Founded in 1996, Shanghai Rongde Engineering Equipment Co., Ltd. is set scientific research production engineering and one of the company. Rongde is Jointly Operated Enterprise of China Shipbuilding Industry Corporation, one of the Shanghai high-tech enterprises, and Pudong New Area Enterprise R & D Center. Company has obtained ISO9002 Quality System Approval in 2003, and our first“China Metrology Certification”in Pudong New Area in 2004, and completed the coal mine equipment type tests which required by the“State Administration of Work Safety”in 2014. Rongde has consistently made energetic efforts in the research and development of new products, and constantly improving performances of products which have high technical content, high market share, high additional value and independent intellectual property rights. And gradually, company form Liquid Level Measuring System, Valve Remote Control Units, Fire Fighting equipment, Anti Pollution Device, Magnet Coupling & Speed Regulating Device, etc. Company have been authorized thirty one (31) invention patents and utility model patents, three (3) software copyrights. Further, company’s application for six (6) invention patent, two (2) utility model patents, and three (3) trade mark registration have been accepted. With eleven (11) invention patents and software copyrights, the “Ocean Petroleum & Liquid Cargo Loading and Unloading Integrated Device” as one of the“Shanghai Industrialization Key Projects”got the national financial aid in 2010. The Valve Remote Control Unit products was identified as“High-Tech Achievement Transformation Project”in Shanghai in 2012. “Modern Rare Earths Permanent Magnet Coupling and Speed Control Device”which with independent intellectual property rights was included in the“ShanghaiAnnual Plan for Absorption and Innovation of Introduced Technology” in 2014. In respect of product quality, Rongde is willing to persist on “Quality is the life of enterprise”, always put quality as the first consideration. Rongde many products have been type approved by CCS, ABS, BV, DNV, GL, LR, NK, RS, KR classification societies, got forty seven (47) type approval certificates and twenty nine (29) explosion-proof certificates issued by national safety supervision and inspection station. At the same time, to ensure the quality of products, company continued to purchase or homemade advanced test equipments, such as testing tools for pressure, temperature and combustible gas sensor transmitters, test equipment for hydraulic engineering, and magnetic couple test tables with different power and in different size. So that Company can not only guarantee accurate test hardware for every products, but also through ERP software management system to ensure the detection software for correct production process. Rongde will try to provides perfect quality products for our customers.In the 2015 national “Private Enterprises Join Military Industry”, Shanghai Rongde has been included in the first list of the Military Weapons and Equipments Procurement Information Website. In respect of after-sale service, in order to meet the needs of our customer, Rongde persevere with timely and high accuracy rate service. At the same time, in order to inform the global service outlets the delivered products, each quarter Rongde publish in English a RONGDE newspaper which list quarterly delivery and latest products. Now we have more than twenty (20) global service outlets, and continually adjust and broaden the range of service according to customer demands. Rongde is 24-hour on service throughout the year. Shanghai Rongde Engineering Equipment Co., Ltd. is a private enterprise, has set up Party branch, union and Youth League branch successively since 2004. Over several years, company always pay attention to the corporate culture construction, the assessment of management ability of administrators, and the comprehensive quality training of staffs. Rongde has obtain many Shanghai city honorary titles, such as the“Excellent Party Organization of Shanghai Two New Organizations”, the“Model Home of Workers in Shanghai”, the“Workers the Most satisfactory Enterprise in Shanghai”, the“Model Unit in Shanghai”, the“Workers Vanguard in Shanghai”, the“Civilization Team in Shanghai”, the“Red Flag Civilization Post in Shanghai”, the“Model Points of Party Construction in Pudong New Area”, the“Honest Demonstration Unit of Labor Security in Pudong New Area”, etc.

