjustmeant on liquid level. 2. Glass bottle capping machine is qualified for Chinese capping standard, and no air leakage at all, machine capping rate is 99.5%. 3. About oxygen content, we have device nitrogen filling for replace air. 4. About gems sterilizing, we could use bottle invertor for the cap, and pasteurization for juice, hot filling for can. and sterilizing tunnel (with cooling spray) for second steilizing and cool off. 3. Aluminum cap and crown cap are ok problem working on our capping machine(different capping head), We use our own technical drawing and own processing machine, to make sure our capping head quality and always easy to purchase. 4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part. 5. About machine automation, we are able to do what client required. 6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out. 7. Consider of product various ability, we are able to make machine for replace air from the can package. For this production line you might be interested in: 1> Carton packing machine 2> Pallet winding machine 3> Sticker labeling machine 4> Liquid level detective machine 5> Metal element detective machine 6> Nitrogen filling machine 7> CIP cleaning system 8> Pasteurization, inventor and sterilizing tunnel. 9> Glass bottle air washing machine Related machines are: Glass bottle filling machine, glass bottle capper, glass bottling companies, bottle filling machine, bottle equiment, bottle filling, bottle filling capping machine, bottle filler, bottle capper, bottle capping machine, crown bottle capper, bottle capping machine price, Whisky filling capping machine, vodka filling capping machine, liquor filling machine, spirit filling machine. Lately news for shipment: We sold one to

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for drink business client since 1999 year. With over decades production and installation, we become more experienced and the boss has absorb aboard technique, in our city (zhangjiagang) we become one skillful and quality assured factory.

Contact Supplier-

Agriculture Machinery & Equipment

- Farm Machinery

- Agricultural Sprayer

- Balers

- Biomass Briquette Machines

- Compost Making Machines

- Cultivators

- Egg Incubators

- Farm Irrigation System

- Farm Trailer

- Feed Processing Machines

- Fertilizer Spreaders

- Harvesters

- Milking Machines

- Oil Pressers

- Other Farm Machines

- Seeders & Transplanters

- Shellers

- Silos

- Slaughtering Equipment

- Towable Backhoe

- Tractors

- UTV

- Apparel

- Apparel & Textile Machinery

- Automobiles & Motorcycles

-

Building Material Machinery

- Chemical

- Chemical Machinery & Equipment

- Construction & Real Estate

- Construction & Real Estate

- Electrical Equipment & Supplies

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Electronic Products Machinery

- Energy & Mineral Equipment

- Engineering & Construction Machinery

- Environment

-

Food & Beverage Machinery

- Furniture

-

General Industrial Equipment

- Air Cleaning Equipment

- Air Cleaning Equipment Parts

- Air Shower

- Industrial Dehumidifier

- Industrial Humidifier

- Other Air Cleaning Equipment

- Cleaning Equipments

- Abrator

- Cleaning Equipment Parts

- Corner Cleaning Machines

- Floor Sweeper

- High Pressure Cleaner

- Industrial Ultrasonic Cleaner

- Industrial Vacuum Cleaner

- Industrial Washer

- Other Cleaning Equipment

- Sandblaster

- Industrial Filtration Equipment

- Air Filter

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Material Handling Equipment

- Bridge Cranes

- Conveyors

- Forklifts

- Hoists

- Lift Tables

- Magnetic Lifter

- Manipulator

- Other Material Handling Equipment

- Stacker & Reclaimer

- Vacuum Lifter

- Ventilation Fans

- Axial Flow Fans

- Centrifugal Fans

- Cross Flow Fans

- Other Ventilation Fans

- Radial Fans

- Ventilation Fan Parts

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliance

- Home Product Making Machinery

- Industry Laser Equipment

- Jade

- Machine Tool Equipment

- Machinery

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Mechanical Parts & Fabrication Services

- Medical Devices

- Medical Equipment

-

Metal & Metallurgy Machinery

- Minerals & Metallurgy

- Office & School Supplies

- Other Machinery & Industry Equipment

- Packaging & Printing

-

Packaging Machine

- Paper Production Machinery

- Pharmaceutical Machinery

- Physical Therapy

- Plastic & Rubber Machinery

- Power Tools

-

Printing Machine

- Refrigeration & Heat Exchange Equipment

- Rubber & Plastics

- Security & Protection

- Security & Protection

- Security & Protection

- Shoes & Accessories

- Solar Energy Products

- Sports & Entertainment

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Tool

- Tools

- Transportation

-

Woodworking Machinery