-

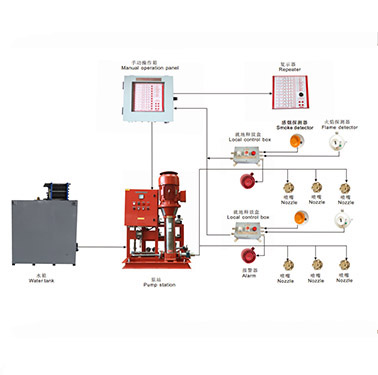

Fixed Water-Based Local Application Fire-Fighting System

RDFF Fixed Water-Based Local Application Fire-Fighting System is a modern marine fire fighting product developed in accordance with SOLAS regulation II-2/10.5.6. It has characteristics of quick startup, good fire fighting and low water consumption. And it can extinguish or control fire on time wi

-

Level Monitoring and Alarm System

RDLM Series Level Monitoring and Alarm System is composed by level detectors (radar sensor, microwave sensor, magnetic type liquid level sensor, float level switch, pressure sensor and electric-pneumatic type level sensors), safety barrier (or junction box), analog digital conversion unit, and mo

- Contacter: Marine

- Tel: 0086-21-68532791

- Fax: 0086-21-58212204

- Email: sale@rongded.com

-

Company Address:

14th Floor, No 1 Lane, 1695, Pudong Ave, shanghai, china

Fixed Water-Based Local Application Fire-Fighting System

RDFF Fixed Water-Based Local Application Fire-Fighting System is a modern marine fire fighting product developed in accordance with SOLAS regulation II-2/10.5.6. It has characteristics of quick startup, good fire fighting and low water consumption. And it can extinguish or control fire on time without engine shut down, personnel evacuation, shutting down of forced ventilation fans or sealing of the space. Its mainly used in the place where high fire danger, quick spreading speed, bad fire effect and hard extinguishing.Immediate inquiry

Feature:

- 1.5L/min per 2m water discharge capacity, so that the potential water damage is reduced to a minimum,

- The durative of fire-extinguishing is very long since the easy water source,

- Efficaciously control the fire and its very fine droplets of water spray prevent heat extending,

- Efficaciously extinguish the liquid fire which is a kind of lower flash point,

- Supply the main alarm panel with the processing PLC or PCB,

- Type approval: CCS, LR, EC.

Fixed Water-Based Local Application Fire-Fighting System

RDFF Fixed Water-Based Local Application Fire-Fighting System is a modern marine fire fighting product developed in accordance with SOLAS regulation II-2/10.5.6. It has characteristics of quick startup, good fire fighting and low water consumption. And it can extinguish or control fire on time without engine shut down, personnel evacuation, shutting down of forced ventilation fans or sealing of the space. Its mainly used in the place where high fire danger, quick spreading speed, bad fire effect and hard extinguishing.Immediate inquiry

Feature:

- 1.5L/min per 2m water discharge capacity, so that the potential water damage is reduced to a minimum,

- The durative of fire-extinguishing is very long since the easy water source,

- Efficaciously control the fire and its very fine droplets of water spray prevent heat extending,

- Efficaciously extinguish the liquid fire which is a kind of lower flash point,

- Supply the main alarm panel with the processing PLC or PCB,

- Type approval: CCS, LR, EC.

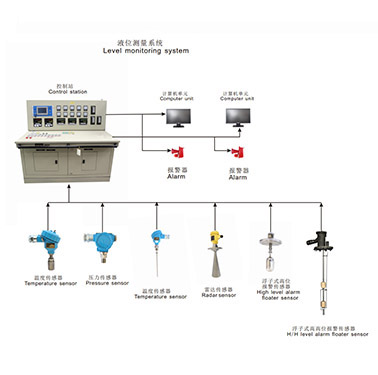

Level Monitoring and Alarm System

RDLM Series Level Monitoring and Alarm System is composed by level detectors (radar sensor, microwave sensor, magnetic type liquid level sensor, float level switch, pressure sensor and electric-pneumatic type level sensors), safety barrier (or junction box), analog digital conversion unit, and monitor unit (industry computer, data collection card, various intelligent instrumentation) and so on.

(1) RDLM- □□-GM/RA Radar Type Level Gauge

(2) RDLM- □□-FR/FM Floater Type Level Gauge with Temperature & Pressure Monitoring

(3) RDLM- □□-LP Pressure Type Level Gauge, with Draft Gauging System

(4) RDLM-□□-QP Air-purge Type Level Gauge with Draft Gauging System

(5) RDLM-02-EP Electric-Pneumatic Type Level Gauge, with Draft Gauging System ,

(6) RDLM-04-LS C/H H/HH Level Alarm System

(1) RDLM- □□-GM/RA Radar Type Level Gauge

(2) RDLM- □□-FR/FM Floater Type Level Gauge with Temperature & Pressure Monitoring

(3) RDLM- □□-LP Pressure Type Level Gauge, with Draft Gauging System

(4) RDLM-□□-QP Air-purge Type Level Gauge with Draft Gauging System

(5) RDLM-02-EP Electric-Pneumatic Type Level Gauge, with Draft Gauging System ,

(6) RDLM-04-LS C/H H/HH Level Alarm System

Level Monitoring and Alarm System

RDLM Series Level Monitoring and Alarm System is composed by level detectors (radar sensor, microwave sensor, magnetic type liquid level sensor, float level switch, pressure sensor and electric-pneumatic type level sensors), safety barrier (or junction box), analog digital conversion unit, and monitor unit (industry computer, data collection card, various intelligent instrumentation) and so on.

(1) RDLM- □□-GM/RA Radar Type Level Gauge

(2) RDLM- □□-FR/FM Floater Type Level Gauge with Temperature & Pressure Monitoring

(3) RDLM- □□-LP Pressure Type Level Gauge, with Draft Gauging System

(4) RDLM-□□-QP Air-purge Type Level Gauge with Draft Gauging System

(5) RDLM-02-EP Electric-Pneumatic Type Level Gauge, with Draft Gauging System ,

(6) RDLM-04-LS C/H H/HH Level Alarm System

(1) RDLM- □□-GM/RA Radar Type Level Gauge

(2) RDLM- □□-FR/FM Floater Type Level Gauge with Temperature & Pressure Monitoring

(3) RDLM- □□-LP Pressure Type Level Gauge, with Draft Gauging System

(4) RDLM-□□-QP Air-purge Type Level Gauge with Draft Gauging System

(5) RDLM-02-EP Electric-Pneumatic Type Level Gauge, with Draft Gauging System ,

(6) RDLM-04-LS C/H H/HH Level Alarm System

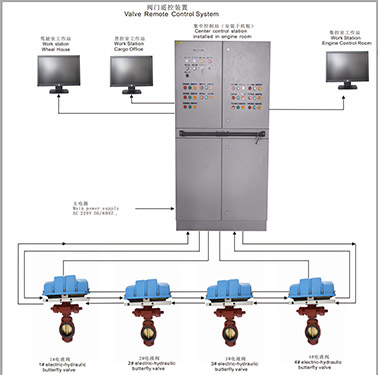

Valve Remote Control System

RDFK Valve Remote Control System is used for the remote centralized management of butterfly valve through the oil pressure, pneumatic pressure and electric. Meanwhile, it indicates the position of butterfly valve. It is not only used in vessel industry, such as, ballast pipeline system, bilge system, cargo oil pipeline, and so on; but also in pipeline of other fields , such as, petroleum, chemical industry, drilling platform and so on. When the liquid is corrosive, inflammable and explosive, please declare the condition and requirement.

The valve remote control system is included followed types:

1. Hydraulic type valve remote control system

2. Pneumatic type valve remote control system

3. Electric type valve remote control system

4. Screw-down valve control system

5. Manual hydraulic control stand

Valve Remote Control System

RDFK Valve Remote Control System is used for the remote centralized management of butterfly valve through the oil pressure, pneumatic pressure and electric. Meanwhile, it indicates the position of butterfly valve. It is not only used in vessel industry, such as, ballast pipeline system, bilge system, cargo oil pipeline, and so on; but also in pipeline of other fields , such as, petroleum, chemical industry, drilling platform and so on. When the liquid is corrosive, inflammable and explosive, please declare the condition and requirement.

The valve remote control system is included followed types:

1. Hydraulic type valve remote control system

2. Pneumatic type valve remote control system

3. Electric type valve remote control system

4. Screw-down valve control system

5. Manual hydraulic control stand

Adjustable Speed Permanent Magnet Eddy Current Transmission

Working principle:

Generally copper rotor (Steel rotor with copper ring) connect with motor shaft, permanent magnet rotor (aluminum rotor with permanent magnets) connect with load shaft. There is only a air-gap between copper rotor and permanent magnet rotor without mechanical connection for transmition the torque. When the motor rotates, the copper ring of copper rotor cut the magnetic field lines of permanent magnet, generate inductive eddy current and creates a magnetic field in copper rotor, thereby transmitting torque across the air-gap. Smaller air-gap, stronger the force of transmitted torque. Otherwise, weaker the force of transmitted torque. Vary the air-gap spacing by actuator component which is operated by hand or automatic control system.

Technical advantage:

Few day-maintenance,low operation cost, almost maintenance-free products.

Accept misalignment, the error of centration 5mm (max).

With overload protection function, so as to improve the safety, the reliability of the whole system,completely eliminate the damage to the system caused by overload.

The device is with soft starting performance in order to improves motor starting capability, soft start.motor or soft stop. Besides,reduce the motor start instantly on impact and vibration equipment.

For the special structure, the vibrating is not passed between motor and the device in order to effectively reduces the system vibration and prolong the service life of its component.

Simple structure, small size, easy to install, adapt to work in harsh conditions.

Adjust air-gap for getting required torque and speed with significant energy-saving effect.

Adjustable Speed Permanent Magnet Eddy Current Transmission

Working principle:

Generally copper rotor (Steel rotor with copper ring) connect with motor shaft, permanent magnet rotor (aluminum rotor with permanent magnets) connect with load shaft. There is only a air-gap between copper rotor and permanent magnet rotor without mechanical connection for transmition the torque. When the motor rotates, the copper ring of copper rotor cut the magnetic field lines of permanent magnet, generate inductive eddy current and creates a magnetic field in copper rotor, thereby transmitting torque across the air-gap. Smaller air-gap, stronger the force of transmitted torque. Otherwise, weaker the force of transmitted torque. Vary the air-gap spacing by actuator component which is operated by hand or automatic control system.

Technical advantage:

Few day-maintenance,low operation cost, almost maintenance-free products.

Accept misalignment, the error of centration 5mm (max).

With overload protection function, so as to improve the safety, the reliability of the whole system,completely eliminate the damage to the system caused by overload.

The device is with soft starting performance in order to improves motor starting capability, soft start.motor or soft stop. Besides,reduce the motor start instantly on impact and vibration equipment.

For the special structure, the vibrating is not passed between motor and the device in order to effectively reduces the system vibration and prolong the service life of its component.

Simple structure, small size, easy to install, adapt to work in harsh conditions.

Adjust air-gap for getting required torque and speed with significant energy-saving effect.

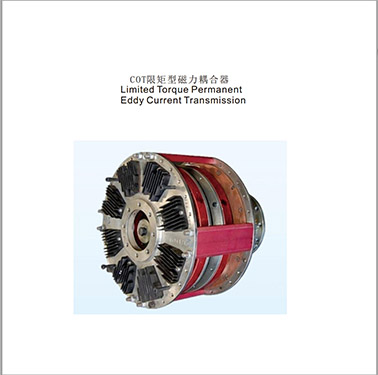

Limited Torque Permanent Magnet Eddy Current Transmission

Working principle:

At the initial position, the air-gap is 3mm between copper rotor and permanent magnet rotor. When the motor rotates, the copper ring of copper rotor cut the magnetic field lines of permanent magnet,generate inductive eddy current and creates a magnetic field in copper rotor. Between the two fields,there is force which is not only transfer torque between the motor and work machine, but also transfer the axial force between sub-rotors. Compared with the speed slip between copper rotor and permanent mangnet rotor, the air-gap is from 3mm to 5mm for achieving better soft-start.

When the work machine suddenly overloaded or stuck in the case, the speed of permanent magnet rotor decreased rapidly, or reduce to zero immediately. But, the speed of the motor and the copper rotor almost the same, due to the axial force between sub-rotors enlarge the air-gap till max. Thereby reducing transmitted torque between the copper rotor and the permanent magnet rotor till a small value.And, even the load exceeding a certain limit value, the motor is fully protected

Technical advantage:

Few day-maintenance,low operation cost, almost maintenance-free products

Accept misalignment, centration error 5mm (max), angular error 2 (max) 。

With overload protection, increase overall system reliability, eliminate the damage of system for overload. When the loading is in normal, the system automatically return to working or can be directly re-start.

Improve the motor starting capability and come true the motor soft start / stop. Specially, suitable for big torque, high inertia loads.

Reduce shock and vibration, coordinate between multi-machine-driven load distribution.

Simple structure, small size, easy to install, adapt to work in harsh conditions.

Extend the life of the transmission system components.

Limited Torque Permanent Magnet Eddy Current Transmission

Working principle:

At the initial position, the air-gap is 3mm between copper rotor and permanent magnet rotor. When the motor rotates, the copper ring of copper rotor cut the magnetic field lines of permanent magnet,generate inductive eddy current and creates a magnetic field in copper rotor. Between the two fields,there is force which is not only transfer torque between the motor and work machine, but also transfer the axial force between sub-rotors. Compared with the speed slip between copper rotor and permanent mangnet rotor, the air-gap is from 3mm to 5mm for achieving better soft-start.

When the work machine suddenly overloaded or stuck in the case, the speed of permanent magnet rotor decreased rapidly, or reduce to zero immediately. But, the speed of the motor and the copper rotor almost the same, due to the axial force between sub-rotors enlarge the air-gap till max. Thereby reducing transmitted torque between the copper rotor and the permanent magnet rotor till a small value.And, even the load exceeding a certain limit value, the motor is fully protected

Technical advantage:

Few day-maintenance,low operation cost, almost maintenance-free products

Accept misalignment, centration error 5mm (max), angular error 2 (max) 。

With overload protection, increase overall system reliability, eliminate the damage of system for overload. When the loading is in normal, the system automatically return to working or can be directly re-start.

Improve the motor starting capability and come true the motor soft start / stop. Specially, suitable for big torque, high inertia loads.

Reduce shock and vibration, coordinate between multi-machine-driven load distribution.

Simple structure, small size, easy to install, adapt to work in harsh conditions.

Extend the life of the transmission system components.

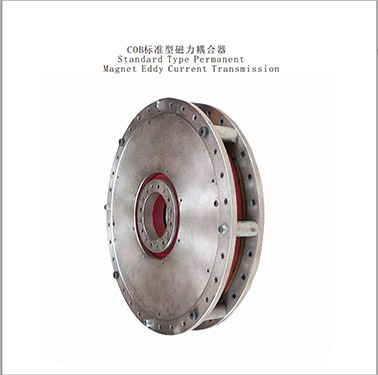

Standard Type Permanent Magnet Eddy Current Transmission

Working principle:

Standard Type Permanent Magnet Eddy Current Transmission mainly include the copper rotor,permanent magnet rotor. Generally copper rotor (Steel rotor with copper ring) connect with motor shaft,permanent magnet rotor (aluminum rotor with permanent magnets) connect with load shaft. There is only a air-gap between copper rotor and permanent magnet rotor without mechanical connection for transmission the torque.

Technical advantage:

Few day-maintenance,low operation cost, almost maintenance-free products

Accept misalignment, the error of centration 5mm (max), angular error 2.5 (max) 。

With overload protection, increase overall system reliability, eliminate the damage of system for overload

Improve the motor starting capability and come true the motor soft start / stop. And, reduce shock and

vibration, coordinate between multi-machine-driven load distribution.

Extend the life of the transmission system components.

Simple structure, small size, easy to install, adapt to work in harsh conditions.

Allowed adjusted the air-gap to achieve the required torque transmission and speed delivery requirements.

Supply a variety of special shaft or installation size.

Standard Type Permanent Magnet Eddy Current Transmission

Working principle:

Standard Type Permanent Magnet Eddy Current Transmission mainly include the copper rotor,permanent magnet rotor. Generally copper rotor (Steel rotor with copper ring) connect with motor shaft,permanent magnet rotor (aluminum rotor with permanent magnets) connect with load shaft. There is only a air-gap between copper rotor and permanent magnet rotor without mechanical connection for transmission the torque.

Technical advantage:

Few day-maintenance,low operation cost, almost maintenance-free products

Accept misalignment, the error of centration 5mm (max), angular error 2.5 (max) 。

With overload protection, increase overall system reliability, eliminate the damage of system for overload

Improve the motor starting capability and come true the motor soft start / stop. And, reduce shock and

vibration, coordinate between multi-machine-driven load distribution.

Extend the life of the transmission system components.

Simple structure, small size, easy to install, adapt to work in harsh conditions.

Allowed adjusted the air-gap to achieve the required torque transmission and speed delivery requirements.

Supply a variety of special shaft or installation size.